What Is Monitoring Equipment . In the context of an application, the measured data. Condition monitoring consists of measuring equipment parameters that indicate failure. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan.

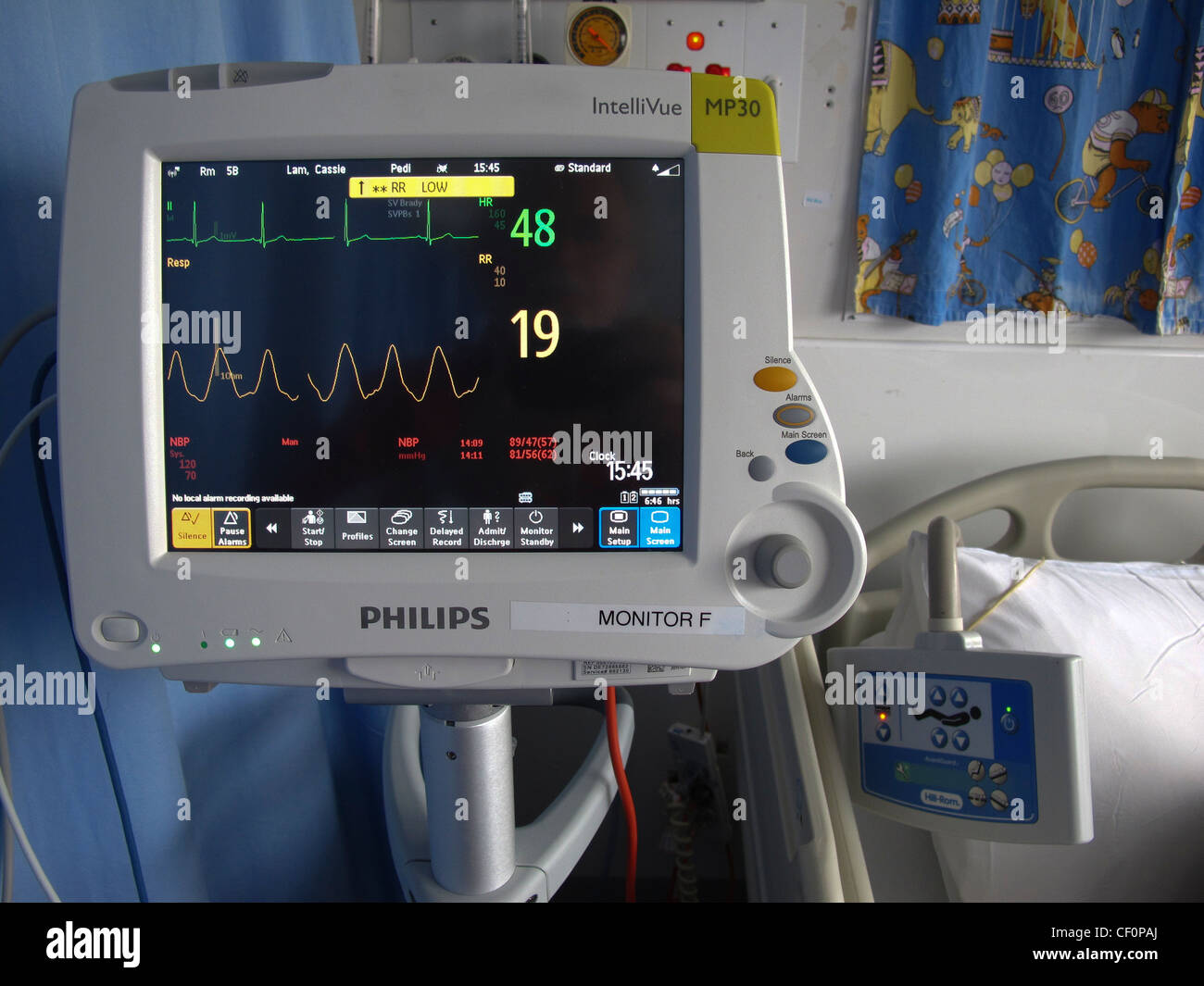

from www.alamy.com

Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring consists of measuring equipment parameters that indicate failure. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. In the context of an application, the measured data. With effective equipment monitoring, businesses can reduce. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify.

