Drill Point Angle For Different Materials . the more common twist drill point geometries often are not the best for the job at hand. learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. They are typically used for cutting into soft metals such as. are you overwhelmed by the options of materials, coatings, and geometries? By choosing the best point for the material being drilled,. learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. This guide breaks down the key factors to consider when. the general purpose drill points found on most jobber drills are 118° angled drills. The point angle is measured like this:

from www.sharpeninghandbook.info

By choosing the best point for the material being drilled,. learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. This guide breaks down the key factors to consider when. learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. the more common twist drill point geometries often are not the best for the job at hand. The point angle is measured like this: are you overwhelmed by the options of materials, coatings, and geometries? the general purpose drill points found on most jobber drills are 118° angled drills.

Sharpening Handbook

Drill Point Angle For Different Materials This guide breaks down the key factors to consider when. the more common twist drill point geometries often are not the best for the job at hand. The point angle is measured like this: This guide breaks down the key factors to consider when. By choosing the best point for the material being drilled,. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. They are typically used for cutting into soft metals such as. are you overwhelmed by the options of materials, coatings, and geometries? learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. the general purpose drill points found on most jobber drills are 118° angled drills.

From www.mecholic.com

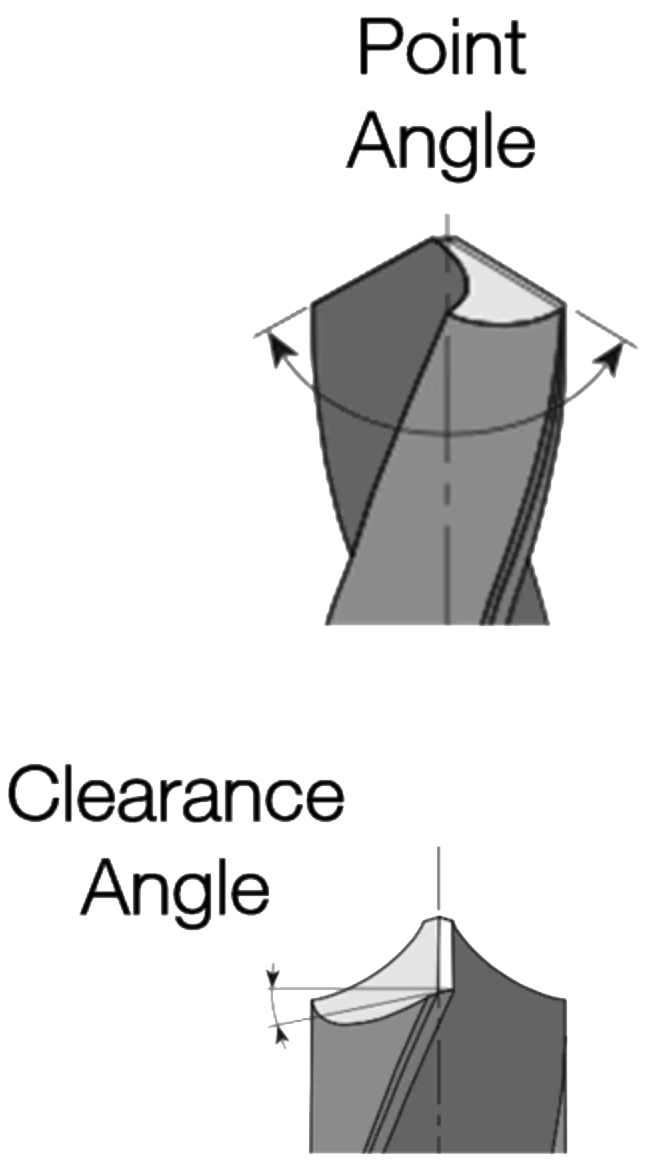

Different angles in twist drill Drill Point Angle For Different Materials learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. learn how the point angle, helix angle and other features of a twist drill influence tool. Drill Point Angle For Different Materials.

From www.sharpeninghandbook.info

Sharpening Handbook Drill Point Angle For Different Materials the more common twist drill point geometries often are not the best for the job at hand. learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. This guide breaks down the key factors to consider when. the general purpose drill points found on most jobber drills. Drill Point Angle For Different Materials.

From www.mmc-carbide.com

Parts of drill Technical Info / Cutting Formula MITSUBISHI Drill Point Angle For Different Materials the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. This guide breaks down the key factors to consider when. The point angle is measured like this:. Drill Point Angle For Different Materials.

From dxoohxnae.blob.core.windows.net

How To Drill At An Angle at Randy Justice blog Drill Point Angle For Different Materials the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. the more common twist drill point geometries often are not the best for the job at. Drill Point Angle For Different Materials.

From www.pinterest.co.kr

Drill bit angles 'Easily Explained', angles for materials Drill Point Angle For Different Materials are you overwhelmed by the options of materials, coatings, and geometries? learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. The point angle is measured like this: This guide breaks down the key factors to consider when. Find out the pros and cons of standard and split. Drill Point Angle For Different Materials.

From www.youtube.com

How to Measure the Point Angle of a Drill YouTube Drill Point Angle For Different Materials Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. the more common twist drill point geometries often are not the best for the job at hand. They are typically used for cutting into soft metals such as. By choosing the best point for the material being drilled,.. Drill Point Angle For Different Materials.

