Cutting Speed Of Carbide Tools . Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. Cutting speed is defined as the speed at the outside edge of the tool as it is. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Explain how to correctly set up for power feed tapping. Calculate cutting speeds and feeds for end milling operations. If this condition exists, convential milling. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut.

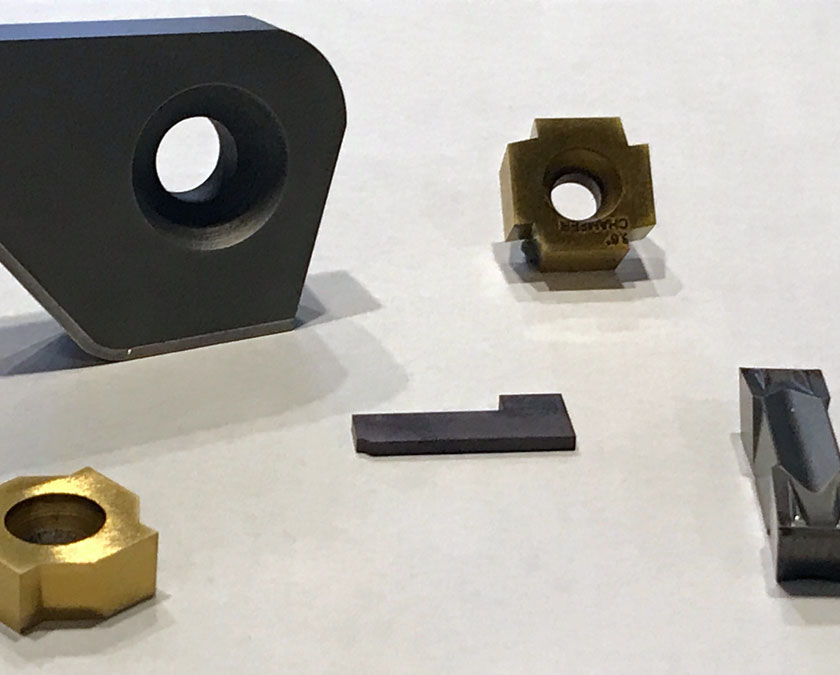

from www.spartancarbide.com

Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. Cutting speed is defined as the speed at the outside edge of the tool as it is. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. If this condition exists, convential milling. Explain how to correctly set up for power feed tapping. Calculate cutting speeds and feeds for end milling operations. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators.

Custom Cutting Tools & Inserts Spartan Carbide

Cutting Speed Of Carbide Tools Cutting speed is defined as the speed at the outside edge of the tool as it is. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. If this condition exists, convential milling. Calculate cutting speeds and feeds for end milling operations. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Cutting speed is defined as the speed at the outside edge of the tool as it is. Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. Explain how to correctly set up for power feed tapping.

From www.indiamart.com

Carbide Cutting Tools at Rs 48000/piece Hyderabad ID 7442953762 Cutting Speed Of Carbide Tools If this condition exists, convential milling. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Explain how to correctly set up for power feed tapping. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application.. Cutting Speed Of Carbide Tools.

From www.slideserve.com

PPT CHAPTER 8 MaterialRemoval Processes Cutting PowerPoint Cutting Speed Of Carbide Tools View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills. Cutting Speed Of Carbide Tools.

From www.slideserve.com

PPT Cutting Speed, Feed, and Depth of Cut PowerPoint Presentation Cutting Speed Of Carbide Tools Cutting speed is defined as the speed at the outside edge of the tool as it is. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. If this condition exists, convential milling. Cutting speed is the spindle speed, while it can be regarded as. Cutting Speed Of Carbide Tools.

From www.alicobangalore.com

Carbide Cutting Tools,Ceratizit Cutting Tools,Kennametal,Sandvik Cutting Speed Of Carbide Tools Calculate cutting speeds and feeds for end milling operations. If this condition exists, convential milling. Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut.. Cutting Speed Of Carbide Tools.

From edmtechman.com

Poco EDM Technical Manual Cutting Speed Of Carbide Tools Cutting speed is defined as the speed at the outside edge of the tool as it is. Calculate cutting speeds and feeds for end milling operations. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Cutting speed is the spindle speed, while it can. Cutting Speed Of Carbide Tools.

