How To Stop Air Suspension . Diagnose common problems like air leaks and ride height sensor faults. Learn when to call a mechanic and when to diy for air suspension leak repair. Repair failed components like compressors and valves. Save money and get the job done right with this comprehensive guide. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. Should an air line break, get your car or truck on some kind of stands to keep it steady. Common problems with air suspension. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair.

from www.fleetequipmentmag.com

Should an air line break, get your car or truck on some kind of stands to keep it steady. Diagnose common problems like air leaks and ride height sensor faults. Save money and get the job done right with this comprehensive guide. Learn when to call a mechanic and when to diy for air suspension leak repair. Repair failed components like compressors and valves. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Common problems with air suspension. Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency.

Truck air suspension ride height setting, service tips

How To Stop Air Suspension Common problems with air suspension. Learn when to call a mechanic and when to diy for air suspension leak repair. Should an air line break, get your car or truck on some kind of stands to keep it steady. Save money and get the job done right with this comprehensive guide. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Common problems with air suspension. Repair failed components like compressors and valves. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Diagnose common problems like air leaks and ride height sensor faults. Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair.

From www.youtube.com

Dodge Ram air suspension problems How to fix YouTube How To Stop Air Suspension Diagnose common problems like air leaks and ride height sensor faults. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. Common problems with air suspension. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a. How To Stop Air Suspension.

From www.youtube.com

bmw air suspension location on an f11 and problems fixed YouTube How To Stop Air Suspension Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Repair failed components like compressors and valves.. How To Stop Air Suspension.

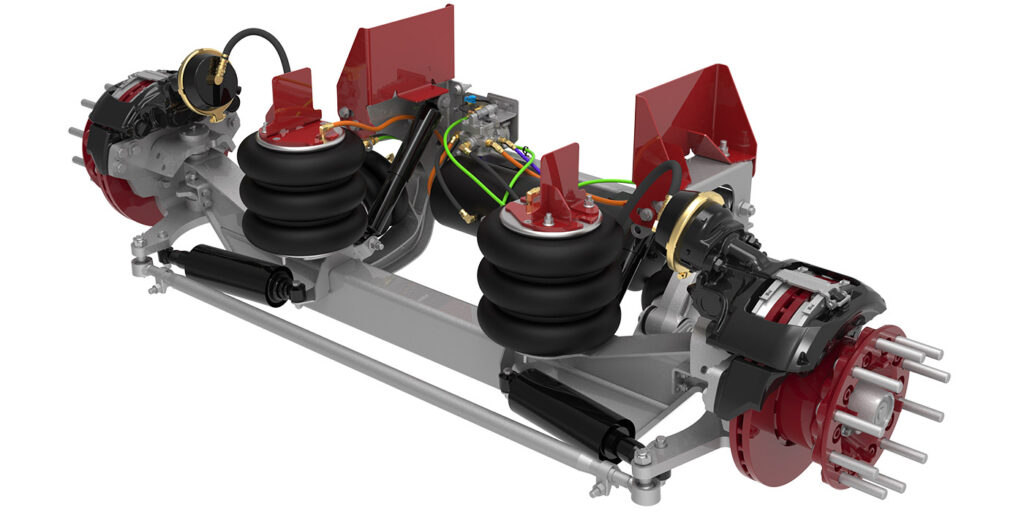

From www.gooddealgps.com

A Trailer Suspension That Drivers Love Good Deal GPS How To Stop Air Suspension Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Learn when to call a mechanic and when to diy for air suspension leak repair. Common problems with air suspension. Save. How To Stop Air Suspension.

From autoglobes.com

How To Reset Ram 1500 Air Suspension? (Explained) AutoGlobes How To Stop Air Suspension These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Common problems with air suspension. Diagnose common problems like air leaks and ride height sensor faults. Save money and get the job done right with this comprehensive guide. Despite their benefits, air suspension systems can encounter several problems that require diagnosis. How To Stop Air Suspension.

From www.fastcar.co.uk

Air Ride Suspension Guide Explaining How It Works Fast Car How To Stop Air Suspension If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Should an air line break, get your car or truck on some kind of stands to keep it steady. Learn when to. How To Stop Air Suspension.

From mechanicalelements.com

Trailer Air Suspension Is It Right For You? Mechanical Elements How To Stop Air Suspension Repair failed components like compressors and valves. Learn when to call a mechanic and when to diy for air suspension leak repair. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Diagnose common problems like air leaks and ride height sensor faults. Save money and get the job done right. How To Stop Air Suspension.

