Laminated Glass Bubbles . The purpose of this test method is to measure. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. However, sometimes we may notice. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. The percentage of the length of edge affected by defects varied from only 3% up to 75%.

from www.slideshare.net

When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The percentage of the length of edge affected by defects varied from only 3% up to 75%. The purpose of this test method is to measure. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. However, sometimes we may notice. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions.

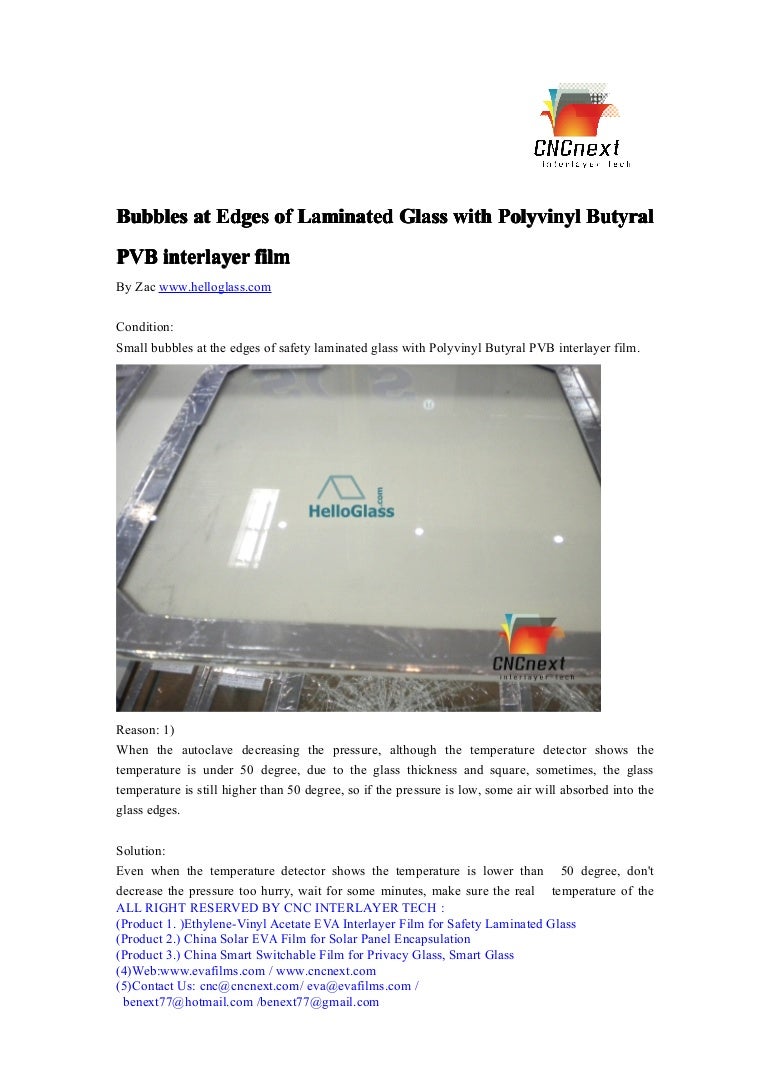

Bubbles at edges of laminated glass with polyvinyl butyral pvb interl…

Laminated Glass Bubbles The percentage of the length of edge affected by defects varied from only 3% up to 75%. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. The purpose of this test method is to measure. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The percentage of the length of edge affected by defects varied from only 3% up to 75%. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. However, sometimes we may notice. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass.

From www.pinterest.com.au

bubblesinmiddlesafetylaminatedglassofpolyvinylbutyralpvb Laminated Glass Bubbles The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. The percentage of the length of edge affected by defects varied from only 3% up to 75%. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. Edge stability is defined as the ability for the. Laminated Glass Bubbles.

From creativemarket.com

Bubbles in the glass featuring bubbles, glass, and texture High Laminated Glass Bubbles However, sometimes we may notice. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The percentage of the length of edge. Laminated Glass Bubbles.

