Wire Rope To Sheave Ratio . That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. In other words, the smaller the sheave. Wire rope with a 10″ dia. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. To account for the effect of bend radius on wire rope strength when selecting a sheave,. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. bending wire rope reduces its strength.

from allrigging.com

Wire rope with a 10″ dia. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. bending wire rope reduces its strength. To account for the effect of bend radius on wire rope strength when selecting a sheave,. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. In other words, the smaller the sheave.

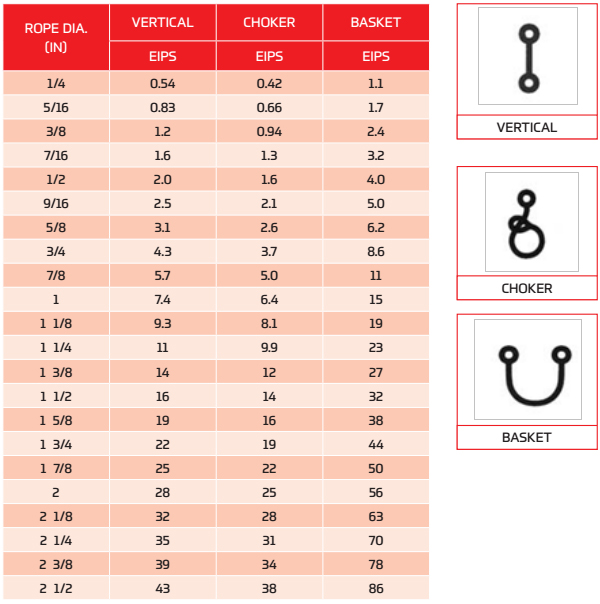

Wire Rope Sling Capacities All Rigging Co. Rigging Equipment

Wire Rope To Sheave Ratio many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. In other words, the smaller the sheave. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. bending wire rope reduces its strength. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. To account for the effect of bend radius on wire rope strength when selecting a sheave,. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. Wire rope with a 10″ dia. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of.

From www.certex.dk

Wire Rope Pulley Sheave CERTEX Denmark Wire Rope To Sheave Ratio To account for the effect of bend radius on wire rope strength when selecting a sheave,. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. sheave opening angle should be 35˚. Wire Rope To Sheave Ratio.

From www.samselsupply.com

HOWTO Order Wire Rope Sheaves Wire Rope To Sheave Ratio In other words, the smaller the sheave. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. bending wire rope reduces its strength. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. sheave opening angle should be 35˚ to. Wire Rope To Sheave Ratio.

From www.youtube.com

Pulley Rope Bending Ratio (D/d Ratio) YouTube Wire Rope To Sheave Ratio the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. . Wire Rope To Sheave Ratio.

From www.certex.se

Wire Rope Sheave 7100, black chrome sheave CERTEX Svenska Wire Rope To Sheave Ratio That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. In other words, the smaller the sheave. To account for the effect of bend radius on wire rope strength when selecting a. Wire Rope To Sheave Ratio.

From www.pacificindustrial.com

Sheaves With Bushings (Domestic) Pacific Industrial Supply Co. Wire Rope To Sheave Ratio the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. Wire rope with a 10″ dia. sheave opening angle should be 35˚ to 45˚ for applications with fleet. Wire Rope To Sheave Ratio.

From techdiagrammer.com

Unlocking the Secrets Mastering Wire Rope Design Calculations Wire Rope To Sheave Ratio the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. Wire rope with a 10″ dia. sheave opening angle should be 35˚ to 45˚ for. Wire Rope To Sheave Ratio.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope To Sheave Ratio In other words, the smaller the sheave. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. To account for the effect of bend radius on wire rope strength when selecting a sheave,. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the. Wire Rope To Sheave Ratio.

From www.grainger.com

GRAINGER APPROVED Sheave, Designed For Wire Rope, 3/16 in Max. Cable Wire Rope To Sheave Ratio sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. many. Wire Rope To Sheave Ratio.

From www.pinterest.pt

This document shows you how to make an effective and useful pulley Wire Rope To Sheave Ratio the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. To account for the effect of bend radius on wire rope strength when selecting. Wire Rope To Sheave Ratio.

From www.certex.dk

Wire Rope Sheave, type SR CERTEX Denmark Wire Rope To Sheave Ratio In other words, the smaller the sheave. To account for the effect of bend radius on wire rope strength when selecting a sheave,. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20. Wire Rope To Sheave Ratio.

From www.mazzellacompanies.com

Why Sheave Design is Critical to Wire Rope Service Life Wire Rope To Sheave Ratio That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size. Wire Rope To Sheave Ratio.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope To Sheave Ratio Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. To account for the effect of bend radius on wire rope strength when selecting a sheave,. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. bending. Wire Rope To Sheave Ratio.

From www.animalia-life.club

Wire Rope Rigging Basics Wire Rope To Sheave Ratio many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. To account for the effect of bend radius on wire rope strength when selecting a sheave,. bending wire rope reduces its strength. the pressure per unit area of rope on sheave groove for a given load. Wire Rope To Sheave Ratio.

From www.slideshare.net

Basic riggingworkbook Wire Rope To Sheave Ratio sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared. Wire Rope To Sheave Ratio.

From www.mazzellacompanies.com

Why Sheave Design is Critical to Wire Rope Service Life Wire Rope To Sheave Ratio the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. To account for the effect of bend radius on wire rope strength when selecting a sheave,. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. In other words, the. Wire Rope To Sheave Ratio.

