Which Are The 3 Main Tools In Lean Management . Clean and inspect work area. The lean tool of the five whys would have been designed by sakichi toyoda. Sequence the key developments in the evolution of continuous improvement methodologies. Key tools include 5s for organization, kaizen for continuous. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Lean tools are methods to improve efficiency and reduce waste. It is one of the important tools.

from www.mjvinnovation.com

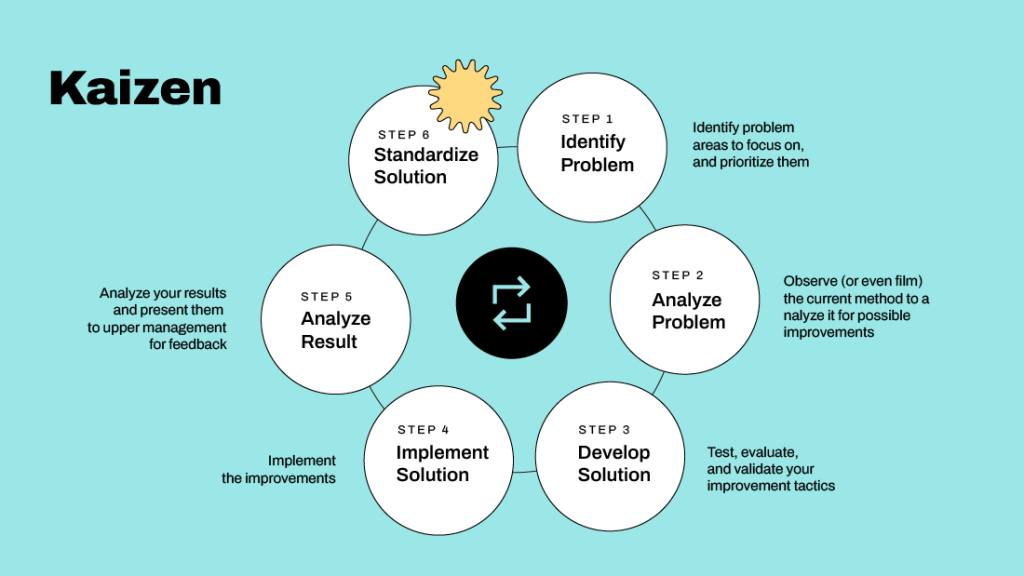

Key tools include 5s for organization, kaizen for continuous. The lean tool of the five whys would have been designed by sakichi toyoda. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Lean tools are methods to improve efficiency and reduce waste. Sequence the key developments in the evolution of continuous improvement methodologies. Clean and inspect work area. It is one of the important tools. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity.

Top 10 Lean Tools for Continuous Improvement MJV Innovation

Which Are The 3 Main Tools In Lean Management Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Clean and inspect work area. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. It is one of the important tools. Key tools include 5s for organization, kaizen for continuous. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Sequence the key developments in the evolution of continuous improvement methodologies. The lean tool of the five whys would have been designed by sakichi toyoda. Lean tools are methods to improve efficiency and reduce waste.

From www.cmtc.com

5 Necessary Lean Manufacturing Tools [Infographic] Which Are The 3 Main Tools In Lean Management Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Key tools include 5s for organization, kaizen for continuous. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Lean tools are methods to improve efficiency and reduce waste. Clean and inspect work area. The lean tool of. Which Are The 3 Main Tools In Lean Management.

From leanmanufacturingtools.org

Lean Tools Lean Manufacturing Tools Which Are The 3 Main Tools In Lean Management Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Lean tools are methods to improve efficiency and reduce waste. Clean and inspect work area. It is one of the important tools. Key tools include 5s for organization, kaizen for continuous. The lean tool of the five whys would have been designed by. Which Are The 3 Main Tools In Lean Management.

From www.webnetcreative.com

Lean Six Sigma Principles and Tools and Their Applications Which Are The 3 Main Tools In Lean Management Key tools include 5s for organization, kaizen for continuous. Sequence the key developments in the evolution of continuous improvement methodologies. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. The lean tool of the five whys would have been designed by sakichi toyoda. Lean manufacturing tools offer a systematic approach to optimize. Which Are The 3 Main Tools In Lean Management.

