Worm Wheel Gear Diameter . 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. A crownless worm gear results when it is made by using a hob that has an. These functions are useful for design of complementary gears of steel worm and plastic worm gear. Cut worm gear with a hob cutter of greater pitch diameter than the worm. Zar3+ calculates tooth thickness and over pin/ball diameters (opd). Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. The program solves the following tasks: You can enter pin diameter and. The calculation is used for geometrical and strength designs and worm gearing check.

from khkgears.net

The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. The program solves the following tasks: Cut worm gear with a hob cutter of greater pitch diameter than the worm. You can enter pin diameter and. The calculation is used for geometrical and strength designs and worm gearing check. A crownless worm gear results when it is made by using a hob that has an. Zar3+ calculates tooth thickness and over pin/ball diameters (opd).

Surface Durability of Worm Gear KHK Gears

Worm Wheel Gear Diameter The program solves the following tasks: The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. A crownless worm gear results when it is made by using a hob that has an. 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. You can enter pin diameter and. The calculation is used for geometrical and strength designs and worm gearing check. Zar3+ calculates tooth thickness and over pin/ball diameters (opd). It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: Cut worm gear with a hob cutter of greater pitch diameter than the worm. Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. These functions are useful for design of complementary gears of steel worm and plastic worm gear. The program solves the following tasks:

From dpoksystems.weebly.com

Worm gear design calculation pdf to excel dpoksystems Worm Wheel Gear Diameter The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. A crownless worm gear results when it is. Worm Wheel Gear Diameter.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Worm Wheel Gear Diameter The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: The program solves the following tasks: 204 rows in this document, the permissible torque. Worm Wheel Gear Diameter.

From framo-morat.com

Worm Gear Sets A65 Framo Morat Your idea Our drive Worm Wheel Gear Diameter Zar3+ calculates tooth thickness and over pin/ball diameters (opd). The program solves the following tasks: These functions are useful for design of complementary gears of steel worm and plastic worm gear. Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. Cut worm gear with a hob cutter of greater pitch diameter than the worm. The. Worm Wheel Gear Diameter.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Worm Wheel Gear Diameter Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. These functions are useful for design of complementary gears of steel worm and plastic worm gear. A crownless worm gear results when it is made by using a hob that has an. 204 rows in this document, the permissible torque for a worm gear is limited. Worm Wheel Gear Diameter.

From www.tec-science.com

Worms and worm gears tecscience Worm Wheel Gear Diameter Zar3+ calculates tooth thickness and over pin/ball diameters (opd). These functions are useful for design of complementary gears of steel worm and plastic worm gear. You can enter pin diameter and. Cut worm gear with a hob cutter of greater pitch diameter than the worm. The calculation is used for geometrical and strength designs and worm gearing check. Double enveloping. Worm Wheel Gear Diameter.

From www.youtube.com

Worm Gear terminology/Nomenclature and velocity ratio YouTube Worm Wheel Gear Diameter A crownless worm gear results when it is made by using a hob that has an. Cut worm gear with a hob cutter of greater pitch diameter than the worm. 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. Zar3+ calculates tooth thickness and over. Worm Wheel Gear Diameter.

From www.researchgate.net

(a) Details of the worm gear [20], and (b) worm gear profile and bull Worm Wheel Gear Diameter A crownless worm gear results when it is made by using a hob that has an. The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. Zar3+ calculates tooth thickness and over pin/ball diameters (opd). The calculation is used for geometrical and. Worm Wheel Gear Diameter.

From framo-morat.com

Worm Gear Sets A50 Framo Morat Your idea Our drive Worm Wheel Gear Diameter These functions are useful for design of complementary gears of steel worm and plastic worm gear. The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. Zar3+ calculates tooth thickness and over pin/ball diameters (opd). 204 rows in this document, the permissible. Worm Wheel Gear Diameter.

From premium-transmission.com

A Comprehensive Guide On The Worm Gears Premium Transmission Worm Wheel Gear Diameter The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. You can enter pin diameter and. Cut worm gear with a hob cutter of greater pitch diameter than the worm. Double enveloping gearsets require accurate alignment of both the worm and the. Worm Wheel Gear Diameter.

From www.youtube.com

Bevel Gears and Worm Gears Part IV YouTube Worm Wheel Gear Diameter Zar3+ calculates tooth thickness and over pin/ball diameters (opd). Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. A crownless worm gear results when it is made by using a hob that has an. The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number. Worm Wheel Gear Diameter.

From www.researchgate.net

Coordinate system of globoid worm drive. Download Scientific Diagram Worm Wheel Gear Diameter Zar3+ calculates tooth thickness and over pin/ball diameters (opd). A crownless worm gear results when it is made by using a hob that has an. Cut worm gear with a hob cutter of greater pitch diameter than the worm. These functions are useful for design of complementary gears of steel worm and plastic worm gear. 204 rows in this document,. Worm Wheel Gear Diameter.

