Tube Drawing Calculations . The process has two main steps: The important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. The purpose of tube drawing can be any one of the following: When the process is finished, the tube’s od matches the die’s id. Drawing a tube from one size to another sounds simple. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. (i) to regulate the outer diameter only. The appendix contains a set of charts, graphs, and other helpful tables

from www.manufacturingguide.com

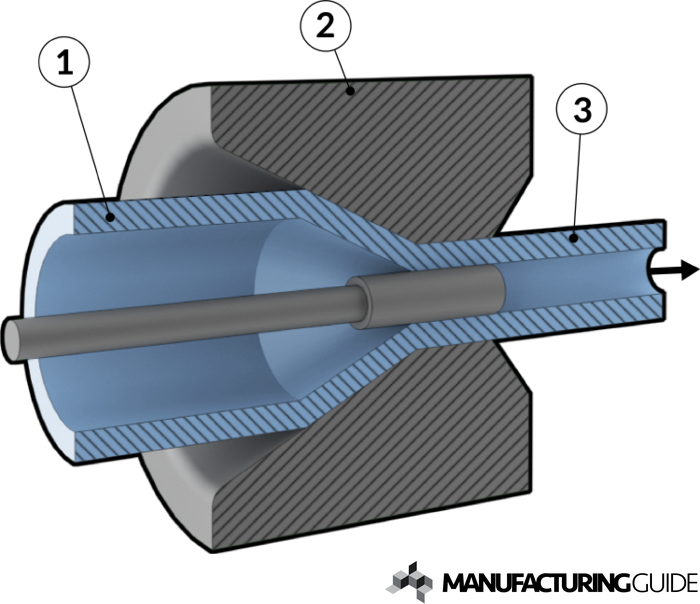

The process has two main steps: Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. When the process is finished, the tube’s od matches the die’s id. Drawing a tube from one size to another sounds simple. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. The important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. (i) to regulate the outer diameter only. • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. The appendix contains a set of charts, graphs, and other helpful tables

Tube drawing Find suppliers, processes & material

Tube Drawing Calculations (i) to regulate the outer diameter only. • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. The important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. The appendix contains a set of charts, graphs, and other helpful tables Drawing a tube from one size to another sounds simple. (i) to regulate the outer diameter only. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. The purpose of tube drawing can be any one of the following: The process has two main steps: Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. When the process is finished, the tube’s od matches the die’s id. Part ii covers some specific calculations and their formulas and has examples of how to do such calculations.

From www.roguefab.com

Tube Calculator Round, Rectangular & Square Pipes Capacity Rogue Tube Drawing Calculations • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. The purpose of tube drawing can be any one of the following: (i) to regulate the outer diameter only. Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. (ii) to regulate the outer diameter and to have. Tube Drawing Calculations.

From www.chemicalslearning.com

Pitot Tube Working Principle and Pitot Tube Derivation Tube Drawing Calculations The process has two main steps: (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. (i) to regulate the outer diameter only. When the process is finished, the tube’s. Tube Drawing Calculations.

From www.youtube.com

How to draw Test tube Test Tube drawing science apparatus YouTube Tube Drawing Calculations The appendix contains a set of charts, graphs, and other helpful tables When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. Drawing a tube from one size to another. Tube Drawing Calculations.

From www.thefabricator.com

Tips on designing tubular parts for bending Tube Drawing Calculations Drawing a tube from one size to another sounds simple. When the process is finished, the tube’s od matches the die’s id. The process has two main steps: (i) to regulate the outer diameter only. (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. • drawing steel rod from φ= 13 mm to. Tube Drawing Calculations.

From www.youtube.com

how to draw a test tube step by step test tube drawing YouTube Tube Drawing Calculations The purpose of tube drawing can be any one of the following: Drawing a tube from one size to another sounds simple. • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. The appendix contains a set of charts, graphs, and other helpful tables The process has two main steps: The important parameters which affect the. Tube Drawing Calculations.

From www.youtube.com

Drawing 101 How to draw tubes YouTube Tube Drawing Calculations The process has two main steps: (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. The appendix contains a set of charts, graphs, and other helpful tables When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. When the. Tube Drawing Calculations.

