How To Read A Regulator Gauge . When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: There are three basic operating components in most regulators: The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into the tank. If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. (2) the right inlet pressure; The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. A loading mechanism, a sensing element, and a control element. To locate the right curve for your system, look for (1) the right set pressure; And (3) the right range of flows.

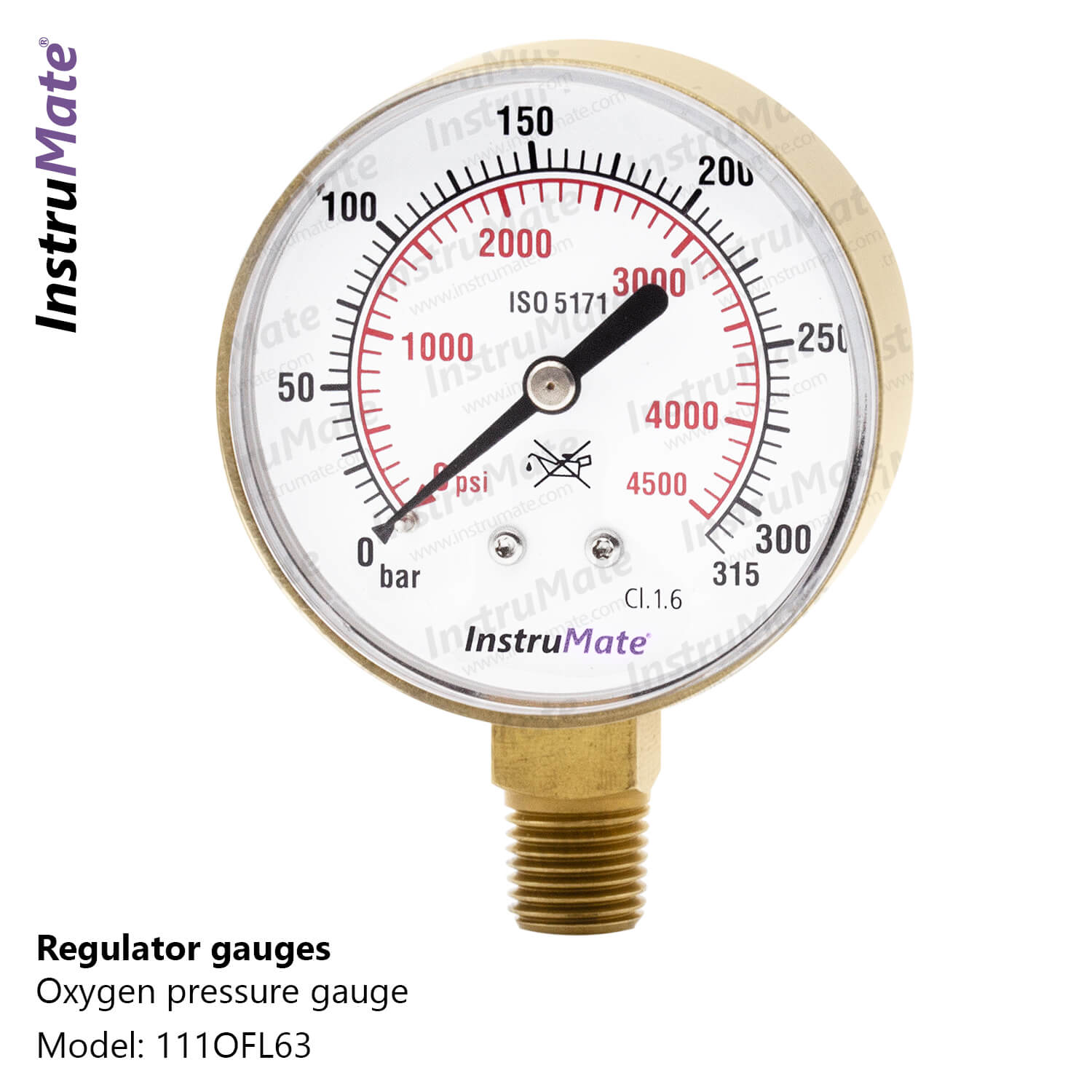

from instrumate.com

If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into the tank. (2) the right inlet pressure; If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. To locate the right curve for your system, look for (1) the right set pressure; The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: There are three basic operating components in most regulators: The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. And (3) the right range of flows. If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder.

Oxygen/Acetylene pressure gauge 111OF Instrumate

How To Read A Regulator Gauge The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. To locate the right curve for your system, look for (1) the right set pressure; When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into the tank. And (3) the right range of flows. (2) the right inlet pressure; The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. A loading mechanism, a sensing element, and a control element. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. There are three basic operating components in most regulators:

From www.metalworks.com

Replacement Gauge For Regulators Shop Welding Tools & Accessories How To Read A Regulator Gauge And (3) the right range of flows. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. A loading mechanism, a sensing element, and a control element. If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into. How To Read A Regulator Gauge.

From www.amazon.in

04000 PSI Oxygen Gas Regulator Welding Cutting Torch Pressure Gauge How To Read A Regulator Gauge If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. (2) the right inlet pressure; To locate the right curve for your system, look. How To Read A Regulator Gauge.

