Mould Filling Time Formula . 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. Time needed by a melt to completely fill the mold cavity. T = casting time in s v = casting. The optimal filling time depends on the speed of flow of the molten metal. The casting time for filling the mold cavity can be calculated according to the following eq. The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected by the following factors: Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. Molders use several methods to establish a fill time, some of which begin with one of the following methods: This mostly varies within the gating channels and the mold.

from www.chegg.com

Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The optimal filling time depends on the speed of flow of the molten metal. T = casting time in s v = casting. Time needed by a melt to completely fill the mold cavity. Molders use several methods to establish a fill time, some of which begin with one of the following methods: This mostly varies within the gating channels and the mold. 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected by the following factors: The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. The casting time for filling the mold cavity can be calculated according to the following eq.

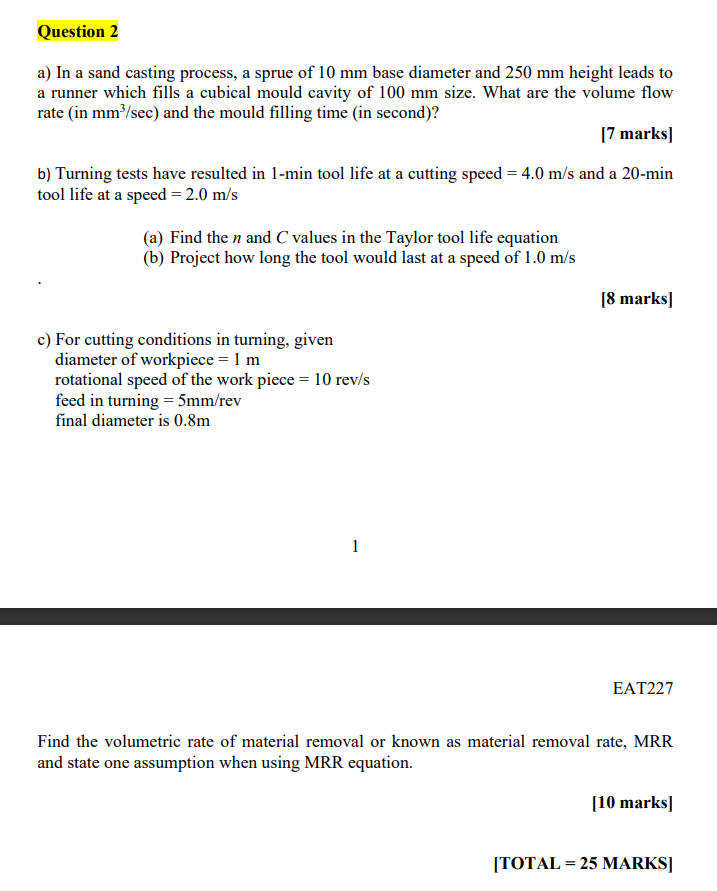

Solved Question 2 a) In a sand casting process, a sprue of

Mould Filling Time Formula T = casting time in s v = casting. The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. Time needed by a melt to completely fill the mold cavity. The optimal filling time depends on the speed of flow of the molten metal. The casting time for filling the mold cavity can be calculated according to the following eq. 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. Molders use several methods to establish a fill time, some of which begin with one of the following methods: T = casting time in s v = casting. This mostly varies within the gating channels and the mold. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected by the following factors:

From www.researchgate.net

Comparison of the mold filling between the experiments and the Mould Filling Time Formula Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected by the following factors: The optimal filling time depends on the speed of flow. Mould Filling Time Formula.

From www.chegg.com

1. The calculation formulas of mold size can be given Mould Filling Time Formula Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The casting time for filling the mold cavity can be calculated according to the following eq. This mostly varies within the gating channels and the mold. T = casting time in s v = casting. The mold filling time. Mould Filling Time Formula.

From www.youtube.com

Optimizing Injection Molding Cycle Time Using Simulation|Intro YouTube Mould Filling Time Formula Molders use several methods to establish a fill time, some of which begin with one of the following methods: Time needed by a melt to completely fill the mold cavity. This mostly varies within the gating channels and the mold. 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. T = casting time in s v =. Mould Filling Time Formula.

From www.youtube.com

Resin Transfer Moulding Flow Modelling Calculating the Mould Mould Filling Time Formula The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. The casting time for filling the mold cavity can be calculated according to the following eq. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. This mostly varies within. Mould Filling Time Formula.

From www.youtube.com

Mould filling time calculation by Shubham NITW YouTube Mould Filling Time Formula The optimal filling time depends on the speed of flow of the molten metal. T = casting time in s v = casting. Molders use several methods to establish a fill time, some of which begin with one of the following methods: Time needed by a melt to completely fill the mold cavity. Establishing optimum fill time one of the. Mould Filling Time Formula.

