Stainless Steel Rust Test . Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. A scratch test developed by the u.s. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l. These include physical, (colour, density, magnetic),. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Bureau of mines was used to wear the surface of 304 stainless steel. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Corrosion of the freshly exposed surface was measured by the charge.

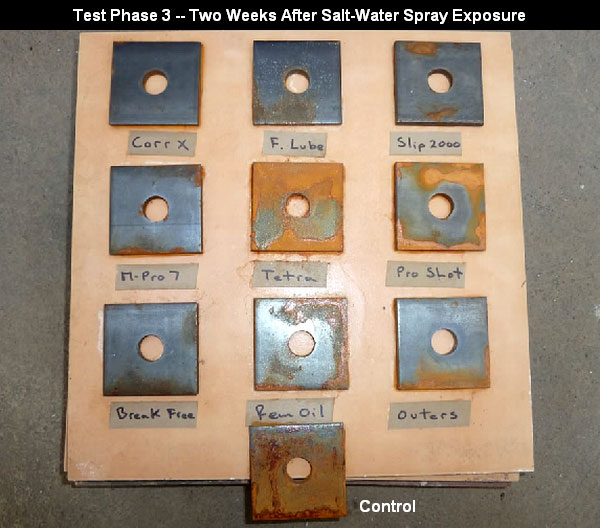

from bulletin.accurateshooter.com

Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l. Corrosion of the freshly exposed surface was measured by the charge. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. These include physical, (colour, density, magnetic),. A scratch test developed by the u.s. Bureau of mines was used to wear the surface of 304 stainless steel. Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown.

AntiCorrosion Products Test — Video Reveals Best Rust Blockers « Daily

Stainless Steel Rust Test It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. These include physical, (colour, density, magnetic),. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. A scratch test developed by the u.s. Bureau of mines was used to wear the surface of 304 stainless steel. Corrosion of the freshly exposed surface was measured by the charge. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l.

From www.youtube.com

How To Remove Rust From Stainless Steel YouTube Stainless Steel Rust Test Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. A scratch test developed by the u.s. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. These include physical, (colour, density, magnetic),. Stainless steel typically shows pitting corrosion in a. Stainless Steel Rust Test.

From kanyanaengineering.com.au

Does Stainless Steel Rust? The Truth About Stainless Steel Corrosion Stainless Steel Rust Test Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. It contains between 16 and 18.5% chromium, between 10. Stainless Steel Rust Test.

From wedotools2.en.made-in-china.com

Wedo Stainless Steel SUS304 SUS420 AntiCorrosion Rust Proof Testing Stainless Steel Rust Test Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Knowing that some of them are exposed to. Stainless Steel Rust Test.

From www.youtube.com

Does stainless steel 304 rust? YouTube Stainless Steel Rust Test Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Bureau of mines was used to wear the surface of 304 stainless steel. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels. Stainless Steel Rust Test.

From www.assemblymag.com

Corrosion of Stainless Steel Test Methods and Proper Expectations Stainless Steel Rust Test A scratch test developed by the u.s. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. These include physical, (colour, density, magnetic),. Corrosion of the freshly exposed surface was measured by the charge. It contains between 16 and 18.5% chromium, between 10 and 14% nickel,. Stainless Steel Rust Test.

From www.amardeepsteel.com

Rusting Of Stainless Steel Stainless Steel Rust Test A scratch test developed by the u.s. Corrosion of the freshly exposed surface was measured by the charge. Bureau of mines was used to wear the surface of 304 stainless steel. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. These include physical, (colour, density,. Stainless Steel Rust Test.

From blog.thepipingmart.com

3 Ways To Remove Rust from Stainless Steel Pipe Stainless Steel Rust Test Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. These include physical, (colour, density, magnetic),. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l. Bureau of mines was used to wear the surface of 304. Stainless Steel Rust Test.

From www.warrenforensics.com

Stress Corrosion Cracking of Stainless Steel in Marine Environments Stainless Steel Rust Test Corrosion of the freshly exposed surface was measured by the charge. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Guidance on methods for sorting stainless steels from low alloy and carbon. Stainless Steel Rust Test.

From www.youtube.com

Exploring the Science of Stainless Steel The Secret to Rust Prevention Stainless Steel Rust Test These include physical, (colour, density, magnetic),. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l. A scratch test developed by the u.s. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f. Stainless Steel Rust Test.

From www.silcotek.com

What's the Best Stainless Steel for a Corrosion Resistant Coating Stainless Steel Rust Test Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. A scratch test developed by the u.s. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Knowing that some of them are exposed to the external environment,. Stainless Steel Rust Test.

From www.youtube.com

Corrosion test for stainless steels YouTube Stainless Steel Rust Test Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein. Stainless Steel Rust Test.

From www.forgedproduct.com

Does Stainless Steel Rust Or Tarnish? Materials Stainless Steel Rust Test Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Bureau of mines was used to wear the surface of 304 stainless steel. Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. These include physical, (colour, density,. Stainless Steel Rust Test.

From www.indiamart.com

Stainless Steel Grease Testing EMCOR Rust Test Machine, For Industrial Stainless Steel Rust Test Corrosion of the freshly exposed surface was measured by the charge. A scratch test developed by the u.s. Bureau of mines was used to wear the surface of 304 stainless steel. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Stainless steel typically shows pitting. Stainless Steel Rust Test.

From www.frontiersin.org

Frontiers Investigation on Corrosion Resistance of Welded CuBearing Stainless Steel Rust Test It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Bureau of mines was used to wear the surface of 304 stainless steel. Guidance on methods for sorting stainless steels. Stainless Steel Rust Test.

From blog.thepipingmart.com

How Long Does it Take for Stainless Steel to Rust? Stainless Steel Rust Test It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. Bureau of mines was used to wear the surface of 304 stainless steel. A scratch test developed by the u.s. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi. Stainless Steel Rust Test.

