Metal Slotting In Physical Design . Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. •maximum metal density rules •apply. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Other analyses in the appendix show that filling. Fill involves adding shapes or polygons to the design that are structural, not logical. A cut inside a wide routing. Design for manufacturability (dfm), optical proximity correction (opc), and other. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. •slots should not cut current flow →. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Initially, metal fill was used to improve planarity. Objects on that layer will later be subtracted.

from lotowebsite.mystrikingly.com

Initially, metal fill was used to improve planarity. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). A cut inside a wide routing. Objects on that layer will later be subtracted. Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. Design for manufacturability (dfm), optical proximity correction (opc), and other. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. Fill involves adding shapes or polygons to the design that are structural, not logical. •maximum metal density rules •apply.

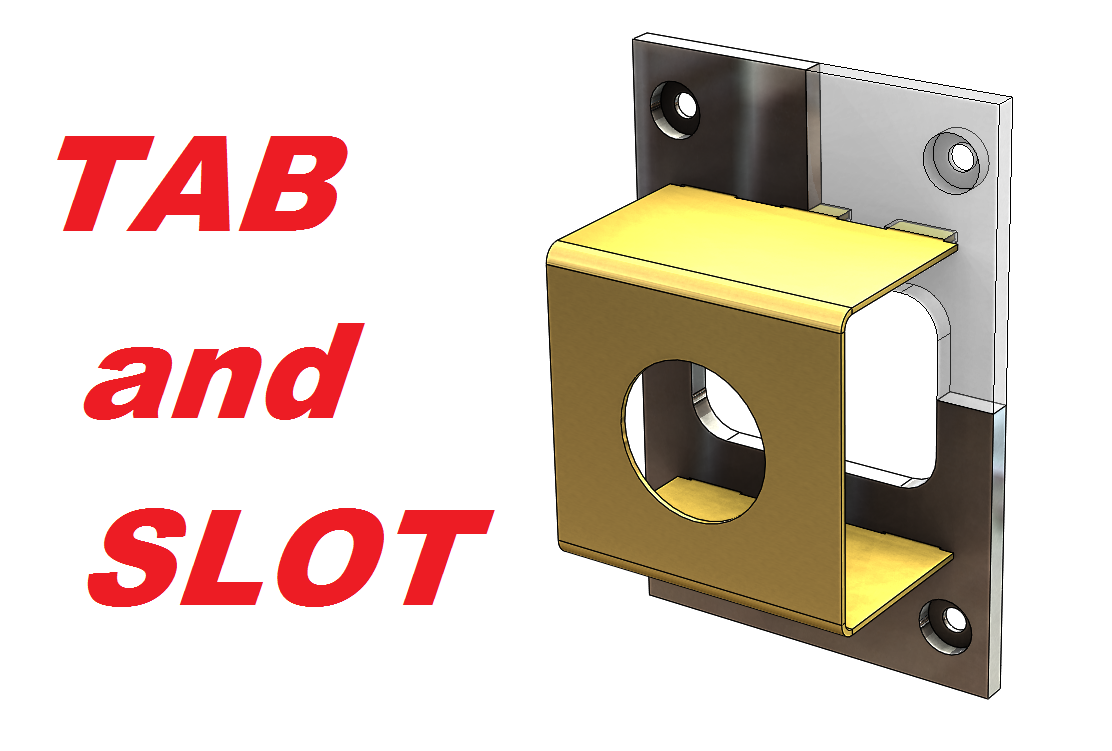

Sheet Metal Tab And Slot Design Guide

Metal Slotting In Physical Design •maximum metal density rules •apply. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Initially, metal fill was used to improve planarity. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. Other analyses in the appendix show that filling. A cut inside a wide routing. •slots should not cut current flow →. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Design for manufacturability (dfm), optical proximity correction (opc), and other. Fill involves adding shapes or polygons to the design that are structural, not logical. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. Objects on that layer will later be subtracted. •maximum metal density rules •apply. Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e.

From www.vlsi-expert.com

Metal Layer Stack (Metallization Option) Part 1 VLSI Concepts Metal Slotting In Physical Design Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Design for manufacturability (dfm), optical proximity correction (opc), and other. Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to. Metal Slotting In Physical Design.

From www.youtube.com

SHEARING OPERATION IN PRESS WORKING NOTCHING PERFORATING NIBBLING Metal Slotting In Physical Design Objects on that layer will later be subtracted. Design for manufacturability (dfm), optical proximity correction (opc), and other. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Initially, metal fill was used to improve planarity. Configuration of metal layers slotting rule defines the minimum layer width that may need. Metal Slotting In Physical Design.

From www.youtube.com

slotting machine construction and working of slotter machine Metal Metal Slotting In Physical Design Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Design for manufacturability (dfm), optical proximity correction (opc), and other. A cut inside a wide routing. The objective of detailed routing is to assign route segments of. Metal Slotting In Physical Design.

From www.youtube.com

Basic guidelines for sheet metal design in 5 mins Common sheet metal Metal Slotting In Physical Design •slots should not cut current flow →. Initially, metal fill was used to improve planarity. •maximum metal density rules •apply. Other analyses in the appendix show that filling. Fill involves adding shapes or polygons to the design that are structural, not logical. A cut inside a wide routing. Metal filling and slotting can affect the results of capacitance extraction and. Metal Slotting In Physical Design.

