Electrical Gloves Testing Frequency . The law requires electrical equipment to be maintained to prevent danger. maintaining electrical equipment safety. Hse and other organisations have produced guidance on electrical safety that is suitable for a. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. electrical inspection and testing. hse provides guidance on how to maintain equipment including the use of pat. the most common periods currently range from 30 days to 90 days. The test consists of air inflation to check for air leaks and a. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. Health and safety executive (hse) answers;.

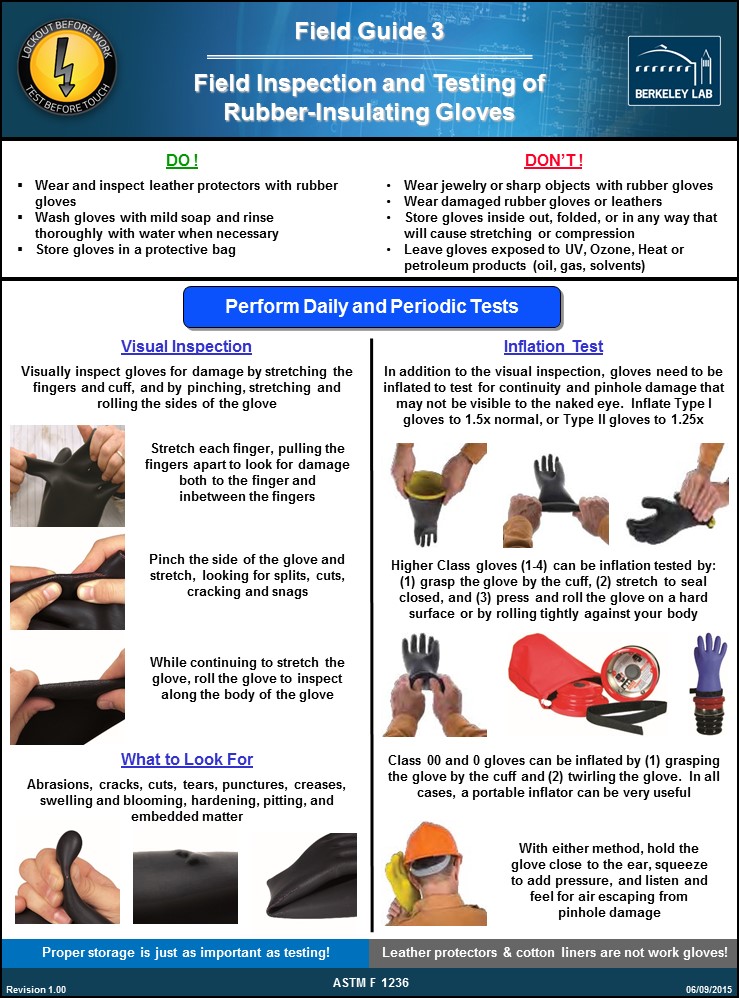

from electricalsafety.lbl.gov

electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. maintaining electrical equipment safety. The test consists of air inflation to check for air leaks and a. Hse and other organisations have produced guidance on electrical safety that is suitable for a. hse provides guidance on how to maintain equipment including the use of pat. electrical inspection and testing. Health and safety executive (hse) answers;. The law requires electrical equipment to be maintained to prevent danger. the most common periods currently range from 30 days to 90 days.

Glove Inspection Single Point Handout Electrical Safety

Electrical Gloves Testing Frequency Hse and other organisations have produced guidance on electrical safety that is suitable for a. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. The law requires electrical equipment to be maintained to prevent danger. hse provides guidance on how to maintain equipment including the use of pat. electrical inspection and testing. the most common periods currently range from 30 days to 90 days. The test consists of air inflation to check for air leaks and a. maintaining electrical equipment safety. Health and safety executive (hse) answers;. Hse and other organisations have produced guidance on electrical safety that is suitable for a.

From www.dcis.ca

Electrical Electrical Gloves Testing Frequency The test consists of air inflation to check for air leaks and a. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. Health and safety executive (hse) answers;. The law requires electrical equipment to be maintained to prevent danger. Hse and other organisations have produced guidance on electrical safety that is suitable. Electrical Gloves Testing Frequency.

