Solder For Dip . A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. Solder melting, component cleaning, pcb placement,. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. This article provides an overview of dip soldering, its. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. There are five basic steps involved in the wave soldering process: The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux.

from wpo-altertechnology.com

This article provides an overview of dip soldering, its. The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. Solder melting, component cleaning, pcb placement,. There are five basic steps involved in the wave soldering process: A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied.

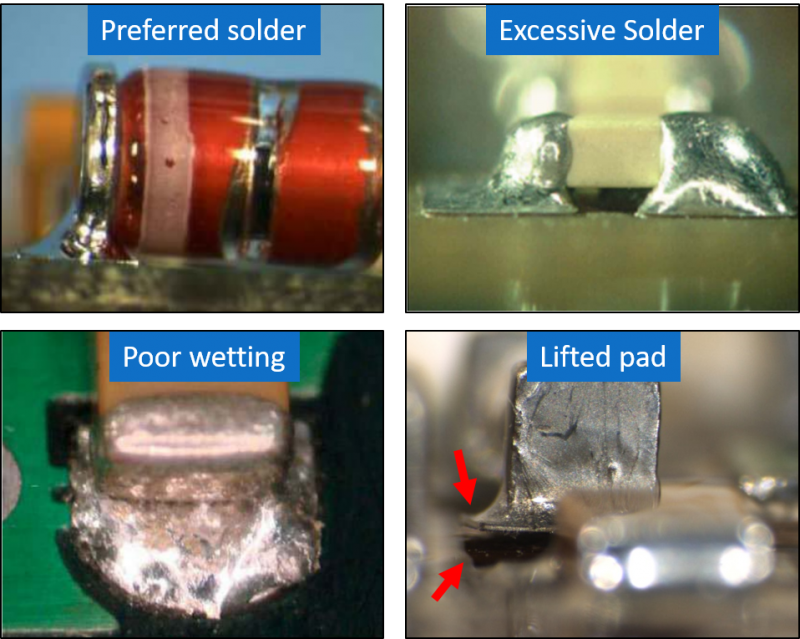

Soldering Verification Processes

Solder For Dip To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. There are five basic steps involved in the wave soldering process: Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. Solder melting, component cleaning, pcb placement,. The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. This article provides an overview of dip soldering, its.

From www.chemtronics.com

Ultimate Guide to Temporary Solder Mask Chemtronics Solder For Dip The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. Solder melting, component cleaning, pcb placement,.. Solder For Dip.

From www.youtube.com

Dip Soldering YouTube Solder For Dip A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. This article provides an overview. Solder For Dip.

From www.eevblog.com

How to solder DIP onto SMD footprint on a commercial PCB. Page 1 Solder For Dip There are five basic steps involved in the wave soldering process: This article provides an overview of dip soldering, its. The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w.. Solder For Dip.

From www.youtube.com

Full PCB Board Soldering in One Step Fast Dip Process of Soldering Solder For Dip Solder melting, component cleaning, pcb placement,. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. A solder paste for dip transfer. Solder For Dip.

From www.youtube.com

How to Make Soldering Pot YouTube Solder For Dip There are five basic steps involved in the wave soldering process: To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. The molten solder will infiltrate and diffuse over. Solder For Dip.

From www.renhotecev.com

100A floating board to board connector 6mm contact straight female two Solder For Dip Solder melting, component cleaning, pcb placement,. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. This article provides an overview of dip soldering, its. There are five basic steps involved in the wave soldering process: The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the. Solder For Dip.

From tanksalot.net

Solder Dipping Pot Solder For Dip Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. There are five basic steps involved in the wave soldering process: The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. The first solder wave is the random wave that will print the welding flux. Solder For Dip.

From www.morvelevona.co.il

220V 300W Stainless Steel Melting Solder 100MM Soldering Pot Solder For Dip Solder melting, component cleaning, pcb placement,. A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. The first solder wave is the random wave that will print the welding. Solder For Dip.

From absolutepcbassembly.com

IPC JSTD001 Standard for Soldering Absolute Electronics Solder For Dip Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. There are five basic steps involved in the wave soldering process: This article provides an overview of dip soldering, its. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. The first solder wave. Solder For Dip.

From dir.indiamart.com

Dip Soldering Machine Solder Dip Machine Latest Price, Manufacturers Solder For Dip This article provides an overview of dip soldering, its. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. There are five basic steps involved in the wave soldering process: A solder paste for dip. Solder For Dip.

From www.smtfactory.com

I.C.T Dip Soldering Machine for Heat Exchanger PCB Wave Soldering THT Solder For Dip There are five basic steps involved in the wave soldering process: A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. Solder melting, component cleaning, pcb placement,. This article provides an overview of dip soldering,. Solder For Dip.

From www.naa.edu

9 Essential Electronics Soldering Tips and Tricks for Beginners Solder For Dip The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. There are five basic steps involved. Solder For Dip.

From titoma.com

How to Solder Components? Guide to an Expert Titoma Solder For Dip Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. There are five basic steps involved in the wave soldering process: To. Solder For Dip.

From wpo-altertechnology.com

Soldering Verification Processes Solder For Dip A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. There are five basic steps involved in the wave soldering process: This article provides an overview of dip soldering, its.. Solder For Dip.

From www.doeeet.com

Hot Solder Dip Acceptance Criteria for Flat Pack Packages Solder For Dip Solder melting, component cleaning, pcb placement,. This article provides an overview of dip soldering, its. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. To reduce solder bridging between smd components and/or leads, the pcb design. Solder For Dip.