From www.pinterest.com

Glass iridescent bubbles. Public art London. VERHOEVEN VERHOEVEN Laminated Glass Bubbles Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. The purpose of this test method is to measure. The percentage of the length of edge affected by defects varied from only 3% up to 75%. The qualified laminated glass looks crystal clear without bubbles or. Laminated Glass Bubbles.

From sa-glass.blogspot.com

В стекольном мире... Обсудим Пузырьки в ламинированном стекле Laminated Glass Bubbles The percentage of the length of edge affected by defects varied from only 3% up to 75%. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or. Laminated Glass Bubbles.

From www.hollanderglass.com

Bubbles Hollander Specialty Glass Laminated Glass Bubbles Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration,. Laminated Glass Bubbles.

From www.imageafter.com

Image*After photos glass bubbles abstract Laminated Glass Bubbles When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. However, sometimes we may notice. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes. Laminated Glass Bubbles.

From www.pioneer.glass

Laminated Glass Assured Protection Pioneer Glass Laminated Glass Bubbles However, sometimes we may notice. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. The purpose of this test method is to measure. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. When large in amount. Laminated Glass Bubbles.

From kalvanna.net

5x7 Bubble Texture Glass Base The Kalvanna Line Laminated Glass Bubbles Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. However, sometimes we may notice. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated. Laminated Glass Bubbles.

From www.slideshare.net

Bubbles at edges of laminated glass with polyvinyl butyral pvb interl… Laminated Glass Bubbles The purpose of this test method is to measure. However, sometimes we may notice. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. The percentage of the length of edge affected by defects varied from only 3% up to 75%. Edge stability is defined as. Laminated Glass Bubbles.

From www.fabglassandmirror.com

Tempered Glass vs Laminated Glass Which is Better and How to Choose? Laminated Glass Bubbles Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in. Laminated Glass Bubbles.

From www.pinterest.com

Round Bubbles Glass Tile Mosaic Crystal Glass Bubbles Round Mosaic Laminated Glass Bubbles The purpose of this test method is to measure. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. The percentage of the length of edge affected by. Laminated Glass Bubbles.

From www.vsomglass.com

Are You Aware of the Common Quality Defects in Laminated Glass Laminated Glass Bubbles The purpose of this test method is to measure. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental. Laminated Glass Bubbles.

From bendheim.com

"Clear Textured Bubble" Architectural Glass Bendheim Laminated Glass Bubbles However, sometimes we may notice. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. The percentage of. Laminated Glass Bubbles.

From www.jingglass.com

PVB Laminated Glass, architectural laminated glass, Laminated safety glass Laminated Glass Bubbles The purpose of this test method is to measure. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. The percentage of the length of edge affected by defects varied from only 3% up to 75%. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will.. Laminated Glass Bubbles.

From www.mornglass.com

EVA laminated glass MORN GLASSBest architectural glass supplier Laminated Glass Bubbles The purpose of this test method is to measure. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. However, sometimes we may notice. Astm1 c1914 (2021) standard test method for bake and boil testing of. Laminated Glass Bubbles.

From www.archdaily.com

Patterned Glass Bubbles from GGI Laminated Glass Bubbles Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. However, sometimes we may. Laminated Glass Bubbles.

From ixceed.ca

Krubble (KraftLaminated Bubble) Bubble Wrap Packing and Shipping Laminated Glass Bubbles The purpose of this test method is to measure. However, sometimes we may notice. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. When large in amount. Laminated Glass Bubbles.

From romaarellano.com

Vintage Controlled Bubbles Art Glass Paperweight Orb Green Center Laminated Glass Bubbles Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. The purpose of this test method is to measure. The qualified laminated glass looks crystal clear without bubbles. Laminated Glass Bubbles.

From www.flickr.com

DSC_7368 glass bubbles, detail glass ball with bubbles Flickr Laminated Glass Bubbles Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. However, sometimes we may notice. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these. Laminated Glass Bubbles.

From learnglassblowing.com

How To Make Glass Bubbles Learn Glass Blowing Laminated Glass Bubbles Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. However, sometimes we may notice. The purpose of this test method is to measure. The percentage of the length of edge affected by defects varied from only 3% up to 75%. When large in amount or when laminated glass (pvb) is under warm conditions (softening of. Laminated Glass Bubbles.