From blog.infodiagram.com

Explain Lean Management Principles with Visuals Which Are The 3 Main Tools In Lean Management Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. The lean tool of the five whys would have been designed by sakichi toyoda. Key tools include 5s for organization, kaizen for continuous. Clean and inspect work area.. Which Are The 3 Main Tools In Lean Management.

From www.lmmiller.com

What is lean management Lean Management Principles Which Are The 3 Main Tools In Lean Management Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. The lean tool of the five whys would have been designed by sakichi toyoda. It is one of the important tools. Key tools include 5s for organization, kaizen for continuous. Sequence the key developments in the evolution of continuous improvement methodologies. Clean and. Which Are The 3 Main Tools In Lean Management.

From www.infodiagram.com

Five basic lean principles illustrated with cycle chart Which Are The 3 Main Tools In Lean Management Key tools include 5s for organization, kaizen for continuous. Sequence the key developments in the evolution of continuous improvement methodologies. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Clean and inspect work area. It is one. Which Are The 3 Main Tools In Lean Management.

From www.dozuki.com

Streamlining Production How Lean Manufacturing Can Revolutionize Your Which Are The 3 Main Tools In Lean Management It is one of the important tools. Clean and inspect work area. Lean tools are methods to improve efficiency and reduce waste. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. The lean tool of the five whys would have been designed by sakichi toyoda. Key tools include 5s for organization, kaizen. Which Are The 3 Main Tools In Lean Management.

From www.iteratorshq.com

What Are the 5 Lean Management Principles? Iterators Which Are The 3 Main Tools In Lean Management It is one of the important tools. The lean tool of the five whys would have been designed by sakichi toyoda. Clean and inspect work area. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Lean tools. Which Are The 3 Main Tools In Lean Management.

From govimana.com

What are Lean Manufacturing Tools? VIMANA Which Are The 3 Main Tools In Lean Management It is one of the important tools. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Lean tools are methods to improve efficiency and reduce waste. Key tools include 5s for organization, kaizen for continuous. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. The lean. Which Are The 3 Main Tools In Lean Management.

From neuroject.com

3 Essential Tools for Lean Management in Construction Neuroject Which Are The 3 Main Tools In Lean Management Sequence the key developments in the evolution of continuous improvement methodologies. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. The lean tool of the five whys would have been designed by sakichi toyoda. Clean and inspect work area. Lean tools are methods to improve efficiency and reduce waste. Key tools include. Which Are The 3 Main Tools In Lean Management.

From www.lbspartners.ie

Understanding the Five Principles of Lean LBSPartners Which Are The 3 Main Tools In Lean Management It is one of the important tools. Key tools include 5s for organization, kaizen for continuous. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Lean tools are methods to improve efficiency and reduce waste. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Sequence the. Which Are The 3 Main Tools In Lean Management.

From www.surajmech.com

Lean Manufacturing Tools Which Are The 3 Main Tools In Lean Management It is one of the important tools. The lean tool of the five whys would have been designed by sakichi toyoda. Key tools include 5s for organization, kaizen for continuous. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Sequence the key developments in the evolution of continuous improvement methodologies. Lean six sigma has. Which Are The 3 Main Tools In Lean Management.

From www.researchgate.net

Lean manufacturing tools and practices [2] Download Scientific Diagram Which Are The 3 Main Tools In Lean Management It is one of the important tools. Lean tools are methods to improve efficiency and reduce waste. Sequence the key developments in the evolution of continuous improvement methodologies. Clean and inspect work area. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Key tools include 5s for organization, kaizen for continuous. Lean. Which Are The 3 Main Tools In Lean Management.

From www.theperfectprocess.co.uk

LEAN MANAGEMENT TOOLS AND TECHNIQUES The Perfect Process Which Are The 3 Main Tools In Lean Management Sequence the key developments in the evolution of continuous improvement methodologies. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. The lean tool of the five whys would have been designed by sakichi toyoda. Key tools include. Which Are The 3 Main Tools In Lean Management.