From www.mazzellacompanies.com

Why Sheave Design is Critical to Wire Rope Service Life Wire Rope To Sheave Ratio Wire rope with a 10″ dia. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. In other words, the smaller the sheave. To account for the effect of bend radius on wire rope strength when selecting a sheave,. many suppliers specify that the ratio of sheave diameter to rope. Wire Rope To Sheave Ratio.

From www.mazzellacompanies.com

How Sheave Size Affects Wire Rope Strength and Efficiency Wire Rope To Sheave Ratio To account for the effect of bend radius on wire rope strength when selecting a sheave,. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. many suppliers specify. Wire Rope To Sheave Ratio.

From www.youtube.com

Lecture on Wire Rope (Method of Diameter and Pitch) YouTube Wire Rope To Sheave Ratio Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. bending wire rope reduces its strength. the basic design of any sheave should conform to the. Wire Rope To Sheave Ratio.

From allrigging.com

Wire Rope Sling Capacities All Rigging Co. Rigging Equipment Wire Rope To Sheave Ratio many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. Wire rope with a 10″ dia. In other words, the smaller the sheave. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. bending wire rope reduces its. Wire Rope To Sheave Ratio.

From suncorstainless.com

PULLPRO® HiLOAD Wire Rope Sheave, Bearing Suncor Stainless Wire Rope To Sheave Ratio In other words, the smaller the sheave. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. the basic design of any sheave should conform to the appropriate. Wire Rope To Sheave Ratio.

From www.researchgate.net

Rope guide mechanism and the sheaves along with their degrees of Wire Rope To Sheave Ratio Wire rope with a 10″ dia. bending wire rope reduces its strength. the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. Sheave, ratio “a” =. Wire Rope To Sheave Ratio.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope To Sheave Ratio bending wire rope reduces its strength. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave. Wire rope with a 10″ dia. many suppliers. Wire Rope To Sheave Ratio.

From mepsystems.com.sg

MORDEC WIRE ROPE SHEAVE GAUGE MEP Deck Solutions Wire Rope To Sheave Ratio To account for the effect of bend radius on wire rope strength when selecting a sheave,. In other words, the smaller the sheave. bending wire rope reduces its strength. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. Sheave, ratio “a” = 10 ÷ 1/2″ =. Wire Rope To Sheave Ratio.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope To Sheave Ratio Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. To account for the effect of bend radius on wire rope strength when selecting a sheave,. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. Wire rope. Wire Rope To Sheave Ratio.

From www.certex.ee

Wire Rope Sheave 8000 Certex Estonia Wire Rope To Sheave Ratio the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. To account for. Wire Rope To Sheave Ratio.

From ubicaciondepersonas.cdmx.gob.mx

Wire Rope Sheave Groove Dimensions ubicaciondepersonas.cdmx.gob.mx Wire Rope To Sheave Ratio That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. Sheave, ratio. Wire Rope To Sheave Ratio.

From www.certex.se

Wire Rope Sheave 6800K Ball Beared CERTEX Svenska Wire Rope To Sheave Ratio sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. bending wire rope reduces its strength. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. the pressure per unit area of rope on sheave groove for a given. Wire Rope To Sheave Ratio.

From www.cmco.com

Wire rope sheave DSR CMCO Wire Rope To Sheave Ratio That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. To account for the effect of bend radius on wire rope strength when selecting a sheave,. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. In other words, the smaller. Wire Rope To Sheave Ratio.

From www.need1.com.au

RIGMATE Wire Rope Sheave 75mm for 6mm Wire Rope To Sheave Ratio Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. To account for the effect of bend radius on wire rope strength when selecting a sheave,. the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave.. Wire Rope To Sheave Ratio.

From www.assemblyspecialty.com

Wire Rope Handling and Installation Assembly Specialty Products Wire Rope To Sheave Ratio That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. To account for the effect of bend radius on wire rope strength when selecting a sheave,. many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. the basic design. Wire Rope To Sheave Ratio.

From www.tecni.uk

Dd Ratios for Cable Pulleys or Sheaves Wire Rope To Sheave Ratio To account for the effect of bend radius on wire rope strength when selecting a sheave,. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. In other words, the smaller the sheave. bending wire rope reduces its strength. the pressure per unit area of rope on sheave groove for. Wire Rope To Sheave Ratio.

From exosbdzrp.blob.core.windows.net

Difference Between Sheave And Pulley at Eva Warrington blog Wire Rope To Sheave Ratio bending wire rope reduces its strength. sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. Wire rope with a 10″ dia. That guideline is given as a ratio between the “pitch diameter” of the shave and the “rope diameter”. Sheave, ratio “a” = 10 ÷ 1/2″ =. Wire Rope To Sheave Ratio.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope To Sheave Ratio the basic design of any sheave should conform to the appropriate minimum pitch diameter/rope diameter sheave ratios of. To account for the effect of bend radius on wire rope strength when selecting a sheave,. Wire rope with a 10″ dia. In other words, the smaller the sheave. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength. Wire Rope To Sheave Ratio.

From guidediagramdadaism.z14.web.core.windows.net

How To Use A Double Pulley System Wire Rope To Sheave Ratio sheave opening angle should be 35˚ to 45˚ for applications with fleet angles up to maximum 1.5˚, particularly for rotation. the pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave. Wire rope with a 10″ dia. bending wire rope reduces its strength. many. Wire Rope To Sheave Ratio.

From blog.loosco.com

Cable service life over pulleys it's all about the Dd Ratio! Wire Rope To Sheave Ratio many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. bending wire rope reduces its strength. Sheave, ratio “a” = 10 ÷ 1/2″ = 20 and the strength efficiency = 91% as compared to the catalog. In other words, the smaller the sheave. the basic design. Wire Rope To Sheave Ratio.