From www.slideshare.net

Glazing cases bubbles around the laminated glass edges Laminated Glass Bubbles The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. However, sometimes we may. Laminated Glass Bubbles.

From www.nathanallan.com

Laminated Wall Panels Air Bubbles Nathan Allan Glass Studios Laminated Glass Bubbles The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. However, sometimes we may notice. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental. Laminated Glass Bubbles.

From www.slideshare.net

Bubbles at edges of laminated glass with polyvinyl butyral pvb interl… Laminated Glass Bubbles When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The purpose of this test method is to measure. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling,. Laminated Glass Bubbles.

From www.youtube.com

Bubbles Solutions of Laminated Glass with EVA Interlayer Film By Peter Laminated Glass Bubbles When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. The purpose. Laminated Glass Bubbles.

From jestersbaubles.blogspot.co.uk

Dana Worley, Fused Glass Designs Fused Glass Bubbles Laminated Glass Bubbles When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. The purpose of this test method is to measure. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. However, sometimes we. Laminated Glass Bubbles.

From www.pinterest.com

W10 Colorful Bubbles Wave Stained Glass window Stained glass Laminated Glass Bubbles However, sometimes we may notice. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. The purpose of this test method is to measure. Laminated glass, when properly laminated, will pass the bake test for 16. Laminated Glass Bubbles.

From www.pinterest.co.uk

Bubble glass tile inspiration for some of our cooler rooms Bubble Laminated Glass Bubbles Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. However, sometimes we may notice. When large in. Laminated Glass Bubbles.

From www.pinterest.com

Vintage paperweight controlled bubble glass clear Etsy Controlled Laminated Glass Bubbles However, sometimes we may notice. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The qualified laminated glass looks crystal clear without bubbles or dust inside the interlayer. The percentage of the length of edge affected by defects varied from only 3% up to 75%. Laminated glass, when properly. Laminated Glass Bubbles.

From www.3m.com

3M™ Glass Bubble S32HS 3M United States Laminated Glass Bubbles The purpose of this test method is to measure. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The qualified laminated glass looks crystal clear. Laminated Glass Bubbles.

From www.creativefabrica.com

3D Orange Green Floating Glass Bubbles Seamless Paper · Creative Fabrica Laminated Glass Bubbles The purpose of this test method is to measure. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. However, sometimes we. Laminated Glass Bubbles.

From www.youtube.com

Reasons for having Bubbles when making laminated glass YouTube Laminated Glass Bubbles Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over time when exposed to environmental conditions. However, sometimes we may notice. The purpose of this test method is to measure. When large in amount. Laminated Glass Bubbles.

From szdragonglass.com

5 Razones Por Las Que La Delaminación Y Soluciones De Vidrio Laminado PVB Laminated Glass Bubbles The purpose of this test method is to measure. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. The qualified laminated glass looks crystal clear without bubbles or dust inside the. Laminated Glass Bubbles.

From www.slideshare.net

Glazing cases bubbles around the laminated glass edges Laminated Glass Bubbles Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. Edge stability is defined as the ability for the edges of laminated glass to resist discoloration, bubbling, delamination, or other blemishes over. Laminated Glass Bubbles.

From www.ylglass.com

Why Laminated Glass Has Bubbles? Laminated Glass Bubbles Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. The percentage of the length of edge affected by defects varied from only 3% up to 75%. However, sometimes we may notice. Laminated glass, when properly laminated, will pass the bake test for 16 hours at 212°f (100 °c) in accordance with astm c1914 standard test.. Laminated Glass Bubbles.

From www.airwrap.co.za

Standard Bubble Dual Laminate Sheets Laminated Glass Bubbles When large in amount or when laminated glass (pvb) is under warm conditions (softening of pvb) these “micro bubbles” will. The percentage of the length of edge affected by defects varied from only 3% up to 75%. Astm1 c1914 (2021) standard test method for bake and boil testing of laminated glass. However, sometimes we may notice. Edge stability is defined. Laminated Glass Bubbles.