Spur Gear Efficiency Formula . Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions.

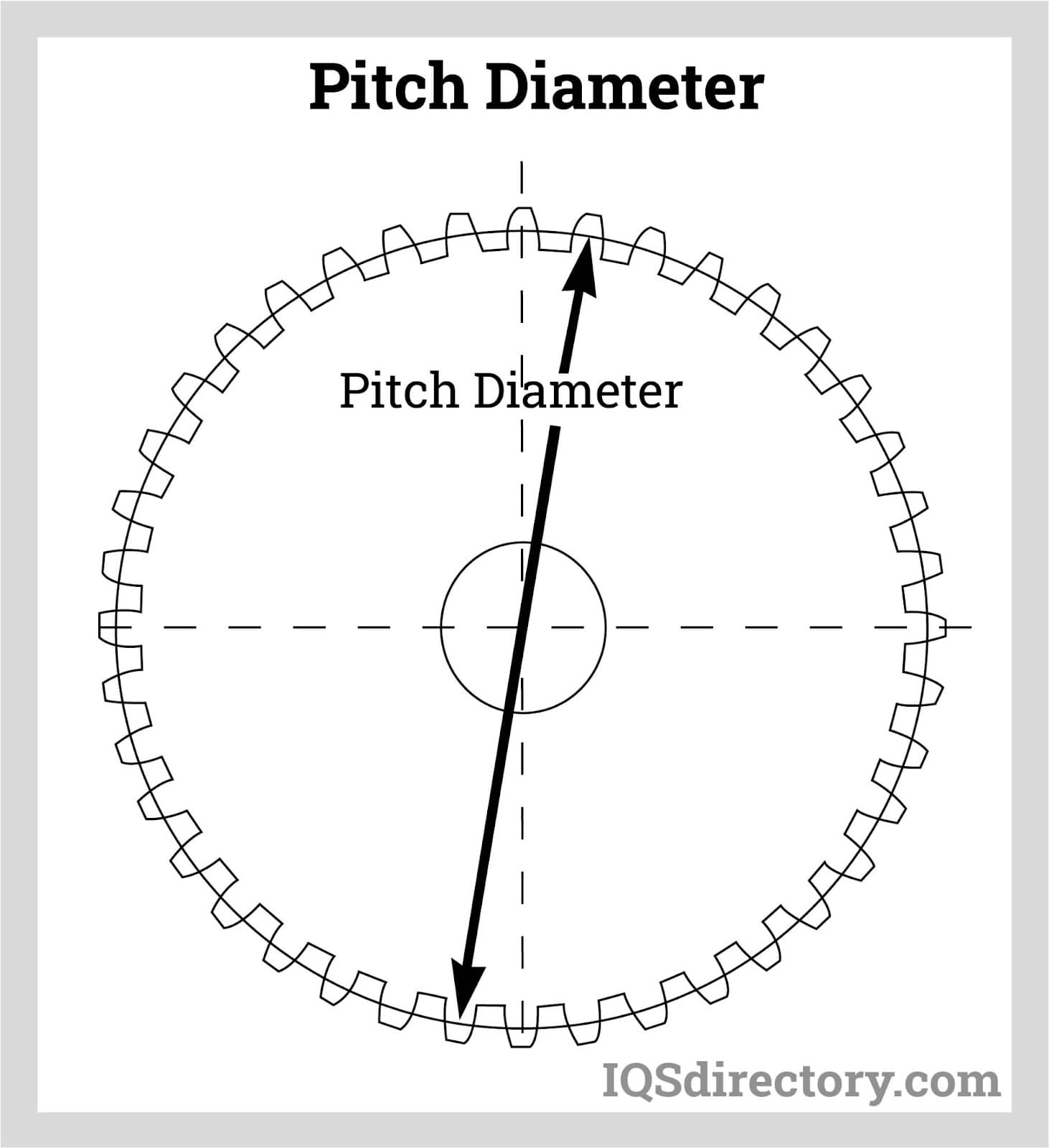

from www.iqsdirectory.com

A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,.

Spur Gears Types, Uses, Benefits, and Manufacturing

Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,.

From www.youtube.com

Spur Gears Force Components Force on Bearings Example 2 YouTube Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. Spur gears / helical gears considering a spur gear a good. Spur Gear Efficiency Formula.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH Spur Gear Efficiency Formula Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power. Spur Gear Efficiency Formula.

From lesamiesdemayalabeille.blogspot.com

Spur Gear Formula Spur Gear Design Project lesamiesdemayalabeille Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Spur gears / helical gears considering a. Spur Gear Efficiency Formula.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power.. Spur Gear Efficiency Formula.

From lesamiesdemayalabeille.blogspot.com

Spur Gear Formula Spur Gear Design Project lesamiesdemayalabeille Spur Gear Efficiency Formula Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from. Spur Gear Efficiency Formula.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Efficiency Formula Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting. Spur Gear Efficiency Formula.

From www.usarollerchain.com

Metric Spur Gears Metric Spur Gear Sizes USA Roller Chain Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. A model for the assessment of the energy efficiency of spur. Spur Gear Efficiency Formula.

From dplasopa513.weebly.com

Fillet Radius Of Spur Gear Formula dplasopa Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power.. Spur Gear Efficiency Formula.

