Thermowell Diameter . P is the process connection diameter of the thermowell. Their diameter decreases gradually over the. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. The thermowells model sd 400 s are welded into the process. Q is the root diameter of the thermowell. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. The reduced surface area allows smoother velocities and faster temperature response for sensing devices. They are suitable for high process loads, that might occur as a result of flow,. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. This can also be referred to as the od of the temperature sensor side of the well or id of the flange. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion.

from www.bravocontrols.com

Their diameter decreases gradually over the. The reduced surface area allows smoother velocities and faster temperature response for sensing devices. P is the process connection diameter of the thermowell. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. They are suitable for high process loads, that might occur as a result of flow,. This can also be referred to as the od of the temperature sensor side of the well or id of the flange. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. Q is the root diameter of the thermowell.

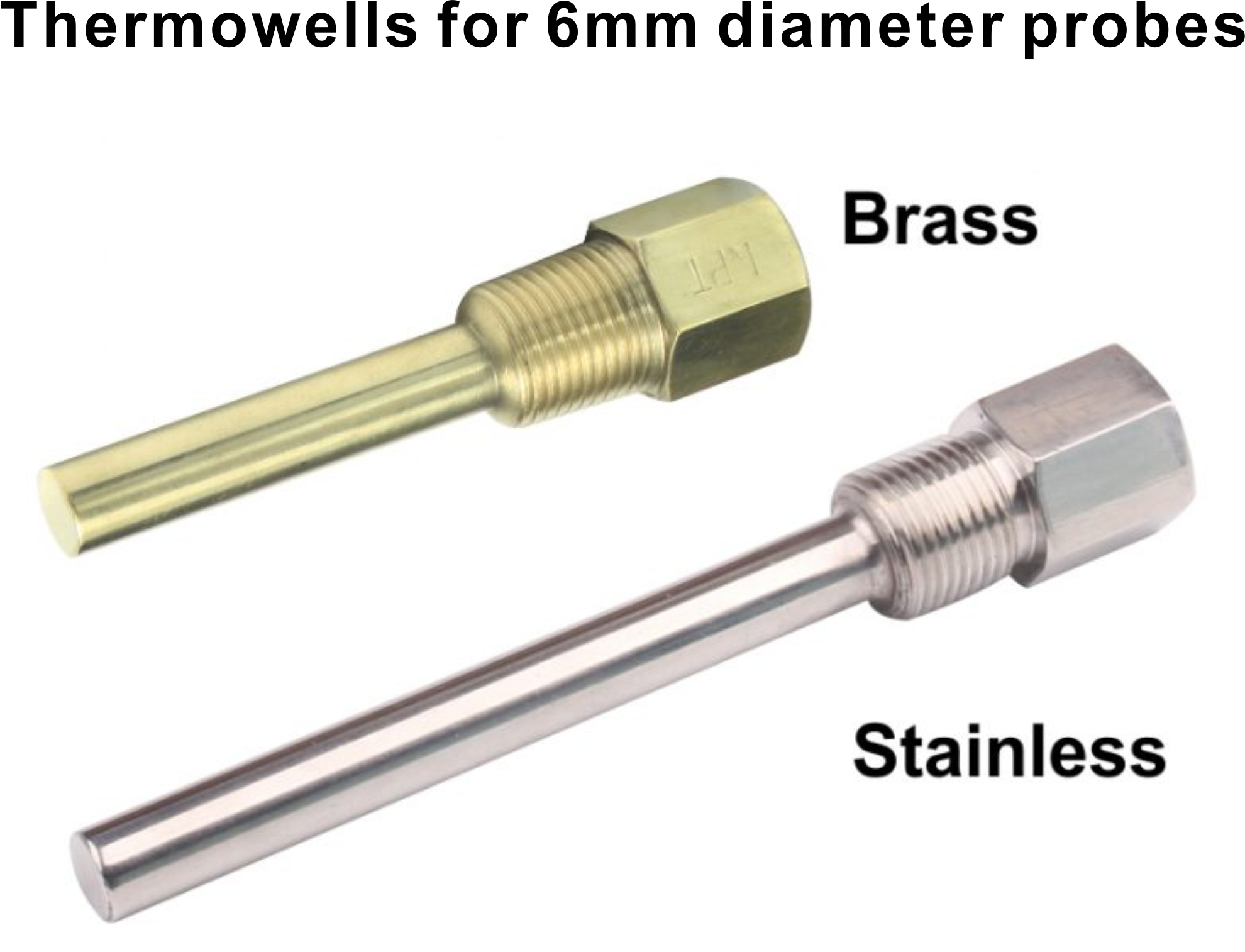

Brass & Stainless Steel Thermowells Bravo Controls

Thermowell Diameter This can also be referred to as the od of the temperature sensor side of the well or id of the flange. They are suitable for high process loads, that might occur as a result of flow,. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. Q is the root diameter of the thermowell. Their diameter decreases gradually over the. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. The reduced surface area allows smoother velocities and faster temperature response for sensing devices. P is the process connection diameter of the thermowell. The thermowells model sd 400 s are welded into the process. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. This can also be referred to as the od of the temperature sensor side of the well or id of the flange.

