Self Tapping Screw Tolerances . It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. 0.98 x basic nominal thread major diameter. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force.

from sendcutsend.com

0.98 x basic nominal thread major diameter. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut.

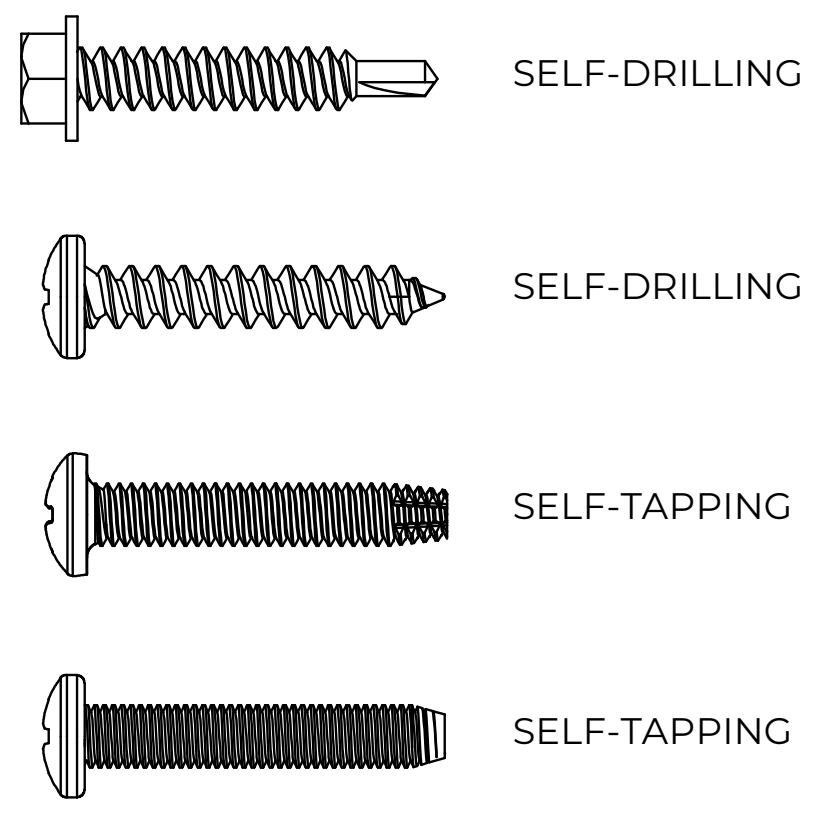

SelfDrilling vs SelfTapping Screws What's the Best Fastening Solution?

Self Tapping Screw Tolerances Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. 0.98 x basic nominal thread major diameter.

From yardandgardenguru.com

Self Tapping Screws Sizes Chart Self Tapping Screw Tolerances Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing standards for these screws, such as bs. Self Tapping Screw Tolerances.

From dxottdlwk.blob.core.windows.net

Self Tapping Brick Screws at Mark Simmons blog Self Tapping Screw Tolerances 0.98 x basic nominal thread major diameter. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates. Self Tapping Screw Tolerances.

From engineeringproductdesign.com

Types of selftapping screws for plastic and its characteristics Self Tapping Screw Tolerances Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing standards for these screws, such as bs. Self Tapping Screw Tolerances.

From www.belmey.co.uk

Belmey industrial supplies Self Tapping Screw Tolerances It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. 0.98 x basic nominal thread major diameter. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Lower tolerance (iso 1) generates. Self Tapping Screw Tolerances.

From www.scribd.com

Self Tapping Screws PDF Screw Metalworking Self Tapping Screw Tolerances It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on. Self Tapping Screw Tolerances.

From blog.thepipingmart.com

SelfTapping Screws Vs NonSelfTapping Screws What's the Difference Self Tapping Screw Tolerances It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. 0.98 x basic nominal thread major diameter. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended. Self Tapping Screw Tolerances.

From dxoxuseay.blob.core.windows.net

What Are Self.tapping Screws at Sally Bryant blog Self Tapping Screw Tolerances It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. 0.98 x basic nominal thread major diameter. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is. Self Tapping Screw Tolerances.

From www.mudgefasteners.com

How to Select a Drill Point Size Self Tapping Screw Tolerances 0.98 x basic nominal thread major diameter. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is. Self Tapping Screw Tolerances.

From www.eurodima.com

Selftapping concrete screw EURODIMA GmbH & Co KG Self Tapping Screw Tolerances Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. 0.98 x basic nominal thread major diameter. Lower tolerance (iso 1) generates. Self Tapping Screw Tolerances.

From www.ejot.com.mx

Types of screws Selfdrilling screws Guidebook Part 1 EJOT Mexico Self Tapping Screw Tolerances Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. 0.98 x basic nominal thread major diameter. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. It references various manufacturing. Self Tapping Screw Tolerances.

From dxoxuseay.blob.core.windows.net

What Are Self.tapping Screws at Sally Bryant blog Self Tapping Screw Tolerances It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. 0.98 x basic nominal thread major diameter. Lower tolerance (iso 1) generates. Self Tapping Screw Tolerances.

