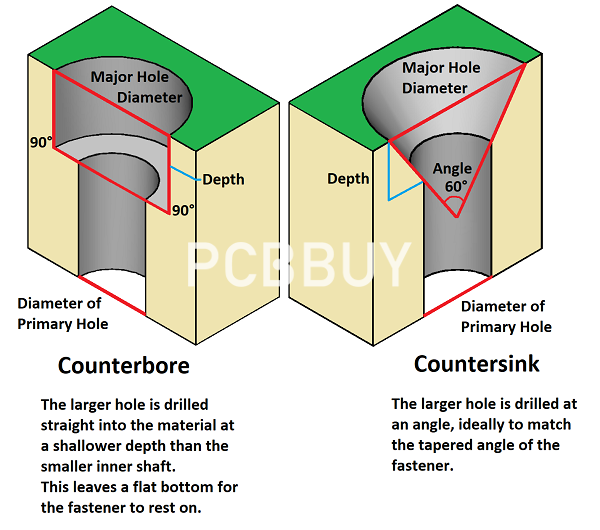

Countersink Uncountable . In this guide you’ll learn: A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk screw or bolt to. The different types of holes used in machining. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface. What the difference is between. This is a complete guide to the types of holes found in machining. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below the surface of the workpiece. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material.

from www.pcbbuy.com

Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk screw or bolt to. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. This is a complete guide to the types of holes found in machining. Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. The different types of holes used in machining. What the difference is between. In this guide you’ll learn:

When to use countersink VS counterbore?

Countersink Uncountable It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. This is a complete guide to the types of holes found in machining. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk screw or bolt to. The different types of holes used in machining. Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. What the difference is between. Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below the surface of the workpiece. In this guide you’ll learn:

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Uncountable A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk screw or bolt to. This is a complete guide to the types of holes found in machining. Countersinking is a machining process that creates a conical hole matching the angled shape. Countersink Uncountable.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersink Uncountable Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below the surface of the workpiece. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. Countersinking is a machining process that creates. Countersink Uncountable.

From www.snappytools.com

40030 5 Piece Countersink Set Make it Snappy Tools Countersink Uncountable This is a complete guide to the types of holes found in machining. The different types of holes used in machining. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Counterboring and countersinking are done on top of a drilled hole to allow the screw or. Countersink Uncountable.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Uncountable The different types of holes used in machining. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk screw or bolt to. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating. Countersink Uncountable.

From calculator.services

Countersink Depth Calculator How to Use Calculator Services Countersink Uncountable This is a complete guide to the types of holes found in machining. What the difference is between. In this guide you’ll learn: Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Countersink depth is the depth of a countersink hole, which is a conical hole cut into. Countersink Uncountable.

From drillbitguru.com

We Review The 6 Best Countersink Bits (2024) Countersink Uncountable What the difference is between. Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below the surface of the workpiece. Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to. Countersink Uncountable.

From www.kvtooling.com

Countersinks Single Flute KV Tooling Systems Countersink Uncountable Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface. It allows the. Countersink Uncountable.

From www.grainger.com

KEO Countersink Set Cobalt, Bright (Uncoated) Finish, 5/16 in Smallest Countersink Uncountable Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface. What the difference is between. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole. Countersink Uncountable.

From www.lincolnwelding.co.uk

HMT VERSADRIVE® 90° COUNTERSINK (SET OF 5) Countersink Uncountable What the difference is between. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. This is a complete guide to the types of holes found in machining. In this guide you’ll learn: Countersink depth is the depth of a countersink hole, which is a conical hole. Countersink Uncountable.

From sendcutsend.com

Countersink Design Best Practices SendCutSend Countersink Uncountable The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. What the difference is between. The different types of holes used in machining. In this guide you’ll learn: It allows the fastener’s head to sit flush with the surface of the material or. Countersink Uncountable.

From www.xometry.com

What are Countersink Holes in Engineering? Xometry Countersink Uncountable The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk.. Countersink Uncountable.

From www.wisc-online.com

Countersink Example2 OER Countersink Uncountable A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below the surface of the workpiece. This. Countersink Uncountable.

From www.walmart.com

Irwin 1877720 Metal Countersink 3 Piece Set Countersink Uncountable Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes. Countersink Uncountable.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersink Uncountable It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below the surface of the workpiece. Countersink depth is the depth of a countersink hole, which is. Countersink Uncountable.

From www.wisc-online.com

Countersink Example3 OER Countersink Uncountable Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface. A countersink is. Countersink Uncountable.