From mungfali.com

Tools Of Lean Manufacturing Which Are The 3 Main Tools In Lean Management Key tools include 5s for organization, kaizen for continuous. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Sequence the key developments in the evolution of continuous improvement methodologies. The lean tool of the five whys would have been designed by sakichi toyoda. It is one of the important tools. Clean and. Which Are The 3 Main Tools In Lean Management.

From mungfali.com

Continuous Improvement Lean Manufacturing Which Are The 3 Main Tools In Lean Management Sequence the key developments in the evolution of continuous improvement methodologies. Key tools include 5s for organization, kaizen for continuous. The lean tool of the five whys would have been designed by sakichi toyoda. It is one of the important tools. Clean and inspect work area. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance. Which Are The 3 Main Tools In Lean Management.

From james-wilson.medium.com

Best Lean Manufacturing Tools and Techniques by James Wilson Medium Which Are The 3 Main Tools In Lean Management Lean tools are methods to improve efficiency and reduce waste. The lean tool of the five whys would have been designed by sakichi toyoda. It is one of the important tools. Clean and inspect work area. Key tools include 5s for organization, kaizen for continuous. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity.. Which Are The 3 Main Tools In Lean Management.

From www.webnetcreative.com

Lean Six Sigma Principles and Tools and Their Applications Which Are The 3 Main Tools In Lean Management Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Lean tools are methods to improve efficiency and reduce waste. Sequence the key developments in the evolution of continuous improvement methodologies. It is one of the important tools. The lean tool of the five whys would have been designed by sakichi toyoda. Key tools include. Which Are The 3 Main Tools In Lean Management.

From pecb.com

Lean Management A Comprehensive Guide PECB Which Are The 3 Main Tools In Lean Management The lean tool of the five whys would have been designed by sakichi toyoda. Lean tools are methods to improve efficiency and reduce waste. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Key tools include 5s for organization, kaizen for continuous. Lean manufacturing tools offer a systematic approach to optimize processes,. Which Are The 3 Main Tools In Lean Management.

From opexmc.weebly.com

Experiential Learning Lean Management OPEX Management Services Which Are The 3 Main Tools In Lean Management Sequence the key developments in the evolution of continuous improvement methodologies. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Key tools include 5s for organization, kaizen for continuous. Lean tools are methods to improve efficiency and reduce waste. The lean tool of the five whys would have been designed by sakichi. Which Are The 3 Main Tools In Lean Management.

From www.mjvinnovation.com

Top 10 Lean Tools for Continuous Improvement MJV Innovation Which Are The 3 Main Tools In Lean Management Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Sequence the key developments in the evolution of continuous improvement methodologies. Clean and inspect work area. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Lean tools are methods to improve efficiency and reduce waste. Key tools. Which Are The 3 Main Tools In Lean Management.

From mungfali.com

Tools Of Lean Manufacturing Which Are The 3 Main Tools In Lean Management Sequence the key developments in the evolution of continuous improvement methodologies. Lean tools are methods to improve efficiency and reduce waste. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. It is one of the important tools. The lean tool of the five whys would have been designed by sakichi toyoda. Key tools include. Which Are The 3 Main Tools In Lean Management.

From blog.infodiagram.com

Explain Lean Management Principles with Visuals Which Are The 3 Main Tools In Lean Management Clean and inspect work area. Lean tools are methods to improve efficiency and reduce waste. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Sequence the key developments in the evolution of continuous improvement methodologies. Key tools include 5s for organization, kaizen for continuous. Lean manufacturing tools offer a systematic approach to. Which Are The 3 Main Tools In Lean Management.

From neuroject.com

3 Essential Tools for Lean Management in Construction Neuroject Which Are The 3 Main Tools In Lean Management Lean tools are methods to improve efficiency and reduce waste. Key tools include 5s for organization, kaizen for continuous. Clean and inspect work area. Sequence the key developments in the evolution of continuous improvement methodologies. The lean tool of the five whys would have been designed by sakichi toyoda. Lean manufacturing tools offer a systematic approach to optimize processes, reduce. Which Are The 3 Main Tools In Lean Management.