From www.youtube.com

The Ultimate Suspension Improves Comfort, Handling and Safety YouTube How To Stop Air Suspension Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Critically inspect the air suspension strut or. How To Stop Air Suspension.

From www.youtube.com

Air over leaf suspension//Deep dive and installation; Shoebox Ford Ep25 How To Stop Air Suspension If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Repair failed components like compressors and valves. Common problems with air suspension. Learn when to call a mechanic and when to diy. How To Stop Air Suspension.

From www.carparts.com

How Does the Air Suspension in Your Truck Work? In The Garage with How To Stop Air Suspension Learn when to call a mechanic and when to diy for air suspension leak repair. Repair failed components like compressors and valves. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. If you're daily driving your rig, or even if you're cruising it out to a big show, bring. How To Stop Air Suspension.

From www.motortrend.com

How Air Suspensions Work How To Stop Air Suspension Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. Should an air line break, get your car or truck on some kind of stands to keep it steady. Learn when to call a mechanic and when to diy for air suspension leak repair. These problems can include air leaks, compressor failure, worn or damaged. How To Stop Air Suspension.

From www.youtube.com

Lecture 11 Air Suspension YouTube How To Stop Air Suspension Repair failed components like compressors and valves. Save money and get the job done right with this comprehensive guide. Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Should an air line break, get your. How To Stop Air Suspension.

From ubicaciondepersonas.cdmx.gob.mx

Suspension Bump Stop ubicaciondepersonas.cdmx.gob.mx How To Stop Air Suspension Should an air line break, get your car or truck on some kind of stands to keep it steady. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Diagnose common problems. How To Stop Air Suspension.

From wirepartrecaptions.z21.web.core.windows.net

Simple Air Suspension Diagram How To Stop Air Suspension Learn when to call a mechanic and when to diy for air suspension leak repair. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Save money and get the job done. How To Stop Air Suspension.

From discover.hubpages.com

Car Air Suspension How It Works HubPages How To Stop Air Suspension Save money and get the job done right with this comprehensive guide. Repair failed components like compressors and valves. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. Should an air line break, get your. How To Stop Air Suspension.

From www.youtube.com

AIR SUSPENSION to a new level! YouTube How To Stop Air Suspension Repair failed components like compressors and valves. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Common problems with air suspension. Should an air line break, get your car or truck on some kind of stands to keep it steady. Learn when to call a mechanic and when to diy. How To Stop Air Suspension.

From www.fleetequipmentmag.com

Truck air suspension ride height setting, service tips How To Stop Air Suspension Save money and get the job done right with this comprehensive guide. Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. Diagnose common problems like air leaks and ride height sensor faults. Learn when. How To Stop Air Suspension.

From www.autodaily.com.au

How air suspension helps more than ride quality Automotive Daily How To Stop Air Suspension Repair failed components like compressors and valves. Learn when to call a mechanic and when to diy for air suspension leak repair. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool.. How To Stop Air Suspension.

From solomotorsports.com

Rear Bump Stop Mounts / 19801996 Ford Bronco Solo Motorsports How To Stop Air Suspension Learn when to call a mechanic and when to diy for air suspension leak repair. Save money and get the job done right with this comprehensive guide. Common problems with air suspension. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. If you're daily driving your rig, or even. How To Stop Air Suspension.

From wilesgiczewski.blogspot.com

air ride suspension installation shops near me wilesgiczewski How To Stop Air Suspension These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Should an air line break, get your car or truck on some kind of stands to keep it steady. Common problems with air suspension. Diagnose common problems like air leaks and ride height sensor faults. Save money and get the job. How To Stop Air Suspension.

From diyautoservice.com

Air Suspension vs. Coilovers What is Better for You? DIY Auto Service How To Stop Air Suspension Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. Should an air line break, get your car or truck on some kind of stands to keep it steady. Diagnose common problems like air leaks and ride height sensor faults. Save money and get the job done right with this. How To Stop Air Suspension.

From auto.howstuffworks.com

How Car Suspensions Work HowStuffWorks How To Stop Air Suspension These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Common problems with air suspension. Save money and get the job done right with this comprehensive guide. Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. Critically inspect the air suspension strut or shock absorber. How To Stop Air Suspension.

From shockabsorberpro.com

How To Reset AIRmatic Suspension In 12 Easy Steps Shock Absorber Pro How To Stop Air Suspension Save money and get the job done right with this comprehensive guide. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. Diagnose common problems like air leaks and ride height sensor faults. Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. These problems. How To Stop Air Suspension.

