Plug Gage Class X Tolerances . Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages. Either way, these gages are. These gages are used where greater precision is needed. Thread gages are made to class x tolerances. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Cylindrical plug gage go member.

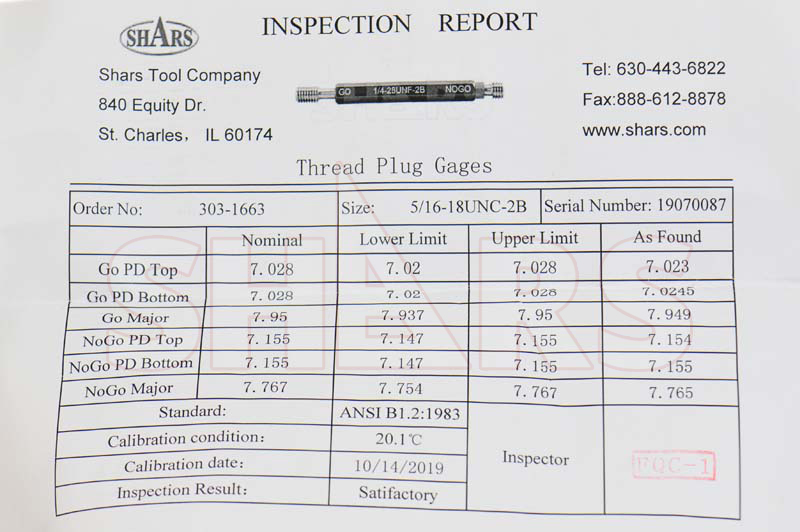

from www.shars.com

Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. These gages are used where greater precision is needed. Cylindrical plug gage go member. Either way, these gages are. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Thread gages are made to class x tolerances. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side.

5/1618 Go/No Go Double End Thread Plug Gage

Plug Gage Class X Tolerances Thread gages are made to class x tolerances. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. These gages are used where greater precision is needed. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Cylindrical plug gage go member. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Either way, these gages are. Thread gages are made to class x tolerances. Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly.

From www.judgetool.com

Thread Plug Gages STI (HELICOIL) Titanium Nitride Coated (Inch Plug Gage Class X Tolerances Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. Thread gages are made to class x tolerances. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin. Plug Gage Class X Tolerances.

From www.beaverdrillstore.com

Class X Plus Tolerance Pin Gage Beaver Drill Store Plug Gage Class X Tolerances Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. Either way, these gages are. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages. See asme b89.7.3.1 for more information on the 10% rule. Plug Gage Class X Tolerances.

From www.ebay.com

2pcs Class x Steel Pin Gage 1.70mm Dia Metric Tolerance 0.001mm Plug Plug Gage Class X Tolerances These gages are used where greater precision is needed. Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. Thread gages are made to class x tolerances. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages. Cylindrical. Plug Gage Class X Tolerances.

From titangage.com

Thread Ring & Setting Plug Gages Titan Gage Plug Gage Class X Tolerances See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Thread gages are made to class x tolerances. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Either way, these gages are. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance.. Plug Gage Class X Tolerances.

From kesriclinic.in

Metric Thread Plug Gauge Standard Tolerances 6h Go Nogo 6g, 42 OFF Plug Gage Class X Tolerances Cylindrical plug gage go member. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock. Plug Gage Class X Tolerances.

From www.teachtoearn.in

Gagemakers Tolerance Chart Willich Precision Instruments, 40 OFF Plug Gage Class X Tolerances Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Thread gages are made to class x tolerances. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread. Plug Gage Class X Tolerances.

From mavink.com

Gage Makers Tolerance Chart Plug Gage Class X Tolerances These gages are used where greater precision is needed. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. For many years, gage manufacturers have offered both class “x” and “w” tolerance. Plug Gage Class X Tolerances.

From mungfali.com

Gage Block Tolerance Chart Plug Gage Class X Tolerances Thread gages are made to class x tolerances. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. These gages are used where greater precision is needed. Either way, these gages. Plug Gage Class X Tolerances.

From www.grainger.com

VERMONT GAGE Threaded Plug Gauge, Thread Type UNF, Thread Size 1032 Plug Gage Class X Tolerances Thread gages are made to class x tolerances. Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. Cylindrical plug gage go member. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Either way, these gages are. Tolerance direction cylindrical ring gage go member. Plug Gage Class X Tolerances.

From mavink.com

Plug Gauge Tolerance Chart Plug Gage Class X Tolerances These gages are used where greater precision is needed. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Thread gages are made to class x tolerances. Either way, these gages are. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Differences between classes of gages from meyer gage's. Plug Gage Class X Tolerances.

From mavink.com

Gage Block Tolerances Plug Gage Class X Tolerances These gages are used where greater precision is needed. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. See asme b89.7.3.1 for more information on the 10% rule and options. Plug Gage Class X Tolerances.

From www.tanfel.com

Industrial Metrology GO and NOGO Thread Plug Gauges Thread Gages Plug Gage Class X Tolerances Thread gages are made to class x tolerances. Cylindrical plug gage go member. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Either way, these gages are.. Plug Gage Class X Tolerances.

From mungfali.com

Gage Block Tolerance Chart Plug Gage Class X Tolerances Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. Either way, these gages are. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. To calculate gage tolerances, the general rule of thumb is to use 10% of your part. Plug Gage Class X Tolerances.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Plug Gage Class X Tolerances Either way, these gages are. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Thread gages are made to class x tolerances. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 30 rows click here to see how major, minor and pitch diameter tolerances are applied.. Plug Gage Class X Tolerances.

