End Mill Cutting Angle . End mills with high helix angles ensure better chip evacuation as they. The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. An end mill's cutting force consists of an axial and radial component. Dish ensures that a flat surface is produced by. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and the tool’s. Better chip removal and less vibration during cutting. The teeth or cutting edges at the very top of the end mill,. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. While the axial component presses the end mill against the holder, the radial component tends to bend the. The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. Cutting edges are only on a top.

from www.cobanengineering.com

End mills with high helix angles ensure better chip evacuation as they. An end mill's cutting force consists of an axial and radial component. Better chip removal and less vibration during cutting. Dish ensures that a flat surface is produced by. While the axial component presses the end mill against the holder, the radial component tends to bend the. Cutting edges are only on a top. The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and the tool’s. The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge.

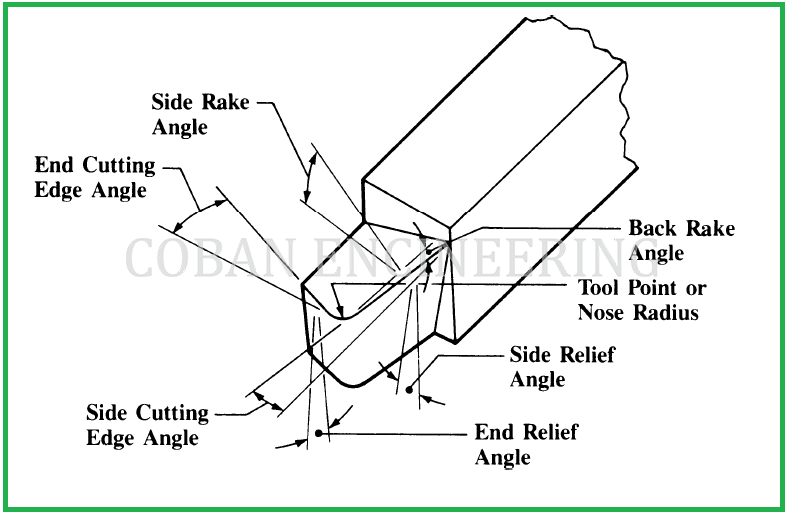

Back Rake, Side Rake, Rake angle, wedge angle and flank angles,the

End Mill Cutting Angle The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. An end mill's cutting force consists of an axial and radial component. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. Cutting edges are only on a top. The teeth or cutting edges at the very top of the end mill,. Better chip removal and less vibration during cutting. The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. While the axial component presses the end mill against the holder, the radial component tends to bend the. End mills with high helix angles ensure better chip evacuation as they. Dish ensures that a flat surface is produced by. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and the tool’s.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe End Mill Cutting Angle This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and the tool’s. End mills with high helix angles ensure better chip evacuation as they. Cutting edges are only on a top. The teeth or cutting edges at. End Mill Cutting Angle.

From www.ebay.com

1/4" Diameter O Flute Upcut End Mill CNC Router Bit 1/4" Shank End Mill Cutting Angle Better chip removal and less vibration during cutting. Cutting edges are only on a top. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. The teeth or cutting edges at the very top of the end mill,. Dish ensures that a flat. End Mill Cutting Angle.

From www.ar15.com

Bits for 80... End Mill Cutting Angle While the axial component presses the end mill against the holder, the radial component tends to bend the. Better chip removal and less vibration during cutting. End mills with high helix angles ensure better chip evacuation as they. Cutting edges are only on a top. Dish ensures that a flat surface is produced by. An end mill's cutting force consists. End Mill Cutting Angle.

From conicalendmills.com

Conical Tapered End Mills, Cutting Tools, Metalworking, Terminology End Mill Cutting Angle An end mill's cutting force consists of an axial and radial component. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and the tool’s. Cutting edges are only on a top. Better chip removal and less vibration. End Mill Cutting Angle.

From www.globalspec.com

Dovetail Cutters Selection Guide Types, Features, Applications End Mill Cutting Angle The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and. End Mill Cutting Angle.

From www.pngegg.com

Cutting tool End mill Tungsten carbide, angle, india png PNGEgg End Mill Cutting Angle The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. End mills with high helix angles ensure better chip evacuation as they. An end mill's cutting force consists of an axial and radial component. The helix angle of an end mill is a. End Mill Cutting Angle.