From www.manufacturingguide.com

Tube drawing Find suppliers, processes & material Tube Drawing Calculations The appendix contains a set of charts, graphs, and other helpful tables (i) to regulate the outer diameter only. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. The important parameters which affect. Tube Drawing Calculations.

From www.youtube.com

Tube Drawing Process YouTube Tube Drawing Calculations Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. The purpose of tube drawing can be any one of the following: Tube sinking, floating plug drawing, xed. Tube Drawing Calculations.

From helloartsy.com

Draw a Test Tube HelloArtsy Tube Drawing Calculations Drawing a tube from one size to another sounds simple. When the process is finished, the tube’s od matches the die’s id. • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. The important parameters which affect the. Tube Drawing Calculations.

From www.mech4study.com

Types of Drawing Process Wire Drawing, Rod Drawing and Tube Drawing Tube Drawing Calculations • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. The purpose of tube drawing can be any one of the following: Part ii covers some specific calculations and their formulas and has examples of how to do such calculations.. Tube Drawing Calculations.

From www.thefabricator.com

Drawing tube with a varying wall thickness Tube Drawing Calculations The important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. When the process is finished, the tube’s od matches the die’s id. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. (i) to regulate the. Tube Drawing Calculations.

From www.academia.edu

(PDF) Numerical and experimental analysis of tube drawing with fixed Tube Drawing Calculations When the process is finished, the tube’s od matches the die’s id. Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. (i) to regulate the outer diameter only. The important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. The purpose of. Tube Drawing Calculations.

From getdrawings.com

Steel Pipe Drawing at GetDrawings Free download Tube Drawing Calculations The purpose of tube drawing can be any one of the following: When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. The important parameters which. Tube Drawing Calculations.

From nativeamericanartdrawingssimple.blogspot.com

wire drawing die series calculator nativeamericanartdrawingssimple Tube Drawing Calculations The important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. Drawing a tube from one size to another sounds simple. Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing,. Tube Drawing Calculations.

From www.youtube.com

Tube Drawing YouTube Tube Drawing Calculations (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. The process has two main steps: The purpose of tube drawing can be any one of the following: When the process is finished, the tube’s od matches the die’s id. (i) to regulate the outer diameter only. Tube sinking, floating plug drawing, xed fi. Tube Drawing Calculations.

From www.researchgate.net

(PDF) A mathematical analysis of an isothermal tube drawing process Tube Drawing Calculations When the process is finished, the tube’s od matches the die’s id. The process has two main steps: When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. Drawing a tube from one size to another sounds simple. • drawing steel rod from φ= 13 mm. Tube Drawing Calculations.

From www.manufacturingguide.com

Tube drawing Find suppliers, processes & material Tube Drawing Calculations The important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. The appendix contains a set of charts, graphs, and other helpful tables The process has two. Tube Drawing Calculations.

From www.javelin-tech.com

Calculating Bend Allowance, Bend Deduction, and KFactor Tube Drawing Calculations When the process is finished, the tube’s od matches the die’s id. The purpose of tube drawing can be any one of the following: When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. Crushing one end (also known as pointing the tube), then drawing it. Tube Drawing Calculations.

From www.mdpi.com

Metals Free FullText Tube Drawing Process with Diameter Expansion Tube Drawing Calculations (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. (i) to regulate the outer diameter only. The purpose of tube drawing can be any one of the following: • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. When a hollow tube is drawn through a die, generally a. Tube Drawing Calculations.

From fyodslwxn.blob.core.windows.net

Quick Tube Calculations at Rachel Preble blog Tube Drawing Calculations Drawing a tube from one size to another sounds simple. Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. The purpose of tube drawing can be any one of the following: • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. The important parameters which affect the. Tube Drawing Calculations.

From www.vecteezy.com

measuring tube drawing art illustration 8147463 Vector Art at Vecteezy Tube Drawing Calculations Drawing a tube from one size to another sounds simple. When the process is finished, the tube’s od matches the die’s id. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. (i) to regulate the outer diameter only. Crushing one end (also known as pointing. Tube Drawing Calculations.

