Difference Between D Tooling And B Tooling Compression Machine . B type and d type. Dies are of four types of tooling i.e. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. The tsm punch head configurations have an angled top profile versus the domed head profile of eu. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. D type, b type, bb type and bbs type. Punch length in eu standard is 0.010 inches longer than tsm. the dual rotary tablet compression machine utilizes two primary types of tooling: For b tooling the od is 19mm. B type tooling is characterized. the main differences between these two tablet press tool designs are: differences between tsm & eu tooling configurations. punches are of two types of tooling i.e. “b” type and “d” type.

from mechanicstips.blogspot.com

the dual rotary tablet compression machine utilizes two primary types of tooling: B type tooling is characterized. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. B type and d type. For b tooling the od is 19mm. The tsm punch head configurations have an angled top profile versus the domed head profile of eu. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. “b” type and “d” type. Punch length in eu standard is 0.010 inches longer than tsm. Dies are of four types of tooling i.e.

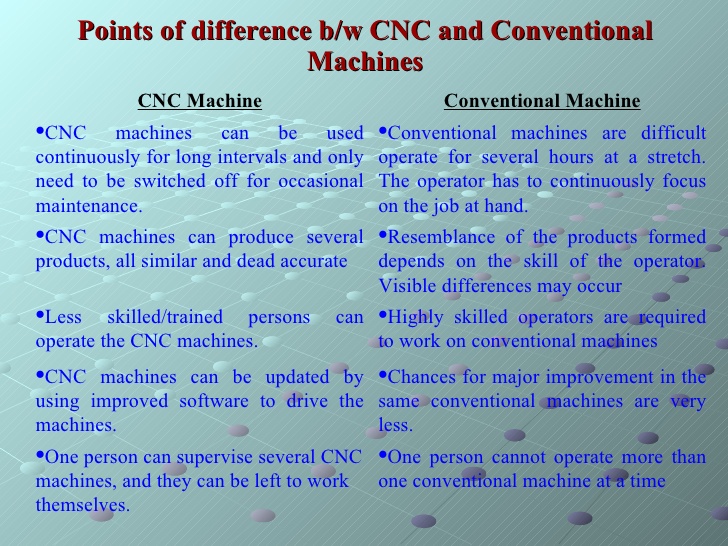

Difference Between CNC and Conventional Machines MechanicsTips

Difference Between D Tooling And B Tooling Compression Machine differences between tsm & eu tooling configurations. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. differences between tsm & eu tooling configurations. Dies are of four types of tooling i.e. the dual rotary tablet compression machine utilizes two primary types of tooling: The tsm punch head configurations have an angled top profile versus the domed head profile of eu. B type and d type. Punch length in eu standard is 0.010 inches longer than tsm. B type tooling is characterized. For b tooling the od is 19mm. the main differences between these two tablet press tool designs are: punches are of two types of tooling i.e. “b” type and “d” type. D type, b type, bb type and bbs type. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes.

From www.saintytec.com

11 Critical Tablet Compression Machine Parts You Must Know to Optimize Difference Between D Tooling And B Tooling Compression Machine Punch length in eu standard is 0.010 inches longer than tsm. the main differences between these two tablet press tool designs are: B type tooling is characterized. differences between tsm & eu tooling configurations. punches are of two types of tooling i.e. For b tooling the od is 19mm. the major difference between b and d. Difference Between D Tooling And B Tooling Compression Machine.

From pharmainterview.com

Tablet Tooling in Pharma An Overview Difference Between D Tooling And B Tooling Compression Machine “b” type and “d” type. Punch length in eu standard is 0.010 inches longer than tsm. punches are of two types of tooling i.e. B type tooling is characterized. the main differences between these two tablet press tool designs are: D type, b type, bb type and bbs type. differences between tsm & eu tooling configurations. Dies. Difference Between D Tooling And B Tooling Compression Machine.

From www.indiamart.com

SITX D26 26 Station D Tooling Tablet Press, दवाई की Difference Between D Tooling And B Tooling Compression Machine d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. The tsm punch head configurations have an angled top profile versus the domed head profile of eu. Dies are of four types of tooling i.e. punches are of two types of tooling i.e. D. Difference Between D Tooling And B Tooling Compression Machine.

