Brazing Copper Tools . If you line up the two pieces correctly, they will fuse when heated to 250°c. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. This article will explain exactly what a copper. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. A brazing rod is used to create a fusion between the pieces of copper.

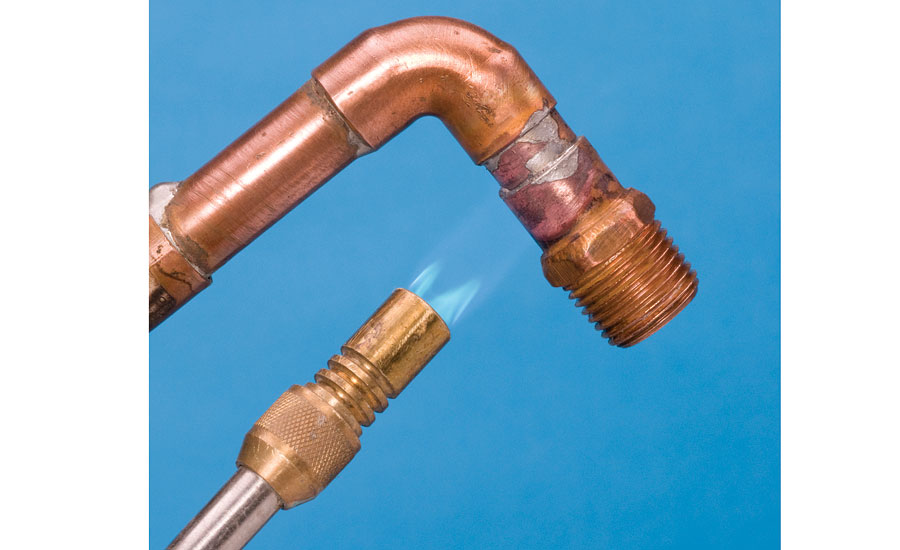

from www.pmmag.com

Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. This article will explain exactly what a copper. If you line up the two pieces correctly, they will fuse when heated to 250°c. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. A brazing rod is used to create a fusion between the pieces of copper. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys.

Soldering vs. brazing when piping is involved 20160928 Plumbing

Brazing Copper Tools Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. If you line up the two pieces correctly, they will fuse when heated to 250°c. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. This article will explain exactly what a copper. A brazing rod is used to create a fusion between the pieces of copper. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use.

From www.youtube.com

How to Solder Copper Pipe DIY HowTo Basics YouTube Brazing Copper Tools A brazing rod is used to create a fusion between the pieces of copper. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. Brazing. Brazing Copper Tools.

From www.youtube.com

Brazing Copper Tubing to Copper Tubing with UBraze YouTube Brazing Copper Tools This article will explain exactly what a copper. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. It's possible to make. Brazing Copper Tools.

From www.alamy.com

Worker working on brazing copper closeup Stock Photo Alamy Brazing Copper Tools Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. It's possible to make sound joints that are just as strong. Brazing Copper Tools.

From www.aliexpress.com

BCuP 2 Copper Brazing Rods 3.2x1x400mm 50pcs for Copper Based Gas Braze Brazing Copper Tools But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. If you line up the two pieces correctly, they will fuse when heated to 250°c. A. Brazing Copper Tools.

From www.harrisproductsgroup.com.au

How Brazing Works Capillary Action Harris Products Group Brazing Copper Tools But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. A brazing rod is used to create a fusion between the pieces of copper. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. If you line up the two pieces correctly,. Brazing Copper Tools.

From www.dreamstime.com

Tools and Materials for Brazing Copper Pipes Stock Photo Image of Brazing Copper Tools It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal. Brazing Copper Tools.

From www.skillcatapp.com

Brazing & Soldering Safety Measure your need to Follow Brazing Copper Tools A brazing rod is used to create a fusion between the pieces of copper. This article will explain exactly what a copper. But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use.. Brazing Copper Tools.

From www.youtube.com

How To Braze Copper Pipe Like A Pro (HVAC Refrigerant Lines) YouTube Brazing Copper Tools Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. If you line up the two pieces correctly, they will fuse. Brazing Copper Tools.

From ultraflexpower.com

Induction Brazing UltraFlex Power Technologies, Inc. Brazing Copper Tools Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. This article will explain exactly what a copper. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. A brazing rod. Brazing Copper Tools.

From www.youtube.com

Induction Brazing of Copper Pipes YouTube Brazing Copper Tools If you line up the two pieces correctly, they will fuse when heated to 250°c. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. A brazing rod is used to create a fusion between the pieces of copper. Brazing copper is suitable for joining copper alloys. Brazing Copper Tools.

From www.youtube.com

Copper Brazing for the Heat Exchanger Industry Two Brazing Point Brazing Copper Tools A brazing rod is used to create a fusion between the pieces of copper. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. It's possible to. Brazing Copper Tools.

From dw-inductionheater.com

induction brazing automotive copper heating exchanger pipes Brazing Copper Tools If you line up the two pieces correctly, they will fuse when heated to 250°c. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler. Brazing Copper Tools.

From www.youtube.com

Brazing Copper to Brass with SilFos® YouTube Brazing Copper Tools But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. A brazing rod is used to create a fusion between the pieces of copper. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. If you line up the two pieces. Brazing Copper Tools.