From nabgauge.com

PLAIN PLUG AND RING GAUGES (CLASS Z, Y, X, XX) Northern Gauge Plug Gage Class X Tolerances Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. These gages are used where greater precision is needed. Either way, these gages are. 30 rows click here to see how major, minor and. Plug Gage Class X Tolerances.

From kesriclinic.in

Metric Thread Plug Gauge Standard Tolerances 6h Go Nogo 6g, 42 OFF Plug Gage Class X Tolerances Cylindrical plug gage go member. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. These gages are used where greater precision is needed. See asme b89.7.3.1 for. Plug Gage Class X Tolerances.

From informacionpublica.svet.gob.gt

Source Metric Thread Plug Gauge Standard Tolerances 6H Go Plug Gage Class X Tolerances Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. Thread gages are made to class x tolerances. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. These gages are used where greater precision is needed. Cylindrical. Plug Gage Class X Tolerances.

From www.suncoasttools.com

.3758" Class X Go (Plus) Plug Gage, Class X Tolerance (+.00004"/.00000 Plug Gage Class X Tolerances For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Standard class x go. Plug Gage Class X Tolerances.

From www.ebay.com

21.607 & 21.695 CLASS X METRIC PIN PLUG GAGE GO NO GO 22.000 .393 22 Plug Gage Class X Tolerances Cylindrical plug gage go member. Either way, these gages are. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. These gages are used where greater precision is needed. Thread gages are made to class x tolerances. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread. Plug Gage Class X Tolerances.

From vermontgage.com

Standard Pin Gages & Sets Vermont Gage Plug Gage Class X Tolerances To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Thread gages are made to class x tolerances. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti. Plug Gage Class X Tolerances.

From mungfali.com

Gage Block Tolerance Chart Plug Gage Class X Tolerances These gages are used where greater precision is needed. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Cylindrical plug gage go member. Either way, these gages are. Differences between classes of gages from meyer gage's product. Plug Gage Class X Tolerances.

From kesriclinic.in

Metric Thread Plug Gauge Standard Tolerances 6h Go Nogo 6g, 42 OFF Plug Gage Class X Tolerances Either way, these gages are. Cylindrical plug gage go member. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. These gages are used where. Plug Gage Class X Tolerances.

From kidsforpeaceglobal.org

7piece Metric Thread Plug Gauge Set HighPrecision Thread detection Plug Gage Class X Tolerances Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. Either way, these gages are. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. These. Plug Gage Class X Tolerances.

From jarnalmensal.com

Ø60mm Smooth Plug Gauge Plug Gage Tolerance H7 Select Size Ø2mm Plug Gage Class X Tolerances Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Thread gages are made to class x tolerances. These gages are used where greater precision is needed. For many years, gage. Plug Gage Class X Tolerances.

From www.tillescenter.org

Tolerance Class X 0.1257 Gage Diameter Vermont Gage Steel NoGo Plug Plug Gage Class X Tolerances Thread gages are made to class x tolerances. These gages are used where greater precision is needed. Either way, these gages are. Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. Cylindrical plug gage go member. 30 rows click here to see how major, minor and pitch diameter tolerances. Plug Gage Class X Tolerances.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Plug Gage Class X Tolerances 30 rows click here to see how major, minor and pitch diameter tolerances are applied. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages. Thread gages are made to class x tolerances. Either way, these gages are. Tolerance direction cylindrical ring gage go member is to the. Plug Gage Class X Tolerances.

From www.judgetool.com

Thread Plug Gages METRIC Hardened Steel Judge Tool & Gage Plug Gage Class X Tolerances These gages are used where greater precision is needed. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Cylindrical plug gage go member. Either way, these gages are. To calculate gage. Plug Gage Class X Tolerances.

From www.sumipol.com

THREAD LIMIT PLUG GAUGE (ISO TYPE JIS / GPNP) Sumipol Plug Gage Class X Tolerances Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. These gages are used where greater precision is needed. Cylindrical plug gage go member. Either way, these gages are. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Standard. Plug Gage Class X Tolerances.

From www.ezo-usa.com

Tolerance, Class, Chamfer Dimension of Bearings SPBUSA, LLC Plug Gage Class X Tolerances Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages.. Plug Gage Class X Tolerances.

From willrich.com

Gagemakers Tolerance Chart Willich Precision Instruments Plug Gage Class X Tolerances These gages are used where greater precision is needed. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. Either way, these gages are. 30 rows click here to see. Plug Gage Class X Tolerances.

From grmetrology.com

Plug Gage Calibration GR Metrology Plug Gage Class X Tolerances To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages. Thread gages are made to class. Plug Gage Class X Tolerances.

From jo-plug.com

Tolerances Spence Industries, Inc. Plug Gage Class X Tolerances Standard class x go and nogo plug gages are used as masters to calibrate equipment or to gage parts directly. Either way, these gages are. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Cylindrical plug gage go member. 30 rows click here to see how major, minor and pitch diameter tolerances. Plug Gage Class X Tolerances.

From www.scribd.com

10. Gage Tolerances PDF Plug Gage Class X Tolerances Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. These gages are used where greater precision is needed. Either way, these gages are. Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. See asme b89.7.3.1 for. Plug Gage Class X Tolerances.

From mungfali.com

Plain Plug Gauge Tolerance Chart Plug Gage Class X Tolerances Differences between classes of gages from meyer gage's product lines including english and metric plug & pin gages, ring gages, trilock & taperlock. For many years, gage manufacturers have offered both class “x” and “w” tolerance thread plug gages, as options for sti thread gages. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is. Plug Gage Class X Tolerances.

From www.shars.com

5/1618 Go/No Go Double End Thread Plug Gage Plug Gage Class X Tolerances 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Cylindrical plug gage go member. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Either way, these gages are. These. Plug Gage Class X Tolerances.