Lubrication Maintenance Chart . Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Establishment of a map of lubrification points. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Key features of the skf lubrication planner: Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. Develop and follow up your lubrication plan. The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a.

from www.yam-r125.net

Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Develop and follow up your lubrication plan. The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Key features of the skf lubrication planner: Establishment of a map of lubrification points. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing.

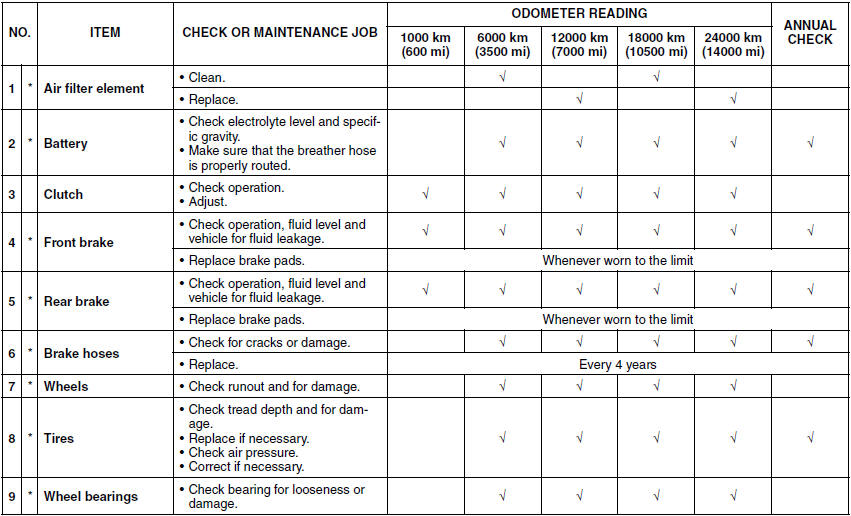

Yamaha YZFR125 Owners Manual General maintenance and lubrication

Lubrication Maintenance Chart Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Develop and follow up your lubrication plan. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Key features of the skf lubrication planner: Establishment of a map of lubrification points.

From www.hemmings.com

Lubrication charts chassis maintenance sure isn Hemmings Daily Lubrication Maintenance Chart Establishment of a map of lubrification points. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging. Lubrication Maintenance Chart.

From www.researchgate.net

Lubrication diagrams are one way of highlighting machine lubrication Lubrication Maintenance Chart Establishment of a map of lubrification points. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Develop and follow up your lubrication plan. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Equipment lubrication management is an. Lubrication Maintenance Chart.

From es.scribd.com

Group 21 Lubrication Charts and Specifications Automatic Transmission Lubrication Maintenance Chart Key features of the skf lubrication planner: Develop and follow up your lubrication plan. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Engineers apply their expertise to. Lubrication Maintenance Chart.

From waterstorage.tpub.com

ENGINE MAINTENANCE SCHEDULE CHARTS Lubrication Maintenance Chart Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. By leveraging proper lubrication. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Lubrication Maintenance Chart Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. The skf lubrication planner has been developed to help in the administration of a lubrication. Lubrication Maintenance Chart.

From www.scribd.com

TDS11SA Lubrication and Maintenance Guidelines Lubricant Lubrication Maintenance Chart Key features of the skf lubrication planner: Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Establishment of a map of lubrification points. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Engineers apply their expertise to help you develop. Lubrication Maintenance Chart.

From mgaguru.com

Lubrication chart for MGA (by Morris) Lubrication Maintenance Chart Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Key features of the skf lubrication planner: The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Develop and follow up your lubrication plan.. Lubrication Maintenance Chart.

From pt.scribd.com

Lube Oil Equivalent Chart PDF Machines Mechanical Engineering Lubrication Maintenance Chart Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment. Lubrication Maintenance Chart.

From www.priestelectric.com

Relubrication of Bearings Priest Electric Lubrication Maintenance Chart Establishment of a map of lubrification points. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Develop and follow up your lubrication plan. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. Key features of the skf lubrication planner: Equipment lubrication management is. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Maintenance And Lubrication Charts Maintenance And Lubrication Maintenance Chart Key features of the skf lubrication planner: Establishment of a map of lubrification points. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Engineers. Lubrication Maintenance Chart.

From www.scribd.com

D 50 Lubrication Fluid Maintenance Chart PDF Lubricant Lubrication Maintenance Chart Establishment of a map of lubrification points. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Key features of the skf lubrication planner: The skf lubrication planner has been developed to. Lubrication Maintenance Chart.

From www.vintage-car-profiles.com

Lubrication charts for the Alvis TJ 12/50 Lubrication Maintenance Chart The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil. Lubrication Maintenance Chart.

From nelsontractorco.com

When to Take Your Brand New Tractor for Its First Service Nelson Lubrication Maintenance Chart Key features of the skf lubrication planner: The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Develop and follow up your lubrication plan. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing.. Lubrication Maintenance Chart.

From www.mgaguru.com

Lubrication chart for MGA Twin Cam (MG Car Co Ltd) Lubrication Maintenance Chart Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Key features of the skf lubrication planner: The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Browse our oil and grease maintenance guide. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Maintenance And Lubrication Charts Maintenance And Lubrication Maintenance Chart Develop and follow up your lubrication plan. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. Establishment of a map of lubrification points. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Key features of the. Lubrication Maintenance Chart.

