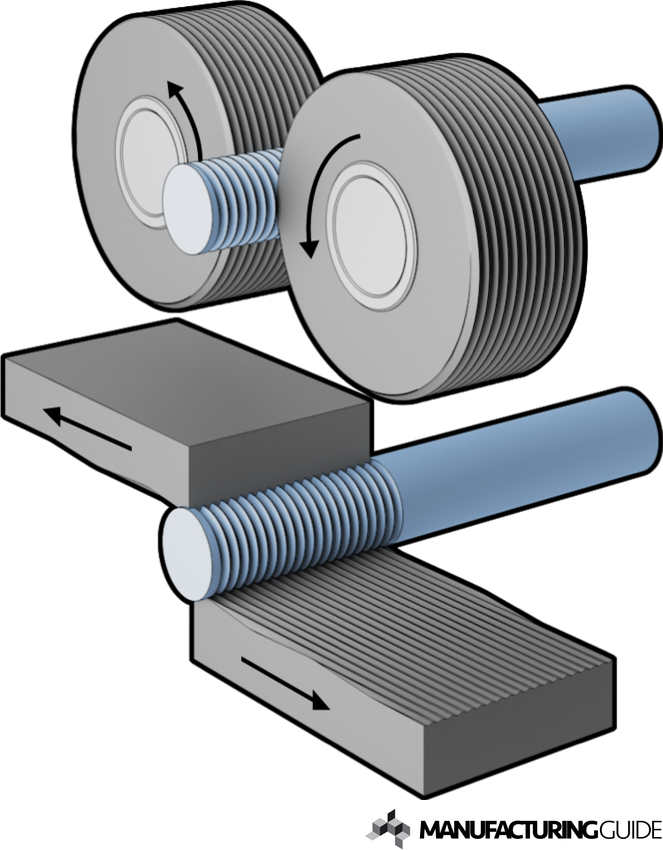

Thread Rolling Standards . In the configurations shown, the. Thread rolling is the method of choice for high volume production threading applications. Planetary die thread rolling equipment is. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is essentially a cold forging operation. British standard whitworth (bsw) threads are used primarily in older machinery. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. The thread rolls, when forced onto. Different styles depend on part orientation to the collet. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. British standard threads (bsw, bsf, bsp):

from www.manufacturingguide.com

In the configurations shown, the. Planetary die thread rolling equipment is. British standard threads (bsw, bsf, bsp): Thread rolling is essentially a cold forging operation. Thread rolling is the method of choice for high volume production threading applications. Different styles depend on part orientation to the collet. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. British standard whitworth (bsw) threads are used primarily in older machinery.

Thread Rolling Find suppliers, processes & material

Thread Rolling Standards In the configurations shown, the. Planetary die thread rolling equipment is. Different styles depend on part orientation to the collet. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. British standard threads (bsw, bsf, bsp): Thread rolling is essentially a cold forging operation. British standard whitworth (bsw) threads are used primarily in older machinery. Thread rolling is the method of choice for high volume production threading applications. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. The thread rolls, when forced onto. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. In the configurations shown, the.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Standards British standard threads (bsw, bsf, bsp): Thread rolling is the method of choice for high volume production threading applications. In the configurations shown, the. British standard whitworth (bsw) threads are used primarily in older machinery. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Understanding the load requirements for thread rolling. Thread Rolling Standards.

From www.scribd.com

Thread Rolling Standards RolokSemblex PDF Screw Extrusion Thread Rolling Standards The thread rolls, when forced onto. Thread rolling is the method of choice for high volume production threading applications. British standard whitworth (bsw) threads are used primarily in older machinery. In the configurations shown, the. Planetary die thread rolling equipment is. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads. Thread Rolling Standards.

From www.undergraceovercoffee.com

Metric Thread Rolling Diameter Chart Reviews Of Chart Thread Rolling Standards Different styles depend on part orientation to the collet. In the configurations shown, the. Thread rolling is essentially a cold forging operation. British standard threads (bsw, bsf, bsp): The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is the method of choice for high volume production threading applications. Understanding. Thread Rolling Standards.

From www.fastenerdata.co.uk

Fastenerdata THREAD CHART 10b Fastener Specifications Thread Rolling Standards British standard whitworth (bsw) threads are used primarily in older machinery. British standard threads (bsw, bsf, bsp): Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. The thread rolls, when forced onto. Different styles depend on part orientation to the collet. The fastest, most economical method for producing highly accurate threads,. Thread Rolling Standards.