From instrumate.com

Oxygen/Acetylene pressure gauge 111OF Instrumate How To Read A Regulator Gauge There are three basic operating components in most regulators: The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: (2) the right inlet pressure; A loading. How To Read A Regulator Gauge.

From exyplsazd.blob.core.windows.net

How To Read A Gas Cylinder Regulator at Edward Foster blog How To Read A Regulator Gauge If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. There are three basic operating components in most regulators: If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. The best way to select a regulator for. How To Read A Regulator Gauge.

From read.iesanfelipe.edu.pe

Reading Ac Gauges R134a read.iesanfelipe.edu.pe How To Read A Regulator Gauge When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. There are three basic operating components in most regulators: A loading mechanism, a sensing element, and. How To Read A Regulator Gauge.

From www.walmart.com

04000 psi and 015 LPM Gauges for Oxygen Regulator 2 inches (PAIR How To Read A Regulator Gauge The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. To locate the right curve for your system, look for (1) the right set pressure; There are. How To Read A Regulator Gauge.

From www.nellisauction.com

Flame Tech Flow Gauge Argon Regulator, Easy to Read 2” DualScale How To Read A Regulator Gauge The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: And (3) the right range of flows. If your regulator has two display gauges, the second. How To Read A Regulator Gauge.

From gatedata.com.br

Sporting Goods UK PRESSURE GAUGE LEVEL INDICATOR PROPANE GAS BOTTLE How To Read A Regulator Gauge If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If your regulator has two display gauges, the second one will read the inlet. How To Read A Regulator Gauge.

From www.ttlcal.com

Harris 8700 Oxygen Pressure Regulator Tool Testing Lab Inc. How To Read A Regulator Gauge A loading mechanism, a sensing element, and a control element. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. The best way to. How To Read A Regulator Gauge.

From content.kegworks.com

Under Pressure A Guide to CO2 and Nitrogen Beer Regulators How To Read A Regulator Gauge There are three basic operating components in most regulators: When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: And (3) the right range of flows. A loading mechanism, a sensing element, and a control element. The best way to select a regulator for your application is to examine. How To Read A Regulator Gauge.

From www.keystonehomebrew.com

Replacement Regulator Gauge, 060 psi, 1/8in mpt Keystone Homebrew Supply How To Read A Regulator Gauge There are three basic operating components in most regulators: If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. The best way to select. How To Read A Regulator Gauge.

From econosuperstore.com

CGA580 Argon CO2 Regulator Gauge Flow Meter for Mig Tig Welding Gas How To Read A Regulator Gauge If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. To locate the right curve for your system, look for (1) the right set pressure; And (3) the right range of flows. (2) the right inlet pressure; A loading mechanism, a sensing element, and a control element. The best way. How To Read A Regulator Gauge.

From thegascentre.co.uk

Propane Regulator With Gauge Screw In How To Read A Regulator Gauge And (3) the right range of flows. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. To locate the right curve for your system, look for (1) the right set pressure; The best way to select a regulator for your application is to examine its flow. How To Read A Regulator Gauge.

From www.forneyind.com

Regulator Gauge, 2 in, 0400 PSI How To Read A Regulator Gauge A loading mechanism, a sensing element, and a control element. When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: To locate the right curve for your system, look for (1) the right set pressure; If your regulator has two display gauges, the second one will read the inlet. How To Read A Regulator Gauge.

From www.mcgillmotorsport.com

LiquidFilled Fuel Regulator Pressure Gauge Black Face How To Read A Regulator Gauge If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. There are three basic operating components in most regulators: The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. The best way to select. How To Read A Regulator Gauge.

From www.desertcart.in

Buy FGHJQ Oxygen Bottle Regulators O2 Reducing Pressure Acetylene How To Read A Regulator Gauge If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. To locate the right curve for your system, look for (1) the right set pressure; The best way to select a regulator for your application is to examine its flow curve, which is often provided by the. How To Read A Regulator Gauge.

From www.youtube.com

How To Read A Gauge Metered Pressure Gas Regulator YouTube How To Read A Regulator Gauge The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. (2) the right inlet pressure; A loading mechanism, a sensing element, and a control element. And (3) the right range of flows. There are three basic operating components in most regulators: To locate the right curve for. How To Read A Regulator Gauge.

From www.plantedtank.net

Need help reading CO2 regulator gauges The Planted Tank Forum How To Read A Regulator Gauge There are three basic operating components in most regulators: The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. And (3) the right range of flows. The. How To Read A Regulator Gauge.

From www.finishsystems.com

Diaphragm Air Regulator & Gauge for HVLP Spray Guns (060 psi) Finish How To Read A Regulator Gauge To locate the right curve for your system, look for (1) the right set pressure; If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. There are three basic operating components in most regulators: If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure. How To Read A Regulator Gauge.

From aipweldingsupplies.co.uk

Single Stage 2 Gauge Regulator Range AIP Welding How To Read A Regulator Gauge The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. A loading mechanism, a sensing element, and a control element. If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into the tank. The best way to select. How To Read A Regulator Gauge.