From www.carbiderotaryburr.com

Carbide Burr Double Cut Cutting Tools Alloy Rotary File High Quality Cutting Speed Of Carbide Tools Calculate cutting speeds and feeds for end milling operations. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Cutting speed is defined as the speed at the outside edge of the tool as. Cutting Speed Of Carbide Tools.

From www.santoolsme.com

Amazing Advantages Of Carbide Tipped Cutting Tools SAN Tools Cutting Speed Of Carbide Tools Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the. Cutting Speed Of Carbide Tools.

From waykenrm.com

Feed Rate and Cutting Speed Difference in CNC Machining WayKen Cutting Speed Of Carbide Tools Explain how to correctly set up for power feed tapping. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Cutting speed is the spindle speed, while it. Cutting Speed Of Carbide Tools.

From www.indiamart.com

Solid Carbide Cutting Tools, 65 Hrc at Rs 200 in Mumbai ID 25846450933 Cutting Speed Of Carbide Tools Calculate cutting speeds and feeds for end milling operations. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. If this condition exists, convential milling. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Free. Cutting Speed Of Carbide Tools.

From mavink.com

Tabel Cutting Speed Cutting Speed Of Carbide Tools Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. Explain how to correctly set up for power feed tapping. Cutting speed is defined as. Cutting Speed Of Carbide Tools.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine Cutting Speed Of Carbide Tools View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. Cutting speed is defined as the speed at the outside edge of the tool as it is. Calculate cutting speeds and feeds for end milling operations. Cutting speed is the spindle speed, while it can be regarded as the speed of. Cutting Speed Of Carbide Tools.

From www.kodiakcuttingtools.com

Carbide End Mill Speeds and Feeds Kodiak Cutting Tools® Carbide End Mills Cutting Speed Of Carbide Tools Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Cutting speed is defined as the speed at the outside edge of the tool as it is. If this condition exists, convential milling. Calculate cutting speeds and feeds for end milling operations. Explain how to. Cutting Speed Of Carbide Tools.

From blog.carbideprocessors.com

Band Saw Blade Feed Speed » Carbide Processors Blog Cutting Speed Of Carbide Tools Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Cutting speed is defined as the speed at the outside edge of the tool as it is. Explain. Cutting Speed Of Carbide Tools.

From mungfali.com

Cutting Speeds And Feeds Chart Cutting Speed Of Carbide Tools Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Cutting speed is defined as the speed at the outside. Cutting Speed Of Carbide Tools.

From www.spartancarbide.com

Custom Cutting Tools & Inserts Spartan Carbide Cutting Speed Of Carbide Tools Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Cutting speed is defined as the speed at the outside edge of the tool as it is. Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. View full chart in new tab. Cutting Speed Of Carbide Tools.

From brunei.desertcart.com

Buy VEVOR Indexable Carbide Lathe Tools 1/2" Metal Lathe Cutting Tools Cutting Speed Of Carbide Tools If this condition exists, convential milling. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Explain how to correctly set up for power feed tapping. Cutting speed. Cutting Speed Of Carbide Tools.

From sumicarbide.com

SMD Replaceable Tip Drills Drilling Tools Sumitomo Electric Carbide Cutting Speed Of Carbide Tools If this condition exists, convential milling. Calculate cutting speeds and feeds for end milling operations. Explain how to correctly set up for power feed tapping. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Cutting speed is the spindle speed, while it can be. Cutting Speed Of Carbide Tools.

From www.accuromm.com

Carbide Cutting Tools Highest Quality Accuromm USA Cutting Speed Of Carbide Tools Calculate cutting speeds and feeds for end milling operations. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Explain how to correctly set up for power feed tapping. Cutting speed is defined as the speed at the outside edge of the tool as it. Cutting Speed Of Carbide Tools.

From www.vevor.ca

VEVOR Indexable Carbide Lathe Tools 1/2" Metal Lathe Cutting Tools 7 Cutting Speed Of Carbide Tools Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Calculate cutting speeds and feeds for end milling operations. Cutting speed is defined as the speed at the outside edge of the tool as it is. If this condition exists, convential milling. Explain how to correctly set up for power feed tapping. Using. Cutting Speed Of Carbide Tools.

From clinetool.com

Ingersoll Cutting Tools Cutting Speeds Up To 36 Times Greater than Cutting Speed Of Carbide Tools If this condition exists, convential milling. Explain how to correctly set up for power feed tapping. Cutting speed is defined as the speed at the outside edge of the tool as it is. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Free cnc. Cutting Speed Of Carbide Tools.

