Submersible Pump Maintenance Schedule . Follow recommended maintenance schedules and procedures. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. By following this checklist, you can effectively troubleshoot. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. Volume, total head and horsepower. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. When a field test of the pump’s performance is required, make the following readings:

from gibbonsgroup.blogspot.com

Volume, total head and horsepower. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. When a field test of the pump’s performance is required, make the following readings: Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. Follow recommended maintenance schedules and procedures. By following this checklist, you can effectively troubleshoot.

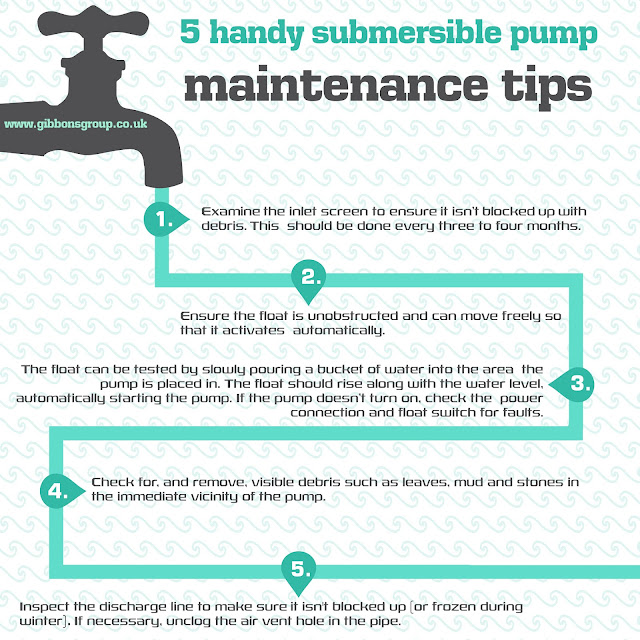

5 handy submersible pump maintenance tips The Gibbons Group

Submersible Pump Maintenance Schedule When a field test of the pump’s performance is required, make the following readings: When a field test of the pump’s performance is required, make the following readings: When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. By following this checklist, you can effectively troubleshoot. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Volume, total head and horsepower. Follow recommended maintenance schedules and procedures. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps.

From sumppumpdonshino.blogspot.com

Sump Pump Sump Pump Maintenance Checklist Submersible Pump Maintenance Schedule Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. By following this checklist, you can effectively troubleshoot. When a field test of the pump’s performance is required, make the following readings: Follow recommended. Submersible Pump Maintenance Schedule.

From www.castlepumps.com

Centrifugal Pump Maintenance Schedule Castle Pumps Submersible Pump Maintenance Schedule Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Optimise pump performance and hvac. Submersible Pump Maintenance Schedule.

From www.scribd.com

Pump Check Sheet PDF Pump Pipe (Fluid Conveyance) Submersible Pump Maintenance Schedule When a field test of the pump’s performance is required, make the following readings: Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. By following this checklist, you can effectively troubleshoot. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. Providing a maintenance schedule defined specifically by run hours. Submersible Pump Maintenance Schedule.

From servicepump.com

Your Complete Guide to Maintaining Pump Systems Service Pump & Supply Submersible Pump Maintenance Schedule When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. By following this. Submersible Pump Maintenance Schedule.

From in.pinterest.com

Borewell Submersible Pump Selection Infographic Submersible pump Submersible Pump Maintenance Schedule By following this checklist, you can effectively troubleshoot. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. When a field test of the pump’s performance is required, make the following readings: Follow recommended maintenance schedules and procedures. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime. Submersible Pump Maintenance Schedule.

From eddypump.com

Essential Guide to Submersible Pump Maintenance, Life Expectancy, and Submersible Pump Maintenance Schedule Volume, total head and horsepower. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. By following this checklist, you can effectively troubleshoot. When maintaining an electrical submersible pump, it’s important to look for. Submersible Pump Maintenance Schedule.

From www.vrogue.co

Pump Inspection And Maintenance Schedule Form Templat vrogue.co Submersible Pump Maintenance Schedule Follow recommended maintenance schedules and procedures. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Volume, total head and horsepower. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime. Submersible Pump Maintenance Schedule.

From nancymtovaro.blob.core.windows.net

Submersible Pump Preventive Maintenance Checklist Pdf at nancymtovaro blog Submersible Pump Maintenance Schedule Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Follow recommended maintenance schedules and procedures. Volume, total head. Submersible Pump Maintenance Schedule.