From tech-publish.com

Tablet Tooling Die And Punch Techpublish Difference Between D Tooling And B Tooling Compression Machine the main differences between these two tablet press tool designs are: B type and d type. D type, b type, bb type and bbs type. B type tooling is characterized. “b” type and “d” type. For b tooling the od is 19mm. the dual rotary tablet compression machine utilizes two primary types of tooling: the major difference. Difference Between D Tooling And B Tooling Compression Machine.

From unitedpharmatek.com

Tablet Presses Tablet Press Machine United Pharmatek Difference Between D Tooling And B Tooling Compression Machine punches are of two types of tooling i.e. B type and d type. differences between tsm & eu tooling configurations. Punch length in eu standard is 0.010 inches longer than tsm. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. “b” type. Difference Between D Tooling And B Tooling Compression Machine.

From www.youtube.com

Difference between Machine tool & cutting tool Production Technology Difference Between D Tooling And B Tooling Compression Machine D type, b type, bb type and bbs type. The tsm punch head configurations have an angled top profile versus the domed head profile of eu. “b” type and “d” type. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. the major difference. Difference Between D Tooling And B Tooling Compression Machine.

From www.indiamart.com

Legend Tablet Compression Machine, Legend Pharma Technologies ID Difference Between D Tooling And B Tooling Compression Machine B type and d type. D type, b type, bb type and bbs type. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. differences between tsm & eu tooling configurations. d tooling dies and punches are usually have a greater diameter of the tip of punches. Difference Between D Tooling And B Tooling Compression Machine.

From themedicinemaker.com

Compression Tooling From The Industry’s Leader Difference Between D Tooling And B Tooling Compression Machine differences between tsm & eu tooling configurations. Punch length in eu standard is 0.010 inches longer than tsm. B type tooling is characterized. the dual rotary tablet compression machine utilizes two primary types of tooling: the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. The tsm. Difference Between D Tooling And B Tooling Compression Machine.

From www.automatictabletpressmachine.com

TSM / EU Type Tablet Press Punches And Dies Tooling , Multi Shaped Difference Between D Tooling And B Tooling Compression Machine Dies are of four types of tooling i.e. B type and d type. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. punches are of two types of tooling i.e. differences between tsm & eu tooling configurations. B type tooling is characterized.. Difference Between D Tooling And B Tooling Compression Machine.

From www.researchgate.net

What are the differences between punch type B and type D on tablet Difference Between D Tooling And B Tooling Compression Machine Punch length in eu standard is 0.010 inches longer than tsm. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. “b” type and “d” type. B type and d type. the dual rotary tablet compression machine utilizes two primary types of tooling: . Difference Between D Tooling And B Tooling Compression Machine.

From www.scribd.com

Understanding the Differences Between Soft Tooling and Hard Tooling for Difference Between D Tooling And B Tooling Compression Machine D type, b type, bb type and bbs type. punches are of two types of tooling i.e. B type tooling is characterized. B type and d type. Dies are of four types of tooling i.e. the dual rotary tablet compression machine utilizes two primary types of tooling: The tsm punch head configurations have an angled top profile versus. Difference Between D Tooling And B Tooling Compression Machine.

From sudharsankumar.blogspot.com

sudharsan different b/w compound tool and progressive tool Difference Between D Tooling And B Tooling Compression Machine D type, b type, bb type and bbs type. B type tooling is characterized. Punch length in eu standard is 0.010 inches longer than tsm. punches are of two types of tooling i.e. the main differences between these two tablet press tool designs are: the major difference between b and d tooling lies in their od(outer diameter). Difference Between D Tooling And B Tooling Compression Machine.

From www.youtube.com

How To Operate Digimatic Compression Machine 2000 kN YouTube Difference Between D Tooling And B Tooling Compression Machine differences between tsm & eu tooling configurations. the dual rotary tablet compression machine utilizes two primary types of tooling: D type, b type, bb type and bbs type. The tsm punch head configurations have an angled top profile versus the domed head profile of eu. B type tooling is characterized. Punch length in eu standard is 0.010 inches. Difference Between D Tooling And B Tooling Compression Machine.

From www.youtube.com

Tablet Compression Machine ToolingB TypeD TypeBBDB YouTube Difference Between D Tooling And B Tooling Compression Machine d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. For b tooling the od is 19mm. Dies are of four types of tooling i.e. Punch length in eu standard is 0.010 inches longer than tsm. B type and d type. the dual rotary. Difference Between D Tooling And B Tooling Compression Machine.

