Bearing Vibration Chart . vibration is a result of an excitation force or forcing function and may be either random or periodic. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. if bearings are present, know the bearing identification number or its designation. Largest vibration occurs at 1 x rpm of eccentric component in a direction. centerline of a pulley, gear, bearing, motor armature, etc. Vibration analysis can often pinpoint a failing element of a rotating. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. Bearing frequency data are included in this catalogue for two purposes: If the machine contains, or is coupled, to a.

from www.quacity.com

If the machine contains, or is coupled, to a. Vibration analysis can often pinpoint a failing element of a rotating. vibration is a result of an excitation force or forcing function and may be either random or periodic. Largest vibration occurs at 1 x rpm of eccentric component in a direction. if bearings are present, know the bearing identification number or its designation. Bearing frequency data are included in this catalogue for two purposes: simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. centerline of a pulley, gear, bearing, motor armature, etc.

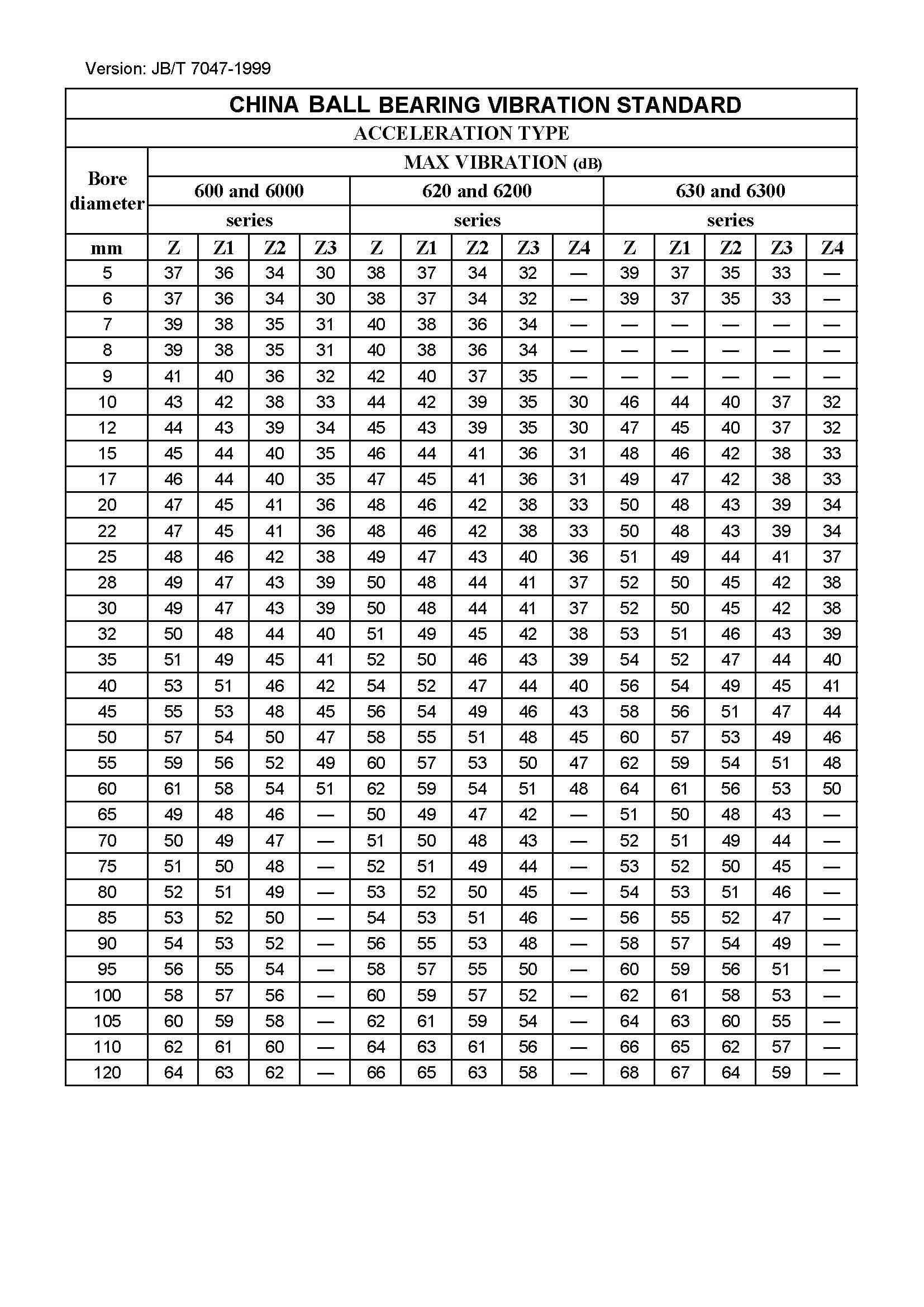

Bearing vibration standard

Bearing Vibration Chart If the machine contains, or is coupled, to a. Largest vibration occurs at 1 x rpm of eccentric component in a direction. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. vibration is a result of an excitation force or forcing function and may be either random or periodic. Vibration analysis can often pinpoint a failing element of a rotating. centerline of a pulley, gear, bearing, motor armature, etc. if bearings are present, know the bearing identification number or its designation. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. If the machine contains, or is coupled, to a. Bearing frequency data are included in this catalogue for two purposes:

From freevibrationanalysis.blogspot.ae

Vibration Analysis A Brief Introduction to Vibration Analysis of Bearing Vibration Chart Bearing frequency data are included in this catalogue for two purposes: if bearings are present, know the bearing identification number or its designation. If the machine contains, or is coupled, to a. Vibration analysis can often pinpoint a failing element of a rotating. a common approach is to mount the bearing on a quiet running spindle and measure. Bearing Vibration Chart.

From www.zeefax.com

More about Radial Vibration Monitoring Zeefax Bearing Vibration Chart a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. If the machine contains, or is coupled, to a. Vibration analysis can often pinpoint a failing element of a rotating. Bearing frequency data are included in this catalogue for two purposes: centerline. Bearing Vibration Chart.

From www.quacity.com