From energypara.web.fc2.com

Worm Gear Design Calculation Pdf Worm Wheel Gear Diameter The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. A crownless worm gear results when it is made by using a hob that has an. Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. It is. Worm Wheel Gear Diameter.

From www.engineerknow.com

How to calculate gear ratio of Worm gear Worm Wheel Gear Diameter The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. You can enter pin diameter and. 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. Cut worm. Worm Wheel Gear Diameter.

From www.vlr.eng.br

Worm Gear What Is It? How Is It Made? Types Of, Uses vlr.eng.br Worm Wheel Gear Diameter 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. The calculation is used for geometrical and strength designs and worm gearing check. Cut worm gear with a hob cutter of greater pitch diameter than the worm. Zar3+ calculates tooth thickness and over pin/ball diameters (opd).. Worm Wheel Gear Diameter.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Worm Wheel Gear Diameter You can enter pin diameter and. A crownless worm gear results when it is made by using a hob that has an. Zar3+ calculates tooth thickness and over pin/ball diameters (opd). The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. The. Worm Wheel Gear Diameter.

From maedlernorthamerica.com

Precision worm wheel centre distance 40mm i=10 30 teeth SKU 32231000 Worm Wheel Gear Diameter It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: These functions are useful for design of complementary gears of steel worm and plastic worm gear. The program solves the following tasks: The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the. Worm Wheel Gear Diameter.

From www.researchgate.net

Model of worm wheel with separate detail and marked regions of the Worm Wheel Gear Diameter Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. The program solves the following tasks: It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: Cut worm gear with a hob cutter of greater pitch diameter than the worm. You can enter pin diameter and. 204 rows. Worm Wheel Gear Diameter.

From framo-morat.com

Worm Gear Sets A35 Framo Morat Your idea Our drive Worm Wheel Gear Diameter You can enter pin diameter and. A crownless worm gear results when it is made by using a hob that has an. These functions are useful for design of complementary gears of steel worm and plastic worm gear. The program solves the following tasks: The calculation is used for geometrical and strength designs and worm gearing check. Cut worm gear. Worm Wheel Gear Diameter.

From tstr.update-this.com

Worm Gear Design Calculation Pdf Viewer Worm Wheel Gear Diameter Cut worm gear with a hob cutter of greater pitch diameter than the worm. 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. The calculation is used for geometrical and strength designs and worm gearing check. It is the greatest diameter of worm gear, while. Worm Wheel Gear Diameter.

From khkgears.net

Technical Information of Worm Gear KHK Gears Worm Wheel Gear Diameter Cut worm gear with a hob cutter of greater pitch diameter than the worm. The program solves the following tasks: The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. 204 rows in this document, the permissible torque for a worm gear. Worm Wheel Gear Diameter.

From www.mtdparts.com

Worm Gear 20 Teeth 1720933 MTD Parts Worm Wheel Gear Diameter The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. The program solves the following tasks: These functions. Worm Wheel Gear Diameter.

From www.researchgate.net

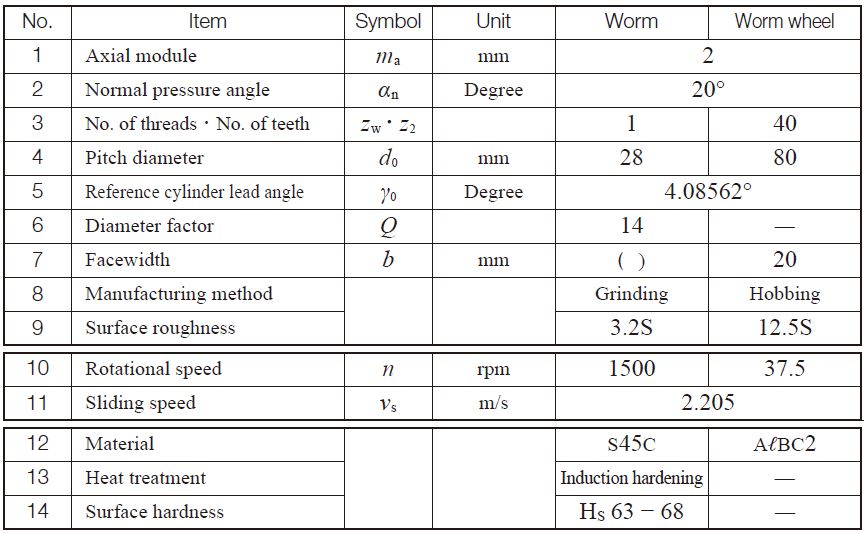

Parameters of worms and gears Download Table Worm Wheel Gear Diameter The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. Cut worm gear with a hob cutter of greater pitch diameter than the worm. These functions are useful. Worm Wheel Gear Diameter.

