Baffles Mixing . Baffles and their configuration can have a significant impact on industrial mixing efficiency. Gail pogal and richard o. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. How baffle configuration can optimize industrial mixing. Baffles are needed to stop the swirl in a mixing tank. Understand the role of baffles and best practices for them. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. Their addition can reduce mixing time, and also yield a better product. If you’re still uncertain how to. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to.

from lob-gmbh.de

Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. Understand the role of baffles and best practices for them. Their addition can reduce mixing time, and also yield a better product. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. How baffle configuration can optimize industrial mixing. If you’re still uncertain how to. Baffles are needed to stop the swirl in a mixing tank. Gail pogal and richard o.

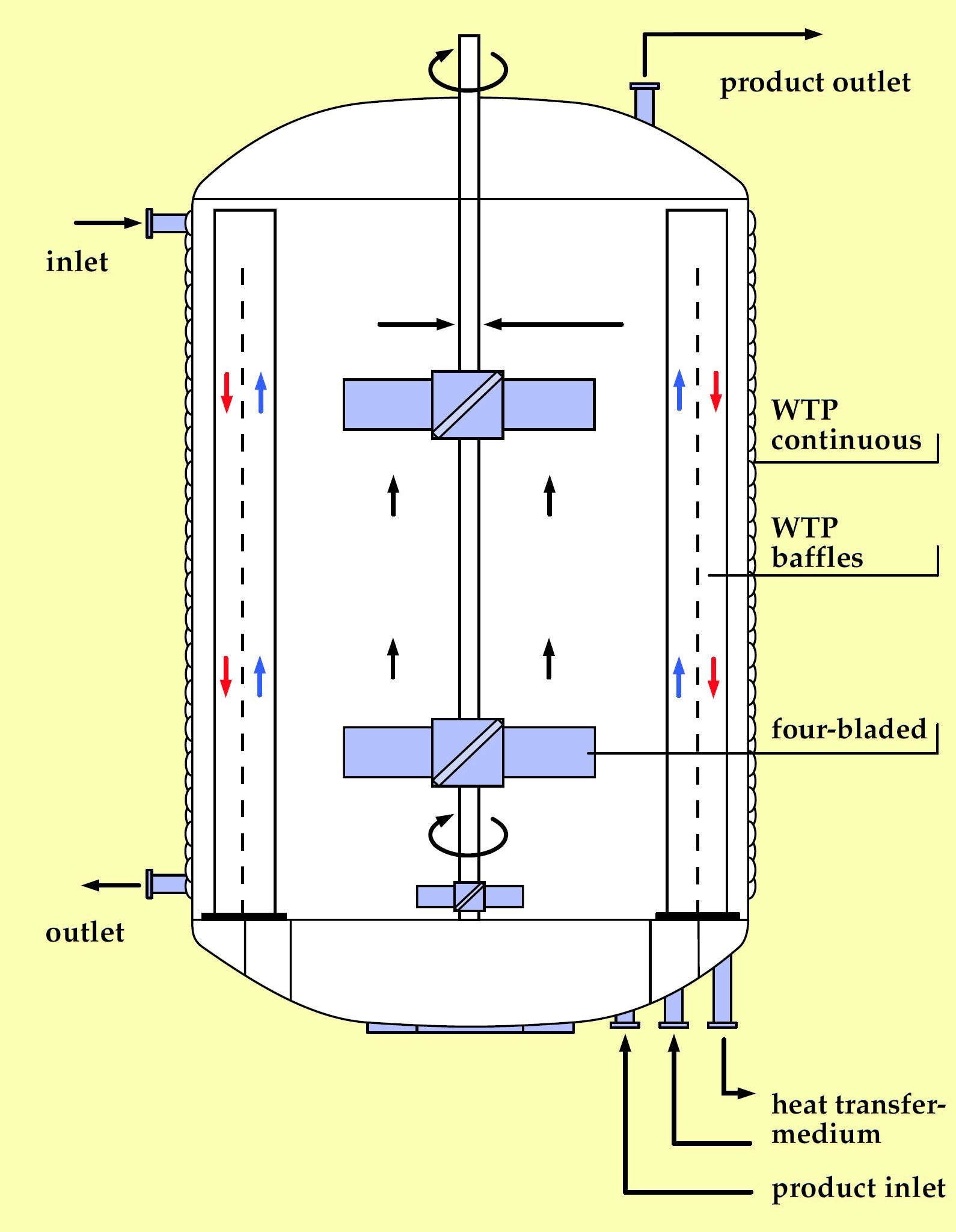

Baffles with WTPSystem® for perfect temperature LOB

Baffles Mixing Understand the role of baffles and best practices for them. Baffles and their configuration can have a significant impact on industrial mixing efficiency. Understand the role of baffles and best practices for them. Gail pogal and richard o. Their addition can reduce mixing time, and also yield a better product. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. How baffle configuration can optimize industrial mixing. Baffles are needed to stop the swirl in a mixing tank. If you’re still uncertain how to. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such.