From blog.thepipingmart.com

How to Braze Copper to Copper An Overview Brazing Copper Tools A brazing rod is used to create a fusion between the pieces of copper. But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. If you line up the two pieces correctly, they will fuse when heated to 250°c. Brazing is a welding process that joins two pieces of metal of copper or. Brazing Copper Tools.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Brazing Copper Tools This article will explain exactly what a copper. A brazing rod is used to create a fusion between the pieces of copper. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. Brazing is done by heating the copper, then running a layer of constantan (a type of metal. Brazing Copper Tools.

From rosipinkqq.blogspot.com

Brazing Copper To Brass / Copper Nickel Brazing Unified Engineering Brazing Copper Tools It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. This article will explain exactly what a copper. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. A brazing rod is used to create. Brazing Copper Tools.

From www.youtube.com

EP 62 First Attempts at Brazing Copper YouTube Brazing Copper Tools This article will explain exactly what a copper. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. Brazing is done by heating the copper,. Brazing Copper Tools.

From www.pinterest.com

Silver Brazing Demo Stainless Steel, Brass, & Copper Brazing Brazing Copper Tools Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. This article will explain exactly what a copper. But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. It's possible to make sound joints that are just as strong as the. Brazing Copper Tools.

From www.tooled-up.com

Sealey Oxyacetylene Welding and Brazing Torch Kit Tips & Torches Brazing Copper Tools But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to. Brazing Copper Tools.

From www.youtube.com

How To Braze Copper Fittings For An Air Conditioner Full Video Of Brazing Copper Tools This article will explain exactly what a copper. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. A brazing rod is. Brazing Copper Tools.

From www.youtube.com

How to Braze Copper to Steel YouTube Brazing Copper Tools If you line up the two pieces correctly, they will fuse when heated to 250°c. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys.. Brazing Copper Tools.

From www.pinterest.com

How to Braze Copper to Steel with Handy One® Brazing, Metal Brazing Copper Tools Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. This article will explain exactly what a copper. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. If you line up the two pieces correctly,. Brazing Copper Tools.

From www.youtube.com

Copper Rod to Copper Plate Braze YouTube Brazing Copper Tools This article will explain exactly what a copper. If you line up the two pieces correctly, they will fuse when heated to 250°c. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. A brazing rod is used to create a fusion between. Brazing Copper Tools.

From www.aliexpress.com

BCu Copper Brazing Filler Metal Soldering Sheet Copper Based Braze Brazing Copper Tools A brazing rod is used to create a fusion between the pieces of copper. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical. Brazing Copper Tools.

From dw-inductionheater.com

Brazing Copper Tubing with Induction Brazing System Brazing Copper Tools A brazing rod is used to create a fusion between the pieces of copper. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. It's possible to. Brazing Copper Tools.

From hvacrschool.com

Jose A Martinez Basic Refrigerant Circuit Course December 21, 2022, 2 Brazing Copper Tools Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. A brazing rod is used to create a fusion between the pieces of copper. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and. Brazing Copper Tools.

From www.plumbingsupply.com

How to Solder and Braze Copper Brazing Copper Tools Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. A brazing rod is used to create a fusion between the pieces of copper. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity). Brazing Copper Tools.

From www.dreamstime.com

Tools and Materials for Brazing Copper Pipes Stock Photo Image of Brazing Copper Tools Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. Brazing copper is suitable for joining copper alloys but it's. Brazing Copper Tools.

From www.pmmag.com

Soldering vs. brazing when piping is involved 20160928 Plumbing Brazing Copper Tools Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. If you line up the two pieces correctly, they will fuse when heated to 250°c. This article will explain exactly what. Brazing Copper Tools.

From www.youtube.com

ZoomLock BrazeFree pipe Connectors How to Connect HVAC/R Tubes Brazing Copper Tools Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. A brazing rod is used to create a fusion between the pieces of copper. But first you have to know basic brazing concepts, including joint design, filler metal behavior, and metallurgy. Brazing is. Brazing Copper Tools.

From www.youtube.com

Induction Brazing Copper Pipe YouTube Brazing Copper Tools This article will explain exactly what a copper. If you line up the two pieces correctly, they will fuse when heated to 250°c. A brazing rod is used to create a fusion between the pieces of copper. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. Brazing. Brazing Copper Tools.

From ultraflexpower.com

Brazing with Induction of Copper Fittings to Copper UltraFlex Power Brazing Copper Tools A brazing rod is used to create a fusion between the pieces of copper. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal. Brazing Copper Tools.

From www.youtube.com

How to Braze Air Conditioning Copper YouTube Brazing Copper Tools If you line up the two pieces correctly, they will fuse when heated to 250°c. Brazing copper is suitable for joining copper alloys but it's important to be able to identify which filler metals to use. Brazing is a welding process that joins two pieces of metal of copper or brass with a filler metal called brazing alloys. But first. Brazing Copper Tools.

From ultraflexpower.com

Brazing with Induction of Copper Tubing and Fittings Brazing Copper Tools It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. A brazing rod is used to create a fusion between. Brazing Copper Tools.

From www.pipsisland.com

10 Simple Steps to Braze Copper Pipe (Extended Tips) Brazing Copper Tools It's possible to make sound joints that are just as strong as the copper tube, easier to braze, and less expensive to produce. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. Brazing copper is suitable for joining copper alloys but it's. Brazing Copper Tools.