Sheet Metal Cut And Bent . sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance.

from www.china-machining.com

this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise.

Sheet Metal Bending Basics, Types, and Tips for Product Designers

Sheet Metal Cut And Bent the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for.

From www.youtube.com

18 types of bending operations in sheet metal Sheet metal bending Sheet Metal Cut And Bent it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. the strength of the. Sheet Metal Cut And Bent.

From www.eng-tips.com

Correct measuring practice for sheet metal parts QC, Inspection Sheet Metal Cut And Bent this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the. Sheet Metal Cut And Bent.

From www.cmrp.com

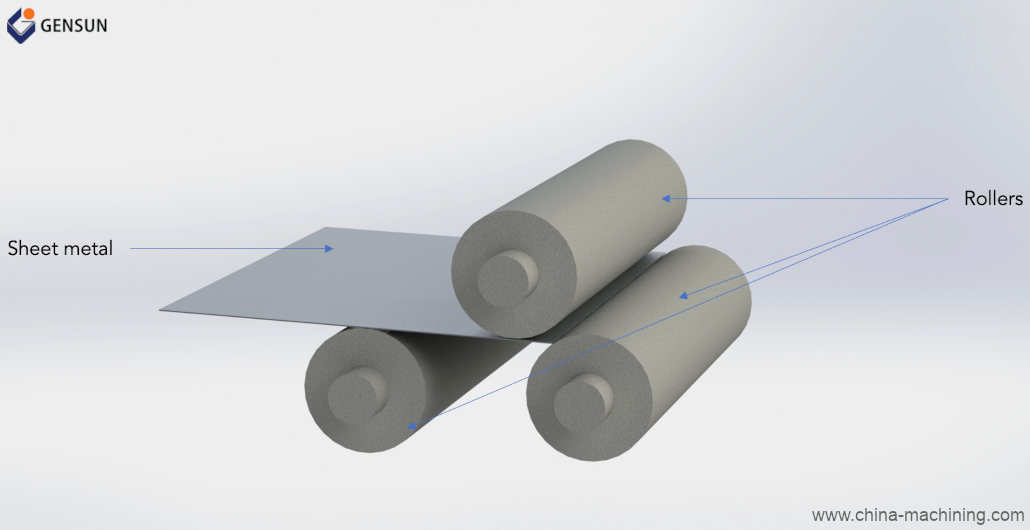

Custom Sheet Metal Bending Custom Rolled Sheet Metal Sheet Metal Cut And Bent Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component. Sheet Metal Cut And Bent.

From www.chegg.com

Solved A piece of sheet metal, w = 14 inches wide, is bent Sheet Metal Cut And Bent it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through. Sheet Metal Cut And Bent.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Sheet Metal Cut And Bent it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. Sheet metal parts are usually. Sheet Metal Cut And Bent.

From www.minifaber.com

The art of sheet metal bending Sheet Metal Cut And Bent sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness.. Sheet Metal Cut And Bent.

From unitymanufacture.com

How To Bend Sheet Metal Into A Cylinder? Unity Manufacture Sheet Metal Cut And Bent Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. the strength of the sheet metal bend needs to be ensured during the. Sheet Metal Cut And Bent.

From www.thelibraryofmanufacturing.com

Sheet Metal Bending Sheet Metal Cut And Bent this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise.. Sheet Metal Cut And Bent.

From www.thelibraryofmanufacturing.com

Sheet Metal Bending Sheet Metal Cut And Bent it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend. Sheet Metal Cut And Bent.

From www.approvedsheetmetal.com

Sheet Metal Offsets Without Custom Tooling Approved Sheet Metal Sheet Metal Cut And Bent the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. it involves a series of steps, starting from picking the. Sheet Metal Cut And Bent.

From www.youtube.com

SolidWorks Sheet Metal How to create the axis of a bent hole YouTube Sheet Metal Cut And Bent this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness.. Sheet Metal Cut And Bent.

From www.cmrp.com

Metal Bending Steel Bar Rolled Easy Way The Chicago Curve Sheet Metal Cut And Bent the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure. Sheet Metal Cut And Bent.