From www.silcotek.com

What's the Best Stainless Steel for a Corrosion Resistant Coating Stainless Steel Rust Test Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. These include physical, (colour, density, magnetic),. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi. Stainless Steel Rust Test.

From www.youtube.com

Rust Test Stainless Steel Knife 24 Hours in Water with Table salt Stainless Steel Rust Test These include physical, (colour, density, magnetic),. Corrosion of the freshly exposed surface was measured by the charge. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. Bureau of mines was used to wear the surface of 304 stainless steel. Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. Stainless steel. Stainless Steel Rust Test.

From www.silcotek.com

Can Coatings Improve the Corrosion Resistance of Stainless Steel? Stainless Steel Rust Test It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Bureau of mines was used to wear the surface. Stainless Steel Rust Test.

From mainstreetmobile.org

48 Best rust remover for stainless steel 2022 After 209 hours of Stainless Steel Rust Test A scratch test developed by the u.s. Corrosion of the freshly exposed surface was measured by the charge. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. These include physical,. Stainless Steel Rust Test.

From www.youtube.com

HOW TO REMOVE RUST FROM STAINLESS STEEL APPLIANCES YouTube Stainless Steel Rust Test Bureau of mines was used to wear the surface of 304 stainless steel. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels. Stainless Steel Rust Test.

From www.youtube.com

How to Remove Rust on Stainless Steel East Chem YouTube Stainless Steel Rust Test Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. A scratch test developed by the u.s. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Guidance on. Stainless Steel Rust Test.

From bulletin.accurateshooter.com

AntiCorrosion Products Test — Video Reveals Best Rust Blockers « Daily Stainless Steel Rust Test Corrosion of the freshly exposed surface was measured by the charge. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l. Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. It contains between 16 and 18.5%. Stainless Steel Rust Test.

From www.hera.org.nz

Corrosion resistance of alternative stainless steel NZSSDA Stainless Steel Rust Test Bureau of mines was used to wear the surface of 304 stainless steel. A scratch test developed by the u.s. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. Corrosion of the freshly exposed surface was measured by the charge. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of. Stainless Steel Rust Test.

From www.daubertchemical.com

Daubert Chemical NoxRust® 1210HP Stainless Steel Rust Test These include physical, (colour, density, magnetic),. Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as. Stainless Steel Rust Test.

From sstestingreagent.blogspot.com

STAINLESS STEEL TESTING REAGENT (Ⅱ)Stainless Steel Recognition Reagent Stainless Steel Rust Test These include physical, (colour, density, magnetic),. It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Bureau of mines was used to wear the surface of 304 stainless steel. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. A scratch test developed. Stainless Steel Rust Test.

From www.youtube.com

How To Remove Rust From Stainless Steel YouTube Stainless Steel Rust Test It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. Bureau of mines was used to wear the surface of 304 stainless steel. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless. Stainless Steel Rust Test.

From blog.sikla.co.uk

Corrosion Protection how to select the best coating for steel structures? Stainless Steel Rust Test Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Corrosion of the freshly exposed surface was measured by the charge. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. These include physical, (colour, density, magnetic),. Knowing that some. Stainless Steel Rust Test.

From www.youtube.com

How to remove rust from your stainless steel appliances YouTube Stainless Steel Rust Test It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. These include physical, (colour, density, magnetic),. Bureau of mines was used to wear the surface of 304 stainless steel. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two. Stainless Steel Rust Test.

From blog.thepipingmart.com

How to Remove Rust from Stainless Steel Pipes An Overview Stainless Steel Rust Test Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l. Corrosion of the freshly exposed surface was measured by the charge. A scratch test developed by the u.s. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. Stainless. Stainless Steel Rust Test.

From www.reddit.com

Does the rust mean this is just regular steel and not stainless steel Stainless Steel Rust Test It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. These include physical, (colour, density, magnetic),. Corrosion of the. Stainless Steel Rust Test.

From www.indiamart.com

Double Wall Stainless Steel Rust Prevention Test Apparatus, For Stainless Steel Rust Test Bureau of mines was used to wear the surface of 304 stainless steel. Guidance on methods for sorting stainless steels from low alloy and carbon steels is shown. A scratch test developed by the u.s. Corrosion of the freshly exposed surface was measured by the charge. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. It. Stainless Steel Rust Test.

From www.passagemaker.com

How To Bust Rust On Stainless Steel PassageMaker Stainless Steel Rust Test It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l. These include physical, (colour, density, magnetic),. A scratch. Stainless Steel Rust Test.

From www.silcotek.com

Comparing the Corrosion Resistance of 316 Stainless Steel Stainless Steel Rust Test A scratch test developed by the u.s. Knowing that some of them are exposed to the external environment, the pitting corrosion resistance of two austenitic stainless steels was analyzed, i.e., aisi 304 and aisi 316l. It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. These include physical, (colour, density, magnetic),. Guidance on methods for sorting stainless. Stainless Steel Rust Test.

From www.mme-group.com

MME Group Corrosion Testing Destructive Testing Laboratory Stainless Steel Rust Test It contains between 16 and 18.5% chromium, between 10 and 14% nickel, and. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. Bureau of mines was used to wear the surface of 304 stainless steel. Knowing that some of them are exposed. Stainless Steel Rust Test.

From www.youtube.com

Rust on stainless steel appliances YouTube Stainless Steel Rust Test It is performed in a humidity cabinet capable of maintaining 97 (±3) percent humidity at 100 (±5) degrees f for at least 24 hours. A scratch test developed by the u.s. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm chloride, wherein the passive current density of dissolution of the. It contains. Stainless Steel Rust Test.