From www.clecofasteners.com

Cleco Industrial Fasteners Specifications SELF TAPPING SCREWS Self Tapping Screw Tolerances Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. 0.98 x basic nominal thread major diameter. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing. Self Tapping Screw Tolerances.

From www.anzor.co.nz

Self Tapping Screws / Pilot Hole Diameter for Self Tapping Screws An Self Tapping Screw Tolerances Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately. Self Tapping Screw Tolerances.

From www.belmey.co.uk

Belmey industrial supplies Self Tapping Screw Tolerances Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. 0.98 x basic nominal thread major diameter. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is. Self Tapping Screw Tolerances.

From www.scribd.com

Self Tapping Screw Standards Screw Metalworking Self Tapping Screw Tolerances 0.98 x basic nominal thread major diameter. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended. Self Tapping Screw Tolerances.

From www.lwfasteners.com.tw

Threads and Points for Types BSD and CSD SelfDrilling Tapping Screws Self Tapping Screw Tolerances Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. 0.98 x basic nominal thread major diameter. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. It references various manufacturing. Self Tapping Screw Tolerances.

From mx.misumi-ec.com

Self Tapping Screws Pan Head, Phillips Drive, Cross Recessed, Type 4 Self Tapping Screw Tolerances Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Normal tap tolerance is iso 2 (6h), which generates an average. Self Tapping Screw Tolerances.

From www.accuratescrew.com

Screw Sizes Screw Sizing Chart & Socket Cap Screw Data ASM Self Tapping Screw Tolerances Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. 0.98 x basic nominal thread major diameter. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates. Self Tapping Screw Tolerances.

From woodworking.stackexchange.com

What is the difference between selfdrilling and selftapping screws Self Tapping Screw Tolerances Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on. Self Tapping Screw Tolerances.

From www.alibaba.com

High Quality Metal M2 M2.5 Small Self Tapping Screw For Plastic Buy Self Tapping Screw Tolerances 0.98 x basic nominal thread major diameter. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates. Self Tapping Screw Tolerances.

From engineeringproductdesign.com

Types of selftapping screws for plastic and its characteristics Self Tapping Screw Tolerances 0.98 x basic nominal thread major diameter. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing. Self Tapping Screw Tolerances.

From bdnfasteners.com

10 Different SelfTapping screw head types BDN Fasteners Self Tapping Screw Tolerances Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. 0.98 x basic nominal thread major diameter. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing. Self Tapping Screw Tolerances.

From www.longtonsteel.com

Screw Thread Tolerances, According to ISO 965 Self Tapping Screw Tolerances It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average. Self Tapping Screw Tolerances.

From www.linkedin.com

TYPE AB SELF TAPPING SCREWS Self Tapping Screw Tolerances Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. 0.98 x basic nominal thread major diameter. It references various manufacturing. Self Tapping Screw Tolerances.

From sendcutsend.com

SelfDrilling vs SelfTapping Screws What's the Best Fastening Solution? Self Tapping Screw Tolerances Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. 0.98 x basic nominal thread major diameter. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing. Self Tapping Screw Tolerances.

From www.rs-fastener.com

M4.8 410 Stainless Steel Phillips Rounded Head Drilling SelfTapping Self Tapping Screw Tolerances It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Normal tap tolerance is iso 2 (6h), which generates an average. Self Tapping Screw Tolerances.

From www.sstls.com

No 4 Self Tapping Screw Dimensions Chart Self Tapping Screw Tolerances Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. 0.98 x basic nominal thread major diameter. Recommended. Self Tapping Screw Tolerances.

From www.ebay.com

M1.0 M1.2 M1.4 M1.7 M2 BK ZINC Round Phillips Pan Head Self Tapping Self Tapping Screw Tolerances Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. 0.98 x basic nominal thread major diameter. It references various manufacturing. Self Tapping Screw Tolerances.

From dxoxuseay.blob.core.windows.net

What Are Self.tapping Screws at Sally Bryant blog Self Tapping Screw Tolerances Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. 0.98 x basic nominal thread major diameter. It references various manufacturing. Self Tapping Screw Tolerances.

From www.sstls.com

Self Tapping Screw Sizes JIS Standard Self Tapping Screw Tolerances Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. 0.98 x basic nominal thread major diameter. It references various manufacturing. Self Tapping Screw Tolerances.

From bdnfasteners.com

How to Master Use of SelfDrilling Screws (Tek screws) Self Tapping Screw Tolerances Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Lower tolerance (iso 1) generates a fine fit without a gap on. Self Tapping Screw Tolerances.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Self Tapping Screw Tolerances 0.98 x basic nominal thread major diameter. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing. Self Tapping Screw Tolerances.

From yardandgardenguru.com

Self Tapping Screws Sizes Chart Self Tapping Screw Tolerances Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on. Self Tapping Screw Tolerances.

From www.almabolt.com

SelfTapping Screws Self Tapping Screw Tolerances Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing standards for these screws, such as bs 4174, din 7970, and iso 1478. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on. Self Tapping Screw Tolerances.

From joivqotzb.blob.core.windows.net

How To Use Metal Self Tapping Screws at Becky Alfano blog Self Tapping Screw Tolerances 0.98 x basic nominal thread major diameter. Normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks between screw and nut. Recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. It references various manufacturing. Self Tapping Screw Tolerances.