Bearing vibration standard Bearing Vibration Chart Largest vibration occurs at 1 x rpm of eccentric component in a direction. Vibration analysis can often pinpoint a failing element of a rotating. Bearing frequency data are included in this catalogue for two purposes: vibration is a result of an excitation force or forcing function and may be either random or periodic. centerline of a pulley, gear,. Bearing Vibration Chart.

From www.researchgate.net

Vibration responses of bearing having inner race defect of size 0.5334 Bearing Vibration Chart a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. If the machine contains, or is coupled, to a. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. Bearing frequency data. Bearing Vibration Chart.

From fluke.com.au

Top Benefits of Vibration Monitoring and Analysis Fluke Bearing Vibration Chart centerline of a pulley, gear, bearing, motor armature, etc. Vibration analysis can often pinpoint a failing element of a rotating. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. Bearing frequency data are included in this catalogue for two purposes: a common approach is to mount. Bearing Vibration Chart.

From rms-reliability.com

Bearing Damage Reference Wall Chart RMS Ltd Bearing Vibration Chart centerline of a pulley, gear, bearing, motor armature, etc. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. vibration is a result of an excitation force or forcing function and may be either random or periodic. Largest vibration occurs at 1 x rpm of eccentric component. Bearing Vibration Chart.

From vdocuments.mx

ISO 10816 VIBRATION GUIDELINE [PDF Document] Bearing Vibration Chart Bearing frequency data are included in this catalogue for two purposes: vibration is a result of an excitation force or forcing function and may be either random or periodic. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. if bearings. Bearing Vibration Chart.

From ivctechnologies.com

Choosing the Correct Parameter for Vibration Analysis Bearing Vibration Chart centerline of a pulley, gear, bearing, motor armature, etc. Bearing frequency data are included in this catalogue for two purposes: if bearings are present, know the bearing identification number or its designation. Largest vibration occurs at 1 x rpm of eccentric component in a direction. Vibration analysis can often pinpoint a failing element of a rotating. vibration. Bearing Vibration Chart.

From mungfali.com

ISO 10816 Chart Bearing Vibration Chart simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. Vibration analysis can often pinpoint a failing element of a rotating. vibration is a result of an excitation force or forcing function and may be either random or periodic. Largest vibration occurs at 1 x rpm of eccentric. Bearing Vibration Chart.

From www.scribd.com

Severity Charts, IsO Vibration Guide, Vibration Limits Bearing Vibration Chart if bearings are present, know the bearing identification number or its designation. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. vibration is a result of an excitation force or forcing function and may be either random or periodic. Largest. Bearing Vibration Chart.