From www.cromwell.co.uk

Sherwood Countersink Set, Countersink, Straight Shank, Set of 6, Cobalt Countersink Uncountable This is a complete guide to the types of holes found in machining. Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface. In this guide you’ll learn: Countersinking is a machining process that. Countersink Uncountable.

From www.richconn-cnc.com

What is Counter Sink? Your Comprehensive Guide Shenzhen Richconn Countersink Uncountable A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. This is a complete guide to the types of holes found in machining. Countersinking is a machining process that creates a conical hole matching the angled shape. Countersink Uncountable.

From www.clevelandsteeltool.com

Countersink Tools Cleveland Steel Tool Countersink Uncountable Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even. Countersink Uncountable.

From www.wwgoa.com

5Piece Countersink Set WoodWorkers Guild of America Countersink Uncountable The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. This is a complete guide to the types of holes found in machining. What the difference is between. Countersinking is a machining process that creates a conical hole matching the angled shape of. Countersink Uncountable.

From www.grainger.com

MONSTER Countersink Set, 82 ° Countersink Angle, Number of Pieces 4 Countersink Uncountable Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. This is a complete guide to the types of holes found in machining. What the difference is between. Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below. Countersink Uncountable.

From www.gdandtbasics.com

Countersink GD&T Basics Countersink Uncountable Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below the surface of the workpiece. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. In this guide you’ll learn: A countersink. Countersink Uncountable.

From www.hoffmann-group.com

Simply buy Highprecision countersink, extra long 90° uncoated Countersink Uncountable The different types of holes used in machining. This is a complete guide to the types of holes found in machining. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head. Countersink Uncountable.

From www.homedepot.com

Milwaukee 6/8/10 Wood Countersink Set (3Piece) 48135003 The Countersink Uncountable It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. The different types of holes used in machining. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface. Countersink Uncountable.

From www.grainger.com

CLEVELAND, Cobalt, Bright (Uncoated) Finish, Countersink Set 445V37 Countersink Uncountable What the difference is between. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. This is a complete guide to the types of holes found in machining. Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below. Countersink Uncountable.

From www.cnclathing.com

Counterbore vs. Countersink in CNC Drilling Differences in Symbols Countersink Uncountable Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. What the difference is between. In this guide you’ll learn: A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk. Countersink Uncountable.

From www.mscdirect.com

Corehog Countersink 100 ° Included Angle, 2 Flutes, Polycrystalline Countersink Uncountable The different types of holes used in machining. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk screw or bolt to. Countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to. Countersink Uncountable.

From www.pntools.com.au

COUNTERSINK SET HSS M2 QUICKBIT HEX SHANK 4PC P&N P&N Tools Countersink Uncountable A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. In this guide you’ll learn: The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates. Countersink Uncountable.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersink Uncountable In this guide you’ll learn: A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk screw or bolt to. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to. Countersink Uncountable.

From triaticinc.com

Diamond Countersink 1/2" X 1/4"28; 100 deg., .098" (40) integrated Countersink Uncountable This is a complete guide to the types of holes found in machining. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a. Countersink Uncountable.

From store.evolutionpowertools.com

82 Degree Countersink With 3/4 in Shank Evolution Power Tools LLC Countersink Uncountable What the difference is between. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk screw or bolt to. In this guide you’ll learn: Countersink depth is the depth of a countersink hole, which is a conical hole cut into a. Countersink Uncountable.

From www.sears.com

Craftsman 5/8 in. HSS Countersink Countersink Uncountable A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. The different types of holes used in machining. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw,. Countersink Uncountable.

From www.pcbbuy.com

When to use countersink VS counterbore? Countersink Uncountable The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. The different types of holes used in machining. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the. Countersink Uncountable.

From www.youtube.com

What are Counterbore and Countersink? PCB Knowledge YouTube Countersink Uncountable This is a complete guide to the types of holes found in machining. In this guide you’ll learn: Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below the surface of the workpiece. The most noted difference between a countersink and counterbore is the size and shape of the. Countersink Uncountable.

From www.thehandymansdaughter.com

Countersink vs Counterbore The Handyman's Daughter Countersink Uncountable The different types of holes used in machining. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows the head of a countersunk screw or bolt to. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw,. Countersink Uncountable.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Uncountable Counterboring and countersinking are done on top of a drilled hole to allow the screw or bolt head to stay below the surface of the workpiece. In this guide you’ll learn: What the difference is between. A countersink drill bit, also known as fluted countersink, is a specialized tool used to create a conical hole in a workpiece that allows. Countersink Uncountable.