Molding Flash . the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. Adjusting processing parameters like temperature and pressure can also help. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting line of the mold or the gap between two mold sections. This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. First and the most common cause of flash is a misalignment of the two halves of the mold. Get expert tips and techniques for. Let’s examine these causes that lead to flash in injection molding. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. learn what causes flash in injection molding, how to fix it, and prevent it from happening.

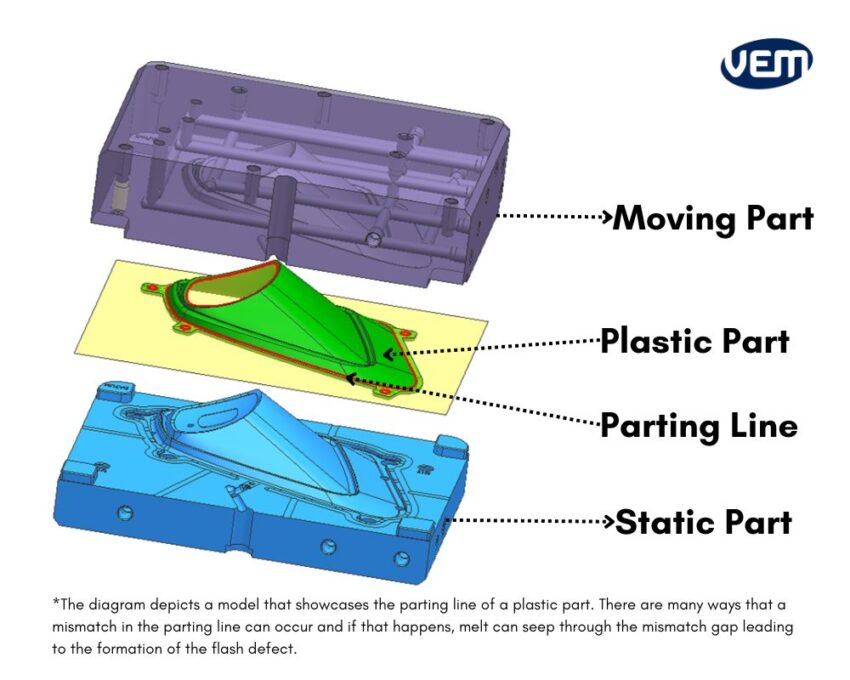

from www.vem-tooling.com

the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. Get expert tips and techniques for. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. learn what causes flash in injection molding, how to fix it, and prevent it from happening. First and the most common cause of flash is a misalignment of the two halves of the mold. Let’s examine these causes that lead to flash in injection molding. This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting line of the mold or the gap between two mold sections. Adjusting processing parameters like temperature and pressure can also help.

Flash

Molding Flash — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting line of the mold or the gap between two mold sections. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. Adjusting processing parameters like temperature and pressure can also help. First and the most common cause of flash is a misalignment of the two halves of the mold. Get expert tips and techniques for. learn what causes flash in injection molding, how to fix it, and prevent it from happening. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting line of the mold or the gap between two mold sections. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. Let’s examine these causes that lead to flash in injection molding. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line.

From www.optimim.com

Flash and Witness Lines Metal Injection Molding OptiMIM Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. — flash in injection molding (also known as deflashing) refers to the excess plastic material. Molding Flash.

From www.plasticmoulds.net

Troubleshooting Product Defects In Injection Moldingflash,short Shot Molding Flash the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. Adjusting processing parameters like temperature and pressure can also help. First and the most common cause of flash is a misalignment of the two halves of the mold. This defect typically occurs along the edges or seams of molded parts, particularly in. Molding Flash.

From www.plastopialtd.com

Flash Injection Molding Plastopia Molding Flash — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. learn what causes flash in injection molding, how to fix it, and prevent it from happening. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished. Molding Flash.

From www.kemalmfg.com

9 Common Causes of Injection Molding Flash and How to Fix Them Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. Get expert tips and techniques for. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting. Molding Flash.

From info.crescentind.com

How to Avoid Plastic Injection Molding Flash Molding Flash Adjusting processing parameters like temperature and pressure can also help. Let’s examine these causes that lead to flash in injection molding. First and the most common cause of flash is a misalignment of the two halves of the mold. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the. Molding Flash.

From www.vem-tooling.com

Flash Molding Flash — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting line of the mold or the gap between two mold sections. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the.. Molding Flash.

From www.vem-tooling.com

Flash Molding Flash — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. Adjusting processing parameters like temperature and pressure can also help. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from. Molding Flash.

From www.kemalmfg.com

9 Common Causes of Injection Molding Flash and How to Fix Them Molding Flash Adjusting processing parameters like temperature and pressure can also help. learn what causes flash in injection molding, how to fix it, and prevent it from happening. Let’s examine these causes that lead to flash in injection molding. Get expert tips and techniques for. — flash in injection molding (also known as deflashing) refers to the excess plastic material. Molding Flash.

From www.elastomer.kuraray.com

What is injection molding? Kuraray Elastomer Molding Flash — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting line of the mold or the gap between two mold sections. Let’s examine these causes that lead to flash in injection molding. Adjusting processing parameters like temperature and pressure. Molding Flash.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Molding Flash First and the most common cause of flash is a misalignment of the two halves of the mold. learn what causes flash in injection molding, how to fix it, and prevent it from happening. Get expert tips and techniques for. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the. Molding Flash.