From vdocuments.site

DuBoisChemicals Maintenance Lubricant Cross Maintenance Lubricant Cross Lubrication Maintenance Chart Establishment of a map of lubrification points. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Develop and follow up your lubrication plan. Key features of the skf lubrication planner: Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Engineers. Lubrication Maintenance Chart.

From www.yam-r125.net

Yamaha YZFR125 Owners Manual General maintenance and lubrication Lubrication Maintenance Chart Develop and follow up your lubrication plan. Key features of the skf lubrication planner: By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Establishment of a map of lubrification points. The skf lubrication planner has been developed to help in the administration of a lubrication. Lubrication Maintenance Chart.

From constructiongrader.tpub.com

Lubrication and Maintenance Chart continued 668960426 Lubrication Maintenance Chart Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Key features of the skf lubrication planner: Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Maintenance Interval Charts Maintenance Interval Lubrication Maintenance Chart Key features of the skf lubrication planner: Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Maintenance And Lubrication Charts Maintenance And Lubrication Maintenance Chart By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Develop and follow up your lubrication plan. The skf lubrication planner has been developed to. Lubrication Maintenance Chart.

From www.pinterest.com

Lubrication Chart Oil Equivalents Iv Compatibility Chevron Grease Lubrication Maintenance Chart The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Establishment of a map of lubrification points. Develop and follow up your lubrication plan. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. Browse our oil. Lubrication Maintenance Chart.

From www.barrett-jackson.com

Choice 1940s Ford Lubrication and Maintenance Chart service d Lubrication Maintenance Chart By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Establishment of a map of lubrification points. Develop and follow up your lubrication plan. The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the. Lubrication Maintenance Chart.

From www.inpaspages.com

Cleaning lubrication inspection tightening Schedule and format Lubrication Maintenance Chart The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Key features of the skf lubrication planner: Develop and follow up your lubrication plan. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing.. Lubrication Maintenance Chart.

From studebaker-info.org

Bob Johnstones Studebaker Resource site (Lubrication Charts ) Lubrication Maintenance Chart By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Develop and follow up your lubrication plan. Key features of the skf lubrication planner: Establishment of a map of lubrification points. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed. Lubrication Maintenance Chart.

From newsmilitary.com

AR 15 Lubrication Chart Ultimate Guide for Proper Maintenance News Lubrication Maintenance Chart Develop and follow up your lubrication plan. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Establishment of a map of lubrification points. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. The. Lubrication Maintenance Chart.

From constructiongrader.tpub.com

Lubrication and Maintenance Chart Lubrication Maintenance Chart By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Establishment of a map of lubrification points. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Equipment lubrication management is an essential method for ensuring the normal operation. Lubrication Maintenance Chart.

From www.scribd.com

Lubricant Cross Reference Chart Lubrication Chemical Substances Lubrication Maintenance Chart Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Develop and follow up your lubrication plan. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Establishment of a map of lubrification points. Browse. Lubrication Maintenance Chart.

From www.yam-r125.net

Yamaha YZFR125 Owners Manual General maintenance and lubrication Lubrication Maintenance Chart Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products.. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Maintenance And Lubrication Charts Maintenance And Lubrication Maintenance Chart By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Maintenance Interval Charts Maintenance Interval Lubrication Maintenance Chart Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. Develop and follow up. Lubrication Maintenance Chart.

From www.meppon.com

74A1515 MAINTENANCE CHART,LUBRICATION Meppon Co., Ltd Lubrication Maintenance Chart The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Establishment of a map of lubrification points. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly improving the. Equipment lubrication management is. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Maintenance And Lubrication Charts Maintenance And Lubrication Maintenance Chart Develop and follow up your lubrication plan. The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Key features of the skf lubrication planner: Establishment of a map of lubrification points. By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Specifications And Maintenance Charts Lubrication Maintenance Chart Browse our oil and grease maintenance guide for equipment lubrication involving grease and oil for kubota's products. Develop and follow up your lubrication plan. Establishment of a map of lubrification points. Key features of the skf lubrication planner: By leveraging proper lubrication techniques, machine uptime and service intervals may be extended and maintenance and operating costs can be lowered, greatly. Lubrication Maintenance Chart.

From www.autozone.com

Repair Guides Maintenance And Lubrication Charts Maintenance And Lubrication Maintenance Chart Establishment of a map of lubrification points. Key features of the skf lubrication planner: Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear on equipment parts, increasing. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. Browse our oil and grease maintenance guide. Lubrication Maintenance Chart.

From ancient-engines.blogspot.com

ENGINES WORLD December 2014 Lubrication Maintenance Chart The skf lubrication planner has been developed to help in the administration of a lubrication plan, thereby bridging the gap between the need for a. Engineers apply their expertise to help you develop a thorough lubrication instruction plan, providing detailed instructions for equipment,. Equipment lubrication management is an essential method for ensuring the normal operation of the equipment, reducing wear. Lubrication Maintenance Chart.