From www.metes.be

Sheet metal bending Sheet Metal Cut And Bent sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design.. Sheet Metal Cut And Bent.

From thelibraryofmanufacturing.com

Sheet Metal Bending Sheet Metal Cut And Bent the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. it involves a series of steps, starting from picking the. Sheet Metal Cut And Bent.

From interprise-solution.pl

Product for industrial technology, cut out of sheet metal and bent Sheet Metal Cut And Bent it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. sheet metal bending is. Sheet Metal Cut And Bent.

From sendcutsend.com

Hand Bending Sheet Metal A Guide Sheet Metal Cut And Bent the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure. Sheet Metal Cut And Bent.

From xometry.eu

Sheet Metal Design Tips For Bending Xometry Europe Sheet Metal Cut And Bent Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into. Sheet Metal Cut And Bent.

From www.javelin-tech.com

Learn Sheet Metal Design Terminology including Bend Deduction Sheet Metal Cut And Bent sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal parts are usually fabricated from a single sheet of. Sheet Metal Cut And Bent.

From www.protocase.co.uk

Sheet Metal Bending Tolerances Sheet Metal Cut And Bent Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into. Sheet Metal Cut And Bent.

From sendcutsend.com

Sheet Metal Bending Calculator SendCutSend Sheet Metal Cut And Bent this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing. Sheet Metal Cut And Bent.

From www.kovinc.com

Cutting and Bending of Sheet Metal Kovinc d.o.o. Sheet Metal Cut And Bent the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.. Sheet Metal Cut And Bent.

From mech4study.blogspot.com

mech4study Different Sheet Metal Bending Process Sheet Metal Cut And Bent this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally. Sheet Metal Cut And Bent.

From www.cmrp.com

Custom Sheet Metal Bending Custom Rolled Sheet Metal Sheet Metal Cut And Bent Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. the strength of the sheet metal bend needs to be ensured during the. Sheet Metal Cut And Bent.

From reganindustrial.com

6 Sheet Metal Rolling Defects and How to Avoid Them Sheet Metal Cut And Bent it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. the basic bending design. Sheet Metal Cut And Bent.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Cut And Bent sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design.. Sheet Metal Cut And Bent.

From www.youtube.com

SolidWorks Sheet Metal Normal Cuts and Simplify Bends YouTube Sheet Metal Cut And Bent this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing. Sheet Metal Cut And Bent.

From makezine.com

How to Choose, Cut, and Bend Sheet Metal Make Sheet Metal Cut And Bent sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing. Sheet Metal Cut And Bent.

From metalprofy.com

How to Bend Aluminum Guide for Beginners MetalProfy Sheet Metal Cut And Bent sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall. Sheet Metal Cut And Bent.

From www.china-machining.com

Sheet Metal Bending Basics, Types, and Tips for Product Designers Sheet Metal Cut And Bent the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for. this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness,. Sheet Metal Cut And Bent.

From www.komaspec.com

An Engineers’ Guide to Sheet Metal Bending & Laser Cutting Komaspec Sheet Metal Cut And Bent it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the. Sheet Metal Cut And Bent.

From ar.inspiredpencil.com

Sheet Metal Bending Techniques Sheet Metal Cut And Bent this guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally. Sheet Metal Cut And Bent.

From makeitfrommetal.com

Tips for Bending Sheet Metal Make It From Metal Sheet Metal Cut And Bent sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. the strength of the sheet metal bend needs to be. Sheet Metal Cut And Bent.

From chnsmile.en.made-in-china.com

Custom Stainless Steel Laser Cut and Bent Sheet Metal Parts China Sheet Metal Cut And Bent the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure. Sheet Metal Cut And Bent.

From www.jmaxengineering.com.au

Sheet Metal Bending JMAX Engineering Sheet Metal Cut And Bent it involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for.. Sheet Metal Cut And Bent.

From www.madearia.com

Sheet metal fabrication design guide Bending Aria Online Sheet Metal Cut And Bent the strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for. sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise. the basic bending design guidelines that a designer needs to consider when modelling a. Sheet Metal Cut And Bent.