From www.chegg.com

Solved Question 2 a) In a sand casting process, a sprue of Mould Filling Time Formula Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. The time required for filling the molten metal into the mold cavity under the pressure until is full is the. Mould Filling Time Formula.

From www.zhycasting.com

Mold filling simulation process and analysis of lost foam casting Mould Filling Time Formula 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. The casting time for filling the mold cavity can be calculated according to the following eq. The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected by the following factors: The optimal filling. Mould Filling Time Formula.

From www.engineerknow.com

Time take to fill Bottom Gating Casting formula derivation Mould Filling Time Formula 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. This mostly varies within the gating channels and the mold. Time needed by a melt to completely fill the mold cavity. Molders use several methods to establish a fill time, some of which begin with one of the following methods: The casting time for filling the mold cavity. Mould Filling Time Formula.

From www.tainstruments.com

Evaluation Of The Loss Of Polymer Strength And Durability Due To Mould Filling Time Formula Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The casting time for filling the mold cavity can be calculated according to the following eq. The optimal filling time depends on the speed of flow of the molten metal. Time needed by a melt to completely fill the. Mould Filling Time Formula.

From www.procad-tech.com

mold filling analysis Mould Filling Time Formula Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. Time needed by a melt to completely fill the mold cavity. Molders use several methods to establish a fill time, some of which begin with one of the following methods: The time required for filling the molten metal into. Mould Filling Time Formula.

From www.numerade.com

SOLVED A mould having dimensions 100 mm x 90 mm x 20 mm is filled with Mould Filling Time Formula This mostly varies within the gating channels and the mold. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. Time needed by a melt to completely fill the mold cavity. Molders use several methods to establish a fill time, some of which begin with one of the following. Mould Filling Time Formula.

From www.researchgate.net

Plots of phase contours at different mold filling times. Download Mould Filling Time Formula Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The casting time for filling the mold cavity can be calculated according to the following eq. Molders use several methods to establish a fill time, some of which begin with one of the following methods: T = casting time. Mould Filling Time Formula.

From www.zhycasting.com

Mold filling and solidification simulation of lost foam casting process Mould Filling Time Formula Time needed by a melt to completely fill the mold cavity. The optimal filling time depends on the speed of flow of the molten metal. The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected by the following factors: T = casting time in s. Mould Filling Time Formula.

From www.youtube.com

9 Solved Question for Mould Filling Time with Friction Losses Mould Filling Time Formula The casting time for filling the mold cavity can be calculated according to the following eq. The optimal filling time depends on the speed of flow of the molten metal. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. This mostly varies within the gating channels and the. Mould Filling Time Formula.

From www.youtube.com

How to calculate injection molding cycle times. YouTube Mould Filling Time Formula The optimal filling time depends on the speed of flow of the molten metal. The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. Time needed by a melt to completely fill the mold cavity. The casting time for filling the mold cavity can be calculated according to the following eq.. Mould Filling Time Formula.

From www.giessereilexikon.com

Mold filling time Mould Filling Time Formula 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. The optimal filling time depends on the speed of flow of the molten metal. T = casting time in s v = casting. This mostly varies within the gating channels and the mold. The casting time for filling the mold cavity can be calculated according to the following. Mould Filling Time Formula.

From www.chegg.com

Solved Calculate the time to fill the mold, as depicted Mould Filling Time Formula The casting time for filling the mold cavity can be calculated according to the following eq. Molders use several methods to establish a fill time, some of which begin with one of the following methods: This mostly varies within the gating channels and the mold. 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. Time needed by. Mould Filling Time Formula.

From www.chegg.com

Solved In a sand casting process, molten metal is poured Mould Filling Time Formula T = casting time in s v = casting. 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. The casting time for filling the mold cavity can be calculated according to the following eq. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The optimal. Mould Filling Time Formula.

From fimmtech.com

Tech Articles Resources for Scientific Molding and Scientific Processing Mould Filling Time Formula 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. T = casting time in s v = casting. This mostly varies within the gating channels and the mold. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The casting time for filling the mold cavity. Mould Filling Time Formula.

From www.grefeemold.com

The Calculation Formulas for Injection Molding grefee mold company Mould Filling Time Formula T = casting time in s v = casting. 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. This mostly varies within the gating channels and the mold. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The mold filling time needs to be known. Mould Filling Time Formula.

From www.youtube.com

Mold filling time and runner system design in Metal casting YouTube Mould Filling Time Formula The optimal filling time depends on the speed of flow of the molten metal. This mostly varies within the gating channels and the mold. The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. Establishing optimum fill time one of the important process parameters to establish and record for any injection. Mould Filling Time Formula.