From www.grainger.com

Electrical Gloves 5 Things You Should Know Grainger KnowHow Electrical Gloves Testing Frequency The law requires electrical equipment to be maintained to prevent danger. hse provides guidance on how to maintain equipment including the use of pat. the most common periods currently range from 30 days to 90 days. electrical inspection and testing. Hse and other organisations have produced guidance on electrical safety that is suitable for a. electrical. Electrical Gloves Testing Frequency.

From www.aplussafety.com.sg

Electrical Glove Testing Protective Equipment & Safety Solutions Electrical Gloves Testing Frequency electrical inspection and testing. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. the most common periods currently range from 30 days to 90 days. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. maintaining electrical. Electrical Gloves Testing Frequency.

From leafelectricalsafety.com

Electrical Safety Gloves Rating, Classification and Classes Electrical Gloves Testing Frequency The law requires electrical equipment to be maintained to prevent danger. hse provides guidance on how to maintain equipment including the use of pat. Health and safety executive (hse) answers;. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. the most common periods currently range from 30 days to 90. Electrical Gloves Testing Frequency.

From www.electricalsafetypub.com

How to Choose the Right Electrical Gloves for the Task at Hand Electrical Gloves Testing Frequency hse provides guidance on how to maintain equipment including the use of pat. The test consists of air inflation to check for air leaks and a. maintaining electrical equipment safety. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. The law requires electrical equipment to be maintained to prevent danger.. Electrical Gloves Testing Frequency.

From exobashxu.blob.core.windows.net

How To Test Rubber Electrical Gloves at Lucy blog Electrical Gloves Testing Frequency the most common periods currently range from 30 days to 90 days. electrical inspection and testing. The test consists of air inflation to check for air leaks and a. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. The law requires electrical equipment to be. Electrical Gloves Testing Frequency.

From www.youtube.com

Behind the Scenes FirstEnergy's inhouse electrical glove testing Electrical Gloves Testing Frequency Hse and other organisations have produced guidance on electrical safety that is suitable for a. The test consists of air inflation to check for air leaks and a. The law requires electrical equipment to be maintained to prevent danger. hse provides guidance on how to maintain equipment including the use of pat. electrical inspection and testing. maintaining. Electrical Gloves Testing Frequency.

From hjarnett.com

NAIL Accredited Rubber Glove & PPE Testing Lab Industries, LLC Electrical Gloves Testing Frequency Hse and other organisations have produced guidance on electrical safety that is suitable for a. Health and safety executive (hse) answers;. hse provides guidance on how to maintain equipment including the use of pat. electrical inspection and testing. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge. Electrical Gloves Testing Frequency.

From oberoncompany.com

Electrical Glove Inspection Tool Oberon Company Electrical Gloves Testing Frequency electrical inspection and testing. The test consists of air inflation to check for air leaks and a. Health and safety executive (hse) answers;. hse provides guidance on how to maintain equipment including the use of pat. Hse and other organisations have produced guidance on electrical safety that is suitable for a. the most common periods currently range. Electrical Gloves Testing Frequency.

From www.servicetitan.com

10 Best Electrical Gloves Keep Electricians Safe Electrical Gloves Testing Frequency Hse and other organisations have produced guidance on electrical safety that is suitable for a. hse provides guidance on how to maintain equipment including the use of pat. The test consists of air inflation to check for air leaks and a. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. The. Electrical Gloves Testing Frequency.

From www.aplussafety.com.sg

Electrical Glove Testing Our Services Protective Equipment & Safety Electrical Gloves Testing Frequency Health and safety executive (hse) answers;. The law requires electrical equipment to be maintained to prevent danger. Hse and other organisations have produced guidance on electrical safety that is suitable for a. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. maintaining electrical equipment safety. hse provides guidance on how. Electrical Gloves Testing Frequency.

From jmtest.com

Electrical Glove Testing Services • High Voltage Dielectric Rubber Test Lab Electrical Gloves Testing Frequency The test consists of air inflation to check for air leaks and a. Hse and other organisations have produced guidance on electrical safety that is suitable for a. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. maintaining electrical equipment safety. Health and safety executive (hse) answers;. the most common. Electrical Gloves Testing Frequency.

