Ultrasonic Inspection Of Composites . For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. These sound waves bounce back signals which can reveal key. While ultrasonic ndt has previously been used for. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. The probe transmits ultrasonic waves at precise.

from www.mdpi.com

For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. The probe transmits ultrasonic waves at precise. While ultrasonic ndt has previously been used for. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. These sound waves bounce back signals which can reveal key. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded.

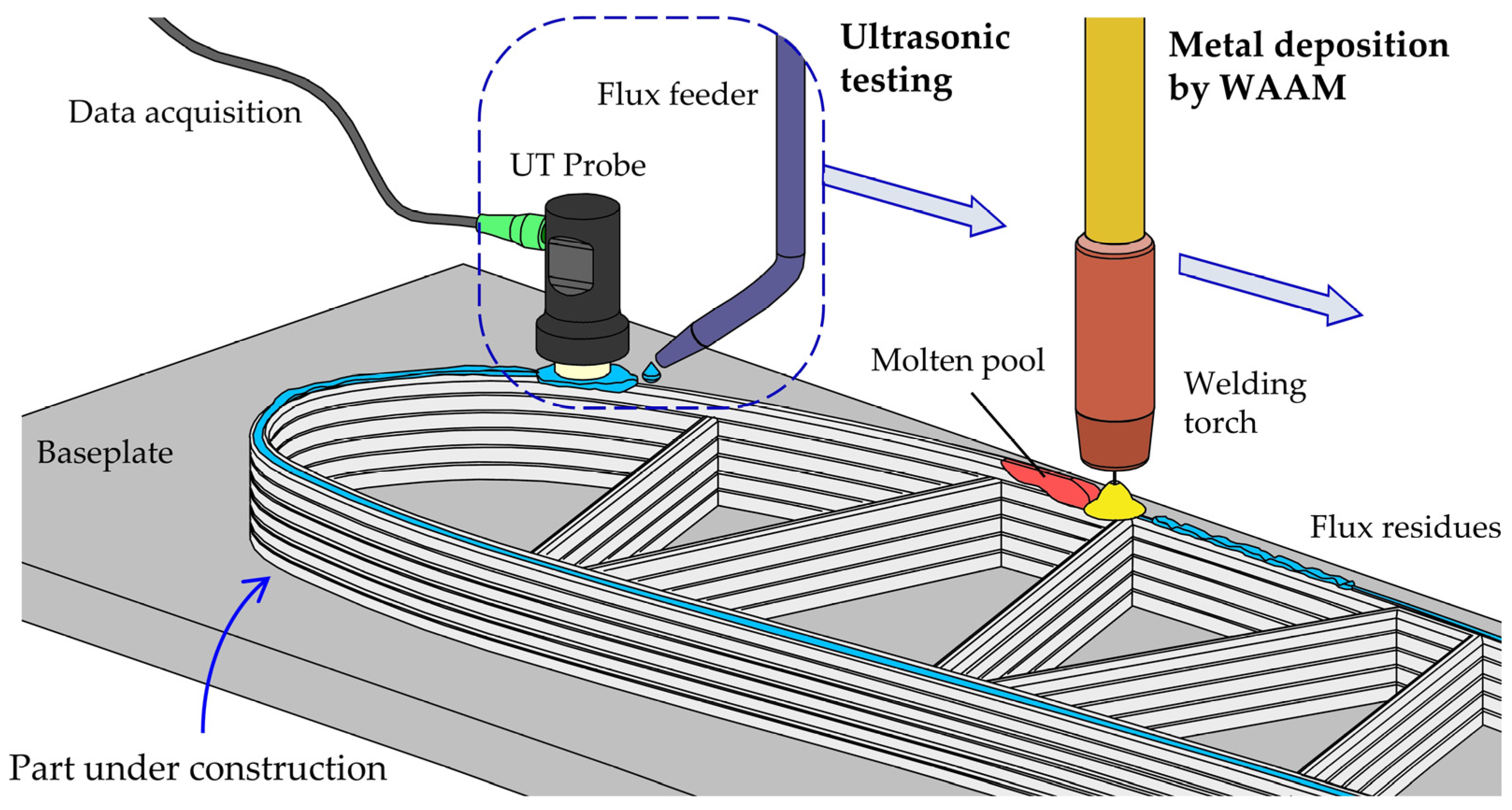

Machines Free FullText In Situ Ultrasonic Testing for Wire Arc

Ultrasonic Inspection Of Composites Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. These sound waves bounce back signals which can reveal key. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. The probe transmits ultrasonic waves at precise. While ultrasonic ndt has previously been used for. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the.

From www.mdpi.com

Machines Free FullText In Situ Ultrasonic Testing for Wire Arc Ultrasonic Inspection Of Composites This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. The probe transmits ultrasonic waves at precise. Ultrasonic inspection is intended to detect disband and delaminations. Ultrasonic Inspection Of Composites.

From scanmaster-irt.com

Ultrasonic Inspection of Composites ScanMaster Ultrasonic Inspection Of Composites In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. These sound waves bounce back signals which can reveal key. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and. Ultrasonic Inspection Of Composites.

