Engraving With Spot Drill . I started with a.05 ball mill that was working great until i plunged it and the holder into a part. We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not have the. Center drill should be allowed for engrave. Spot drills are essential for enhancing the precision of secondary drilling operations. By leaving a chamfer, screw heads sit flush with the part once inserted. They can also be used for chamfering,. A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. Next, i settled on an 1/8 center drill. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. They can also be used for chamfering, countersinking, v. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more.

from jimmore.en.taiwantrade.com

Spot drills are essential for enhancing the precision of secondary drilling operations. Next, i settled on an 1/8 center drill. Center drill should be allowed for engrave. By leaving a chamfer, screw heads sit flush with the part once inserted. They can also be used for chamfering,. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not have the. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. I started with a.05 ball mill that was working great until i plunged it and the holder into a part.

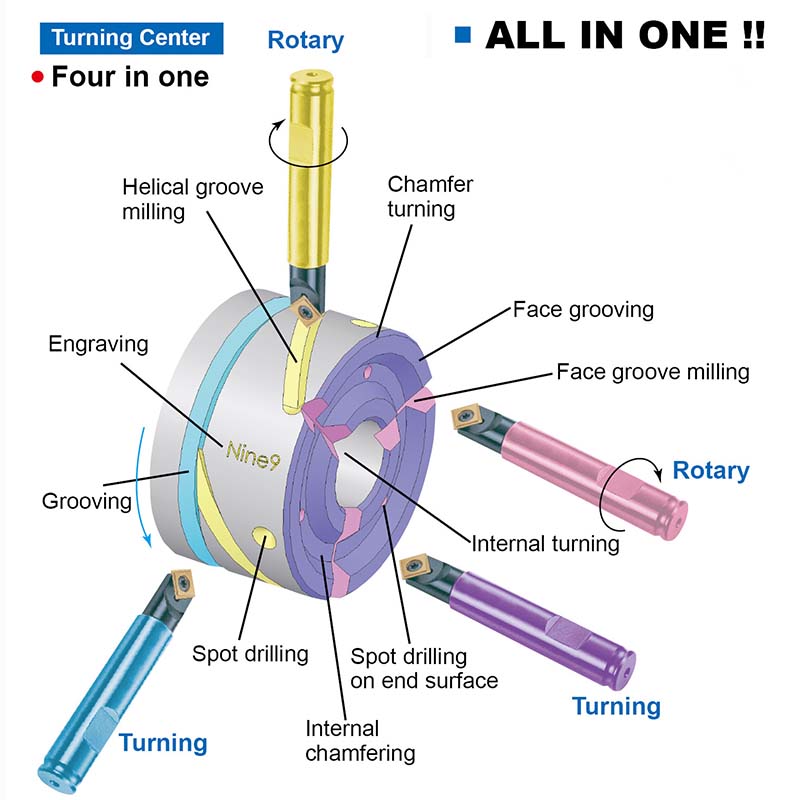

90° NC Spot Drill with carbide insert_suit spotting, engraving, grooving, chamfering and facing

Engraving With Spot Drill Spot drills are essential for enhancing the precision of secondary drilling operations. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. They can also be used for chamfering,. Spot drills are essential for enhancing the precision of secondary drilling operations. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. By leaving a chamfer, screw heads sit flush with the part once inserted. Center drill should be allowed for engrave. They can also be used for chamfering, countersinking, v. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not have the. Next, i settled on an 1/8 center drill.

From pxhere.com

Free Images drill, engraving, drilling, chips, machining, machine tool, milling machine Engraving With Spot Drill I started with a.05 ball mill that was working great until i plunged it and the holder into a part. Spot drills are essential for enhancing the precision of secondary drilling operations. Next, i settled on an 1/8 center drill. They can also be used for chamfering, countersinking, v. Spot drilling is crucial for enhancing the accuracy of secondary hole. Engraving With Spot Drill.

From drillsboss.com

Spot Drill vs Center Drill Unveiling Key Differences Engraving With Spot Drill By leaving a chamfer, screw heads sit flush with the part once inserted. Center drill should be allowed for engrave. Next, i settled on an 1/8 center drill. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. A spotting drill’s purpose is to create a small divot to correctly. Engraving With Spot Drill.

From www.taiwantrade.com

Engraving Drill Taiwantrade Engraving With Spot Drill By leaving a chamfer, screw heads sit flush with the part once inserted. They can also be used for chamfering, countersinking, v. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. A spotting drill’s purpose is to create a small divot to correctly locate the center of a. Engraving With Spot Drill.

From www.pinterest.ca

Mini Cordless Drill Rechargeable USB Woodworking Wireless Engraving Pen With LED Micro Rotary Engraving With Spot Drill By leaving a chamfer, screw heads sit flush with the part once inserted. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not. Engraving With Spot Drill.