From hkaa2011.en.made-in-china.com

High Quality Aluminum Bronze Gear Worm Gear and Worm Wheel Tip Diameter Worm Wheel Gear Diameter It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: Cut worm gear with a hob cutter of greater pitch diameter than the worm. You can enter pin diameter and. These functions are useful for design of complementary gears of steel worm and plastic worm gear. The unique feature of a worm. Worm Wheel Gear Diameter.

From www.vlr.eng.br

Worm Gear What Is It? How Is It Made? Types Of, Uses vlr.eng.br Worm Wheel Gear Diameter Zar3+ calculates tooth thickness and over pin/ball diameters (opd). It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. The program solves the following tasks: Double enveloping gearsets. Worm Wheel Gear Diameter.

From exykbuqdo.blob.core.windows.net

Worm Gear Meaning And Examples at Freddie Vargas blog Worm Wheel Gear Diameter Cut worm gear with a hob cutter of greater pitch diameter than the worm. These functions are useful for design of complementary gears of steel worm and plastic worm gear. Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. 204 rows in this document, the permissible torque for a worm gear is limited by considerations. Worm Wheel Gear Diameter.

From www.amazon.com

D DOLITY 60T Brass Worm Gear Wheel + 5mm Hole Diameter Worm Gear Shaft Worm Wheel Gear Diameter The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. The program solves the following tasks: The calculation is used for geometrical and strength designs and worm gearing check. Zar3+ calculates tooth thickness and over pin/ball diameters (opd). These functions are useful. Worm Wheel Gear Diameter.

From khkgears.net

Surface Durability of Worm Gear KHK Gears Worm Wheel Gear Diameter Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. These functions are useful for design of complementary gears of steel worm and plastic worm gear. Zar3+ calculates tooth thickness and over pin/ball diameters (opd). It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: Cut worm gear. Worm Wheel Gear Diameter.

From www.youtube.com

Worm and Wheel Gearbox Gear ratio Calculation How to calculate worm Worm Wheel Gear Diameter The calculation is used for geometrical and strength designs and worm gearing check. The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. Cut worm gear with a. Worm Wheel Gear Diameter.

From framo-morat.com

Worm Gear Sets A31 Framo Morat Your idea Our drive Worm Wheel Gear Diameter The calculation is used for geometrical and strength designs and worm gearing check. The program solves the following tasks: Zar3+ calculates tooth thickness and over pin/ball diameters (opd). You can enter pin diameter and. 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. It is. Worm Wheel Gear Diameter.

From hkaa2011.en.made-in-china.com

Precision Brass Worm Gear and Stainless Steel Worm Wheel China Worm Worm Wheel Gear Diameter You can enter pin diameter and. These functions are useful for design of complementary gears of steel worm and plastic worm gear. Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. A crownless worm gear results when it is made by using a hob that has an. The calculation is used for geometrical and strength. Worm Wheel Gear Diameter.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Worm Wheel Gear Diameter These functions are useful for design of complementary gears of steel worm and plastic worm gear. A crownless worm gear results when it is made by using a hob that has an. Zar3+ calculates tooth thickness and over pin/ball diameters (opd). You can enter pin diameter and. The unique feature of a worm gear pair is that you can maintain. Worm Wheel Gear Diameter.

From grabcad.com

How to Calculate the Centre to CentreDistance between Worm and Wrom Worm Wheel Gear Diameter The program solves the following tasks: 204 rows in this document, the permissible torque for a worm gear is limited by considerations of surface stress (conveniently referred to as wear. Double enveloping gearsets require accurate alignment of both the worm and the wormwheel to. Zar3+ calculates tooth thickness and over pin/ball diameters (opd). A crownless worm gear results when it. Worm Wheel Gear Diameter.

From klamqmbbt.blob.core.windows.net

Worm Gear Design Calculation at Virginia Kilburn blog Worm Wheel Gear Diameter The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. The calculation is used for geometrical and strength designs and worm gearing check. The program solves the following tasks: These functions are useful for design of complementary gears of steel worm and. Worm Wheel Gear Diameter.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Worm Wheel Gear Diameter It is the greatest diameter of worm gear, while the approximate recommended value as per din 3975 is: These functions are useful for design of complementary gears of steel worm and plastic worm gear. You can enter pin diameter and. The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the. Worm Wheel Gear Diameter.

From www.indiamart.com

Max Upto 300 mm (od) Worm Wheel Gear at Rs 250/piece in Bengaluru ID Worm Wheel Gear Diameter You can enter pin diameter and. The calculation is used for geometrical and strength designs and worm gearing check. The unique feature of a worm gear pair is that you can maintain the diameter of the worm, and the number of teeth of the worm wheel, and. A crownless worm gear results when it is made by using a hob. Worm Wheel Gear Diameter.