From www.electricalsafetypub.com

Electrical Gloves Best Practices for Building an Electrical Safety Electrical Gloves Testing Frequency the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. electrical inspection and testing. Health and safety executive (hse) answers;. The law requires electrical equipment to be maintained to prevent. Electrical Gloves Testing Frequency.

From jmtest.com

Electrical Glove Sizing [With Size Chart] Electrical Gloves Testing Frequency electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. The test consists of air inflation to check for air leaks and a. maintaining electrical equipment safety. electrical inspection and testing. Hse and other organisations have produced guidance on electrical safety that is suitable for a. the most common periods. Electrical Gloves Testing Frequency.

From www.youtube.com

Testing Electrical Rubber Gloves and Tips For a Successful Glove Safety Electrical Gloves Testing Frequency Health and safety executive (hse) answers;. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. electrical inspection and testing. The test consists of air inflation to check for air. Electrical Gloves Testing Frequency.

From jmtest.com

Electrical Glove Sizing [With Size Chart] Electrical Gloves Testing Frequency The law requires electrical equipment to be maintained to prevent danger. maintaining electrical equipment safety. The test consists of air inflation to check for air leaks and a. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. the most common periods currently range from 30 days to 90 days. . Electrical Gloves Testing Frequency.

From www.magidglove.com

Electrical Glove Testing Magid Glove Electrical Gloves Testing Frequency hse provides guidance on how to maintain equipment including the use of pat. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. Hse and other organisations have produced guidance on electrical safety that is suitable for a. The law requires electrical equipment to be maintained to prevent danger. The test consists. Electrical Gloves Testing Frequency.

From www.electric-test.com

30kV Electrical Glove Inspection Dielectric Insulated Gloves Testing Electrical Gloves Testing Frequency electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. the most common periods currently range from 30 days to 90 days. The law requires electrical equipment to be maintained to prevent danger. electrical inspection and testing. the applicable astm specifications state that the minimum distance between the edge of. Electrical Gloves Testing Frequency.

From oberoncompany.com

Electrical Glove Inspection Tool Oberon Company Electrical Gloves Testing Frequency Health and safety executive (hse) answers;. the most common periods currently range from 30 days to 90 days. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. The law requires electrical equipment to be maintained to prevent danger. electrical inspection and testing. The test consists of air inflation to check. Electrical Gloves Testing Frequency.

From www.fluke.com

How To Measure Frequency Fluke Electrical Gloves Testing Frequency maintaining electrical equipment safety. The test consists of air inflation to check for air leaks and a. Hse and other organisations have produced guidance on electrical safety that is suitable for a. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. electrical inspection and testing. the most common periods. Electrical Gloves Testing Frequency.

From www.fireballedstudio.com

The Importance of Proper Electrical Glove Testing Electrical Gloves Testing Frequency electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. maintaining electrical equipment safety. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. hse provides guidance on how to maintain equipment including the use of pat. The test. Electrical Gloves Testing Frequency.

From dekumstreetdoorway.com

Electrical Gloves Testing An Overview Dekum Street Doorway Electrical Gloves Testing Frequency Health and safety executive (hse) answers;. the most common periods currently range from 30 days to 90 days. maintaining electrical equipment safety. hse provides guidance on how to maintain equipment including the use of pat. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. the applicable astm specifications. Electrical Gloves Testing Frequency.

From leafelectricalsafety.com

Electrical Safety Gloves Rating, Classification and Classes Electrical Gloves Testing Frequency the most common periods currently range from 30 days to 90 days. Hse and other organisations have produced guidance on electrical safety that is suitable for a. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. Health and safety executive (hse) answers;. electrical insulation gloves. Electrical Gloves Testing Frequency.

From exobashxu.blob.core.windows.net

How To Test Rubber Electrical Gloves at Lucy blog Electrical Gloves Testing Frequency the most common periods currently range from 30 days to 90 days. hse provides guidance on how to maintain equipment including the use of pat. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. The law requires electrical equipment to be maintained to prevent danger. electrical inspection and testing.. Electrical Gloves Testing Frequency.

From jmtest.com

Electrical Glove Sizing [With Size Chart] Electrical Gloves Testing Frequency the most common periods currently range from 30 days to 90 days. hse provides guidance on how to maintain equipment including the use of pat. The law requires electrical equipment to be maintained to prevent danger. Health and safety executive (hse) answers;. electrical inspection and testing. Hse and other organisations have produced guidance on electrical safety that. Electrical Gloves Testing Frequency.