From stellartechnical.com

How to Use a Solder Pot What is a Solder Pot Solder For Dip There are five basic steps involved in the wave soldering process: The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. The first solder wave is the random wave that. Solder For Dip.

From www.sanshinechina.com

Leadfree dip soldering pot (SSTT01) Solder For Dip This article provides an overview of dip soldering, its. There are five basic steps involved in the wave soldering process: The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. The molten solder will infiltrate and diffuse. Solder For Dip.

From www.alibaba.com

Dip Soldering Machine/ About 60kg Solder Pot Size 450*300*70mm Solder For Dip There are five basic steps involved in the wave soldering process: Solder melting, component cleaning, pcb placement,. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. A solder paste for dip transfer has. Solder For Dip.

From exootrukg.blob.core.windows.net

What Is Solder Retention at Rick Woolf blog Solder For Dip Solder melting, component cleaning, pcb placement,. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to. Solder For Dip.

From www.renhotecev.com

100A floating board to board connector 6mm contact bend male two Solder For Dip The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. To reduce solder bridging between smd components. Solder For Dip.

From www.pinterest.com

This is a large "solder pot" that allows me to dip a circuit board in Solder For Dip Solder melting, component cleaning, pcb placement,. The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. There are five basic steps involved in the wave soldering process: This article provides an overview of dip soldering, its. The first solder wave is the random wave that will print the welding flux. Solder For Dip.

From www.1clicksmt.com

Auto Dip Soldering Machine ADS3530G Auto Dip Soldering Machine ADS Solder For Dip Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. There are five basic steps involved in the wave soldering process: The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. This article provides an overview of dip soldering, its. The first solder wave is. Solder For Dip.

From www.tech-sparks.com

Distribution process for soldering circuit boardsTechSparks Solder For Dip The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. This article provides an overview of dip soldering, its. Dip soldering is accomplished by submerging parts to be joined into. Solder For Dip.

From www.raypcb.com

What is the Difference Between SMD Soldering and DIP Soldering? RAYPCB Solder For Dip There are five basic steps involved in the wave soldering process: The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. Solder melting, component cleaning, pcb placement,. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end,. Solder For Dip.

From www.youtube.com

ADS3530C Auto Dip Soldering Machine YouTube Solder For Dip To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. There are five basic steps involved in the wave soldering process: A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. Dip soldering is accomplished by submerging parts to. Solder For Dip.

From www.obsmt.com

semiauto DIP soldering machine SHENZHEN OUBEL TECHNOLOGY CO., LTD Solder For Dip Solder melting, component cleaning, pcb placement,. To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. There are five basic steps involved in the wave soldering process: The first. Solder For Dip.

From dir.indiamart.com

Dip Soldering Machine Solder Dip Machine Latest Price, Manufacturers Solder For Dip A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. This article provides an overview of dip soldering, its. Solder melting, component cleaning, pcb placement,. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. The first solder wave is the random wave that will. Solder For Dip.

From www.exportersindia.com

Electric 7 KG Dip Soldering Machine manual, Voltage 220V at Rs 5500 Solder For Dip The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. A solder paste for dip transfer has. Solder For Dip.

From www.youtube.com

Dip Soldering MachineRavindra Electronics delhi[MADE IN INDIA Solder For Dip To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. Solder melting, component cleaning, pcb placement,. There are five basic steps involved in the wave soldering process: A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. The first. Solder For Dip.

From szwenzhan.en.made-in-china.com

Multi Wave Solder Dipping Machine Fully Automatic SMT Lead Free Dual Solder For Dip Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. A solder paste for dip transfer has similar feature, with solder powder content typically ranging from 80 to 85% w/w. The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. This article provides an overview. Solder For Dip.

From www.youtube.com

Method for Soldering and Inspecting a DIP YouTube Solder For Dip There are five basic steps involved in the wave soldering process: The molten solder will infiltrate and diffuse over the surface of the metal that has been cleaned by the flux. This article provides an overview of dip soldering, its. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. A solder paste for dip. Solder For Dip.

From loeckfvzz.blob.core.windows.net

What Size Solder For Circuit Boards at Ebony Williams blog Solder For Dip There are five basic steps involved in the wave soldering process: Solder melting, component cleaning, pcb placement,. This article provides an overview of dip soldering, its. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. Dip. Solder For Dip.

From devicemart.blogspot.com

솔더링(납땜) 방법 스루 홀 솔더링(납땜 기초) Solder For Dip To reduce solder bridging between smd components and/or leads, the pcb design guidelines for wave or dip soldering should be applied. Solder melting, component cleaning, pcb placement,. There are five basic steps involved in the wave soldering process: This article provides an overview of dip soldering, its. Dip soldering is accomplished by submerging parts to be joined into a molten. Solder For Dip.

From www.matronics.eu

Solder for dipping, 100g, Lead free ELSOLD SN100 MAS Matronics Solder For Dip There are five basic steps involved in the wave soldering process: This article provides an overview of dip soldering, its. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. Dip soldering is accomplished by submerging parts. Solder For Dip.

From www.solderconnection.com

Industrial Soldering Solder Connection Solder, Fluxes & Wires Solder For Dip This article provides an overview of dip soldering, its. Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. The first solder wave is the random wave that will print the welding flux to all the solder plates, the component solder end, and the pin of the bottom of the printed plate. The molten solder. Solder For Dip.