From cehxzrri.blob.core.windows.net

Carbide Drill Speeds And Feeds Calculator at Jerry Bass blog Cutting Speed Of Carbide Tools Explain how to correctly set up for power feed tapping. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. Calculate cutting speeds and feeds for end milling operations. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the. Cutting Speed Of Carbide Tools.

From toolgrindcoat.com

What Are the Carbide Cutting Tools? Cutting Speed Of Carbide Tools If this condition exists, convential milling. Calculate cutting speeds and feeds for end milling operations. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. Using the data tables and the milling formulas. Cutting Speed Of Carbide Tools.

From woodworkadvice.com

Drill Press Speed Chart Your 2021 Guide Woodwork Advice Cutting Speed Of Carbide Tools Calculate cutting speeds and feeds for end milling operations. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. If this condition exists, convential milling. Determine. Cutting Speed Of Carbide Tools.

From www.cnccookbook.com

Carbide Drill Speeds and Feeds [Plus Tips and Techniques] Cutting Speed Of Carbide Tools Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. Cutting Speed Of Carbide Tools.

From bceweb.org

Lathe Cutting Speeds And Feeds Chart Metric A Visual Reference of Cutting Speed Of Carbide Tools Calculate cutting speeds and feeds for end milling operations. Cutting speed is defined as the speed at the outside edge of the tool as it is. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Free cnc speed and feed calculator allows cnc machinists. Cutting Speed Of Carbide Tools.

From www.lathematters.com

HSS vs. Carbide Cutting Tools What's the Difference? Cutting Speed Of Carbide Tools Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. If this condition exists, convential milling. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. Using the data tables and the milling formulas below, you can calculate the speeds and. Cutting Speed Of Carbide Tools.

From fmcarbide.com

Carbide Cutting Tools The Most Common Uses for Carbide FM Carbide Cutting Speed Of Carbide Tools Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Cutting speed is the spindle speed, while it can be regarded as the speed of. Cutting Speed Of Carbide Tools.

From www.toolhit.com

Carbide Reamer Speeds Feeds ToolHIT Cutting Speed Of Carbide Tools Calculate cutting speeds and feeds for end milling operations. Cutting speed is defined as the speed at the outside edge of the tool as it is. If this condition exists, convential milling. Explain how to correctly set up for power feed tapping. Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. Cutting Speed Of Carbide Tools.

From sherline.com

1/4" Brazed Tip Carbide Tool Set Sherline Products Cutting Speed Of Carbide Tools Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Explain how to correctly set up for power feed tapping. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills.. Cutting Speed Of Carbide Tools.

From www.swordtools.com

Carbide Drills for Highspeed MachiningDrillsWuhan Sword Cutting Cutting Speed Of Carbide Tools Cutting speed is defined as the speed at the outside edge of the tool as it is. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool application. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of. Cutting Speed Of Carbide Tools.

From www.scribd.com

Stellram Turning Cutting Speeds Inch PDF Stainless Steel Steel Cutting Speed Of Carbide Tools Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Cutting speed is defined as the speed at the outside edge of the tool as it is. View full chart in new tab chip class material being machined material examples brinell hardness chip description tool. Cutting Speed Of Carbide Tools.

From www.carbideanddiamondtooling.com

Annular Cutter Speed Carbide Cutting Speed Of Carbide Tools Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. Cutting speed is defined as the speed at the outside edge of the tool as it is. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Using the data tables and the. Cutting Speed Of Carbide Tools.

From www.slideserve.com

PPT Cutting Speeds and Feeds PowerPoint Presentation ID278712 Cutting Speed Of Carbide Tools Calculate cutting speeds and feeds for end milling operations. Free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds and feeds. Explain how to correctly set up for power feed tapping. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at. Cutting Speed Of Carbide Tools.

From gcodetutor.com

Cutting speed charts Cutting Speed Of Carbide Tools Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Calculate cutting speeds and feeds for end milling operations. Explain how to correctly set up for power feed tapping. View full chart in new tab chip class material being machined material examples brinell hardness chip. Cutting Speed Of Carbide Tools.

From www.birlaprecision.com

Solid Carbide Cutting Tool Birla Precision Technologies Cutting Speed Of Carbide Tools If this condition exists, convential milling. Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Calculate cutting speeds and. Cutting Speed Of Carbide Tools.