From www.mdpi.com

Water Free FullText A Perforated Baffle Design to Improve Mixing Baffles Mixing Gail pogal and richard o. Their addition can reduce mixing time, and also yield a better product. Understand the role of baffles and best practices for them. Baffles are needed to stop the swirl in a mixing tank. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process. Baffles Mixing.

From www.thorsteel.eu

Galerii Thorsteel Baffles Mixing In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. Baffles and their configuration can have a significant impact on industrial mixing efficiency. Gail pogal and richard o. If you’re still uncertain how to. Baffles are internals, generally flat plates, used in. Baffles Mixing.

From blog.enduramaxx.co.uk

Why Mixer Baffles Improve Your Mixing Process, Benefits Of Baffles Baffles Mixing Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. Baffles are needed to stop the swirl. Baffles Mixing.

From www.youtube.com

Effect of a baffle on mixing [SLOWMO] YouTube Baffles Mixing Baffles are needed to stop the swirl in a mixing tank. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. Baffles and their configuration can have. Baffles Mixing.

From www.miscible.co.th

Mixing with Baffle and without Baffle miscible Baffles Mixing Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. Gail pogal and richard o. In our previous posting on configuring your mixer, we. Baffles Mixing.

From www.bakeryequipment.net

Stephan VCM 44 Baffle Mixing Assembly. Baffles Mixing Understand the role of baffles and best practices for them. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. Baffles are internals, generally. Baffles Mixing.

From www.youtube.com

What are baffles in mixer tanks? How do baffles improve mixing in food Baffles Mixing Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. Gail pogal and richard o. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing. Baffles Mixing.

From www.physicsforums.com

The Role of Baffles in a Reactor Increasing Mixing & Heat Exchange Baffles Mixing Baffles are needed to stop the swirl in a mixing tank. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. If you’re still uncertain how to. Understand the role of baffles and best practices for them. Their addition can reduce mixing time, and also yield a better product. How baffle configuration. Baffles Mixing.

From www.youtube.com

Industrial Mixing Basics Baffled vs Unbaffled Tanks Part 2 YouTube Baffles Mixing In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. Baffles and their configuration can have a significant impact on industrial mixing efficiency. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they. Baffles Mixing.

From www.micoope.com.gt

What Are Baffles? Why Do We Use Them?, 48 OFF Baffles Mixing It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. Baffles and their configuration can have a significant impact on industrial mixing efficiency. Gail pogal and richard. Baffles Mixing.

From www.sportbiketrackgear.com

Vance & Hines 20172021 HarleyDavidson CVO Street Glide FLHXSE Baffles Mixing If you’re still uncertain how to. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. Understand the role of baffles and best practices for them. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing. Baffles Mixing.

From www.researchgate.net

Geometry of the mixer with reduced length and number of baffles Baffles Mixing It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. How baffle configuration can optimize industrial mixing. Baffles and their configuration can have a significant impact on industrial mixing efficiency. Baffles are needed to stop the swirl in a mixing tank. Baffles are internals, generally flat plates, used in agitated vessels to. Baffles Mixing.

From blog.polyprocessing.com

Using Baffles for Tank Mixing Applications Baffles Mixing Gail pogal and richard o. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. If you’re still uncertain how to. Baffles are needed. Baffles Mixing.

From www.youtube.com

How to Make Hot Rod Exhaust Baffles / Mufflers for Side Pipes YouTube Baffles Mixing How baffle configuration can optimize industrial mixing. Gail pogal and richard o. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. Baffles are needed to stop the swirl in a mixing tank. Understand the role of baffles and best practices for them. Their addition can reduce mixing time, and also yield. Baffles Mixing.

From www.atena-it.com

BAFFLE MIX IN Atena Baffles Mixing Understand the role of baffles and best practices for them. Baffles and their configuration can have a significant impact on industrial mixing efficiency. Baffles are needed to stop the swirl in a mixing tank. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. It. Baffles Mixing.

From www.theengineeringconcepts.com

Longitudinal Flow Baffles Archives The Engineering Concepts Baffles Mixing Baffles are needed to stop the swirl in a mixing tank. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation. Baffles Mixing.

From comsol.com

Fluid Mixing Software Creating Fluid and Chemical Mixing Simulations Baffles Mixing Gail pogal and richard o. Baffles are needed to stop the swirl in a mixing tank. How baffle configuration can optimize industrial mixing. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. Their addition can reduce mixing time, and also yield. Baffles Mixing.

From www.walmart.com

6Tier Corner Bookshelf with Baffles, Industrial Large Corner Bookcase Baffles Mixing Baffles and their configuration can have a significant impact on industrial mixing efficiency. If you’re still uncertain how to. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. It is used in some household stoves [ 1 ] and in some. Baffles Mixing.

