Bearing Shaft Design . Steps in the shaft design are: The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Remarks this table is for. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Design of shafts and housings for optimum operation and performance. Surface of the shaft and housing bore. An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Any inaccuracy in the geometry of shafts or housings impairs the.

from maintenanceworld.com

Any inaccuracy in the geometry of shafts or housings impairs the. Steps in the shaft design are: Remarks this table is for. An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Design of shafts and housings for optimum operation and performance. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. Surface of the shaft and housing bore. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the.

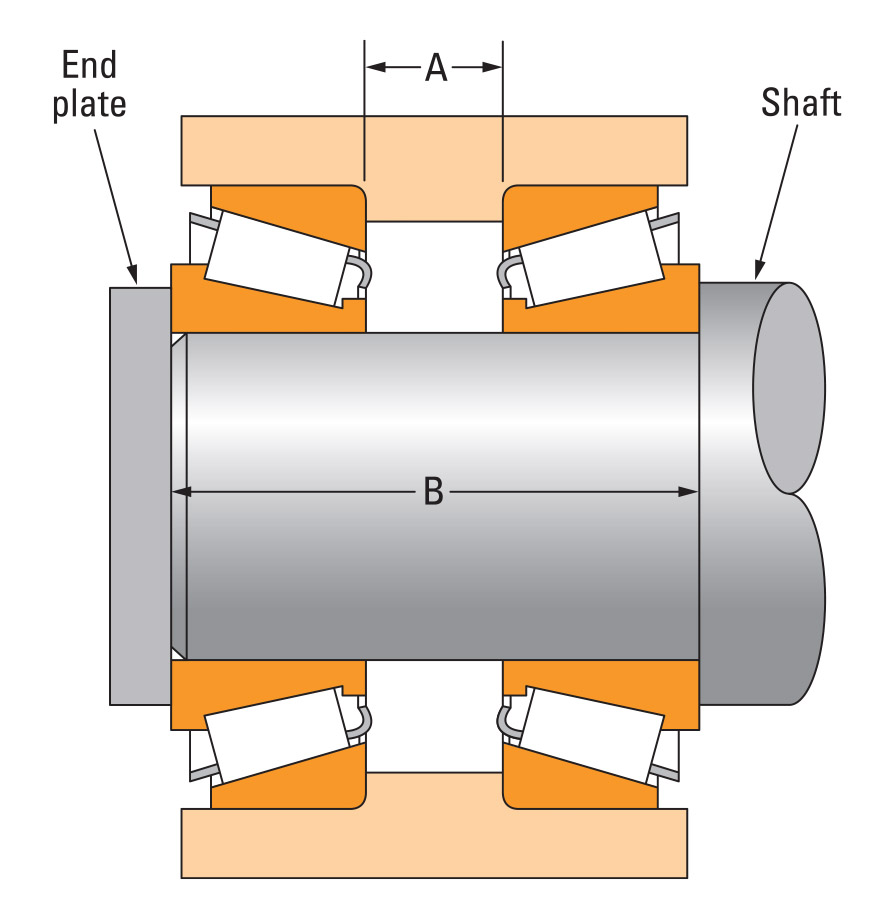

Setting Techniques for Tapered Roller Bearings Maintenance World

Bearing Shaft Design For this reason, it is necessary to pay attention to the following when designing shaft and housing: Surface of the shaft and housing bore. Steps in the shaft design are: Remarks this table is for. For this reason, it is necessary to pay attention to the following when designing shaft and housing: An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Design of shafts and housings for optimum operation and performance. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Any inaccuracy in the geometry of shafts or housings impairs the.

From www.chegg.com

Solved Problem Statement Design a Shaft to support the Bearing Shaft Design Surface of the shaft and housing bore. For this reason, it is necessary to pay attention to the following when designing shaft and housing: An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. Steps in the shaft design are: The accuracy and surface finish of shafts and housings are listed in. Bearing Shaft Design.

From www.skf.com

Typical shaftbearing combinations SKF Bearing Shaft Design Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Surface of the shaft and housing bore. Remarks this table is for. An. Bearing Shaft Design.

From slidingmotion.com

Ultimate Guide on What is Shaft Learn Types, Materials & Design Bearing Shaft Design Surface of the shaft and housing bore. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Design of shafts and housings for optimum operation and performance. An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. Generally, the optimal bearing must be selected. Bearing Shaft Design.