From www.fluidpack.net

High Speed Double Rotary Tablet Presses with 7,77,600 Tablets/Hour Output Difference Between D Tooling And B Tooling Compression Machine Punch length in eu standard is 0.010 inches longer than tsm. punches are of two types of tooling i.e. the main differences between these two tablet press tool designs are: “b” type and “d” type. The tsm punch head configurations have an angled top profile versus the domed head profile of eu. D type, b type, bb type. Difference Between D Tooling And B Tooling Compression Machine.

From shopdelta.eu

COMPRESSION TOOL HLT548 Crimping Tools for Compression Connectors Difference Between D Tooling And B Tooling Compression Machine Dies are of four types of tooling i.e. Punch length in eu standard is 0.010 inches longer than tsm. The tsm punch head configurations have an angled top profile versus the domed head profile of eu. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. B type and. Difference Between D Tooling And B Tooling Compression Machine.

From www.automatictabletpressmachine.com

Large Capacity D Tooling Compression Tablet Press Machine For Medicine Difference Between D Tooling And B Tooling Compression Machine the dual rotary tablet compression machine utilizes two primary types of tooling: punches are of two types of tooling i.e. “b” type and “d” type. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. D type, b type, bb type and bbs. Difference Between D Tooling And B Tooling Compression Machine.

From pepmfg.us

What is the Difference Between CNC Milling and Turning? PEP Mfg., Inc. Difference Between D Tooling And B Tooling Compression Machine “b” type and “d” type. For b tooling the od is 19mm. The tsm punch head configurations have an angled top profile versus the domed head profile of eu. differences between tsm & eu tooling configurations. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling. Difference Between D Tooling And B Tooling Compression Machine.

From learnmech.com

Compression molding Process Advantages and Disadvantages Difference Between D Tooling And B Tooling Compression Machine d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. the main differences between these two tablet press tool designs are: the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. D type,. Difference Between D Tooling And B Tooling Compression Machine.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Difference Between D Tooling And B Tooling Compression Machine B type and d type. Dies are of four types of tooling i.e. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. B type tooling is characterized. “b” type and “d” type. punches are of two types of tooling i.e. Punch length in eu standard is 0.010. Difference Between D Tooling And B Tooling Compression Machine.

From shopdelta.eu

COMPRESSION TOOL HLT548 Crimping Tools for Compression Connectors Difference Between D Tooling And B Tooling Compression Machine Dies are of four types of tooling i.e. “b” type and “d” type. B type and d type. differences between tsm & eu tooling configurations. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. D type, b type, bb type and bbs type. the dual rotary. Difference Between D Tooling And B Tooling Compression Machine.

From www.pharmapproach.com

Tablet Press Types, functional parts, how it works, advantages.. Difference Between D Tooling And B Tooling Compression Machine the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. the main differences between these two tablet press tool designs are: The tsm punch head configurations have an angled top profile versus the domed head profile of eu. For b tooling the od is 19mm. D type, b. Difference Between D Tooling And B Tooling Compression Machine.

From www.saintytec.com

Rotary Tablet Press SaintyTec Difference Between D Tooling And B Tooling Compression Machine The tsm punch head configurations have an angled top profile versus the domed head profile of eu. “b” type and “d” type. B type and d type. punches are of two types of tooling i.e. B type tooling is characterized. differences between tsm & eu tooling configurations. the dual rotary tablet compression machine utilizes two primary types. Difference Between D Tooling And B Tooling Compression Machine.

From www.researchgate.net

Comparison of Conventional, CNC, and RP construction methods Download Difference Between D Tooling And B Tooling Compression Machine Punch length in eu standard is 0.010 inches longer than tsm. B type and d type. For b tooling the od is 19mm. the dual rotary tablet compression machine utilizes two primary types of tooling: d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which. Difference Between D Tooling And B Tooling Compression Machine.

From www.automatictabletpressmachine.com

GMP Standard EUD Tooling Rotary Compression Machine With PLC Touch Difference Between D Tooling And B Tooling Compression Machine B type and d type. D type, b type, bb type and bbs type. differences between tsm & eu tooling configurations. Dies are of four types of tooling i.e. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. “b” type and “d” type.. Difference Between D Tooling And B Tooling Compression Machine.