From www.mdpi.com

Applied Sciences Free FullText A StateoftheArt Review of Non Ultrasonic Inspection Of Composites Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. These sound waves bounce back signals which can reveal key. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. Nondestructive testing (ndt) techniques are an effective way to inspect these composites.. Ultrasonic Inspection Of Composites.

From scanmaster-irt.com

Ultrasonic Inspection of Composites ScanMaster Ultrasonic Inspection Of Composites This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. While ultrasonic ndt has previously been used for. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. The probe transmits ultrasonic waves at precise. For. Ultrasonic Inspection Of Composites.

From nexxis.com.au

The Benefits Of Ultrasonic Testing For Composite Structures Ultrasonic Inspection Of Composites The probe transmits ultrasonic waves at precise. These sound waves bounce back signals which can reveal key. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. While ultrasonic ndt has previously been used for. In. Ultrasonic Inspection Of Composites.

From materials-testing.blogspot.com

Composite Materials Ultrasonic testing Inspection Trinity NDT Ultrasonic Inspection Of Composites Nondestructive testing (ndt) techniques are an effective way to inspect these composites. While ultrasonic ndt has previously been used for. The probe transmits ultrasonic waves at precise. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. These sound waves bounce back signals which can reveal key. For ultrasonic testing, composite materials. Ultrasonic Inspection Of Composites.

From scanmaster-irt.com

Ultrasonic Inspection of Composites ScanMaster Ultrasonic Inspection Of Composites These sound waves bounce back signals which can reveal key. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. In this paper, the experimental results obtained by an ultrasonic methodology on. Ultrasonic Inspection Of Composites.

From www.tcsndt.com.au

Ultrasonic Testing (Thickness) TCS NDT Ultrasonic Inspection Of Composites In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. The probe transmits ultrasonic waves at precise. While ultrasonic ndt has previously been used for. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts. Ultrasonic Inspection Of Composites.

From blaest.com

Ultrasonic inspection Blade test centre Ultrasonic Inspection Of Composites In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. These sound waves bounce back signals which can reveal key. The probe transmits ultrasonic waves at precise. While ultrasonic ndt has previously been used for. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Ultrasonic inspection is. Ultrasonic Inspection Of Composites.

From studylib.net

Nondestructive Ultrasonic Inspection of Composite Materials A Ultrasonic Inspection Of Composites Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. This paper presents a comprehensive overview. Ultrasonic Inspection Of Composites.

From www.youtube.com

iPLUS™ laserultrasonic inspection of a fullbarrel composite YouTube Ultrasonic Inspection Of Composites This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. Ultrasonic inspection is intended to detect disband and delaminations between layers of. Ultrasonic Inspection Of Composites.

From www.academia.edu

(PDF) A comparison of signal consistency of common ultrasonic couplants Ultrasonic Inspection Of Composites For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. The probe transmits ultrasonic waves at precise. Ultrasonic inspection is intended to. Ultrasonic Inspection Of Composites.

From scanmaster-irt.com

Ultrasonic Inspection of Composites ScanMaster Ultrasonic Inspection Of Composites For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. While ultrasonic ndt has previously been used for. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated. Ultrasonic Inspection Of Composites.

From www.sigmandtlab.net

Ultrasonic Testing (UT) NDT Services Sigma Inspection & Testing Pvt Ltd Ultrasonic Inspection Of Composites Nondestructive testing (ndt) techniques are an effective way to inspect these composites. The probe transmits ultrasonic waves at precise. While ultrasonic ndt has previously been used for. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its. Ultrasonic Inspection Of Composites.

From www.kiscosteel.com

Common Misconceptions about Ultrasonic Testing (UT) of Steel Alloy Ultrasonic Inspection Of Composites The probe transmits ultrasonic waves at precise. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. Ultrasonic. Ultrasonic Inspection Of Composites.

From gcotter.com

Ultrasonic Testing (UT) G.Cotter Enterprises Ultrasonic Inspection Of Composites Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. The probe transmits ultrasonic waves at precise. While ultrasonic ndt has previously been used for. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. Nondestructive testing (ndt) techniques are an effective. Ultrasonic Inspection Of Composites.

From www.researchgate.net

Principle of laserultrasonics applied to composite NDT. The light Ultrasonic Inspection Of Composites These sound waves bounce back signals which can reveal key. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. While ultrasonic ndt has previously been used for. This paper presents a comprehensive overview of laser ultrasonic testing. Ultrasonic Inspection Of Composites.

From www.triquestndt.com

Ultrasonic Testing Ultrasonic Inspection Of Composites In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. The probe transmits ultrasonic waves at precise. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. These sound waves bounce back signals which. Ultrasonic Inspection Of Composites.

From amumagazine.com

Today’s Composites AMU Magazine Ultrasonic Inspection Of Composites Nondestructive testing (ndt) techniques are an effective way to inspect these composites. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. The probe transmits ultrasonic waves at precise. This paper presents a comprehensive overview of. Ultrasonic Inspection Of Composites.