From www.youtube.com

60° 90° 120° ACE Spot Drill High rigidity, high performance cutting YouTube Engraving With Spot Drill By leaving a chamfer, screw heads sit flush with the part once inserted. Center drill should be allowed for engrave. Next, i settled on an 1/8 center drill. They can also be used for chamfering,. Spot drills are essential for enhancing the precision of secondary drilling operations. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. With. Engraving With Spot Drill.

From www.youtube.com

Centre Drill vs Spotting Drill YouTube Engraving With Spot Drill A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. Center drill should be allowed for engrave. By leaving a chamfer, screw heads sit flush with the part once inserted. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. I started with a.05 ball mill. Engraving With Spot Drill.

From www.youtube.com

Spot Drill YouTube Engraving With Spot Drill By leaving a chamfer, screw heads sit flush with the part once inserted. Center drill should be allowed for engrave. A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. We use them with engrave all. Engraving With Spot Drill.

From drillsboss.com

Spotting Drill Vs Center Drills Key Differences 2023 Guide Engraving With Spot Drill They can also be used for chamfering,. Next, i settled on an 1/8 center drill. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. By leaving a chamfer, screw heads sit flush with the part once inserted. They can also be used for chamfering, countersinking, v. A spotting. Engraving With Spot Drill.

From glassengraving.com

Our Engraving Processes Engraving With Spot Drill We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not have the. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. They can also be used for chamfering, countersinking, v. They can also be used for chamfering,. Next, i settled on. Engraving With Spot Drill.

From www.youtube.com

Quick Machining Tip 4 Consistent Countersinks and Spot Drills YouTube Engraving With Spot Drill Center drill should be allowed for engrave. By leaving a chamfer, screw heads sit flush with the part once inserted. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. They can also be used for chamfering, countersinking, v. They can also be used for chamfering,. Spot drills are essential for enhancing the precision of secondary drilling operations.. Engraving With Spot Drill.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Machinist Blog Engraving With Spot Drill Next, i settled on an 1/8 center drill. A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. They can also be used for chamfering, countersinking, v. We use them with engrave all the time and it works great, but i have to create an additional tool in. Engraving With Spot Drill.

From www.youtube.com

Engraving Spot Drill Hole with 0.2mm20degree VCutter YouTube Engraving With Spot Drill A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. Spot drills are essential for enhancing the precision of secondary drilling operations. Center drill should be allowed for. Engraving With Spot Drill.

From www.tmd.com.tw

Engraving Drill Taiwan Microdrill Co., Ltd. Engraving With Spot Drill With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. Center drill should be allowed for engrave. By leaving a chamfer, screw heads sit flush with the part once inserted. Next, i settled on an 1/8 center drill. They can also be used for chamfering,. We use them with. Engraving With Spot Drill.

From blog.tormach.com

When to Use a Spot Drill Engraving With Spot Drill By leaving a chamfer, screw heads sit flush with the part once inserted. They can also be used for chamfering, countersinking, v. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. Center drill should be allowed for engrave. They can also be used for chamfering,. I started with. Engraving With Spot Drill.

From www.cnccookbook.com

When to Use a Spot Drill + 7 Useful Tips and Techniques CNCCookbook Be A Better CNC'er Engraving With Spot Drill By leaving a chamfer, screw heads sit flush with the part once inserted. Next, i settled on an 1/8 center drill. They can also be used for chamfering, countersinking, v. They can also be used for chamfering,. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. Center drill should be allowed for engrave. With angles ranging from. Engraving With Spot Drill.

From www.cutwel.co.uk

Spot Drills vs Centre Drills Cutwel Drilling Tool Specialist Cutwel Ltd Engraving With Spot Drill Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. By leaving a chamfer, screw heads sit flush with the part once inserted. With angles ranging from 60° to 120°, spot drills find applications in drilling. Engraving With Spot Drill.

From www.youtube.com

engraving stone with dremel YouTube Engraving With Spot Drill With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. Spot drills are essential for enhancing the precision of secondary drilling operations. We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not have. Engraving With Spot Drill.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Engraving With Spot Drill We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not have the. Center drill should be allowed for engrave. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. A spotting drill’s purpose. Engraving With Spot Drill.

From www.taiwantrade.com

90° NC Spot Drill with carbide insert_suit spotting, engraving, grooving, chamfering and facing Engraving With Spot Drill Next, i settled on an 1/8 center drill. They can also be used for chamfering,. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. By leaving a chamfer, screw heads sit flush with the part once inserted. A spotting drill’s purpose is to create a small divot to. Engraving With Spot Drill.

From www.archcuttingtools.com

Spotting Drills ARCH Cutting Tools Engraving With Spot Drill Next, i settled on an 1/8 center drill. We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not have the. They can also be used for chamfering,. A spotting drill’s purpose is to create a small divot to correctly locate the center of a. Engraving With Spot Drill.

