Powder Metallurgy Vs Mim . Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Meanwhile, both mim and pm technology is. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. The cost of the powdered metal is a key driver when comparing mim and pm materials. Mim powders are typically more. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies.

from www.finemim.com

Mim powders are typically more. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Meanwhile, both mim and pm technology is. The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small.

MIM vs. PM Metal Injection Molding vs. Powder Metallurgy FineMIM

Powder Metallurgy Vs Mim Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. Meanwhile, both mim and pm technology is. Mim powders are typically more. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. The cost of the powdered metal is a key driver when comparing mim and pm materials. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small.

From mim-supplier.com

Metal Powder Injection Molding (MIM) vs Die Casting MIM Supplier Powder Metallurgy Vs Mim Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. The cost of the powdered metal is. Powder Metallurgy Vs Mim.

From www.newayprecision.com

Metal Sintering Process in Powder Metallurgy and MIM Parts Production Powder Metallurgy Vs Mim Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding (mim) combines the principles of. Powder Metallurgy Vs Mim.

From levigatealloys.com

Powders for Metal Injection Moulding(MIM) Levigate Alloys Powder Metallurgy Vs Mim Meanwhile, both mim and pm technology is. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy. Powder Metallurgy Vs Mim.

From www.optimim.com

Powder Metallurgy Feedstock MIM Powder Metallurgy Vs Mim Meanwhile, both mim and pm technology is. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. While mim. Powder Metallurgy Vs Mim.

From www.youtube.com

Powder Metal Sintering PM and MIM YouTube Powder Metallurgy Vs Mim Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. While mim is excellent for niche applications, conventional powder metallurgy. Powder Metallurgy Vs Mim.

From www.zcmim.com

Metal Injection Molding vs Powder Metallurgy MIM vs PM ZCMIM Powder Metallurgy Vs Mim Mim powders are typically more. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. Meanwhile, both mim and pm technology is. Metal injection molding (mim) combines the principles of plastic injection molding. Powder Metallurgy Vs Mim.

From jhmim.com

Metal Injection Molding VS Powder Metallurgy JH MIM Powder Metallurgy Vs Mim Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Mim powders are typically more. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding produces. Powder Metallurgy Vs Mim.

From shlaiwu.en.made-in-china.com

Factory MIM Alloy Powder MIM420W Stainless Steel Powder China Iron Powder Metallurgy Vs Mim Meanwhile, both mim and pm technology is. The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. Mim powders are typically more. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal. Powder Metallurgy Vs Mim.

From www.mdpi.com

Metals Free FullText An Overview of Highly Porous Titanium Powder Metallurgy Vs Mim Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding (mim) combines the principles. Powder Metallurgy Vs Mim.

From www.zcmim.com

Metal Injection Molding vs Powder Metallurgy MIM vs PM ZCMIM Powder Metallurgy Vs Mim Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Meanwhile, both mim and pm technology. Powder Metallurgy Vs Mim.

From www.psmindustries.com

Precision Powdered Metal & MIM Processes PMS Industries Powder Metallurgy Vs Mim Meanwhile, both mim and pm technology is. Mim powders are typically more. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Metal injection molding (mim) combines the principles of plastic injection molding. Powder Metallurgy Vs Mim.

From jhmim.com

Advances in Powder Metallurgy JH MIM Powder Metallurgy Vs Mim The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Mim powders are typically more. Metal injection molding. Powder Metallurgy Vs Mim.

From www.finemim.com

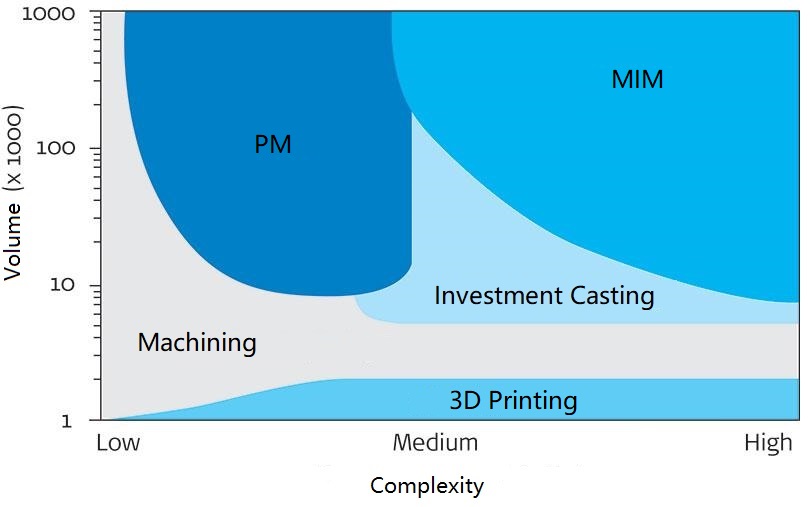

How does MIM compare to other processes? Fine MIM Parts Powder Metallurgy Vs Mim While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Meanwhile, both mim and pm technology. Powder Metallurgy Vs Mim.

From www.researchgate.net

Conventional powder metallurgy process from metal powder to finished Powder Metallurgy Vs Mim Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Mim powders are typically more. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection. Powder Metallurgy Vs Mim.

From www.vacfurnace.com

PIM & MIM, CIM Process SIMUWU Powder Metallurgy Vs Mim Meanwhile, both mim and pm technology is. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. The cost of the powdered metal is a key driver when comparing mim and pm materials. Mim powders are typically more. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in. Powder Metallurgy Vs Mim.