From www.walmart.com

High Pressure Gauge for Oxygen Regulator 04000 psi 2 inches How To Read A Regulator Gauge If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. And (3) the right range of flows. If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. A loading mechanism, a sensing element, and a control element.. How To Read A Regulator Gauge.

From ubicaciondepersonas.cdmx.gob.mx

Regulator Gauge ubicaciondepersonas.cdmx.gob.mx How To Read A Regulator Gauge If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into the tank. And (3) the right range of flows. When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: The best way to select a regulator for your application. How To Read A Regulator Gauge.

From seniorlawcenter.org

Industrial Power Tools Pressure Gauges Nitrogen Regulator for How To Read A Regulator Gauge There are three basic operating components in most regulators: When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: (2) the right inlet pressure; A loading mechanism, a sensing element, and a control element. The best way to select a regulator for your application is to examine its flow. How To Read A Regulator Gauge.

From www.walmart.com

04000 psi and 015 LPM Gauges for Oxygen Regulator 2.5 inches (PAIR How To Read A Regulator Gauge A loading mechanism, a sensing element, and a control element. To locate the right curve for your system, look for (1) the right set pressure; If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into the tank. The best way to select a regulator for your application is to examine. How To Read A Regulator Gauge.

From www.megamedical.com.au

How to Read Oxygen Tank Pressure Gauges Mega Medical How To Read A Regulator Gauge (2) the right inlet pressure; And (3) the right range of flows. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. When managing. How To Read A Regulator Gauge.

From econosuperstore.com

DUAL ARGON CO2 WELDING GAS CYLINDER REGULATOR GAUGES 4 Miller Lincoln How To Read A Regulator Gauge And (3) the right range of flows. (2) the right inlet pressure; If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into the tank. If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. A loading mechanism, a sensing element,. How To Read A Regulator Gauge.

From www.halloweenexpress.com

Gauge For Air Regulator Discontinued How To Read A Regulator Gauge To locate the right curve for your system, look for (1) the right set pressure; The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into the tank.. How To Read A Regulator Gauge.

From exyplsazd.blob.core.windows.net

How To Read A Gas Cylinder Regulator at Edward Foster blog How To Read A Regulator Gauge There are three basic operating components in most regulators: To locate the right curve for your system, look for (1) the right set pressure; A loading mechanism, a sensing element, and a control element. If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. (2) the right. How To Read A Regulator Gauge.

From exyplsazd.blob.core.windows.net

How To Read A Gas Cylinder Regulator at Edward Foster blog How To Read A Regulator Gauge If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If you’re expecting flow rates to reach the regulator’s cv, it is probably not. How To Read A Regulator Gauge.

From www.ebay.com.au

SÜA Oxygen Regulator Welding Gas Gauges 25HX Series eBay How To Read A Regulator Gauge A loading mechanism, a sensing element, and a control element. And (3) the right range of flows. To locate the right curve for your system, look for (1) the right set pressure; When managing your gases for cutting and welding or shielding, it’s important to know which type to use for the job: The best way to select a regulator. How To Read A Regulator Gauge.

From www.nybrewsupply.com

Regulator Replacement Gauge 02000 PSI Left Hand Thread NY Brew Supply How To Read A Regulator Gauge If your regulator has two display gauges, the second one will read the inlet pressure, that’s gas pressure going into the tank. There are three basic operating components in most regulators: A loading mechanism, a sensing element, and a control element. (2) the right inlet pressure; The best way to select a regulator for your application is to examine its. How To Read A Regulator Gauge.

From toolsli.com

How to Read Oxygen Tank Pressure Gauge 12 Easy Steps (2024) How To Read A Regulator Gauge And (3) the right range of flows. A loading mechanism, a sensing element, and a control element. (2) the right inlet pressure; The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. When managing your gases for cutting and welding or shielding, it’s important to know which. How To Read A Regulator Gauge.

From www.ebay.com.au

Low and High Pressure Gauges for Propane Regulator 2 inches 1/4 How To Read A Regulator Gauge If you’re using a dual gauge regulator, chances are it’ll have the ability to bring pressure into and out of your gas cylinder. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If you’re expecting flow rates to reach the regulator’s cv, it is probably not. How To Read A Regulator Gauge.

From www.canadianmetalworking.com

Understanding how to use regulators, regulator flowmeters, and How To Read A Regulator Gauge And (3) the right range of flows. The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. A loading mechanism, a sensing element, and a control element. To locate the right curve for your system, look for (1) the right set pressure; When managing your gases for. How To Read A Regulator Gauge.

From www.emsstuff.com

OnBoard Oxygen Regulator with Large Gauge Medical Warehouse How To Read A Regulator Gauge The best way to select a regulator for your application is to examine its flow curve, which is often provided by the manufacturer. If you’re expecting flow rates to reach the regulator’s cv, it is probably not the right regulator for your system. When managing your gases for cutting and welding or shielding, it’s important to know which type to. How To Read A Regulator Gauge.