From toolnotes.com

Cutting Parameters for Milling ToolNotes End Mill Cutting Angle The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. Dish ensures that a flat surface is produced by. Better chip removal and less vibration during cutting. End mills with high helix angles ensure better chip evacuation as they. An end mill's cutting force consists of an axial and. End Mill Cutting Angle.

From xasentu.en.made-in-china.com

45° Helix Angle 4 Flutes Heavy Cutting Carbide Square End Mills End Mill Cutting Angle Better chip removal and less vibration during cutting. End mills with high helix angles ensure better chip evacuation as they. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. The helix angle of an end mill is a critical parameter that influences. End Mill Cutting Angle.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe End Mill Cutting Angle The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. Better chip removal and less vibration during cutting. The teeth or cutting edges at the very top of the end mill,. The helix angle of a tool is measured by the angle formed between the centerline of the tool. End Mill Cutting Angle.

From www.canadianmetalworking.com

End mill geometry boosts trochoidal milling Canadian Metalworking End Mill Cutting Angle Better chip removal and less vibration during cutting. End mills with high helix angles ensure better chip evacuation as they. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and the tool’s. While the axial component presses. End Mill Cutting Angle.

From huanatools.com

Roughing vs. Finishing End Mill How Do They Differ? Huana Tools End Mill Cutting Angle The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. Dish ensures that a flat surface is produced by. An end mill's cutting force consists of an axial and radial component. While the axial component presses the end mill against the holder, the radial component tends to bend the.. End Mill Cutting Angle.

From www.mmc-carbide.com

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI End Mill Cutting Angle The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. End mills with high helix angles ensure better chip evacuation as they. Better chip removal and less vibration. End Mill Cutting Angle.

From engineeringlearn.com

End Mill Cutter Archives Engineering Learn End Mill Cutting Angle Dish ensures that a flat surface is produced by. Cutting edges are only on a top. The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. End mills with high helix angles ensure better chip evacuation as they. This angle, defined as the angle between the edge of the. End Mill Cutting Angle.

From www.alibaba.com

45 Degree Chamfering Mill Indexable End Mill Cnc Carbide Face Milling End Mill Cutting Angle The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. Dish ensures that a flat surface is produced by. Cutting edges are only on a top. End mills with high helix angles ensure better chip evacuation as they. While the axial component presses the end mill against the holder,. End Mill Cutting Angle.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature End Mill Cutting Angle While the axial component presses the end mill against the holder, the radial component tends to bend the. Cutting edges are only on a top. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. End mills with high helix angles ensure better. End Mill Cutting Angle.

From www.mscdirect.com

Emuge Barrel Cutter End Mills; End Type Circle Segment Oval Form End Mill Cutting Angle Better chip removal and less vibration during cutting. End mills with high helix angles ensure better chip evacuation as they. The teeth or cutting edges at the very top of the end mill,. The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. This angle, defined as the angle. End Mill Cutting Angle.

From www.researchgate.net

Flute profile of the endmill cutter—example 1 Download Scientific End Mill Cutting Angle The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. While the axial component presses the end mill against the holder, the radial component tends to bend the. Better chip removal and less vibration during cutting. The teeth or cutting edges at the very top of the end mill,.. End Mill Cutting Angle.

From www.aliexpress.com

Buy MZG BAP300RC10 10 100 1T Carbide Insert Clamped End Mill Cutting Angle While the axial component presses the end mill against the holder, the radial component tends to bend the. End mills with high helix angles ensure better chip evacuation as they. The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. Cutting edges are only on a top. Better chip. End Mill Cutting Angle.

From www.cnccookbook.com

Ball Nose End Mill [Easy Guide to Ball Cutters] CNCCookbook Be A End Mill Cutting Angle Dish ensures that a flat surface is produced by. An end mill's cutting force consists of an axial and radial component. Better chip removal and less vibration during cutting. The teeth or cutting edges at the very top of the end mill,. The helix angle of a tool is measured by the angle formed between the centerline of the tool. End Mill Cutting Angle.

From www.researchgate.net

(PDF) The millingmilling machining method and its realization End Mill Cutting Angle This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and the tool’s. The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. An end mill's cutting. End Mill Cutting Angle.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe Machinist Blog End Mill Cutting Angle The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. Better chip removal and less vibration during cutting. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency,. End Mill Cutting Angle.