From www.researchgate.net

3 Diagram of Thrust Bearing Loading Mechanism Download Scientific Bearing Shaft Design The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Remarks this table is for. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Any inaccuracy in the geometry of shafts or housings impairs the. Generally, the. Bearing Shaft Design.

From www.eng-tips.com

Thrust Stand Design Bearing design, manufacture and maintenance Eng Bearing Shaft Design Steps in the shaft design are: Surface of the shaft and housing bore. Any inaccuracy in the geometry of shafts or housings impairs the. Remarks this table is for. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. The accuracy and surface finish of shafts. Bearing Shaft Design.

From www.skf.com

Arrangements and their bearing types SKF Bearing Shaft Design Remarks this table is for. Any inaccuracy in the geometry of shafts or housings impairs the. For this reason, it is necessary to pay attention to the following when designing shaft and housing: The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Surface of the. Bearing Shaft Design.

From www.researchgate.net

Schematic diagram of shaft bearing system under study with coordinate Bearing Shaft Design The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Surface of the shaft and housing bore. An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. Steps in the shaft design are: The accuracy and surface finish. Bearing Shaft Design.

From www.skf.com

Arrangements and their bearing types SKF Bearing Shaft Design Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Surface of the shaft and housing bore. Design of shafts and housings for optimum operation and performance. The seating surfaces. Bearing Shaft Design.

From slidingmotion.com

Complete Guide to Footstep Bearings Parts, Functions & Design Bearing Shaft Design The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Design of shafts and housings for optimum operation and performance. Surface of the shaft and housing bore. Remarks this table is for. An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. The seating. Bearing Shaft Design.

From www.researchgate.net

Schematic of the journal bearing and the end thrust bearing formed by Bearing Shaft Design Steps in the shaft design are: Remarks this table is for. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Design of shafts and housings for optimum operation. Bearing Shaft Design.

From www.chegg.com

Solved A design of a shaft with gears and bearings is Bearing Shaft Design Steps in the shaft design are: Design of shafts and housings for optimum operation and performance. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. Surface of the shaft and housing bore. An overall shaft design procedure is presented including consideration of bearing and component mounting. Bearing Shaft Design.

From medias.schaeffler.fr

Design of bearing arrangements Schaeffler medias Bearing Shaft Design Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. Any inaccuracy in the geometry of shafts or housings impairs the. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. An overall. Bearing Shaft Design.

From www.kugellager-express.de

Installation of axial ball bearings Bearing Shaft Design Remarks this table is for. Surface of the shaft and housing bore. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. The seating surfaces for the bearings must. Bearing Shaft Design.

From www.thomsonlinear.com

Bearing Shafts Thomson Thomson Bearing Shaft Design Steps in the shaft design are: For this reason, it is necessary to pay attention to the following when designing shaft and housing: Any inaccuracy in the geometry of shafts or housings impairs the. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Surface of. Bearing Shaft Design.

From maintenanceworld.com

Setting Techniques for Tapered Roller Bearings Maintenance World Bearing Shaft Design An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. Surface of the shaft and housing bore. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Remarks this table is for. Steps in the shaft design are: The seating surfaces for the bearings must. Bearing Shaft Design.

From daemar.com

Design of the Shaft Daemar Inc Bearing Shaft Design Design of shafts and housings for optimum operation and performance. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Surface of the shaft and housing bore. Steps in the shaft design are: The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. An overall. Bearing Shaft Design.

From me-resetsg.blogspot.com

Mechanical Engineering Construction of Bearing!! Bearing Shaft Design Design of shafts and housings for optimum operation and performance. Steps in the shaft design are: An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Remarks this table is for. Generally, the optimal. Bearing Shaft Design.

From www.pumpsandsystems.com

Designing Better Bearing Housings Bearing Shaft Design Design of shafts and housings for optimum operation and performance. Any inaccuracy in the geometry of shafts or housings impairs the. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Remarks this table is for. Generally, the optimal bearing must be selected to suit the. Bearing Shaft Design.

From www.youtube.com

L17 Shafts Shaft Design YouTube Bearing Shaft Design Steps in the shaft design are: Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. Surface of the shaft and housing bore. Any inaccuracy in the geometry of shafts or housings impairs the. The seating surfaces for the bearings must be designed such that the forces. Bearing Shaft Design.

From slidetodoc.com

Bearing Use in Design Bearing Terminology Bearing Raceway Bearing Shaft Design Surface of the shaft and housing bore. Remarks this table is for. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Steps in the shaft design are: Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the. Bearing Shaft Design.