From instrumentationtools.com

General Specification of Thermowell Temperature Measurement Thermowell Diameter Their diameter decreases gradually over the. P is the process connection diameter of the thermowell. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. The thermowells model sd 400 s are welded into the process. A straight thermowell is the same diameter throughout the entire insertion length and. Thermowell Diameter.

From www.jms-se.com

Flanged Thermowells JMS Southeast, Inc. Thermowell Diameter P is the process connection diameter of the thermowell. They are suitable for high process loads, that might occur as a result of flow,. Their diameter decreases gradually over the. This can also be referred to as the od of the temperature sensor side of the well or id of the flange. A straight thermowell is the same diameter throughout. Thermowell Diameter.

From www.bravocontrols.com

Brass & Stainless Steel Thermowells Bravo Controls Thermowell Diameter The reduced surface area allows smoother velocities and faster temperature response for sensing devices. Their diameter decreases gradually over the. This can also be referred to as the od of the temperature sensor side of the well or id of the flange. Q is the root diameter of the thermowell. Stepped thermowells usually have a ¾ diameter at the top. Thermowell Diameter.

From www.grainger.com

Stainless Steel, 1 in MNPT, Threaded Thermowell 61VE4410W1650HT260S Thermowell Diameter The thermowells model sd 400 s are welded into the process. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. P is the process connection diameter of the thermowell. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter. Thermowell Diameter.

From korean.alibaba.com

두금속 온도계를 위한 고품질 스테인리스 물자 Thermowell Buy Thermowell,황동 스테인레스 스틸 재질 열전쌍 Thermowell Diameter Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. They are suitable for high process loads, that might occur as a result of flow,. This can also be referred to as the od of the temperature sensor side of the well or id of the. Thermowell Diameter.

From instrumentationtools.com

What is Thermowell and Howto choose Thermowell Probe Length Thermowell Diameter The thermowells model sd 400 s are welded into the process. This can also be referred to as the od of the temperature sensor side of the well or id of the flange. Q is the root diameter of the thermowell. Their diameter decreases gradually over the. To shorten the thermowell stem or to increase the root and tip diameter,. Thermowell Diameter.

From kodiakcontrols.com

Mastering Thermowell Dimensions A Comprehensive Guide to Accurate Thermowell Diameter This can also be referred to as the od of the temperature sensor side of the well or id of the flange. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. To shorten the thermowell stem or to increase the root and tip diameter, accepting. Thermowell Diameter.

From einvoice.fpt.com.vn

Thermowells Types, Applications, And Purchasing, 47 OFF Thermowell Diameter This can also be referred to as the od of the temperature sensor side of the well or id of the flange. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to. Thermowell Diameter.

From www.tili.eu.org

Thermowell Insertion and Immersion Length Thermowell Diameter The thermowells model sd 400 s are welded into the process. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. P is the process. Thermowell Diameter.

From instrumentationtools.com

Thermowell Insertion and Immersion Length InstrumentationTools Thermowell Diameter Their diameter decreases gradually over the. The reduced surface area allows smoother velocities and faster temperature response for sensing devices. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether. Thermowell Diameter.

From www.intempco.com

What is a Thermowell? Intempco Thermowell Diameter Their diameter decreases gradually over the. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. Q is the root diameter of the thermowell. Stepped. Thermowell Diameter.

From www.wermac.org

Temperature Measurement Thermowells Thermowell Diameter Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. Q is the root diameter of the thermowell. Below, we will explain the terms used on the datasheets of ifm thermowells and. Thermowell Diameter.

From www.noshok.com

50/75/100 Series Thermowells Dimensions Thermowell Diameter The thermowells model sd 400 s are welded into the process. P is the process connection diameter of the thermowell. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. Q is the root diameter of the thermowell. To shorten the thermowell stem or to increase. Thermowell Diameter.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Diameter Their diameter decreases gradually over the. This can also be referred to as the od of the temperature sensor side of the well or id of the flange. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. Stepped thermowells usually have a ¾ diameter at the top which. Thermowell Diameter.

From www.instrumentationtoolbox.com

Thermowells Learning Instrumentation And Control Engineering Thermowell Diameter P is the process connection diameter of the thermowell. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. Their diameter decreases gradually over the. The reduced surface area allows. Thermowell Diameter.

From rosecal.com.au

Thermowell specifications Rose Calibration Company; Quality Thermowell Diameter The thermowells model sd 400 s are welded into the process. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. They are suitable for high process loads, that might occur as. Thermowell Diameter.

From www.thermosensors.com

Thermowells, Threaded, Flanged, Socket Weld, Van Stone, WeldIn Thermowell Diameter Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. P is the process connection diameter of the thermowell. This can also be referred to as the od of the temperature sensor side of the well or id of the flange. They are suitable for high. Thermowell Diameter.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Diameter This can also be referred to as the od of the temperature sensor side of the well or id of the flange. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. To shorten the thermowell stem or to increase the root and tip diameter, accepting. Thermowell Diameter.