From www.scribd.com

Thread Rolling Blank Preparation PDF Thread Rolling Standards Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. British standard whitworth (bsw) threads are used primarily in older machinery. In the configurations shown, the. Different styles depend on part orientation to the collet. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger. Thread Rolling Standards.

From www.slideserve.com

PPT ME 350 Lecture 21 Chapter 19 PowerPoint Presentation, free Thread Rolling Standards The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is the method of choice for high volume production threading applications. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. British standard whitworth (bsw) threads are used primarily in older machinery.. Thread Rolling Standards.

From mungfali.com

Roll Thread Chart Thread Rolling Standards In the configurations shown, the. Thread rolling is essentially a cold forging operation. Different styles depend on part orientation to the collet. British standard threads (bsw, bsf, bsp): Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. British standard whitworth (bsw) threads are used primarily in older. Thread Rolling Standards.

From www.zerofast.com

Thread Chart Standard zero products inc. Thread Rolling Standards Thread rolling is the method of choice for high volume production threading applications. British standard whitworth (bsw) threads are used primarily in older machinery. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Planetary die thread rolling equipment is. British standard threads (bsw, bsf, bsp): Thread rolling. Thread Rolling Standards.

From www.rsvptooling.com

RSVP Tooling, Inc. Axial Thread Rolling System Rolling Speeds Thread Rolling Standards Different styles depend on part orientation to the collet. Planetary die thread rolling equipment is. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. Thread rolling is the method of choice for high volume production threading applications. In the configurations shown, the. British standard threads (bsw, bsf, bsp): The thread rolls,. Thread Rolling Standards.

From www.undergraceovercoffee.com

Metric Thread Rolling Diameter Chart Reviews Of Chart Thread Rolling Standards The thread rolls, when forced onto. In the configurations shown, the. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. Thread rolling is the method of choice for high. Thread Rolling Standards.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Standards Planetary die thread rolling equipment is. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is essentially a cold forging operation. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. The fastest, most economical method for. Thread Rolling Standards.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Thread Rolling Standards British standard threads (bsw, bsf, bsp): Thread rolling is the method of choice for high volume production threading applications. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. Different styles depend on part orientation to the collet. Thread rolling is essentially a cold forging operation. The thread rolls, when forced onto.. Thread Rolling Standards.

From www.rechargecolorado.org

Metric Thread Od Chart Best Picture Of Chart Thread Rolling Standards British standard threads (bsw, bsf, bsp): Different styles depend on part orientation to the collet. In the configurations shown, the. Thread rolling is the method of choice for high volume production threading applications. British standard whitworth (bsw) threads are used primarily in older machinery. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread Rolling Standards.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Standards Different styles depend on part orientation to the collet. British standard whitworth (bsw) threads are used primarily in older machinery. In the configurations shown, the. Thread rolling is essentially a cold forging operation. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. British standard threads (bsw, bsf,. Thread Rolling Standards.

From eicac.co.uk

ImperialThreads Thread Rolling Standards Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. Thread rolling is essentially a cold forging operation. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. The thread rolls, when forced onto. In the configurations shown, the. Thread. Thread Rolling Standards.

From ever-hardware.com

Standard Of Machine Screw Pitch and Thread Rolling Blank Diameter and Thread Rolling Standards British standard whitworth (bsw) threads are used primarily in older machinery. In the configurations shown, the. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. Planetary die thread rolling equipment is. Thread rolling. Thread Rolling Standards.

From www.undergraceovercoffee.com

Metric Thread Rolling Diameter Chart Reviews Of Chart Thread Rolling Standards Thread rolling is essentially a cold forging operation. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. Planetary die thread rolling equipment is. Thread rolling is a threading process that deforms a metal. Thread Rolling Standards.

From www.clecofasteners.com

Cleco Industrial Fasteners Specifications THREAD ROLLING SCREWS Thread Rolling Standards Thread rolling is the method of choice for high volume production threading applications. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. The thread rolls, when forced onto. In the configurations shown, the. Thread rolling is essentially a cold forging operation. Planetary die thread rolling equipment is. British standard threads (bsw,. Thread Rolling Standards.

From www.manufacturingguide.com

Thread Rolling Find suppliers, processes & material Thread Rolling Standards Thread rolling is essentially a cold forging operation. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. British standard whitworth (bsw) threads are used primarily in older machinery. The thread rolls, when forced onto. In the configurations shown, the. British standard threads (bsw, bsf, bsp): Planetary die thread rolling equipment is.. Thread Rolling Standards.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Standards British standard threads (bsw, bsf, bsp): The thread rolls, when forced onto. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. Thread rolling is the method of choice for high volume production threading applications. In the configurations shown, the. Understanding the load requirements for thread rolling is essential to preventing equipment. Thread Rolling Standards.