Hospital bedside monitoring equipment Stock Photo 43658122 Alamy

What Is Monitoring Equipment Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. Condition monitoring consists of measuring equipment parameters that indicate failure. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. In the context of an application, the measured data. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify.

From idataresearch.com

U.S. Patient Monitoring Equipment Market Top 3 Trends What Is Monitoring Equipment Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. In the context of an application, the measured data. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. With effective equipment monitoring, businesses can reduce. Condition monitoring (cm). What Is Monitoring Equipment.

From www.audomed.com

PM2000D multiparameter ambulance equipment medical patient icu monitor What Is Monitoring Equipment In the context of an application, the measured data. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan.. What Is Monitoring Equipment.

From toptechengineeringltd.com

Monitoring Systems Toptech Engineering Limited What Is Monitoring Equipment In the context of an application, the measured data. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. Condition monitoring consists of measuring equipment parameters that indicate failure.. What Is Monitoring Equipment.

From www.promansecuritech.com

What Is CMS (Central Monitoring System)? A Complete Overview Proman What Is Monitoring Equipment With effective equipment monitoring, businesses can reduce. Condition monitoring consists of measuring equipment parameters that indicate failure. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. In the context of an application, the measured data. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on. What Is Monitoring Equipment.

From tractian.com

What Is Condition Monitoring? TRACTIAN What Is Monitoring Equipment Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to. What Is Monitoring Equipment.

From slidesgo.com

Patient Monitoring Equipment Company Profile What Is Monitoring Equipment With effective equipment monitoring, businesses can reduce. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. In the context of an application, the measured data. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Hopefully, you can spot changes in the. What Is Monitoring Equipment.

From www.medicalequipmentblog.com

TOP 10 Patient Monitoring System Medical Equipment Blog What Is Monitoring Equipment Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save. What Is Monitoring Equipment.

From irisvision.com

Top 5 Devices for Remote Patient Monitoring Irisvision What Is Monitoring Equipment Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. With effective equipment monitoring, businesses can reduce. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems. What Is Monitoring Equipment.

From www.alamy.com

Patient monitoring equipment display at the Accident and Emergency dept What Is Monitoring Equipment Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. In the context of an application, the measured data. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. With effective equipment. What Is Monitoring Equipment.

From www.alamy.com

Monitoring equipment in hospital Stock Photo Alamy What Is Monitoring Equipment In the context of an application, the measured data. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. Hopefully, you can spot changes in the. What Is Monitoring Equipment.

From thecustomizewindows.com

Arduino Based Patient Monitoring Overview What Is Monitoring Equipment Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. In the context of an application, the measured data. With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and. What Is Monitoring Equipment.

From www.samsara.com

The Complete Guide to Equipment Monitoring What Is Monitoring Equipment Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. Condition monitoring consists of measuring equipment parameters that indicate failure. In the context of an application,. What Is Monitoring Equipment.

From www.vtgsecurity.ca

Video Monitoring Visionary Technology Group What Is Monitoring Equipment With effective equipment monitoring, businesses can reduce. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. Hopefully, you can spot changes in the usual patterns. What Is Monitoring Equipment.

From blog.atltechnology.com

What are the components of a patient monitoring system? What Is Monitoring Equipment The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. With effective equipment monitoring, businesses can reduce. Condition monitoring (cm) is the process of monitoring a particular condition in. What Is Monitoring Equipment.

From www.youtube.com

i Alert2 Vibration Monitoring System Bluetooth Equipment Health What Is Monitoring Equipment With effective equipment monitoring, businesses can reduce. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. Condition monitoring (cm) is the process of monitoring a particular condition in. What Is Monitoring Equipment.

From www.engineerlive.com

Continuous equipment monitoring Engineer Live What Is Monitoring Equipment Condition monitoring consists of measuring equipment parameters that indicate failure. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. In the context of an application, the measured data. With effective equipment monitoring,. What Is Monitoring Equipment.

From www.fastprojectsoftware.com

Project Monitoring System Based Project Monitoring System What Is Monitoring Equipment Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. In the context of an application, the measured data. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring consists of measuring equipment parameters that indicate failure.. What Is Monitoring Equipment.

From inbound.usisecurity.com

What Are The Benefits Of Remote Surveillance Monitoring? What Is Monitoring Equipment In the context of an application, the measured data. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. Hopefully, you can spot changes in the usual patterns in time to prevent a. What Is Monitoring Equipment.