From www.zcmim.com

Metal Injection Molding vs Powder Metallurgy MIM vs PM ZCMIM Powder Metallurgy Vs Mim While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding produces. Powder Metallurgy Vs Mim.

From maxown.com

Powder Metallurgy VS. Blue Machines Powder Metallurgy Vs Mim While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding (mim) combines the principles. Powder Metallurgy Vs Mim.

From www.optimim.com

Metal Manufacturing Feedstock Powder Metallurgy Powder Metallurgy Vs Mim Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. Powder metallurgy (pm) and metal injection molding (mim). Powder Metallurgy Vs Mim.

From www.machineryoffers.com

OEM Sintered Metal Powder Metallurgy MIM Products Products from Powder Metallurgy Vs Mim Meanwhile, both mim and pm technology is. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. The cost of the powdered metal is a key driver when comparing mim and pm materials. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small.. Powder Metallurgy Vs Mim.

From www.researchgate.net

Flow of metal powder injection molding (MIM) process indicated by bold Powder Metallurgy Vs Mim While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding (mim) and powder metallurgy. Powder Metallurgy Vs Mim.

From www.horizontechnology.biz

CHART Asterisks & Advantages of Powder Metallurgy Vs. Other Methods Powder Metallurgy Vs Mim Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Meanwhile, both mim and pm technology is.. Powder Metallurgy Vs Mim.

From www.jiangsutech.com

Metal Injection Molding (MIM) Process China Metal Parts Manufacturer Powder Metallurgy Vs Mim Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Mim powders are typically more. Meanwhile, both mim and pm technology is. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy. Powder Metallurgy Vs Mim.

From www.sofinepim.com

The similarities and differences of powder metallurgy and casting Powder Metallurgy Vs Mim Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. Meanwhile, both mim and pm technology is. Mim powders are typically more. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology. Powder Metallurgy Vs Mim.

From fanovo.com

What is Powder Metallurgy and How Does it work Fanovo Industries Powder Metallurgy Vs Mim Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Meanwhile, both mim and pm technology is. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the. Powder Metallurgy Vs Mim.

From www.sputtertargets.net

An Introduction to Powder Metallurgy Stanford Advanced Materials Powder Metallurgy Vs Mim Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Meanwhile, both mim and pm technology is. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts,. Powder Metallurgy Vs Mim.

From www.researchgate.net

Schematic for powder metallurgy route for specimen preparation Powder Metallurgy Vs Mim Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Mim powders are typically more. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Powder metallurgy. Powder Metallurgy Vs Mim.

From www.taisei-kogyo.com

What is MIM? Taisei Kogyo Co., Ltd. Powder Metallurgy Vs Mim Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding (mim) combines the principles of plastic injection molding with powdered metallurgy to produce complex. Meanwhile, both mim and pm technology is. Mim powders are typically more. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods. Powder Metallurgy Vs Mim.

From www.mimmolding.com

Copper MIM Powder Metallurgy Powder Metallurgy Vs Mim While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Mim powders are typically more. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. The cost of the powdered metal is a key driver when comparing mim and pm materials. Powder metallurgy. Powder Metallurgy Vs Mim.

From insightsolutionsglobal.com

Problems and Solutions in Manufacturing MIM (Metal Injection Molding Powder Metallurgy Vs Mim The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Meanwhile, both mim and pm technology is. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal. Powder Metallurgy Vs Mim.

From us.bconduct.com

MIM & Powder Metallurgy Bconduct Powder Metallurgy Vs Mim Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. The cost of the powdered metal is a key driver when comparing mim and pm materials. Mim powders are typically more. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding. Powder Metallurgy Vs Mim.

From www.finemim.com

MIM vs. PM Metal Injection Molding vs. Powder Metallurgy FineMIM Powder Metallurgy Vs Mim Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Powder metallurgy (pm) and metal injection molding (mim) are both. Powder Metallurgy Vs Mim.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Powder Metallurgy Vs Mim Meanwhile, both mim and pm technology is. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing. Powder Metallurgy Vs Mim.

From www.machineryoffers.com

OEM Sintered Metal Powder Metallurgy MIM Products Products from Powder Metallurgy Vs Mim The cost of the powdered metal is a key driver when comparing mim and pm materials. Metal injection molding (mim) vs powder metallurgy (pm) are both powder based metalworking technology for metal parts. Metal injection molding (mim) and powder metallurgy (pm) are two popular manufacturing processes used in the production of metal. Metal injection molding produces extremely complex geometries economically. Powder Metallurgy Vs Mim.

From www.tav-vacuumfurnaces.com

Powder Metallurgy do you know your powders? (Part I) Powder Metallurgy Vs Mim While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Metal injection molding produces extremely complex geometries economically and with great repeatability when compared to competing technologies. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each. Meanwhile, both mim and pm technology. Powder Metallurgy Vs Mim.

From www.cf-kneader.com

Metal Powder kneader For MIMEquipment For MIM Powder Metallurgy Vs Mim The cost of the powdered metal is a key driver when comparing mim and pm materials. While mim is excellent for niche applications, conventional powder metallurgy still offers numerous benefits for a wide variety of small. Meanwhile, both mim and pm technology is. Powder metallurgy (pm) and metal injection molding (mim) are both effective methods for manufacturing metal parts, each.. Powder Metallurgy Vs Mim.