From www.cse-sa.com

21/2" Thermowell Stainless Steel 3161/2" NPT Connections Thermowell Diameter Q is the root diameter of the thermowell. P is the process connection diameter of the thermowell. They are suitable for high process loads, that might occur as a result of flow,. The reduced surface area allows smoother velocities and faster temperature response for sensing devices. Stepped thermowells usually have a ¾ diameter at the top which is reduced to. Thermowell Diameter.

From www.clevelandinstrument.com

thermowellspartnumbersforbimetalthermowellswithlagging Thermowell Diameter Q is the root diameter of the thermowell. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. Stepped thermowells usually have a ¾ diameter at the top which is. Thermowell Diameter.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Diameter The reduced surface area allows smoother velocities and faster temperature response for sensing devices. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. P is the. Thermowell Diameter.

From www.youtube.com

Thermowell Types, Purpose, Construction, Specifications and Selection Thermowell Diameter This can also be referred to as the od of the temperature sensor side of the well or id of the flange. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. They are suitable for high process loads, that might occur as a result of flow,. Below, we will explain. Thermowell Diameter.

From www.tc.co.uk

Flanged Thermowells TC Ltd. Thermowell Diameter P is the process connection diameter of the thermowell. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. They are suitable for high process loads, that might occur as a result of flow,. The thermowells model sd 400 s are welded into the process. To shorten the thermowell stem or. Thermowell Diameter.

From asrichards.com

Thermocouple Thermowells Arklay S. Richards Co., Inc. Thermowell Diameter Q is the root diameter of the thermowell. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. The reduced surface area allows smoother velocities and faster temperature response for sensing devices. Their diameter decreases gradually over the. The thermowells model sd 400 s are welded into the process. P is. Thermowell Diameter.

From rosecal.com.au

Types of thermowells Rose Calibration Company; Quality; Calibration Thermowell Diameter Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. This can also be referred to as the od of the temperature sensor side of the well or id of the flange. The reduced surface area allows smoother velocities and faster temperature response for sensing devices.. Thermowell Diameter.

From whatispiping.com

What is a Thermowell? Types of Thermowell What Is Piping All about Thermowell Diameter To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. P is the process connection diameter of the thermowell. Q is the root diameter of the thermowell. Their diameter decreases gradually over the. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against. Thermowell Diameter.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Diameter The reduced surface area allows smoother velocities and faster temperature response for sensing devices. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. Their diameter decreases gradually over the. They are suitable for high process loads, that might occur as a result of flow,. Stepped thermowells usually have a ¾. Thermowell Diameter.

From www.jms-se.com

Flanged Thermowells JMS Southeast, Inc. Thermowell Diameter The reduced surface area allows smoother velocities and faster temperature response for sensing devices. They are suitable for high process loads, that might occur as a result of flow,. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. Their diameter decreases gradually over the. Q is the root. Thermowell Diameter.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Diameter Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. The reduced surface area allows smoother velocities and faster temperature response for sensing devices. The thermowells model sd 400 s are welded into the process. This can also be referred to as the od of the temperature sensor side of the. Thermowell Diameter.

From secureservercdn.net

What is a Thermowell? Types of Thermowell The Engineering Concepts Thermowell Diameter The thermowells model sd 400 s are welded into the process. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. They are suitable for high process loads, that might. Thermowell Diameter.

From asrichards.com

Straight Assemblies Thermowell Arklay S. Richards Co., Inc. Thermowell Diameter Their diameter decreases gradually over the. P is the process connection diameter of the thermowell. This can also be referred to as the od of the temperature sensor side of the well or id of the flange. The reduced surface area allows smoother velocities and faster temperature response for sensing devices. To shorten the thermowell stem or to increase the. Thermowell Diameter.

From www.emerson.com

Rosemount™ Thermowells Emerson IN Thermowell Diameter The reduced surface area allows smoother velocities and faster temperature response for sensing devices. A straight thermowell is the same diameter throughout the entire insertion length and offers protection against corrosion and erosion. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. This can also. Thermowell Diameter.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Diameter The thermowells model sd 400 s are welded into the process. Stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. To shorten the thermowell stem or to increase the root and tip diameter, accepting a longer response time of the thermometer. P is the process connection diameter of the thermowell.. Thermowell Diameter.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Diameter They are suitable for high process loads, that might occur as a result of flow,. The thermowells model sd 400 s are welded into the process. Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. This can also be referred to as the od of. Thermowell Diameter.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Diameter Below, we will explain the terms used on the datasheets of ifm thermowells and provide guidance on how to determine whether a thermowell and. Q is the root diameter of the thermowell. The thermowells model sd 400 s are welded into the process. The reduced surface area allows smoother velocities and faster temperature response for sensing devices. P is the. Thermowell Diameter.