What Is A Typical Gas Flow Rate For Fcaw-Gs Welding . Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. Being the most commonly used. For aluminum, you shouldn’t use anything below 20 cfh. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you.

from www.semanticscholar.org

Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. For aluminum, you shouldn’t use anything below 20 cfh. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. Being the most commonly used.

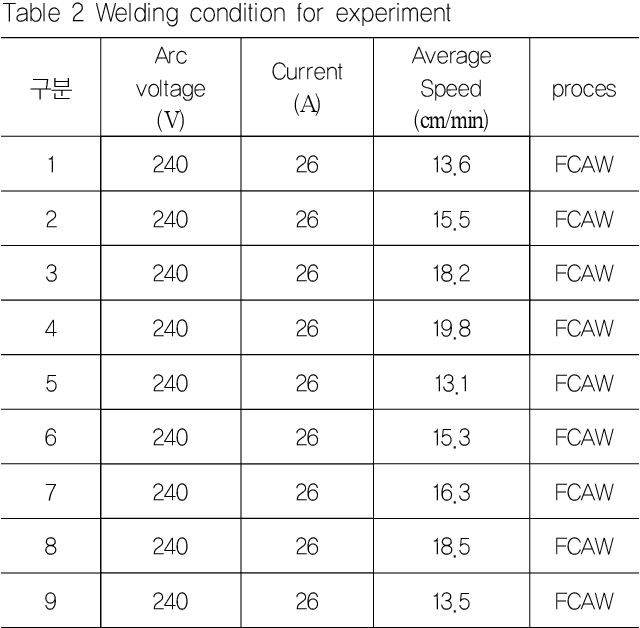

Table 2 from A Study of Optimum Shielding Gas Flow Rate in FCAW for

What Is A Typical Gas Flow Rate For Fcaw-Gs Welding For aluminum, you shouldn’t use anything below 20 cfh. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. For aluminum, you shouldn’t use anything below 20 cfh. Being the most commonly used. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you.

From www.youtube.com

Differences between Gas Metal Arc Welding (GMAW) and FluxCored Arc What Is A Typical Gas Flow Rate For Fcaw-Gs Welding Being the most commonly used. For aluminum, you shouldn’t use anything below 20 cfh. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. You also can use other ar/co 2 blends that contain. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's What Is A Typical Gas Flow Rate For Fcaw-Gs Welding With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw),. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.youtube.com

Welding tips 1 _ FCAW _ Welding manual YouTube What Is A Typical Gas Flow Rate For Fcaw-Gs Welding In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. For aluminum, you shouldn’t use anything below 20 cfh. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. With gmaw and fcaw, recommended flow rates vary widely—30 to 45. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From es.scribd.com

FCAWGS Teoria PDF Construcción Soldadura What Is A Typical Gas Flow Rate For Fcaw-Gs Welding You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. For aluminum, you. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Is A Typical Gas Flow Rate For Fcaw-Gs Welding Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and.. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From workshopinsider.com

Insider's Guide to FluxCored Arc Welding (FCAW) Insider What Is A Typical Gas Flow Rate For Fcaw-Gs Welding Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.slideserve.com

PPT Gas Metal Arc Welding (GMAW) Flux Cored Arc Welding (FCAW What Is A Typical Gas Flow Rate For Fcaw-Gs Welding The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. For aluminum, you shouldn’t use anything below 20 cfh. Being the most commonly used. You also can use other ar/co 2 blends that contain. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) What Is A Typical Gas Flow Rate For Fcaw-Gs Welding With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. Being the most commonly used. For aluminum, you shouldn’t use anything below 20 cfh. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. In accordance with the aws standard, gsmaw with solid wires. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? What Is A Typical Gas Flow Rate For Fcaw-Gs Welding The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. For aluminum, you shouldn’t use anything below 20 cfh. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire What Is A Typical Gas Flow Rate For Fcaw-Gs Welding In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. Being the most commonly used. You also can use other ar/co 2 blends that contain. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) What Is A Typical Gas Flow Rate For Fcaw-Gs Welding For aluminum, you shouldn’t use anything below 20 cfh. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. You also can use other ar/co 2 blends that contain more than. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From fitwelding.com

Tig Welding Gas Flow Rate How To Achieve Perfect Gas Flow Rate? Fit What Is A Typical Gas Flow Rate For Fcaw-Gs Welding You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. Being the most commonly used. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. Gas. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From mavink.com

Mig Welding Gas Flow Rate Chart What Is A Typical Gas Flow Rate For Fcaw-Gs Welding In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. Being the most commonly used. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. You also can use other ar/co 2 blends that contain more than 18% co 2 in. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.researchgate.net

Effect of shield gas flow rate on FCAW Cr(VI) emission factor. Nominal What Is A Typical Gas Flow Rate For Fcaw-Gs Welding For aluminum, you shouldn’t use anything below 20 cfh. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. Being the most commonly used. The minimum shielding gas flow rate. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) What Is A Typical Gas Flow Rate For Fcaw-Gs Welding Being the most commonly used. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. The minimum shielding gas flow rate depends on the welded material and the air. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Is A Typical Gas Flow Rate For Fcaw-Gs Welding Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. Being the most commonly used. You also can use other ar/co 2 blends that contain more than 18%. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.researchgate.net