From comutility.ca

Glove Testing Certified Glove Testing Services Electrical Gloves Testing Frequency electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. electrical inspection and testing. the most common periods currently range from 30 days to 90 days. Health and safety executive (hse) answers;. The test consists of air inflation to check for air leaks and a. hse provides guidance on how. Electrical Gloves Testing Frequency.

From jmtest.com

Electrical Glove Sizing • JM Test Systems Electrical Gloves Testing Frequency The test consists of air inflation to check for air leaks and a. the most common periods currently range from 30 days to 90 days. Health and safety executive (hse) answers;. hse provides guidance on how to maintain equipment including the use of pat. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber. Electrical Gloves Testing Frequency.

From www.electricalsafetypub.com

Understanding Testing and Rating of PPE Rubber Insulating Gloves Electrical Gloves Testing Frequency the most common periods currently range from 30 days to 90 days. maintaining electrical equipment safety. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. Hse and other organisations have produced guidance on electrical safety that is suitable for a. electrical insulation gloves manufactured. Electrical Gloves Testing Frequency.

From www.gloves-online.com

Electrical Glove Testing Information The Glove Guru Electrical Gloves Testing Frequency maintaining electrical equipment safety. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. Health and safety executive (hse) answers;. electrical inspection and testing. The law requires electrical equipment to be maintained to prevent danger. the most common periods currently range from 30 days to 90 days. Hse and other. Electrical Gloves Testing Frequency.

From www.repairerdrivennews.com

Are your high voltage gloves safe to use? Repairer Driven News Electrical Gloves Testing Frequency Health and safety executive (hse) answers;. the applicable astm specifications state that the minimum distance between the edge of the protector and the cuff edge of the. Hse and other organisations have produced guidance on electrical safety that is suitable for a. The test consists of air inflation to check for air leaks and a. hse provides guidance. Electrical Gloves Testing Frequency.

From www.electricalsafetypub.com

Understanding Testing and Rating of PPE Rubber Insulating Gloves Electrical Gloves Testing Frequency the most common periods currently range from 30 days to 90 days. Health and safety executive (hse) answers;. The test consists of air inflation to check for air leaks and a. Hse and other organisations have produced guidance on electrical safety that is suitable for a. electrical inspection and testing. hse provides guidance on how to maintain. Electrical Gloves Testing Frequency.

From www.youtube.com

How to Inspect Your Electrical Gloves YouTube Electrical Gloves Testing Frequency hse provides guidance on how to maintain equipment including the use of pat. electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. Health and safety executive (hse) answers;. electrical inspection and testing. The test consists of air inflation to check for air leaks and a. Hse and other organisations have. Electrical Gloves Testing Frequency.

From www.myxxgirl.com

Astm Labeling Chart For Electrical Gloves My XXX Hot Girl Electrical Gloves Testing Frequency electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. electrical inspection and testing. the most common periods currently range from 30 days to 90 days. maintaining electrical equipment safety. Hse and other organisations have produced guidance on electrical safety that is suitable for a. The law requires electrical equipment. Electrical Gloves Testing Frequency.

From www.ask2world.com

Attention To Detail Get Your Gloves Electrically Tested Ask 2 World Electrical Gloves Testing Frequency electrical insulation gloves manufactured to en60903 and astm d120 standard specification for rubber insulating gloves are. hse provides guidance on how to maintain equipment including the use of pat. The law requires electrical equipment to be maintained to prevent danger. the most common periods currently range from 30 days to 90 days. maintaining electrical equipment safety.. Electrical Gloves Testing Frequency.

From electricalsafety.lbl.gov

Glove Inspection Single Point Handout Electrical Safety Electrical Gloves Testing Frequency Health and safety executive (hse) answers;. The test consists of air inflation to check for air leaks and a. hse provides guidance on how to maintain equipment including the use of pat. Hse and other organisations have produced guidance on electrical safety that is suitable for a. electrical insulation gloves manufactured to en60903 and astm d120 standard specification. Electrical Gloves Testing Frequency.