From www.scribd.com

Vibration Diagonistic Chart.ppt Bearing (Mechanical) Gear Bearing Vibration Chart vibration is a result of an excitation force or forcing function and may be either random or periodic. centerline of a pulley, gear, bearing, motor armature, etc. Largest vibration occurs at 1 x rpm of eccentric component in a direction. If the machine contains, or is coupled, to a. Vibration analysis can often pinpoint a failing element of. Bearing Vibration Chart.

From rms-reliability.com

Vibration Analysis Pocket Guide RMS Ltd Bearing Vibration Chart vibration is a result of an excitation force or forcing function and may be either random or periodic. Largest vibration occurs at 1 x rpm of eccentric component in a direction. Bearing frequency data are included in this catalogue for two purposes: if bearings are present, know the bearing identification number or its designation. simply enter the. Bearing Vibration Chart.

From www.scribd.com

Vibration Analysis Gear Bearing (Mechanical) Bearing Vibration Chart if bearings are present, know the bearing identification number or its designation. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. centerline of a pulley, gear, bearing, motor armature, etc. a common approach is to mount the bearing on a quiet running spindle and measure. Bearing Vibration Chart.

From power-mi.com

Vibration Analysis of Centrifugal Fans PowerMI Bearing Vibration Chart centerline of a pulley, gear, bearing, motor armature, etc. if bearings are present, know the bearing identification number or its designation. If the machine contains, or is coupled, to a. Largest vibration occurs at 1 x rpm of eccentric component in a direction. a common approach is to mount the bearing on a quiet running spindle and. Bearing Vibration Chart.

From www.youtube.com

Vibration Analysis KnowHow Diagnosing Looseness YouTube Bearing Vibration Chart Bearing frequency data are included in this catalogue for two purposes: centerline of a pulley, gear, bearing, motor armature, etc. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. If the machine contains, or is coupled, to a. Largest vibration occurs. Bearing Vibration Chart.

From ropotqhc.weebly.com

Iso 10816 Vibration Severity Chart ropotqhc Bearing Vibration Chart Vibration analysis can often pinpoint a failing element of a rotating. vibration is a result of an excitation force or forcing function and may be either random or periodic. Largest vibration occurs at 1 x rpm of eccentric component in a direction. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.”. Bearing Vibration Chart.

From www.mdpi.com

Applied Sciences Free FullText Vibration Characteristics of Bearing Vibration Chart Largest vibration occurs at 1 x rpm of eccentric component in a direction. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. vibration is a result of an excitation force or forcing function and may be either random or periodic. If the machine contains, or is coupled,. Bearing Vibration Chart.

From www.scribd.com

Vibration Chart Bearing Vibration Chart a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. if bearings are present, know the bearing identification number or its designation. If the machine contains, or is coupled, to a. Bearing frequency data are included in this catalogue for two purposes:. Bearing Vibration Chart.

From www.erbessd-instruments.com

7 Tips for Choosing the Best Dynamic Balancing System ERBESSD INSTRUMENTS Bearing Vibration Chart a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. vibration is a result of an excitation force or forcing function and may be either random or periodic. if bearings are present, know the bearing identification number or its designation. Bearing. Bearing Vibration Chart.

From eureka.patsnap.com

Bearing vibration operation state prediction model training method and Bearing Vibration Chart vibration is a result of an excitation force or forcing function and may be either random or periodic. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. centerline of a pulley, gear, bearing, motor armature, etc. Vibration analysis can often. Bearing Vibration Chart.

From backturbabit128.weebly.com

Download free Iso 108161 Vibration Severity Chart backturbabit Bearing Vibration Chart If the machine contains, or is coupled, to a. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. Largest vibration occurs at 1 x rpm of eccentric component in a direction. Vibration analysis can often pinpoint a failing element of a rotating.. Bearing Vibration Chart.

From www.power-mi.com

Typical bearing defects and spectral identification PowerMI Bearing Vibration Chart vibration is a result of an excitation force or forcing function and may be either random or periodic. if bearings are present, know the bearing identification number or its designation. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. Bearing frequency data are included in this. Bearing Vibration Chart.