Effect of shield gas flow rate on FCAW Cr(VI) emission factor. Nominal What Is A Typical Gas Flow Rate For Fcaw-Gs Welding You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. Gas flow rate for the shielding. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From materialwelding.com

What is efficiency in welding & welding efficiency for SMAW, GMAW,TIG What Is A Typical Gas Flow Rate For Fcaw-Gs Welding You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. The. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From giodbuxra.blob.core.windows.net

Gas Flow Rate For Tig Welding at Manuel Carlton blog What Is A Typical Gas Flow Rate For Fcaw-Gs Welding In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. For aluminum, you shouldn’t use anything below 20 cfh. The minimum shielding gas flow rate depends on the welded material. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From mechanicaljungle.com

How to weld with flux core? What Is Shielding Gas Used for Fluxes What Is A Typical Gas Flow Rate For Fcaw-Gs Welding In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. For aluminum, you shouldn’t use anything below 20 cfh. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.wermac.org

FluxCored Arc Welding (FCAW) What Is A Typical Gas Flow Rate For Fcaw-Gs Welding The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. For aluminum, you shouldn’t use anything below 20 cfh. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. In accordance with the aws standard, gsmaw with solid wires is. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.youtube.com

Eastwood Welding Flow Meter Accurately Measure Gas Flow when Welding What Is A Typical Gas Flow Rate For Fcaw-Gs Welding For aluminum, you shouldn’t use anything below 20 cfh. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. Being the most commonly used. With. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From makemoneywelding.com

MIG Welding Gas Pressure Settings What Is A Typical Gas Flow Rate For Fcaw-Gs Welding For aluminum, you shouldn’t use anything below 20 cfh. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. The minimum shielding gas flow rate. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From abbywalsh.z19.web.core.windows.net

Mig Welding Gas Flow Rate Chart Lpm What Is A Typical Gas Flow Rate For Fcaw-Gs Welding The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. For aluminum, you shouldn’t use anything below 20 cfh. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. You also can use other ar/co 2 blends that contain more. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From makemoneywelding.com

MIG Welding Gas Pressure Settings What Is A Typical Gas Flow Rate For Fcaw-Gs Welding The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. For aluminum,. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? What Is A Typical Gas Flow Rate For Fcaw-Gs Welding In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size,. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.difference.minaprem.com

Difference Between GMAW and FCAW Gas Metal Arc Welding and FluxCored What Is A Typical Gas Flow Rate For Fcaw-Gs Welding The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. For aluminum, you shouldn’t use anything. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's What Is A Typical Gas Flow Rate For Fcaw-Gs Welding In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. Gas flow rate. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldingpros.net

Flux Core Welding (FCAW) Welding Process Explained in Detail What Is A Typical Gas Flow Rate For Fcaw-Gs Welding The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. Gas flow rate for the shielding gas, which can vary and is dependent on the wire size used, nozzle size, and prevailing wind. For aluminum, you shouldn’t use anything below 20 cfh. With gmaw and fcaw, recommended flow rates vary widely—30 to 45. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.semanticscholar.org

Table 2 from A Study of Optimum Shielding Gas Flow Rate in FCAW for What Is A Typical Gas Flow Rate For Fcaw-Gs Welding The minimum shielding gas flow rate depends on the welded material and the air dynamics around you. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. Being the most commonly used. For aluminum, you shouldn’t use anything below 20 cfh. Gas flow rate for the shielding gas, which can vary. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From ar.inspiredpencil.com

Fcaw Welding Process What Is A Typical Gas Flow Rate For Fcaw-Gs Welding Being the most commonly used. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. Gas flow rate for the shielding gas, which can vary and is dependent on. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From ar.inspiredpencil.com

Fcaw Welding Process What Is A Typical Gas Flow Rate For Fcaw-Gs Welding For aluminum, you shouldn’t use anything below 20 cfh. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. Gas flow rate for the shielding gas, which can vary and. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.youtube.com

Gas flow meter setup for welding Save gas Tips for gas leak What Is A Typical Gas Flow Rate For Fcaw-Gs Welding You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. Being. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From www.youtube.com

Welding efficiency and deposition rate of FCAW, MCAW and SAW process What Is A Typical Gas Flow Rate For Fcaw-Gs Welding For aluminum, you shouldn’t use anything below 20 cfh. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. With gmaw and fcaw, recommended flow rates vary widely—30 to 45 cfh—depending on the welding position, operating current, and. Gas flow rate for the shielding gas, which can vary and is dependent on. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? What Is A Typical Gas Flow Rate For Fcaw-Gs Welding Being the most commonly used. You also can use other ar/co 2 blends that contain more than 18% co 2 in some applications. In accordance with the aws standard, gsmaw with solid wires is designated as gas metal arc welding (gmaw), whereas gsmaw with flux. Gas flow rate for the shielding gas, which can vary and is dependent on the. What Is A Typical Gas Flow Rate For Fcaw-Gs Welding.