From www.researchgate.net

Comparison of selected parameters of smooth tube drawing process Tube Drawing Calculations Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. The appendix contains a set of charts, graphs, and other helpful tables (i) to regulate the outer diameter only. When the process is finished, the tube’s od matches the. Tube Drawing Calculations.

From www.vrogue.co

Volume And Area Calculation vrogue.co Tube Drawing Calculations When the process is finished, the tube’s od matches the die’s id. (i) to regulate the outer diameter only. Drawing a tube from one size to another sounds simple. The appendix contains a set of charts, graphs, and other helpful tables Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct. Tube Drawing Calculations.

From www.scribd.com

Tube Drawing Process PDF Annealing (Metallurgy) Rolling Tube Drawing Calculations Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. The appendix contains a set of charts, graphs, and other helpful tables Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. The purpose of tube drawing can be any one of the following: Drawing a tube from one. Tube Drawing Calculations.

From www.youtube.com

U Tube and Inverted U Tube Differential Manometers Formulae Fluid Tube Drawing Calculations Drawing a tube from one size to another sounds simple. The purpose of tube drawing can be any one of the following: Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id.. Tube Drawing Calculations.

From www.scribd.com

Types of Drawing ProcessWire Drawing, Rod Drawing and Tube Drawing Tube Drawing Calculations Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. The process has two main steps: (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. Drawing a tube from. Tube Drawing Calculations.

From www.chegg.com

Solved For the drawing shown, formed by a bar to which a Tube Drawing Calculations The appendix contains a set of charts, graphs, and other helpful tables (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. The purpose of tube drawing can be any one of the following: Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. The important parameters which affect the wire. Tube Drawing Calculations.

From www.youtube.com

Test tube 🧪 drawing for kids Test tube drawing YouTube Tube Drawing Calculations The appendix contains a set of charts, graphs, and other helpful tables Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. (i) to regulate the outer diameter only. Drawing a tube from one size to another sounds simple.. Tube Drawing Calculations.

From www.youtube.com

Draw Tubes Challenge! 15/30 YouTube Tube Drawing Calculations • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. The appendix contains a set of charts, graphs, and other helpful tables When the process is finished, the tube’s od matches the die’s id. (ii) to regulate the outer diameter and to have good surface finish on the inner diameter. (i) to regulate the outer diameter. Tube Drawing Calculations.

From www.youtube.com

How to draw boiler UTUBE How to find U tube developed length Tube Drawing Calculations Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube,. When the process is finished, the tube’s od matches the die’s id. (ii) to regulate the outer diameter. Tube Drawing Calculations.

From www.youtube.com

How to Draw Test Tube Glass YouTube Tube Drawing Calculations The important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. When the process is finished, the tube’s od matches the die’s id. When. Tube Drawing Calculations.

From thelibraryofmanufacturing.com

Metal Drawing Tube Drawing Calculations Drawing a tube from one size to another sounds simple. The process has two main steps: Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. The appendix contains a set of charts, graphs, and other helpful tables (i) to regulate the outer diameter only. When a hollow tube is drawn through a die, generally a mandrel. Tube Drawing Calculations.

From www.researchgate.net

Schematic of tube drawing process with a fixed mandrel Download Tube Drawing Calculations • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. When the process is finished, the tube’s od matches the die’s id. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. Part ii covers some specific calculations and their formulas and has examples of how. Tube Drawing Calculations.

From resources.arcmachines.com

Determining Tube to Tubesheet Thickness in Heat Exchanger Fabrication Tube Drawing Calculations Part ii covers some specific calculations and their formulas and has examples of how to do such calculations. Drawing a tube from one size to another sounds simple. • drawing steel rod from φ= 13 mm to φ= 12 mm @ 1.5. The purpose of tube drawing can be any one of the following: The process has two main steps:. Tube Drawing Calculations.

From www.youtube.com

Shell and Tube Heat Exchanger BEM Design & Cost Estimation v1.2 Excel Tube Drawing Calculations Tube sinking, floating plug drawing, xed fi plug drawing, moving mandrel drawing, tube. The process has two main steps: The important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter. Tube Drawing Calculations.