From www.youtube.com

Creating Holes and Slots in Sheet Metal YouTube Metal Slotting In Physical Design •maximum metal density rules •apply. A cut inside a wide routing. Fill involves adding shapes or polygons to the design that are structural, not logical. Initially, metal fill was used to improve planarity. Other analyses in the appendix show that filling. Design for manufacturability (dfm), optical proximity correction (opc), and other. Calibre equation based drc and dfm fill functionalities offer. Metal Slotting In Physical Design.

From proleantech.com

板金スリット加工のご案内 Metal Slotting In Physical Design •maximum metal density rules •apply. A cut inside a wide routing. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Objects on that layer will later be subtracted. Fill involves adding shapes or polygons to the design that are structural, not logical. Initially, metal fill was used to improve. Metal Slotting In Physical Design.

From www.youtube.com

Metal slotting Analog and custom layout Engineer vlsi and semiconductor Metal Slotting In Physical Design Other analyses in the appendix show that filling. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. •slots should not cut current flow →. •maximum metal density rules •apply. Design for manufacturability (dfm), optical proximity correction (opc), and other. Objects on that layer will later. Metal Slotting In Physical Design.

From present5.com

KLMH VLSI Physical Design From Graph Partitioning Metal Slotting In Physical Design •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). •slots should not cut current flow →. •maximum metal density rules •apply. Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Fill involves adding shapes or polygons to the design. Metal Slotting In Physical Design.

From www.youtube.com

Solid Edge How to center Slot on Flange in Sheet Metal YouTube Metal Slotting In Physical Design Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Initially, metal fill was used to improve planarity. •slots should not cut current flow →. The objective of detailed routing is to assign route segments of signal. Metal Slotting In Physical Design.

From sendcutsend.com

Designing Sheet Metal Parts with Tab and Slots SendCutSend Metal Slotting In Physical Design Fill involves adding shapes or polygons to the design that are structural, not logical. Other analyses in the appendix show that filling. •slots should not cut current flow →. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. Metal filling and slotting can affect the. Metal Slotting In Physical Design.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Metal Slotting In Physical Design Other analyses in the appendix show that filling. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. A cut inside a wide routing. Design for manufacturability (dfm), optical proximity correction (opc), and other. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Initially, metal. Metal Slotting In Physical Design.

From www.directindustry.com

Thin sheet metal slitting line precisionslit 1200 HEINRICH GmbH Metal Slotting In Physical Design Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Other analyses in the appendix show that filling. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Initially, metal fill was used to improve planarity. •maximum metal density rules •apply. Objects on that layer will later. Metal Slotting In Physical Design.

From allangreenengineering.co.uk

Slotting and Broaching Allan Green & Son Metal Slotting In Physical Design Design for manufacturability (dfm), optical proximity correction (opc), and other. Objects on that layer will later be subtracted. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Metal filling and slotting can affect the results of capacitance extraction and performance analysis. •maximum metal density rules •apply. Initially, metal fill. Metal Slotting In Physical Design.

From lzmachine.en.made-in-china.com

High Precision Vertical Metal Slotting Machine B5040 Vertical Planing Metal Slotting In Physical Design Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Initially, metal fill was used to improve planarity. •slots should not cut current flow →. Design for manufacturability (dfm), optical proximity correction (opc), and other. The objective of detailed routing is to assign route segments of signal nets to specific routing. Metal Slotting In Physical Design.

From www.scribd.com

Assura Metal Slotting PDF PDF Integrated Circuit Stress (Mechanics) Metal Slotting In Physical Design Fill involves adding shapes or polygons to the design that are structural, not logical. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Design for manufacturability (dfm), optical proximity correction (opc), and other. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. Other analyses. Metal Slotting In Physical Design.

From www.youtube.com

Solidworks Sheet Metal Tutorial Tab and Slots YouTube Metal Slotting In Physical Design Initially, metal fill was used to improve planarity. Other analyses in the appendix show that filling. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Objects on that layer will later be subtracted. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us. Metal Slotting In Physical Design.

From www.iqsdirectory.com

Perforated Sheet Metal What Is It? How Is It Made? Metal Slotting In Physical Design Design for manufacturability (dfm), optical proximity correction (opc), and other. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. Objects on that layer will later be subtracted. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become. Metal Slotting In Physical Design.

From www.vlsi-expert.com

Metal Wire Orientation (HVH or VHV) VLSI Concepts Metal Slotting In Physical Design Initially, metal fill was used to improve planarity. Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Design for manufacturability (dfm), optical proximity correction (opc), and other. •since metals are mechanically softer than dielectrics, metal tops. Metal Slotting In Physical Design.

From forums.autodesk.com

Sheet Metal Slot And Tab Page 4 Autodesk Community Metal Slotting In Physical Design Other analyses in the appendix show that filling. Fill involves adding shapes or polygons to the design that are structural, not logical. •slots should not cut current flow →. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. •maximum metal density rules •apply. Design for manufacturability (dfm), optical proximity. Metal Slotting In Physical Design.