From pubs.acs.org

Microbubble Dispersion Process Intensification Using Novel Internal Baffles Mixing Their addition can reduce mixing time, and also yield a better product. How baffle configuration can optimize industrial mixing. Understand the role of baffles and best practices for them. If you’re still uncertain how to. Gail pogal and richard o. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and. Baffles Mixing.

From www.mdpi.com

Water Free FullText A Perforated Baffle Design to Improve Mixing Baffles Mixing In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. How baffle configuration can. Baffles Mixing.

From mungfali.com

Septic Tank Baffle Wall Baffles Mixing Their addition can reduce mixing time, and also yield a better product. Gail pogal and richard o. How baffle configuration can optimize industrial mixing. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. It is used in some household stoves [ 1 ] and. Baffles Mixing.

From www.mdpi.com

Water Free FullText Effect of Porous Baffles on the Energy Baffles Mixing In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. If you’re still uncertain how to. Gail. Baffles Mixing.

From www.ddpsinc.com

Baffles Mixing component by De Dietrich Process Systems Baffles Mixing If you’re still uncertain how to. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the. Baffles Mixing.

From www.researchgate.net

Effect of baffles on the mixing capability of the micromixer for Baffles Mixing How baffle configuration can optimize industrial mixing. Their addition can reduce mixing time, and also yield a better product. If you’re still uncertain how to. Understand the role of baffles and best practices for them. Baffles are needed to stop the swirl in a mixing tank. Baffles and their configuration can have a significant impact on industrial mixing efficiency. It. Baffles Mixing.

From cercell.com

Baffle Principles Baffles Mixing Their addition can reduce mixing time, and also yield a better product. Understand the role of baffles and best practices for them. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. Baffles are long, flat plates that are typically attached to the sides of. Baffles Mixing.

From www.wmprocess.com

Seven Reasons to Consider Using Tank Baffles in Your Sanitary Mixing Baffles Mixing Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. How baffle configuration can optimize industrial mixing. Baffles are needed to stop the swirl in a mixing tank. It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks),. Baffles Mixing.

From studylib.net

Optimize Mixing by Using the Proper Baffles Baffles Mixing It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. Understand the role of baffles and best practices for them. Gail pogal and richard o. If you’re still uncertain how to. Their addition can reduce mixing time, and also yield a better product. Baffles are internals, generally flat plates, used in agitated. Baffles Mixing.

From www.mr-cfd.com

Mixing Pipe, baffle configuration effect on mixing CFD Simulation Baffles Mixing Baffles are needed to stop the swirl in a mixing tank. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. Understand the role of baffles and best practices for them. How baffle configuration can optimize industrial mixing. Gail pogal and richard. Baffles Mixing.

From www.youtube.com

Industrial Mixing Basics Baffled vs Unbaffled Tanks Part 1 YouTube Baffles Mixing Gail pogal and richard o. Understand the role of baffles and best practices for them. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. How baffle configuration can optimize industrial mixing. If you’re still uncertain how to. Baffles are needed to. Baffles Mixing.

From newzelindustries.com

Baffle Plates Manufacturers Perforated Baffle Plates Exporters Baffles Mixing If you’re still uncertain how to. Baffles are long, flat plates that are typically attached to the sides of a mixing tank so that they span the height of the tank from top to. Baffles are needed to stop the swirl in a mixing tank. Understand the role of baffles and best practices for them. It is used in some. Baffles Mixing.

From dynamixinc.com

Mixing 101 Baffled by Baffles? Dynamix Agitators Baffles Mixing It is used in some household stoves [ 1 ] and in some industrial process vessels (tanks), such. If you’re still uncertain how to. Baffles and their configuration can have a significant impact on industrial mixing efficiency. Understand the role of baffles and best practices for them. Their addition can reduce mixing time, and also yield a better product. Baffles. Baffles Mixing.

From www.mdpi.com

Designs Free FullText A Study of the Mixing Performance of Baffles Mixing Baffles are needed to stop the swirl in a mixing tank. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. Understand the role of baffles and best practices for them. It is used in some household stoves [ 1 ] and in some industrial. Baffles Mixing.

From lob-gmbh.de

Baffles with WTPSystem® for perfect temperature LOB Baffles Mixing In our previous posting on configuring your mixer, we learned that the tank type and volume, viscosity, specific gravity and the process are key factors the mixing process. Baffles and their configuration can have a significant impact on industrial mixing efficiency. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and. Baffles Mixing.

From www.researchgate.net

Effect of the number of baffles on mixing index. Download Scientific Baffles Mixing Their addition can reduce mixing time, and also yield a better product. Understand the role of baffles and best practices for them. If you’re still uncertain how to. Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. It is used in some household stoves. Baffles Mixing.

From www.drumbaffles.com

Drum Baffles Baffles Mixing Baffles are internals, generally flat plates, used in agitated vessels to optimize and stabilize the mixing flow pattern and minimize variation in agitator power draw. Their addition can reduce mixing time, and also yield a better product. Baffles are needed to stop the swirl in a mixing tank. Baffles are long, flat plates that are typically attached to the sides. Baffles Mixing.