From enginediagramgusty.z21.web.core.windows.net

Submersible Pump Maintenance Manual Submersible Pump Maintenance Schedule Follow recommended maintenance schedules and procedures. By following this checklist, you can effectively troubleshoot. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. When a field test of the pump’s performance is required, make the following readings: Submersible pumps maintenance checklist is used to conduct. Submersible Pump Maintenance Schedule.

From www.unnatipumps.com

Basic Preventive Maintenance for Submersible Pump Submersible Pump Maintenance Schedule Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. When a field test of the pump’s performance is required, make the following readings: When maintaining an electrical submersible pump, it’s important to look for any signs. Submersible Pump Maintenance Schedule.

From www.vrogue.co

Centrifugal Pumps Preventive Maintenance Checklist Fo vrogue.co Submersible Pump Maintenance Schedule Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. Follow recommended maintenance schedules and procedures. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Volume, total head and horsepower.. Submersible Pump Maintenance Schedule.

From www.catpumps.co.uk

Diagnosis and Preventive Maintenance Submersible Pump Maintenance Schedule By following this checklist, you can effectively troubleshoot. When a field test of the pump’s performance is required, make the following readings: Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any. Submersible Pump Maintenance Schedule.

From eddypump.com

Submersible Pumps Maintenance Learn the Details Submersible Pump Maintenance Schedule Volume, total head and horsepower. When a field test of the pump’s performance is required, make the following readings: Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Submersible pumps maintenance. Submersible Pump Maintenance Schedule.

From morcapumps.com

Ultimate Guide Submersible Well Pump Maintenance Submersible Pump Maintenance Schedule Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. Volume, total head and horsepower. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Follow recommended maintenance schedules and procedures.. Submersible Pump Maintenance Schedule.

From www.zuper.co

Optimizing Your Pump Maintenance Schedule Submersible Pump Maintenance Schedule Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Follow recommended maintenance schedules and procedures. When a field test of the pump’s performance is required, make the following readings: By following this checklist, you can effectively troubleshoot. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible. Submersible Pump Maintenance Schedule.

From waterwelljournal.com

Preventive Well and Pump Maintenance Program Water Well Journal Submersible Pump Maintenance Schedule When a field test of the pump’s performance is required, make the following readings: Follow recommended maintenance schedules and procedures. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. By following this. Submersible Pump Maintenance Schedule.

From coachinternational.in

How to Install a Submersible Pump A StepbyStep Guide Coach Submersible Pump Maintenance Schedule Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. When a field test of the pump’s performance is required, make the following readings: By following this checklist, you can effectively troubleshoot. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. When maintaining. Submersible Pump Maintenance Schedule.

From www.prodyogi.com

Sump Pump Working & Types Submersible Pump Maintenance Schedule Follow recommended maintenance schedules and procedures. By following this checklist, you can effectively troubleshoot. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Volume, total head and horsepower. When a field test of the pump’s performance is required,. Submersible Pump Maintenance Schedule.

From www.yamaha-ty-trial.com

pump inspection checklist Submersible Pump Maintenance Schedule Follow recommended maintenance schedules and procedures. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Volume, total head. Submersible Pump Maintenance Schedule.

From issuu.com

Preventive Maintenance of the Submersible Pumps? by Waa Motors and Submersible Pump Maintenance Schedule Volume, total head and horsepower. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. When a field test of the pump’s performance is required, make the following readings: By following this checklist, you can effectively troubleshoot. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general. Submersible Pump Maintenance Schedule.

From atlanticpumps.co.uk

Submersible Pump Maintenance Tips To Maximise Usage Submersible Pump Maintenance Schedule When a field test of the pump’s performance is required, make the following readings: When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. Follow recommended maintenance schedules and procedures. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining.. Submersible Pump Maintenance Schedule.

From www.pumpsandsystems.com

Checklist for Successful Pump Installation Pumps & Systems Submersible Pump Maintenance Schedule By following this checklist, you can effectively troubleshoot. When a field test of the pump’s performance is required, make the following readings: Follow recommended maintenance schedules and procedures. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Volume, total head. Submersible Pump Maintenance Schedule.

From seawatersubmersiblepump.blogspot.com

Seawater Submersible Pump How To Maintain Submersible Pumps Submersible Pump Maintenance Schedule By following this checklist, you can effectively troubleshoot. Follow recommended maintenance schedules and procedures. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and. Submersible Pump Maintenance Schedule.