From greendot.co.in

Top Lean Tools Greendot Management Solutions Which Are The 3 Main Tools In Lean Management Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. It is one of the important tools. The lean tool of the five whys would have been designed by sakichi toyoda. Sequence the key developments in the evolution of continuous improvement methodologies. Clean and inspect work area. Lean six sigma has emerged as a powerful. Which Are The 3 Main Tools In Lean Management.

From kissflow.com

Lean Project Management An Ultimate Guide to Implement Lean Which Are The 3 Main Tools In Lean Management Lean tools are methods to improve efficiency and reduce waste. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. It is one of the important tools. Sequence the key developments in the evolution of continuous improvement methodologies. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity.. Which Are The 3 Main Tools In Lean Management.

From www.linkedin.com

100+ Lean Tools to Run a Better Business Which Are The 3 Main Tools In Lean Management Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Clean and inspect work area. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. It is one of the important tools. The lean tool of the five whys would have been designed by sakichi toyoda. Key tools. Which Are The 3 Main Tools In Lean Management.

From www.smlease.com

Lean Manufacturing Waste, Types, Basic Lean Principles SMLease Design Which Are The 3 Main Tools In Lean Management Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. It is one of the important tools. Sequence the key developments in the evolution of continuous improvement methodologies. The lean tool of the five whys would have been designed by sakichi toyoda. Clean and inspect work area. Key tools include 5s for organization,. Which Are The 3 Main Tools In Lean Management.

From thinkdifferentnetwork.com

The Principles of Lean Think Different Which Are The 3 Main Tools In Lean Management Key tools include 5s for organization, kaizen for continuous. Lean tools are methods to improve efficiency and reduce waste. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. Clean and inspect work area. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. The lean tool of. Which Are The 3 Main Tools In Lean Management.

From www.cyzag.com

Three Lean Tools To Nurture Continuous Improvement [Kaizen, Kaikaku Which Are The 3 Main Tools In Lean Management The lean tool of the five whys would have been designed by sakichi toyoda. Clean and inspect work area. It is one of the important tools. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Lean tools are methods to improve efficiency and reduce waste. Lean six sigma has emerged as a powerful methodology. Which Are The 3 Main Tools In Lean Management.

From amoeboids.com

Lean Product Management A Comprehensive Guide Amoeboids Which Are The 3 Main Tools In Lean Management It is one of the important tools. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Key tools include 5s for organization, kaizen for continuous. Clean and inspect work area. The lean tool of the five whys would have been designed by sakichi toyoda. Sequence the key developments in the evolution of continuous improvement. Which Are The 3 Main Tools In Lean Management.

From www.fulcrumcwi.com

Lean Management System Fulcrum ConsultingWorks Inc. Which Are The 3 Main Tools In Lean Management Sequence the key developments in the evolution of continuous improvement methodologies. It is one of the important tools. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. The lean tool of the five whys would have been designed by sakichi toyoda. Lean manufacturing tools offer a systematic approach to optimize processes, reduce. Which Are The 3 Main Tools In Lean Management.

From www.linkedin.com

Lean tools Which Are The 3 Main Tools In Lean Management Clean and inspect work area. Sequence the key developments in the evolution of continuous improvement methodologies. Key tools include 5s for organization, kaizen for continuous. Lean six sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous. It is one of the important tools. The lean tool of the five whys would have been designed. Which Are The 3 Main Tools In Lean Management.

From www.pinterest.pt

Infographic Top 26 Lean Tools Lean manufacturing, Visual management Which Are The 3 Main Tools In Lean Management Key tools include 5s for organization, kaizen for continuous. Clean and inspect work area. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. It is one of the important tools. Lean tools are methods to improve efficiency and reduce waste. Sequence the key developments in the evolution of continuous improvement methodologies. The lean tool. Which Are The 3 Main Tools In Lean Management.

From www.youtube.com

Introduction to Lean Management (Definition, Lean Principles & Benefits Which Are The 3 Main Tools In Lean Management Clean and inspect work area. It is one of the important tools. Lean manufacturing tools offer a systematic approach to optimize processes, reduce waste, and enhance productivity. Key tools include 5s for organization, kaizen for continuous. Lean tools are methods to improve efficiency and reduce waste. The lean tool of the five whys would have been designed by sakichi toyoda.. Which Are The 3 Main Tools In Lean Management.