From www.hospitalstore.com

What is Patient Monitors & How does a patient monitor Work? Buyers Guide What Is Monitoring Equipment Condition monitoring consists of measuring equipment parameters that indicate failure. In the context of an application, the measured data. With effective equipment monitoring, businesses can reduce. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment. What Is Monitoring Equipment.

From betebt.com

What is Remote Patient Monitoring Scalefocus (2023) What Is Monitoring Equipment Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. Condition monitoring consists of measuring equipment parameters that indicate failure. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. The purpose of equipment monitoring is. What Is Monitoring Equipment.

From www.fourwallssecurity.com.au

How to Choose the Best CCTV Monitoring Cameras What Is Monitoring Equipment The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to. What Is Monitoring Equipment.

From www.realtimenetworks.com

6 Reasons You Need a Remote Monitoring and Control System What Is Monitoring Equipment The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. In the context of an application, the measured data. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. Hopefully, you can spot changes in the usual patterns in. What Is Monitoring Equipment.

From formaspace.com

Why Your Surveillance Team Needs Custom Monitoring Stations Formaspace What Is Monitoring Equipment Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. In the context of an application, the measured data. Condition monitoring consists of measuring equipment parameters. What Is Monitoring Equipment.

From www.alamy.com

monitoring equipment for Caesarian section in operating room, Trios What Is Monitoring Equipment With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. Condition monitoring consists of measuring equipment parameters that indicate failure. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential. What Is Monitoring Equipment.

From www.dreamstime.com

Advanced Monitoring Equipment in a Modern ICU Stock Photo Image of What Is Monitoring Equipment Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. In the context of an application, the measured data. Condition monitoring consists of measuring equipment parameters. What Is Monitoring Equipment.

From ifdesign.com

iF Design Patient Monitoring System What Is Monitoring Equipment Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. The purpose of equipment monitoring is to ensure that. What Is Monitoring Equipment.

From www.machinestalk.com

Industrial Equipment Monitoring MachinesTalk What Is Monitoring Equipment The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring consists of measuring equipment parameters that indicate failure. With effective equipment monitoring, businesses can reduce. In the context of an application, the measured data. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature,. What Is Monitoring Equipment.

From www.elcomponent.co.uk

Realtime Energy Monitoring Displays What Is Monitoring Equipment Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems. What Is Monitoring Equipment.

From www.dpstele.com

Features For Your Network Monitoring Software What Is Monitoring Equipment With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. Condition monitoring consists of measuring equipment parameters that indicate failure. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring. What Is Monitoring Equipment.

From freedomiot.ai

What is Equipment Monitoring? FREEDOM® IoT What Is Monitoring Equipment In the context of an application, the measured data. With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify.. What Is Monitoring Equipment.

From technologcomparison.blogspot.com

6 Best Network Device Monitoring Tools Technology Comparison What Is Monitoring Equipment With effective equipment monitoring, businesses can reduce. Condition monitoring (cm) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems. What Is Monitoring Equipment.

From www.fleetzoom.com

Equipment Monitoring What Is Monitoring Equipment Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. In the context of an application, the measured data. Condition monitoring consists of measuring equipment parameters that indicate failure. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to. What Is Monitoring Equipment.

From datamyte.com

What is a Machine Monitoring System? A Full Guide DataMyte What Is Monitoring Equipment Condition monitoring consists of measuring equipment parameters that indicate failure. With effective equipment monitoring, businesses can reduce. Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential. What Is Monitoring Equipment.

From netilion.endress.com

6 examples of Industrial IoT monitoring solutions! What Is Monitoring Equipment Hopefully, you can spot changes in the usual patterns in time to prevent a breakdown, save on reactive maintenance, and extend your asset’s lifespan. With effective equipment monitoring, businesses can reduce. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. In the context of an application, the measured data. Condition monitoring is. What Is Monitoring Equipment.

From www.alamy.com

Hospital bedside monitoring equipment Stock Photo 43658122 Alamy What Is Monitoring Equipment Condition monitoring is a proactive maintenance strategy that involves the continous monitoring of equipment and systems to detect potential faults or deviations from normal. The purpose of equipment monitoring is to ensure that the equipment is operating efficiently, safely, and reliably. With effective equipment monitoring, businesses can reduce. Condition monitoring (cm) is the process of monitoring a particular condition in. What Is Monitoring Equipment.