From mechanicstips.blogspot.com

shafts design and bearing MechanicsTips Bearing Shaft Design For this reason, it is necessary to pay attention to the following when designing shaft and housing: Remarks this table is for. Steps in the shaft design are: Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. The seating surfaces for the bearings must be designed. Bearing Shaft Design.

From www.youtube.com

Shaft Bearing and Housing Assembly Tutorial in Solidworks YouTube Bearing Shaft Design Any inaccuracy in the geometry of shafts or housings impairs the. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Remarks this table is for. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Design of shafts and housings for optimum operation and. Bearing Shaft Design.

From www.jbj.co.uk

Bearing Supported Stub Shafts designed for side load applications Bearing Shaft Design Steps in the shaft design are: Surface of the shaft and housing bore. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Design of shafts and housings for optimum operation and performance. Any inaccuracy in the geometry of shafts or housings impairs the. Generally, the. Bearing Shaft Design.

From www.iqsdirectory.com

Ball Bearings Types, Design, Function, and Benefits Bearing Shaft Design For this reason, it is necessary to pay attention to the following when designing shaft and housing: The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. Steps in. Bearing Shaft Design.

From www.youtube.com

How to design Roller Shaft With Bearing Housing Industrial design Bearing Shaft Design Any inaccuracy in the geometry of shafts or housings impairs the. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. Design of shafts and housings for optimum operation and performance. An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft. Bearing Shaft Design.

From www.bearingtips.com

Why is preload necessary in some bearing applications? Bearing Tips Bearing Shaft Design Design of shafts and housings for optimum operation and performance. Remarks this table is for. Any inaccuracy in the geometry of shafts or housings impairs the. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Surface of the shaft and housing bore. The seating surfaces for the bearings must be designed. Bearing Shaft Design.

From www.slideshare.net

Taper Roller Bearings Bearing Shaft Design An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. Steps in the shaft design are: The seating surfaces for the bearings must be designed such that the forces. Bearing Shaft Design.

From engineeringlearn.com

Types of Bearings Definition, Function, Uses, Advantages Bearing Shaft Design Remarks this table is for. An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine,. Bearing Shaft Design.

From skyhighelearn.com

Design of mechanical shaft procedure Mechanical shaft design Bearing Shaft Design Steps in the shaft design are: Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. Surface of the shaft and housing bore. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Remarks this table is for. An overall. Bearing Shaft Design.

From www.youtube.com

Gearbox Design Part 3 Design of Key, Assembly of Shaft and Bearing Bearing Shaft Design For this reason, it is necessary to pay attention to the following when designing shaft and housing: Any inaccuracy in the geometry of shafts or housings impairs the. The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. The accuracy and surface finish of shafts and. Bearing Shaft Design.

From www.ctconline.com

Journal Bearing Vibration System Guide CTC Bearing Shaft Design The seating surfaces for the bearings must be designed such that the forces introduced via the bearings do not cause impermissible changes to the. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. Steps in the shaft design are: For this reason, it is necessary to. Bearing Shaft Design.

From www.efficientplantmag.com

Understand Vertical Motor Bearings Efficient Plant Bearing Shaft Design Any inaccuracy in the geometry of shafts or housings impairs the. Remarks this table is for. Surface of the shaft and housing bore. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Design of. Bearing Shaft Design.

From www.ewellix.com

Linear ball bearings and shafts Ewellix Bearing Shaft Design Design of shafts and housings for optimum operation and performance. The accuracy and surface finish of shafts and housings are listed in table 11.1 for normal operating conditions. Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing. An overall shaft design procedure is presented including consideration. Bearing Shaft Design.

From www.engineersedge.com

Bearing Shaft and Housing Installation Tolerances Bearing Shaft Design An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. Design of shafts and housings for optimum operation and performance. Any inaccuracy in the geometry of shafts or housings impairs the. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Steps in the shaft. Bearing Shaft Design.

From medias.schaeffler.us

Design of bearing arrangements Schaeffler medias Bearing Shaft Design Steps in the shaft design are: Any inaccuracy in the geometry of shafts or housings impairs the. An overall shaft design procedure is presented including consideration of bearing and component mounting and shaft dynamics using. Remarks this table is for. For this reason, it is necessary to pay attention to the following when designing shaft and housing: Generally, the optimal. Bearing Shaft Design.