From www.zhycasting.com

Analysis of mold filling process of sand castings ZHY Casting Mould Filling Time Formula This mostly varies within the gating channels and the mold. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The casting time for filling the mold cavity can be calculated according to the following eq. Time needed by a melt to completely fill the mold cavity. 1. clamping. Mould Filling Time Formula.

From www.youtube.com

HOW TO CALCULATE COOLING TIME IN PLASTIC INJECTION MOLD COOLING TIME Mould Filling Time Formula Molders use several methods to establish a fill time, some of which begin with one of the following methods: The casting time for filling the mold cavity can be calculated according to the following eq. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The mold filling time. Mould Filling Time Formula.

From www.youtube.com

Moldflow Analysis Fill Time MoldMan Systems™ YouTube Mould Filling Time Formula The casting time for filling the mold cavity can be calculated according to the following eq. Time needed by a melt to completely fill the mold cavity. This mostly varies within the gating channels and the mold. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The mold. Mould Filling Time Formula.

From www.youtube.com

Metal Casting Example Problem Mold filling time calculation YouTube Mould Filling Time Formula The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. The casting time for filling the mold cavity can be calculated according to the following eq. The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected. Mould Filling Time Formula.

From www.youtube.com

4 Casting Mould Filling Time Side Filling Case YouTube Mould Filling Time Formula Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. Time needed by a melt to completely fill the mold cavity. Molders use several methods to establish a fill time, some of which begin with one of the following methods: The mold filling time needs to be known in. Mould Filling Time Formula.

From www.researchgate.net

Comparison of mold filling time and solidification time Download Table Mould Filling Time Formula The casting time for filling the mold cavity can be calculated according to the following eq. 1. clamping force f(ton) formula: f=am*pv/1000 namely: clamping tonnage= cavity projected area*filling. T = casting time in s v = casting. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. Molders use. Mould Filling Time Formula.

From www.youtube.com

Moldflow simulation tutorial. Autodesk Moldflow Insight. Balancing fill Mould Filling Time Formula Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The casting time for filling the mold cavity can be calculated according to the following eq. Molders use several methods to establish a fill time, some of which begin with one of the following methods: Time needed by a. Mould Filling Time Formula.

From www.linkedin.com

Plastic mold fill time 35 seconds vs mold speed Mold Solutions doo Mould Filling Time Formula The casting time for filling the mold cavity can be calculated according to the following eq. This mostly varies within the gating channels and the mold. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The time required for filling the molten metal into the mold cavity under. Mould Filling Time Formula.

From www.youtube.com

How to calculate Cooling Time in injection Moulding I Cooling Time Mould Filling Time Formula The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected by the following factors: Molders use several methods to establish a fill time, some of which begin with one of the following methods: Establishing optimum fill time one of the important process parameters to establish. Mould Filling Time Formula.

From www.youtube.com

Numerical Estimation To Find Mold Filling Time and Mold Design YouTube Mould Filling Time Formula The casting time for filling the mold cavity can be calculated according to the following eq. The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The optimal filling time. Mould Filling Time Formula.

From 112.220.220.19

Fig. 7. Comparison of mold filling times for a plate pattern with three Mould Filling Time Formula Establishing optimum fill time one of the important process parameters to establish and record for any injection molded part is its. The casting time for filling the mold cavity can be calculated according to the following eq. The mold filling time needs to be known in order be able to mathematically design a casting system, i.e. T = casting time. Mould Filling Time Formula.

From www.coursehero.com

[Solved] A mold sprue is 25 cm long, and the crosssectional area at Mould Filling Time Formula T = casting time in s v = casting. The casting time for filling the mold cavity can be calculated according to the following eq. The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected by the following factors: The optimal filling time depends on. Mould Filling Time Formula.

From www.slideserve.com

PPT IE 337 Materials & Manufacturing Processes PowerPoint Mould Filling Time Formula The time required for filling the molten metal into the mold cavity under the pressure until is full is the filling time, which is affected by the following factors: This mostly varies within the gating channels and the mold. Time needed by a melt to completely fill the mold cavity. The mold filling time needs to be known in order. Mould Filling Time Formula.

From www.chegg.com

B5. Mold design is shown in the figure, please answer Mould Filling Time Formula Time needed by a melt to completely fill the mold cavity. This mostly varies within the gating channels and the mold. The casting time for filling the mold cavity can be calculated according to the following eq. The optimal filling time depends on the speed of flow of the molten metal. The mold filling time needs to be known in. Mould Filling Time Formula.