From www.dgmfmoldclamps.com

What Causes The Injection Molding Flash? Mould Clamps Manufacturer Molding Flash First and the most common cause of flash is a misalignment of the two halves of the mold. Let’s examine these causes that lead to flash in injection molding. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. — flash in injection molding (also known as deflashing). Molding Flash.

From dienamics.com.au

Trial and Error Flashing Dienamics Molding Flash — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the. Molding Flash.

From www.kemalmfg.com

9 Common Causes of Injection Molding Flash and How to Fix Them Molding Flash — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. This defect typically occurs along the edges or seams of molded parts, particularly in areas where. Molding Flash.

From www.rapiddirect.com

Injection Molding Flash Top 9 Causes and How to Fix Them Molding Flash Get expert tips and techniques for. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. Adjusting processing parameters like temperature and pressure can also help. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the. Molding Flash.

From www.seaskymedical.com

What Causes Molding Flash and How to Avoid it Seaskymedical Molding Flash Let’s examine these causes that lead to flash in injection molding. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting. Molding Flash.

From www.seaskymedical.com

What Causes Molding Flash and How to Avoid it Seaskymedical Molding Flash — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. Get expert tips and techniques for. learn what causes flash in injection molding, how to fix it, and prevent it from happening. — flash in injection molding (also known as deflashing) refers to the excess. Molding Flash.

From empslc.com

Injection Molding Terminology Flash And Various Processes EnviroTech Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting line of the mold or the. Molding Flash.

From www.plastopialtd.com

Flash Injection Molding Plastopia Molding Flash — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles,. Molding Flash.

From www.youtube.com

Flash Defect in Injection Molded Products Flash Defect in injection Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. Let’s examine these causes that lead to flash in injection molding. the five. Molding Flash.

From www.zdcpu.com

Dealing with Injection Molding Flash Causes, Prevention, and Removal Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting line of the mold or the. Molding Flash.

From www.kemalmfg.com

9 Common Causes of Injection Molding Flash and How to Fix Them Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. — flash is a flaw in a part that happens when resins ooze out of the mold, typically. Molding Flash.

From www.nitrofreeze.com

Injection Molding Flash and Cryogenic Flash Removal Nitrofreeze Molding Flash the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding process, leaking out from the parting line of the mold or the gap between two mold sections.. Molding Flash.

From prototool.com

Injection Molding Flash Causes & Solutions And How To Avoid Prototool Molding Flash Let’s examine these causes that lead to flash in injection molding. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. learn what causes flash in injection molding, how to fix it, and prevent it from happening. — injection molding flash, often referred to excessive. Molding Flash.

From www.longshengmfg.com

How to Avoid Flash in Injection Molding LONGSHENG Molding Flash First and the most common cause of flash is a misalignment of the two halves of the mold. Let’s examine these causes that lead to flash in injection molding. Adjusting processing parameters like temperature and pressure can also help. This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold. Molding Flash.

From www.pfa-inc.com

How Can You Prevent Injection Mold Flash? PFA, Inc. Molding Flash learn what causes flash in injection molding, how to fix it, and prevent it from happening. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. — flash in injection molding (also known as deflashing) refers to the excess plastic material formed on the finished parts during the injection molding. Molding Flash.

From prototool.com

Injection Molding Flash Causes & Solutions And How To Avoid Prototool Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. learn what causes flash in injection molding, how to fix it, and prevent it from happening. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at. Molding Flash.

From www.fictiv.com

What Causes Injection Molding Flash and How to Prevent It Fictiv Molding Flash Get expert tips and techniques for. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. Let’s examine these causes that lead to flash in injection molding. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded. Molding Flash.

From www.vem-tooling.com

Flash Molding Flash Let’s examine these causes that lead to flash in injection molding. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. Get expert tips and techniques for. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. — flash in. Molding Flash.

From be-cu.com

Troubleshooting Injection Molding Flash Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. learn what causes flash in injection molding, how to fix it, and prevent it from happening. Adjusting processing parameters like temperature and pressure can also help. — flash is a flaw in a part that. Molding Flash.

From www.youtube.com

Molding Flash Sander demonstration YouTube Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. First and the most common cause of flash is a misalignment of the two halves of the mold. Get. Molding Flash.

From www.dgmfmoldclamps.com

What Is Flash Injection Molding? Mould Clamps Manufacturer Molding Flash This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles, reducing the. First and the most common cause of flash is a misalignment of the two halves of the mold. Get. Molding Flash.

From www.seaskymedical.com

What Causes Molding Flash and How to Avoid it Seaskymedical Molding Flash learn what causes flash in injection molding, how to fix it, and prevent it from happening. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the. Molding Flash.

From www.midstatemold.com

Flash Archives Midstate Mold & Engineering Molding Flash — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. Get expert tips and techniques for. This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. — flash in injection molding (also known. Molding Flash.

From www.rapiddirect.com

Injection Molding Design Guide RapidDirect Manufacturing Molding Flash — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. — flash is a flaw in a part that happens when resins ooze out of the mold, typically at the parting line. the five common ways to prevent injection molding flash are incorporating design for manufacturability principles,. Molding Flash.

From www.semanticscholar.org

Figure 8 from Elimination mold flash by mold design enhancement and Molding Flash Let’s examine these causes that lead to flash in injection molding. Adjusting processing parameters like temperature and pressure can also help. learn what causes flash in injection molding, how to fix it, and prevent it from happening. Get expert tips and techniques for. — injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion. Molding Flash.