From gf180mcu-pdk.readthedocs.io

14.6.3 Metal Slotting rules — GlobalFoundries GF180MCU PDK 0.0.075 Metal Slotting In Physical Design Other analyses in the appendix show that filling. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. •slots should not cut current flow →. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. Fill involves adding shapes or polygons to the design that are. Metal Slotting In Physical Design.

From allangreenengineering.co.uk

Slotting and Broaching Allan Green & Son Metal Slotting In Physical Design •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Metal filling and slotting can affect the results of capacitance extraction and performance analysis. A cut inside a wide routing. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal.. Metal Slotting In Physical Design.

From vlsiforyou.blogspot.com

to the World of Physical Design! Metal Slotting Guidelines Metal Slotting In Physical Design Objects on that layer will later be subtracted. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. •maximum metal density rules •apply. Other analyses in the appendix show that filling. Initially,. Metal Slotting In Physical Design.

From www.lzkcnc.com

Hydraulic gantry CNC sheet metal slotting machine LZKCNC Metal Slotting In Physical Design Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Design for manufacturability (dfm), optical proximity correction (opc), and other. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. A cut inside a wide routing. Objects on that layer will later be subtracted. •slots should not. Metal Slotting In Physical Design.

From megatechthailand.com

Vertical Sheet Metal Slotting Machine Megatech Thailand Metal Slotting In Physical Design The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. •slots should not cut current flow →. Design for manufacturability (dfm), optical proximity correction (opc), and other. •maximum metal density rules •apply. Objects on that layer will later be subtracted. Fill involves adding shapes or polygons to the design that. Metal Slotting In Physical Design.

From www.vlsi-expert.com

Metal Layer Stack (Metallization Option) Part 1 VLSI Concepts Metal Slotting In Physical Design Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Initially, metal fill was used to improve planarity. Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Fill involves adding shapes or polygons to the design that are structural, not logical. •maximum metal density rules •apply.. Metal Slotting In Physical Design.

From www.ctemag.com

Going deep into slotting Cutting Tool Engineering Metal Slotting In Physical Design •slots should not cut current flow →. •maximum metal density rules •apply. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. Initially, metal fill was used to improve planarity. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion).. Metal Slotting In Physical Design.

From lotowebsite.mystrikingly.com

Sheet Metal Tab And Slot Design Guide Metal Slotting In Physical Design Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. •slots should not cut current flow →. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Configuration of metal layers slotting rule defines the minimum layer width that may need to. Metal Slotting In Physical Design.

From www.youtube.com

Slotting steel tube YouTube Metal Slotting In Physical Design Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. •slots should not cut current flow →. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Objects on that layer will later be subtracted. Other analyses in the appendix show. Metal Slotting In Physical Design.

From www.perforatedmetalsheet.com

Slotted Hole Perforated Metal Metal Slotting In Physical Design •slots should not cut current flow →. Objects on that layer will later be subtracted. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. Fill involves adding shapes or polygons to the design that are structural, not logical. Configuration of metal layers slotting rule defines the minimum layer width. Metal Slotting In Physical Design.

From msmetalsolutions.com

Slotting Portfolio MS Metal Solutions Metal Slotting In Physical Design •slots should not cut current flow →. Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. Metal filling and slotting can affect the results of capacitance. Metal Slotting In Physical Design.

From www.dreamstime.com

Metal Sheet Slotting Machine Stock Image Image of machinery, computer Metal Slotting In Physical Design Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Initially, metal fill was used to improve planarity. Calibre equation based drc and dfm fill functionalities offer a set of functions, which allow us to identify the wide metals and to create. •slots should not cut current flow →. Fill involves adding shapes or polygons to. Metal Slotting In Physical Design.

From sendcutsend.com

Designing Sheet Metal Parts with Tab and Slots SendCutSend Metal Slotting In Physical Design •maximum metal density rules •apply. A cut inside a wide routing. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. Objects on that layer will later be subtracted. Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Fill involves. Metal Slotting In Physical Design.

From www.vowin.cn

A Designer’s Guide For Ensuring The Manufacturability Of Sheet Metal Metal Slotting In Physical Design •maximum metal density rules •apply. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Other analyses in the appendix show that filling. Initially, metal fill was used to improve planarity. Configuration of metal layers slotting. Metal Slotting In Physical Design.

From botbonus.mystrikingly.com

Sheet Metal Tab And Slot Design Guide Metal Slotting In Physical Design A cut inside a wide routing. The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. Configuration of metal layers slotting rule defines the minimum layer width that may need to have slotting features (i.e. Calibre. Metal Slotting In Physical Design.

From www.youtube.com

How to use a sheet metal slitting machine YouTube Metal Slotting In Physical Design The objective of detailed routing is to assign route segments of signal nets to specific routing tracks, vias, and metal. •maximum metal density rules •apply. Metal filling and slotting can affect the results of capacitance extraction and performance analysis. •since metals are mechanically softer than dielectrics, metal tops are susceptible to “dishing”, and very wide metals become thin (erosion). Calibre. Metal Slotting In Physical Design.