From www.innerspec.com

Innovative solutions in ultrasonic inspection of composites Innerspec Ultrasonic Inspection Of Composites For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. While ultrasonic ndt has previously been used for. The probe transmits ultrasonic waves at precise. These sound waves bounce back signals which can reveal key. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in. Ultrasonic Inspection Of Composites.

From scanmaster-irt.com

Ultrasonic Inspection of Composites ScanMaster Ultrasonic Inspection Of Composites Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. These sound waves bounce back signals which can reveal key. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. The probe transmits ultrasonic. Ultrasonic Inspection Of Composites.

From www.academia.edu

(PDF) Ultrasonic inspection of composites materials Application to Ultrasonic Inspection Of Composites In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. While ultrasonic ndt has previously been used for. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. The probe transmits ultrasonic waves at precise. These. Ultrasonic Inspection Of Composites.

From www.innerspec.com

Innovative solutions in ultrasonic inspection of composites Innerspec Ultrasonic Inspection Of Composites In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. The probe transmits ultrasonic waves at precise. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. While ultrasonic ndt has previously been used for. This paper presents a comprehensive overview of laser ultrasonic testing (lut). Ultrasonic Inspection Of Composites.

From www.researchgate.net

(PDF) Simulation of the Ultrasonic Inspection of Composite Materials Ultrasonic Inspection Of Composites This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. These sound waves bounce back signals which can reveal key. While ultrasonic ndt has previously been used for. The probe transmits ultrasonic waves at precise. In. Ultrasonic Inspection Of Composites.

From www.researchgate.net

Experimental setup of the ultrasonic detection of the composite Ultrasonic Inspection Of Composites This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. While ultrasonic ndt has previously been used for. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. These sound waves bounce back signals which can reveal key. For ultrasonic testing, composite materials can be very. Ultrasonic Inspection Of Composites.

From nexxis.com

The Benefits Of Ultrasonic Testing For Composite Structures Ultrasonic Inspection Of Composites In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. The probe transmits ultrasonic waves at precise. These sound waves bounce back signals which can reveal key. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively. Ultrasonic Inspection Of Composites.

From www.twi-global.com

Inspection of Composites TWI Ultrasonic Inspection Of Composites For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. The probe transmits ultrasonic waves at precise. These sound waves bounce back signals which can reveal key. While ultrasonic ndt has previously been used for. In this paper,. Ultrasonic Inspection Of Composites.

From www.frontiersin.org

Frontiers Infrared Thermographic and Ultrasonic Inspection of Ultrasonic Inspection Of Composites For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. These sound waves bounce back signals which can reveal key. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. While ultrasonic ndt has previously been used for. In this paper, the experimental results. Ultrasonic Inspection Of Composites.

From dokumen.tips

(PDF) A comparison of Techniques for Ultrasonic Inspection ofjoe Ultrasonic Inspection Of Composites The probe transmits ultrasonic waves at precise. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. While ultrasonic ndt has previously been used for. These sound waves bounce back signals which can reveal key. In this paper,. Ultrasonic Inspection Of Composites.

From www.victor-aviation.com

Ultrasonic Inspection Aircraft Engine Overhaul Ultrasonic Inspection Of Composites The probe transmits ultrasonic waves at precise. These sound waves bounce back signals which can reveal key. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. While ultrasonic ndt has previously been used for. For ultrasonic testing,. Ultrasonic Inspection Of Composites.

From www.mdpi.com

Applied Sciences Free FullText Nondestructive Ultrasonic Ultrasonic Inspection Of Composites This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. The probe transmits ultrasonic waves at precise. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. While ultrasonic ndt has previously. Ultrasonic Inspection Of Composites.

From www.rcon-ndt.com

Ultrasonic Inspection of Composites made Easier by Sonatest and RCON NDT Ultrasonic Inspection Of Composites The probe transmits ultrasonic waves at precise. While ultrasonic ndt has previously been used for. These sound waves bounce back signals which can reveal key. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and. Ultrasonic Inspection Of Composites.

From material-properties.org

What is Ultrasonic Testing PulseEcho Method Definition Material Ultrasonic Inspection Of Composites In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Ultrasonic inspection is intended to detect disband and delaminations between layers of laminated material and laminated and bonded. The probe transmits ultrasonic waves at precise. These sound waves. Ultrasonic Inspection Of Composites.

From www.twi-global.com

Phased Array Ultrasonic Testing PAUT NDT Technique TWI Ultrasonic Inspection Of Composites While ultrasonic ndt has previously been used for. The probe transmits ultrasonic waves at precise. In this paper, the experimental results obtained by an ultrasonic methodology on impacted laminates, are described. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. Nondestructive testing (ndt) techniques are an effective way to inspect these composites. For. Ultrasonic Inspection Of Composites.

From www.tec-science.com

Ultrasonic testing (UT) tecscience Ultrasonic Inspection Of Composites The probe transmits ultrasonic waves at precise. For ultrasonic testing, composite materials can be very attenuative, increasing the challenge of inspecting relatively thick parts and limiting the. While ultrasonic ndt has previously been used for. This paper presents a comprehensive overview of laser ultrasonic testing (lut) and its applications in composite. In this paper, the experimental results obtained by an. Ultrasonic Inspection Of Composites.