From khkgears.net

Gear Forces KHK Gears Spur Gear Efficiency Formula Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute. Spur Gear Efficiency Formula.

From www.slideserve.com

PPT Chapter 9 Spur Gear Design PowerPoint Presentation, free download Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. A model for the assessment of the energy efficiency of spur gears is presented in this. Spur Gear Efficiency Formula.

From www.slideserve.com

PPT Force Analysis Spur Gears PowerPoint Presentation, free Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power.. Spur Gear Efficiency Formula.

From www.martinsengineering.com

Gear Formula Information » Martins Corrugator Engineering Spur Gear Efficiency Formula Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Analysis of spur gear sets gives us knowledge regarding the performance characteristics. Spur Gear Efficiency Formula.

From www.youtube.com

Design Of Spur Gear with Equation in SolidWorks YouTube Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. Analysis of spur gear sets gives us knowledge regarding the performance. Spur Gear Efficiency Formula.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH FORCES Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. In this study, the shift coefficients of both the pinion and the. Spur Gear Efficiency Formula.

From studylib.net

Design of Spur Gears Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. In this study, the shift coefficients of both the pinion and the. Spur Gear Efficiency Formula.

From www.youtube.com

Gear Efficiency Part 1 YouTube Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from. Spur Gear Efficiency Formula.

From roymech.org

Gears Gear Efficiency Roy Mech Spur Gear Efficiency Formula Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs,. Spur Gear Efficiency Formula.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH Spur Gear Efficiency Formula Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions.. Spur Gear Efficiency Formula.

From www.youtube.com

Lewis Beam Strength Equation Design of Spur, Helical, Bevel and Worm Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential. Spur Gear Efficiency Formula.

From www.mechical.com

Terminology of Spur Gear and Their Formulas Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. In this study, the shift coefficients of both the pinion and the driven gears were constrained to. Spur Gear Efficiency Formula.

From gearcutting.blogspot.com

Gear Manufacturing (By Cutting) Spur Gear Formulas Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions. Spur Gear Efficiency Formula.

From www.linkedin.com

Understanding Spur Gears The Basics and Applications Spur Gear Efficiency Formula Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Spur gears / helical gears considering a spur gear a good first approximation for average operating. Spur Gear Efficiency Formula.

From www.youtube.com

Gear velocity ratio for Simple and Compound Gear train. Reduction or Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Analysis of spur gear sets gives us. Spur Gear Efficiency Formula.

From www.youtube.com

CALCULATION RACK AND SPUR GEAR EXCEL FORMULA YouTube Spur Gear Efficiency Formula Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power. A model for the. Spur Gear Efficiency Formula.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH FORCES Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. In this study, the shift coefficients of both the pinion and the driven gears were constrained to. Spur Gear Efficiency Formula.

From www.youtube.com

Spur Gear Calculation and Design (MITCalc03) YouTube Spur Gear Efficiency Formula Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Spur gears / helical gears considering a spur gear a good first approximation for average operating. Spur Gear Efficiency Formula.

From www.slideserve.com

PPT Blueprint Reading for the Machine Trades, Sixth Edition Unit 15 Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Gear efficiency can be expressed as the. Spur Gear Efficiency Formula.

From dxolspgwl.blob.core.windows.net

Gear Ratio Equation Physics at Carey Patton blog Spur Gear Efficiency Formula Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power. In this study, the shift coefficients of both the. Spur Gear Efficiency Formula.

From www.youtube.com

Spur gear calculation, Design Details Spur Gear Formula spur gear Spur Gear Efficiency Formula Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential power. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions.. Spur Gear Efficiency Formula.

From www.slideserve.com

PPT Force Analysis Spur Gears PowerPoint Presentation, free Spur Gear Efficiency Formula Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. A model for the assessment of the energy efficiency of spur. Spur Gear Efficiency Formula.

From mechanicaltopdc.blogspot.com

Spur Gear Design Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Gear efficiency can be expressed as the. Spur Gear Efficiency Formula.

From www.scribd.com

Spur Gear Calculations and Formulas Gear Machines Spur Gear Efficiency Formula A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Gear efficiency can be expressed as the. Spur Gear Efficiency Formula.

From www.slideserve.com

PPT Blueprint Reading for the Machine Trades, Sixth Edition Unit 15 Spur Gear Efficiency Formula Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the input shaft to the power. Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute. Spur Gear Efficiency Formula.

From www.slideserve.com

PPT Force Analysis Spur Gears PowerPoint Presentation, free Spur Gear Efficiency Formula Analysis of spur gear sets gives us knowledge regarding the performance characteristics of gear drives like efficiency,. A model for the assessment of the energy efficiency of spur gears is presented in this study, which considers a shifting profile under different operating conditions. Gear efficiency can be expressed as the ratio (expressed as a percentage) of the power from the. Spur Gear Efficiency Formula.

From loewbcsws.blob.core.windows.net

Internal Spur Gear Equations at Rosalie Carrasco blog Spur Gear Efficiency Formula In this study, the shift coefficients of both the pinion and the driven gears were constrained to be equal in absolute value but with opposite signs, fulfilling. Spur gears / helical gears considering a spur gear a good first approximation for average operating conditions is that the power loss at each mesh can be approximated as p% of the potential. Spur Gear Efficiency Formula.