From www.pamperedautocare.com

Car Suspension Maintenance and Repair Austin Round Rock How To Stop Air Suspension Should an air line break, get your car or truck on some kind of stands to keep it steady. Diagnose common problems like air leaks and ride height sensor faults. Repair failed components like compressors and valves. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. Common problems with. How To Stop Air Suspension.

From www.cjponyparts.com

Air Suspension vs Coilovers How To Stop Air Suspension Learn when to call a mechanic and when to diy for air suspension leak repair. Common problems with air suspension. Repair failed components like compressors and valves. Diagnose common problems like air leaks and ride height sensor faults. Should an air line break, get your car or truck on some kind of stands to keep it steady. These problems can. How To Stop Air Suspension.

From www.artofit.org

How air suspensions work Artofit How To Stop Air Suspension Save money and get the job done right with this comprehensive guide. Repair failed components like compressors and valves. Learn when to call a mechanic and when to diy for air suspension leak repair. Common problems with air suspension. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air. How To Stop Air Suspension.

From www.youtube.com

Air suspension Fiat Bogie Air suspension system Explain How To Stop Air Suspension Diagnose common problems like air leaks and ride height sensor faults. Common problems with air suspension. Repair failed components like compressors and valves. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. Save money and get the job done right with this comprehensive guide. Despite their benefits, air suspension. How To Stop Air Suspension.

From www.rangerovers.net

Air Suspension Diagnosis Range Rovers Forum How To Stop Air Suspension If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Diagnose common problems like air leaks and ride height sensor faults. Repair failed components like compressors and valves. Critically inspect the air. How To Stop Air Suspension.

From wroffroad.co.za

Air Suspension WR Off Road Industries How To Stop Air Suspension Diagnose common problems like air leaks and ride height sensor faults. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Should an air line break, get your car or truck on. How To Stop Air Suspension.

From blog.blueinktech.com

How to Change an Air Bag on an Air Suspension for a Tractor Trailer How To Stop Air Suspension Learn when to call a mechanic and when to diy for air suspension leak repair. Should an air line break, get your car or truck on some kind of stands to keep it steady. Common problems with air suspension. Diagnose common problems like air leaks and ride height sensor faults. Critically inspect the air suspension strut or shock absorber for. How To Stop Air Suspension.

From rustyautos.com

Air Suspension Not Working? Try These Simple DIY Fixes First How To Stop Air Suspension Learn when to call a mechanic and when to diy for air suspension leak repair. Diagnose common problems like air leaks and ride height sensor faults. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Common problems with air suspension. Save money and get the job done right with this. How To Stop Air Suspension.

From www.youtube.com

Mercedes Airmatic Suspension Fault Step By Step DIY Diagnostic YouTube How To Stop Air Suspension Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. Repair failed components like compressors and valves. Learn when to call a mechanic and when to diy for air suspension leak repair. Save money and get the job done right with this comprehensive guide. These problems can include air leaks,. How To Stop Air Suspension.

From rangeroverfanatic.com

How To Reset Air Suspension On A Range Rover Fault Reset How To Stop Air Suspension These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Save money and get the job done right with this comprehensive guide. Learn when to call a mechanic and when to diy for air suspension leak repair. Repair failed components like compressors and valves. If you're daily driving your rig, or. How To Stop Air Suspension.

From foreignaffairsauto.com

Tips to Prevent Air Suspension Failure in Your Mercedes Foreign How To Stop Air Suspension Common problems with air suspension. Save money and get the job done right with this comprehensive guide. Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. These problems can include air leaks, compressor failure, worn or damaged air springs, faulty height sensors, and system inconsistency. Diagnose common problems like air leaks and ride height. How To Stop Air Suspension.

From exomfohsc.blob.core.windows.net

How To Remove Air Ride Suspension at Dana Mysliwiec blog How To Stop Air Suspension Despite their benefits, air suspension systems can encounter several problems that require diagnosis and repair. Critically inspect the air suspension strut or shock absorber for function and oil leakage when replacing a leaking air spring. Should an air line break, get your car or truck on some kind of stands to keep it steady. Repair failed components like compressors and. How To Stop Air Suspension.

From discover.hubpages.com

Car Air Suspension How It Works HubPages How To Stop Air Suspension Diagnose common problems like air leaks and ride height sensor faults. If you're daily driving your rig, or even if you're cruising it out to a big show, bring some spare air line and a few union tube connector fittings, some air line and an air line cutter tool. Learn when to call a mechanic and when to diy for. How To Stop Air Suspension.