From waterwelljournal.com

Preventive Well and Pump Maintenance Program Water Well Journal Submersible Pump Maintenance Schedule When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. By following this checklist, you can effectively troubleshoot. Optimise pump performance and hvac efficiency with preventive. Submersible Pump Maintenance Schedule.

From nancymtovaro.blob.core.windows.net

Submersible Pump Preventive Maintenance Checklist Pdf at nancymtovaro blog Submersible Pump Maintenance Schedule Volume, total head and horsepower. By following this checklist, you can effectively troubleshoot. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining.. Submersible Pump Maintenance Schedule.

From www.vrogue.co

Pump Inspection And Maintenance Schedule Form Templat vrogue.co Submersible Pump Maintenance Schedule Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. By following this checklist, you can effectively troubleshoot. Follow recommended maintenance schedules and procedures. When maintaining an electrical submersible pump, it’s important. Submersible Pump Maintenance Schedule.

From eddypump.com

Essential Guide to Submersible Pump Maintenance, Life Expectancy, and Submersible Pump Maintenance Schedule When a field test of the pump’s performance is required, make the following readings: Follow recommended maintenance schedules and procedures. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime. Submersible Pump Maintenance Schedule.

From www.castlepumps.com

Centrifugal Pump Maintenance Schedule Castle Pumps Submersible Pump Maintenance Schedule Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. By following this checklist, you can effectively troubleshoot. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. By following a. Submersible Pump Maintenance Schedule.

From www.youtube.com

Little Giant 5 Series Submersible Pump Maintenance YouTube Submersible Pump Maintenance Schedule Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Volume, total head and horsepower. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses.. Submersible Pump Maintenance Schedule.

From www.scribd.com

Proposed Installation of Pump (Submersible Pump, Deep Well Pump) Method Submersible Pump Maintenance Schedule By following this checklist, you can effectively troubleshoot. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. When a field test of the pump’s performance is required, make the following readings: Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. When maintaining an electrical submersible pump, it’s. Submersible Pump Maintenance Schedule.

From studylib.net

Submersible Pump Maintenance And Repair Submersible Pump Maintenance Schedule Follow recommended maintenance schedules and procedures. Providing a maintenance schedule defined specifically by run hours or yardage pumped serves only as a general guideline given the. Volume, total head and horsepower. By following this checklist, you can effectively troubleshoot. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out. Submersible Pump Maintenance Schedule.

From gibbonsgroup.blogspot.com

5 handy submersible pump maintenance tips The Gibbons Group Submersible Pump Maintenance Schedule By following this checklist, you can effectively troubleshoot. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Follow recommended maintenance schedules and procedures. When a field test of the pump’s performance is required, make the following readings: When maintaining an electrical submersible pump, it’s important to look for any signs of. Submersible Pump Maintenance Schedule.

From www.greydock.com

Sump Pump Maintenance How to Keep Your Basement Dry (+ Checklist Submersible Pump Maintenance Schedule Volume, total head and horsepower. Submersible pumps maintenance checklist is used to conduct scheduled inspections of submersible pumps. By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Follow recommended maintenance schedules and procedures. By following this checklist, you can effectively troubleshoot. When a field test of the pump’s performance is required,. Submersible Pump Maintenance Schedule.

From www.scribd.com

Inspection and Test Plan for Centrifugal Pump Pump Technology Submersible Pump Maintenance Schedule When a field test of the pump’s performance is required, make the following readings: By following a structured maintenance schedule, you can ensure that your pumps operate efficiently, reducing downtime and maintaining. Volume, total head and horsepower. Optimise pump performance and hvac efficiency with preventive maintenance, cutting costs, extending asset life, and streamlining. By following this checklist, you can effectively. Submersible Pump Maintenance Schedule.

From www.fieldinsight.com

Preventive Maintenance Schedule for Pumps FieldInsight Submersible Pump Maintenance Schedule Volume, total head and horsepower. When a field test of the pump’s performance is required, make the following readings: By following this checklist, you can effectively troubleshoot. When maintaining an electrical submersible pump, it’s important to look for any signs of damage to the wiring and swap out any blown fuses. Submersible pumps maintenance checklist is used to conduct scheduled. Submersible Pump Maintenance Schedule.