Sheet Metal Bending Flange . Find out the minimum flange size, bend allowance,. Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. A sheet metal flange can be a projection, a rim, or both. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. This guide covers neutral layer and. What is a sheet metal flange? It adds strength, attaches a part, or creates a flat.

from feltmagnet.com

It adds strength, attaches a part, or creates a flat. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. This guide covers neutral layer and. Find out the minimum flange size, bend allowance,. A sheet metal flange can be a projection, a rim, or both. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more.

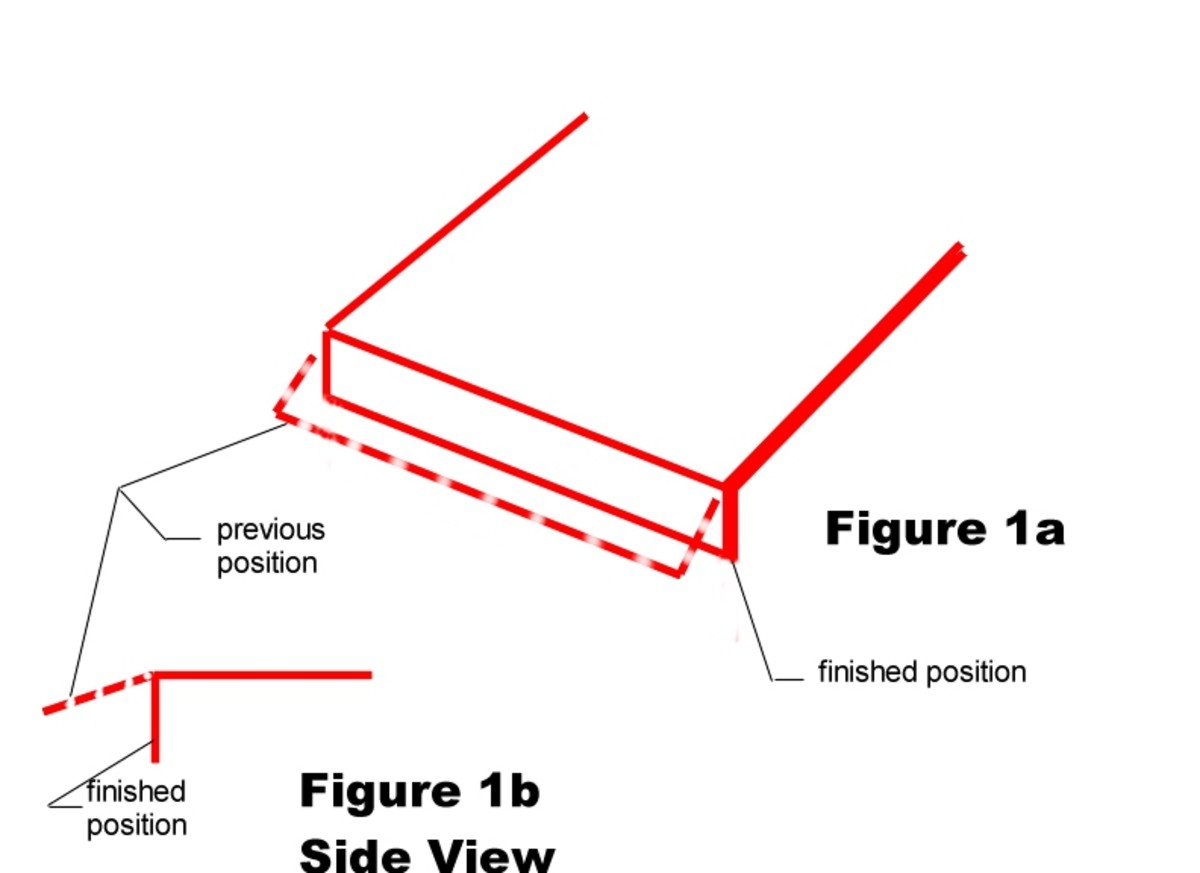

Forming and Flanging Sheet Metal in Stamping Dies

Sheet Metal Bending Flange Find out the minimum flange size, bend allowance,. It adds strength, attaches a part, or creates a flat. Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. What is a sheet metal flange? Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. A sheet metal flange can be a projection, a rim, or both. This guide covers neutral layer and. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. Find out the minimum flange size, bend allowance,.

From www.protocase.co.uk

Sheet Metal Bending Tolerances Sheet Metal Bending Flange Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. Learn how sheet metal stretches,. Sheet Metal Bending Flange.

From www.komaspec.com

An Engineers’ Guide to Sheet Metal Bending & Laser Cutting Komaspec Sheet Metal Bending Flange What is a sheet metal flange? Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. Find out the best practices for wall thickness, bend radii, bend allowance, bend. Sheet Metal Bending Flange.