From www.flickr.com

Compression moulding This resource is a diagram of the com… Flickr Difference Between D Tooling And B Tooling Compression Machine Dies are of four types of tooling i.e. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. “b” type and “d” type. differences between tsm & eu tooling configurations. the major difference between b and d tooling lies in their od(outer diameter). Difference Between D Tooling And B Tooling Compression Machine.

From cemjxopu.blob.core.windows.net

D Tooling Punch Size at Jeffrey Rodriguez blog Difference Between D Tooling And B Tooling Compression Machine punches are of two types of tooling i.e. the main differences between these two tablet press tool designs are: d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. For b tooling the od is 19mm. The tsm punch head configurations have an. Difference Between D Tooling And B Tooling Compression Machine.

From www.youtube.com

Tablet Compression Machine Tooling BB B D Tablet Industrial Difference Between D Tooling And B Tooling Compression Machine B type and d type. B type tooling is characterized. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. D type, b type, bb type and bbs type. For b tooling the od is 19mm. The tsm punch head configurations have an angled top profile versus the domed. Difference Between D Tooling And B Tooling Compression Machine.

From mechanicstips.blogspot.com

Difference Between CNC and Conventional Machines MechanicsTips Difference Between D Tooling And B Tooling Compression Machine For b tooling the od is 19mm. punches are of two types of tooling i.e. the main differences between these two tablet press tool designs are: differences between tsm & eu tooling configurations. D type, b type, bb type and bbs type. The tsm punch head configurations have an angled top profile versus the domed head profile. Difference Between D Tooling And B Tooling Compression Machine.

From www.youtube.com

16Cavity Cap Compression Molding Machine YouTube Difference Between D Tooling And B Tooling Compression Machine B type tooling is characterized. “b” type and “d” type. d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. Punch length in eu standard is 0.010 inches longer than tsm. punches are of two types of tooling i.e. the dual rotary tablet. Difference Between D Tooling And B Tooling Compression Machine.

From www.youtube.com

Tooling For Tableting Tooling For Tablet Press What is Dia & Punch Difference Between D Tooling And B Tooling Compression Machine For b tooling the od is 19mm. D type, b type, bb type and bbs type. The tsm punch head configurations have an angled top profile versus the domed head profile of eu. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. the dual rotary tablet compression. Difference Between D Tooling And B Tooling Compression Machine.

From shopdelta.eu

COMPRESSION TOOL HLT548 Crimping Tools for Compression Connectors Difference Between D Tooling And B Tooling Compression Machine punches are of two types of tooling i.e. the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. D type, b type, bb type and bbs type. B type and d type. “b” type and “d” type. Punch length in eu standard is 0.010 inches longer than tsm.. Difference Between D Tooling And B Tooling Compression Machine.

From www.youtube.com

Difference between Shaper and Planer Machine in hindi with diagrams Difference Between D Tooling And B Tooling Compression Machine d tooling dies and punches are usually have a greater diameter of the tip of punches as compared to b type tolling which makes. punches are of two types of tooling i.e. the dual rotary tablet compression machine utilizes two primary types of tooling: For b tooling the od is 19mm. Dies are of four types of. Difference Between D Tooling And B Tooling Compression Machine.

From pepmfg.us

What is the Difference Between CNC Milling and Turning? PEP Mfg., Inc. Difference Between D Tooling And B Tooling Compression Machine the major difference between b and d tooling lies in their od(outer diameter) dimensions on the punch barrels and dies. the dual rotary tablet compression machine utilizes two primary types of tooling: the main differences between these two tablet press tool designs are: B type and d type. d tooling dies and punches are usually have. Difference Between D Tooling And B Tooling Compression Machine.

From www.adamus.com.pl

How to get the right compression tooling? Adamus S.A. Difference Between D Tooling And B Tooling Compression Machine B type tooling is characterized. For b tooling the od is 19mm. D type, b type, bb type and bbs type. B type and d type. the main differences between these two tablet press tool designs are: the dual rotary tablet compression machine utilizes two primary types of tooling: Punch length in eu standard is 0.010 inches longer. Difference Between D Tooling And B Tooling Compression Machine.