From www.alibaba.com

Hss Self Tapping Thread Rolling Die With Iso Jis Standards Screw Thread Thread Rolling Standards Thread rolling is essentially a cold forging operation. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Planetary die thread rolling equipment is. In the configurations shown, the. Thread rolling is the method of choice for high volume production threading applications. Different styles depend on part orientation. Thread Rolling Standards.

From www.apollointernational.in

British Standard Fine Thread BSF Thread Chart Apollo International Thread Rolling Standards Different styles depend on part orientation to the collet. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. Planetary die thread rolling equipment is. Thread rolling is a threading process that deforms a. Thread Rolling Standards.

From www.slideshare.net

The Basics of Thread Rolling Thread Rolling Standards Thread rolling is the method of choice for high volume production threading applications. British standard threads (bsw, bsf, bsp): In the configurations shown, the. British standard whitworth (bsw) threads are used primarily in older machinery. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Planetary die thread rolling equipment is. Thread. Thread Rolling Standards.

From www.rsvptooling.com

RSVP Tooling, Inc. Axial Thread Rolling System A45 Overview Thread Rolling Standards The thread rolls, when forced onto. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. Different styles depend on part orientation to the collet. British standard threads (bsw, bsf, bsp): Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the. Thread Rolling Standards.

From printablemathias.z13.web.core.windows.net

Thread Rolling Size Chart Thread Rolling Standards Thread rolling is essentially a cold forging operation. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. In the configurations shown, the. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. The thread rolls, when forced onto. This. Thread Rolling Standards.

From accu-components.com

What Are Thread Rolling Screws And When Should You Use Them? Accu Thread Rolling Standards The thread rolls, when forced onto. Thread rolling is essentially a cold forging operation. Different styles depend on part orientation to the collet. Thread rolling is the method of choice for high volume production threading applications. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Planetary die thread rolling equipment is.. Thread Rolling Standards.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Standards In the configurations shown, the. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Different styles depend on part orientation to the collet. Thread rolling is essentially a cold forging operation. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent. Thread Rolling Standards.

From www.rechargecolorado.org

Metric Thread Rolling Diameter Chart Best Picture Of Chart Thread Rolling Standards Different styles depend on part orientation to the collet. In the configurations shown, the. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. British standard threads (bsw, bsf, bsp): Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. Thread rolling is a. Thread Rolling Standards.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Standards Different styles depend on part orientation to the collet. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. Thread rolling is the method of choice for high volume production threading applications. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on. Thread Rolling Standards.

From www.scribd.com

ISO Standard ThreadTap Drill Size Chart Thread Rolling Standards The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. The thread rolls, when forced onto. Thread rolling is the method of choice for high volume production threading applications. Planetary. Thread Rolling Standards.

From www.mudgefasteners.com

Thread Pitch Charts Thread Rolling Standards Planetary die thread rolling equipment is. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. Thread rolling is essentially a cold forging operation. British standard threads (bsw, bsf, bsp): In the configurations shown, the. Thread rolling is the method of choice for high volume production threading applications. The thread rolls, when. Thread Rolling Standards.

From mungfali.com

Roll Thread Chart Thread Rolling Standards Thread rolling is the method of choice for high volume production threading applications. Different styles depend on part orientation to the collet. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable. Thread Rolling Standards.

From www.rechargecolorado.org

Metric Pipe Thread Dimensions Chart Best Picture Of Chart Thread Rolling Standards The thread rolls, when forced onto. This sae standard covers material, dimensional, performance, and test requirements for metric thread rolling screws suitable for use. British standard threads (bsw, bsf, bsp): Thread rolling is the method of choice for high volume production threading applications. Planetary die thread rolling equipment is. The fastest, most economical method for producing highly accurate threads, thread. Thread Rolling Standards.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Standards Thread rolling is essentially a cold forging operation. British standard threads (bsw, bsf, bsp): Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. Different styles depend on part orientation to the collet. British standard whitworth (bsw) threads are used primarily in older machinery. Thread rolling is a threading process that deforms. Thread Rolling Standards.

From www.youtube.com

Rolled Threads Unlimited Unified Thread Rolling Example YouTube Thread Rolling Standards The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is the method of choice for high volume production threading applications. Different styles depend on part orientation to. Thread Rolling Standards.