From www.tmd.com.tw

Center Drill & Spotting Drill Taiwan Microdrill Co., Ltd. Engraving With Spot Drill Center drill should be allowed for engrave. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. They can also be used for chamfering, countersinking, v. Spot drilling is. Engraving With Spot Drill.

From www.youtube.com

Spot Drilling YouTube Engraving With Spot Drill Next, i settled on an 1/8 center drill. Center drill should be allowed for engrave. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. They can also be. Engraving With Spot Drill.

From forums.autodesk.com

Engraving with Center Drill Autodesk Community Engraving With Spot Drill They can also be used for chamfering,. Next, i settled on an 1/8 center drill. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not have the. I started with a.05 ball. Engraving With Spot Drill.

From pxhere.com

Free Images drill, engraving, drilling, chips, machining, machine tool, milling machine Engraving With Spot Drill Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. They can also be used for chamfering,. By leaving a chamfer, screw heads sit flush with the part once inserted. We use them with engrave all the. Engraving With Spot Drill.

From www.finepowertools.com

Spot Drill vs Center Drill. (Differences and Uses) Engraving With Spot Drill A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. Next, i settled on an 1/8 center drill. Center drill should be allowed for engrave. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. Spot drills are. Engraving With Spot Drill.

From viettechview.com

Nine9 NC Spot Drill , center drill, engraving tool Engraving With Spot Drill Spot drills are essential for enhancing the precision of secondary drilling operations. Next, i settled on an 1/8 center drill. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. Center drill should be allowed for engrave. By leaving a chamfer, screw heads sit flush with the part once inserted.. Engraving With Spot Drill.

From www.youtube.com

Spot Drilling YouTube Engraving With Spot Drill With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. They can also be used for chamfering,. Center drill should be allowed for engrave. By leaving a chamfer, screw. Engraving With Spot Drill.

From www.aliexpress.com

Drill Dremel Mini Drill DIY Drill Engraver Electric 180W New Engraving Pen grinder Electric Engraving With Spot Drill Next, i settled on an 1/8 center drill. By leaving a chamfer, screw heads sit flush with the part once inserted. Center drill should be allowed for engrave. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. A spotting drill’s purpose is to create a small divot to. Engraving With Spot Drill.

From www.youtube.com

Tutorial 2 Part 6 Spot Drill and Drill YouTube Engraving With Spot Drill A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. By leaving a chamfer, screw heads sit flush with the part once inserted. We use them with engrave. Engraving With Spot Drill.

From www.youtube.com

Engraving with a center drill YouTube Engraving With Spot Drill They can also be used for chamfering, countersinking, v. Center drill should be allowed for engrave. Next, i settled on an 1/8 center drill. Spot drills are essential for enhancing the precision of secondary drilling operations. Spot drilling is crucial for enhancing the accuracy of secondary hole drilling. By leaving a chamfer, screw heads sit flush with the part once. Engraving With Spot Drill.

From es.industryarena.com

NC Spot Drill Nine9 Cutting Tools Engraving With Spot Drill They can also be used for chamfering,. Next, i settled on an 1/8 center drill. A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. Spot drills are essential for enhancing the precision of secondary drilling operations. We use them with engrave all the time and it works. Engraving With Spot Drill.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Engraving With Spot Drill A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. They can also be used for chamfering,. By leaving a chamfer, screw heads sit flush with the part once inserted. They can also be used for chamfering, countersinking, v. Spot drilling is crucial for enhancing the accuracy of. Engraving With Spot Drill.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Machinist Blog Engraving With Spot Drill They can also be used for chamfering,. Center drill should be allowed for engrave. They can also be used for chamfering, countersinking, v. By leaving a chamfer, screw heads sit flush with the part once inserted. With angles ranging from 60° to 120°, spot drills find applications in drilling spotting holes, bores, engraving, chamfering, deburring, and more. Next, i settled. Engraving With Spot Drill.

From jimmore.en.taiwantrade.com

90° NC Spot Drill with carbide insert_suit spotting, engraving, grooving, chamfering and facing Engraving With Spot Drill They can also be used for chamfering, countersinking, v. A spotting drill’s purpose is to create a small divot to correctly locate the center of a drill when initiating a plunge. We use them with engrave all the time and it works great, but i have to create an additional tool in my library that does not have the. Next,. Engraving With Spot Drill.

From www.youtube.com

Nine9 NC Spot Drill with ACE Spot Drill YouTube Engraving With Spot Drill By leaving a chamfer, screw heads sit flush with the part once inserted. Center drill should be allowed for engrave. I started with a.05 ball mill that was working great until i plunged it and the holder into a part. Spot drills are essential for enhancing the precision of secondary drilling operations. We use them with engrave all the time. Engraving With Spot Drill.