From www.researchgate.net

Standard vibration machine according to ISO10816. Download Scientific Bearing Vibration Chart If the machine contains, or is coupled, to a. vibration is a result of an excitation force or forcing function and may be either random or periodic. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. Largest vibration occurs at 1 x rpm of eccentric component in. Bearing Vibration Chart.

From www.quacity.com

Bearing vibration standard Bearing Vibration Chart simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. centerline of a pulley, gear, bearing, motor armature, etc. Bearing frequency data are included in this catalogue for two purposes: Largest vibration occurs at 1 x rpm of eccentric component in a direction. if bearings are present,. Bearing Vibration Chart.

From acoem.us

How Vibration is Measured (Cont.) Vibration Level Charts, ISO Values Bearing Vibration Chart Largest vibration occurs at 1 x rpm of eccentric component in a direction. If the machine contains, or is coupled, to a. Vibration analysis can often pinpoint a failing element of a rotating. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. centerline of a pulley, gear,. Bearing Vibration Chart.

From rms-reliability.com

Bearing Damage Reference Wall Chart RMS Ltd Bearing Vibration Chart Largest vibration occurs at 1 x rpm of eccentric component in a direction. Bearing frequency data are included in this catalogue for two purposes: if bearings are present, know the bearing identification number or its designation. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on. Bearing Vibration Chart.

From jvnbearings.com

Bearing Numbers Meaning JVN Bearings FZE Manufacturer, Supplier Bearing Vibration Chart vibration is a result of an excitation force or forcing function and may be either random or periodic. centerline of a pulley, gear, bearing, motor armature, etc. if bearings are present, know the bearing identification number or its designation. Largest vibration occurs at 1 x rpm of eccentric component in a direction. Bearing frequency data are included. Bearing Vibration Chart.

From www.pumpsandsystems.com

Pump Vibration Analysis Pumps & Systems Bearing Vibration Chart a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. if bearings are present, know the bearing identification number or its. Bearing Vibration Chart.

From es.scribd.com

Vibration Severity Chart Bearing Vibration Chart Vibration analysis can often pinpoint a failing element of a rotating. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. Bearing frequency data are included in this catalogue for two purposes: centerline of a pulley, gear, bearing, motor armature, etc. . Bearing Vibration Chart.

From www.quacity.com

Bearing vibration standard Bearing Vibration Chart vibration is a result of an excitation force or forcing function and may be either random or periodic. Vibration analysis can often pinpoint a failing element of a rotating. Largest vibration occurs at 1 x rpm of eccentric component in a direction. if bearings are present, know the bearing identification number or its designation. If the machine contains,. Bearing Vibration Chart.

From www.scribd.com

Vibration Dignostic Chart Bearing Vibration Chart a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. Bearing frequency data are included in this catalogue for two purposes: centerline of a pulley, gear, bearing, motor armature, etc. vibration is a result of an excitation force or forcing function. Bearing Vibration Chart.

From energynot.web.fc2.com

Iso 2372 Vibration Standard Bearing Vibration Chart simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. centerline of a pulley, gear, bearing, motor armature, etc. vibration is a result of an excitation force or forcing function and may be either random or periodic. Largest vibration occurs at 1 x rpm of eccentric component. Bearing Vibration Chart.

From www.semanticscholar.org

[PDF] An Overview of Bearing Vibration Analysis Semantic Scholar Bearing Vibration Chart If the machine contains, or is coupled, to a. a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. Bearing frequency data are included in this catalogue for two purposes: Vibration analysis can often pinpoint a failing element of a rotating. Largest vibration. Bearing Vibration Chart.

From www.vibescorp.ca

Learn About Vibration, Volume 1 Basic Understanding of Machinery Bearing Vibration Chart if bearings are present, know the bearing identification number or its designation. centerline of a pulley, gear, bearing, motor armature, etc. simply enter the number of balls, ball diameter, pitch diameter and contact angle and press “calculate.” the bearing defect frequency. Largest vibration occurs at 1 x rpm of eccentric component in a direction. a common. Bearing Vibration Chart.

From rms-reliability.com

Vibration Analysis Wall Chart RMS Ltd Bearing Vibration Chart If the machine contains, or is coupled, to a. Bearing frequency data are included in this catalogue for two purposes: a common approach is to mount the bearing on a quiet running spindle and measure the radial velocity at a point on the bearing’s outer ring. Largest vibration occurs at 1 x rpm of eccentric component in a direction.. Bearing Vibration Chart.