From www.cadtutor.net

Sheet Metal Self Intersecting Flanges Error Autodesk Inventor Sheet Metal Bending Flange This guide covers neutral layer and. What is a sheet metal flange? Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. A sheet metal flange can be a projection, a rim, or both.. Sheet Metal Bending Flange.

From exyzhlnwm.blob.core.windows.net

Mild Steel Sheet Thickness Tolerance at Mary Landis blog Sheet Metal Bending Flange Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. Find out the minimum flange size, bend allowance,. Find out the critical dimensions, tolerances, and best practices for sheet. Sheet Metal Bending Flange.

From www.machinemfg.com

Sheet Metal Forming Processes and Equipment MachineMfg Sheet Metal Bending Flange Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. A sheet metal flange can be a projection, a rim, or both. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Learn the fundamentals of sheet metal. Sheet Metal Bending Flange.

From kr.pinterest.com

Pin de Erik en вент en 2024 Calculo de angulos, Caldereria, Diseño de Sheet Metal Bending Flange Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. What is a sheet metal flange? This guide covers neutral layer and. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Find out the minimum flange size, bend allowance,. Learn. Sheet Metal Bending Flange.

From robu.in

Sheet Metal Design Basics in 2021 Complete List of Things Sheet Metal Bending Flange It adds strength, attaches a part, or creates a flat. A sheet metal flange can be a projection, a rim, or both. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. What is a sheet metal flange? Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and. Sheet Metal Bending Flange.

From www.reece.com.au

Dimax Ductile Iron Bend (Flange x Flange) PN16 B5 150mm x 45 Degrees Sheet Metal Bending Flange This guide covers neutral layer and. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. A sheet metal flange can be a projection, a rim, or both. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. Find out the minimum flange size, bend allowance,. What is. Sheet Metal Bending Flange.

From fractory.com

Sheet Metal Bending Design Tips, Bend Allowance, K Factor Fractory Sheet Metal Bending Flange This guide covers neutral layer and. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. Find out the minimum flange size, bend allowance,. Learn how sheet metal stretches, cracks, and varies during bending and. Sheet Metal Bending Flange.

From metalmaq.shop

Making "flange" or "edges" on the metal sheets, especially on the thinner Sheet Metal Bending Flange What is a sheet metal flange? Find out the minimum flange size, bend allowance,. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. This guide covers neutral layer and. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. A sheet metal flange. Sheet Metal Bending Flange.

From www.youtube.com

SolidWorks Tutorial Sheet Metal Part Design Bend Allowance YouTube Sheet Metal Bending Flange Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Learn how to design sheet metal parts for bending by applying force between two tools by a press. Sheet Metal Bending Flange.

From www.youtube.com

NX Sheet Metal Flange & Bend YouTube Sheet Metal Bending Flange Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Find out the minimum flange size,. Sheet Metal Bending Flange.

From klafwojba.blob.core.windows.net

How To Fix Sheet Metal On Trailer at Paula Bruch blog Sheet Metal Bending Flange Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. What is a sheet metal flange? It adds strength, attaches a part, or creates a flat. A sheet metal flange can be a projection, a rim, or both. Find out the best practices for wall thickness, bend radii, bend allowance, bend. Sheet Metal Bending Flange.

From nascentfittingsinc.com

LAPPED JOINT FLANGE Nascent Fittings INC Sheet Metal Bending Flange Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. This guide covers neutral layer and. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be. Sheet Metal Bending Flange.

From grabcad.com

Can any of you help on a sheet metal design. I want to add a triangle Sheet Metal Bending Flange Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs. Sheet Metal Bending Flange.

From fractory.com

Sheet Metal Hemming Hem Types & Processes Explained Fractory Sheet Metal Bending Flange Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. What is a sheet metal flange? Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. This guide covers neutral layer and. Learn the fundamentals of sheet metal design,. Sheet Metal Bending Flange.

From www.thefabricator.com

What to know about sheet metal bend radius and minimum flange Sheet Metal Bending Flange What is a sheet metal flange? Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. It adds strength,. Sheet Metal Bending Flange.

From www.protoexpedited.com

4 Tips of Sheet Metal Fabrication Proto Expedited Sheet Metal Bending Flange Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. This guide covers neutral layer and. A sheet metal flange can be a projection, a rim, or both. It adds strength, attaches a part, or creates a flat. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and. Sheet Metal Bending Flange.