From toolnotes.com

End Mills ToolNotes End Mill Cutting Angle Dish ensures that a flat surface is produced by. The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the. End Mill Cutting Angle.

From www.ukocarbide.com

What’s the difference between End Mills Helix angle 35° and 45 End Mill Cutting Angle The teeth or cutting edges at the very top of the end mill,. An end mill's cutting force consists of an axial and radial component. Better chip removal and less vibration during cutting. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface. End Mill Cutting Angle.

From www.mdpi.com

Materials Free FullText Parametric Optimization of Trochoidal Step End Mill Cutting Angle An end mill's cutting force consists of an axial and radial component. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and the tool’s. Cutting edges are only on a top. The helix angle of a tool. End Mill Cutting Angle.

From www.cobanengineering.com

Back Rake, Side Rake, Rake angle, wedge angle and flank angles,the End Mill Cutting Angle While the axial component presses the end mill against the holder, the radial component tends to bend the. End mills with high helix angles ensure better chip evacuation as they. The teeth or cutting edges at the very top of the end mill,. The helix angle of an end mill is a critical parameter that influences the performance and outcome. End Mill Cutting Angle.

From www.carbideanddiamondtooling.com

A complete source of Single Angle Milling Cutter Double Angle Milling End Mill Cutting Angle An end mill's cutting force consists of an axial and radial component. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. While the axial component presses the end mill against the holder, the radial component tends to bend the. This angle, defined. End Mill Cutting Angle.

From www.aliexpress.com

bap300r 10 17mm Milling holder for apmt1135 Cutting Shoulder Right End Mill Cutting Angle An end mill's cutting force consists of an axial and radial component. Better chip removal and less vibration during cutting. Cutting edges are only on a top. The teeth or cutting edges at the very top of the end mill,. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a. End Mill Cutting Angle.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe End Mill Cutting Angle Better chip removal and less vibration during cutting. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. An end mill's cutting force consists of an axial and radial component. The cutting edge angle measured from the centerline of the end mill to. End Mill Cutting Angle.

From www.sainsmart.com

Genmitsu FN10A, 1/8'', 2Flute, Flat Nose, Spiral End Mill, 0.8mm3 End Mill Cutting Angle The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. The teeth or cutting edges at the very top of the end mill,. While the axial component presses the end mill against the holder, the radial component tends to bend the. Cutting edges. End Mill Cutting Angle.

From toolnotes.com

End Mills ToolNotes End Mill Cutting Angle The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. This angle, defined as the angle between the edge of the helix. End Mill Cutting Angle.

From mungfali.com

End Mill Drawings End Mill Cutting Angle The helix angle of an end mill is a critical parameter that influences the performance and outcome of a machining operation. This angle, defined as the angle between the edge of the helix and an imaginary line parallel to the mill’s axis, affects the cutting efficiency, the surface finish of the machined part, and the tool’s. An end mill's cutting. End Mill Cutting Angle.

From www.researchgate.net

SEM images of a laserfabricated SCD microcutting tool with multiple End Mill Cutting Angle The teeth or cutting edges at the very top of the end mill,. End mills with high helix angles ensure better chip evacuation as they. The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. The helix angle of an end mill is. End Mill Cutting Angle.

From alexnld.com

5pcs 20mm 45 Degree Dovetail Cutter End Mill Cutter Milling Cutter End Mill Cutting Angle End mills with high helix angles ensure better chip evacuation as they. Dish ensures that a flat surface is produced by. Better chip removal and less vibration during cutting. The teeth or cutting edges at the very top of the end mill,. The helix angle of a tool is measured by the angle formed between the centerline of the tool. End Mill Cutting Angle.

From www.researchgate.net

Tool geometry and principal angles of a taper ballend mill cutter End Mill Cutting Angle Cutting edges are only on a top. Dish ensures that a flat surface is produced by. An end mill's cutting force consists of an axial and radial component. Better chip removal and less vibration during cutting. The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. The teeth or. End Mill Cutting Angle.

From jordonhefner.blogspot.com

roughing end mill cutter diagram Jordon Hefner End Mill Cutting Angle The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. While the axial component presses the end mill against the holder, the radial component tends to bend the. An end mill's cutting force consists of an axial and radial component. End mills with high helix angles ensure better chip. End Mill Cutting Angle.