From www.mech4study.com

Different Sheet Metal Bending Process Mech4study Sheet Metal Bending Flange It adds strength, attaches a part, or creates a flat. A sheet metal flange can be a projection, a rim, or both. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. Learn about the different types of sheet metal bending methods, such as. Sheet Metal Bending Flange.

From exoyusuhu.blob.core.windows.net

What Is Bend Radius Sheet Metal at Richard Fleetwood blog Sheet Metal Bending Flange What is a sheet metal flange? Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. It adds strength, attaches a part, or creates a flat. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Find out. Sheet Metal Bending Flange.

From www.cmrp.com

Metal Bending for Chutes and Ladders (and Pipe Clamps) The Chicago Curve Sheet Metal Bending Flange Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. A sheet metal flange can be a projection, a rim, or both. This guide covers neutral layer and. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more.. Sheet Metal Bending Flange.

From www.ebay.com

Sealey Sheet Metal Flange & Bending Steel Joggler & Flanging Tool RE92 Sheet Metal Bending Flange Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and. Sheet Metal Bending Flange.

From www.thefabricator.com

What to know about sheet metal bend radius and minimum flange Sheet Metal Bending Flange Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. This guide covers neutral layer and. Find out the minimum flange size, bend allowance,. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. Learn how sheet metal stretches, cracks, and varies during bending and how to. Sheet Metal Bending Flange.

From www.smlease.com

Sheet Metal Design Guidelines Design for Manufacturing Sheet Metal Bending Flange What is a sheet metal flange? Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. A sheet metal flange can be a projection, a rim, or both. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. It adds strength,. Sheet Metal Bending Flange.

From www.metalworkingworldmagazine.com

Press Brake Tooling Enables High Quality Sheet Metal Forming Metal Sheet Metal Bending Flange Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. A sheet metal flange can be a projection, a rim, or both. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features,. Sheet Metal Bending Flange.

From www.youtube.com

Making a Radius Bending Fixture for Sheetmetal YouTube Sheet Metal Bending Flange Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. What is a sheet metal flange? Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Find out the. Sheet Metal Bending Flange.

From forum.onshape.com

Sheet Metal Flange Manilupation — Onshape Sheet Metal Bending Flange Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. What is a sheet metal flange? Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Learn about the different types of sheet metal bending methods, such as brake press and. Sheet Metal Bending Flange.

From www.approvedsheetmetal.com

5 Factors Partnering with a Fab Shop (Updated for 2024) ASM Sheet Metal Bending Flange Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. Learn how to design sheet metal parts for bending by applying force between two tools. Sheet Metal Bending Flange.

From www.youtube.com

How To Make Curved Flanges On Sheet Metal Panels Tipping Die YouTube Sheet Metal Bending Flange Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. It adds strength, attaches a part, or creates a flat. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs. Sheet Metal Bending Flange.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bending Flange Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. This guide covers neutral layer and. Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. Learn about the different types of sheet metal bending methods, such as brake press and. Sheet Metal Bending Flange.

From www.wilatooling.com

Bending short flanges WILA Sheet Metal Bending Flange This guide covers neutral layer and. Find out the minimum flange size, bend allowance,. It adds strength, attaches a part, or creates a flat. Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. Find out the critical dimensions, tolerances, and best practices for sheet metal fabrication. Learn. Sheet Metal Bending Flange.

From exoyusuhu.blob.core.windows.net

What Is Bend Radius Sheet Metal at Richard Fleetwood blog Sheet Metal Bending Flange Learn how to design sheet metal parts for bending by applying force between two tools by a press brake. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. What is a sheet metal flange? Learn how to design good sheet metal parts for press bending with. Sheet Metal Bending Flange.

From www.smlease.com

Sheet Metal KFactor, Bend Allowance and Flat Length Calculations Sheet Metal Bending Flange This guide covers neutral layer and. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. Learn how sheet metal stretches, cracks, and varies during bending and how to design flanges and kerfs for fabrication. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and. Sheet Metal Bending Flange.

From unitymanufacture.com

How To Bend Sheet Metal Into A Cylinder? Unity Manufacture Sheet Metal Bending Flange It adds strength, attaches a part, or creates a flat. Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other. Find out the best practices for wall thickness, bend radii, bend allowance, bend relief, edge features, hole features, and more. Learn how to design sheet metal parts for. Sheet Metal Bending Flange.

From feltmagnet.com

Forming and Flanging Sheet Metal in Stamping Dies Sheet Metal Bending Flange A sheet metal flange can be a projection, a rim, or both. Learn about the different types of sheet metal bending methods, such as brake press and rolling, and how they can be used to. Learn the fundamentals of sheet metal design, including bending, forming, cutting, and features. Find out the critical dimensions, tolerances, and best practices for sheet metal. Sheet Metal Bending Flange.