From www.drilldoctor.com

Getting started drill bit sharpening Drill Doctor Drill Point Angle For Different Materials are you overwhelmed by the options of materials, coatings, and geometries? learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. the general purpose drill points found on most jobber drills are 118° angled drills. Find out the pros and cons of standard and split point drill. Drill Point Angle For Different Materials.

From www.researchgate.net

(a) The top view of the drill point, (b) the front view of the drill Drill Point Angle For Different Materials This guide breaks down the key factors to consider when. the general purpose drill points found on most jobber drills are 118° angled drills. They are typically used for cutting into soft metals such as. The point angle is measured like this: the more common twist drill point geometries often are not the best for the job at. Drill Point Angle For Different Materials.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Drill Point Angle For Different Materials the general purpose drill points found on most jobber drills are 118° angled drills. the more common twist drill point geometries often are not the best for the job at hand. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. This guide breaks down the. Drill Point Angle For Different Materials.

From www.researchgate.net

Drillbit geometry. (a) General geometry, (b) Point geometry, and (c Drill Point Angle For Different Materials the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. The point angle is measured like this: By choosing the best point for the material being drilled,.. Drill Point Angle For Different Materials.

From www.slideserve.com

PPT Main Parts of a Drilling Machine PowerPoint Presentation, free Drill Point Angle For Different Materials the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. the more common twist drill point geometries often are not the best for the job at hand. This guide breaks down the key factors to consider when. learn how the point angle, helix angle and other. Drill Point Angle For Different Materials.

From www.mdpi.com

Metals Free FullText Geometric Optimization of Drills Used to Drill Point Angle For Different Materials learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. learn how the point angle, helix angle and other features of a twist drill influence tool life. Drill Point Angle For Different Materials.

From www.finepowertools.com

118 vs 135 Drill Bit Point Angles Explained. (with Pics) Drill Point Angle For Different Materials learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. the more common twist drill point geometries often are not the best for the job at hand. By choosing the best point for the material being drilled,. the general purpose drill points found on most jobber drills. Drill Point Angle For Different Materials.

From www.finepowertools.com

Spot Drill vs Center Drill. (Differences and Uses) Drill Point Angle For Different Materials They are typically used for cutting into soft metals such as. are you overwhelmed by the options of materials, coatings, and geometries? the more common twist drill point geometries often are not the best for the job at hand. The point angle is measured like this: By choosing the best point for the material being drilled,. the. Drill Point Angle For Different Materials.

From www.finepowertools.com

118 vs 135 Drill Bit Point Angles Explained. (with Pics) Drill Point Angle For Different Materials Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. the more common twist drill point geometries often are not the best for the job at hand. the general purpose drill points found on most jobber drills are 118° angled drills. the two most common drill. Drill Point Angle For Different Materials.

From www.regalcuttingtools.com

Which Drill Point Angle Should I Use? Regal Cutting Tools Drill Point Angle For Different Materials the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. the general purpose drill points found on most jobber drills are 118° angled drills. the more common twist drill point geometries often are not the best for the job at hand. learn the difference between. Drill Point Angle For Different Materials.

From www.researchgate.net

Drill geometry (Lindberg, 1990) Download Scientific Diagram Drill Point Angle For Different Materials Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. By choosing the best point for the material being drilled,. This guide breaks down the key factors to consider when. the more common twist drill point geometries often are not the best for the job at hand. . Drill Point Angle For Different Materials.

From www.pinterest.com

Drill Geometry & info on drill bits & drilling Drill Point Angle For Different Materials the general purpose drill points found on most jobber drills are 118° angled drills. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. They are typically used for cutting into soft metals such as. learn how the point angle, helix angle and other features of a. Drill Point Angle For Different Materials.

From www.youtube.com

Twist Drill Tool Nomenclature for Drilling (Parts And Important Angles Drill Point Angle For Different Materials the general purpose drill points found on most jobber drills are 118° angled drills. are you overwhelmed by the options of materials, coatings, and geometries? Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. The point angle is measured like this: the more common twist. Drill Point Angle For Different Materials.

From www.youtube.com

drill point angle for diffrent materials drill point angle drill Drill Point Angle For Different Materials the general purpose drill points found on most jobber drills are 118° angled drills. the more common twist drill point geometries often are not the best for the job at hand. learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. The point angle is measured like. Drill Point Angle For Different Materials.

From www.drillbitwarehouse.com

Exploring the Different Types of Twist Drill Point Angles Drill Point Angle For Different Materials This guide breaks down the key factors to consider when. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. By choosing the best point for the material being drilled,. the general purpose drill points found on most jobber drills are 118° angled drills. learn how. Drill Point Angle For Different Materials.

From www.finepowertools.com

118 vs 135 Drill Bit Point Angles Explained. (with Pics) Drill Point Angle For Different Materials They are typically used for cutting into soft metals such as. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. the general purpose drill points found on most jobber drills are 118° angled drills. the more common twist drill point geometries often are not the best. Drill Point Angle For Different Materials.

From www.youtube.com

Drill bit angles 'Easily Explained', angles for materials Drill Point Angle For Different Materials the general purpose drill points found on most jobber drills are 118° angled drills. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. the more common twist drill point geometries often are not the best for the job at hand. Find out the pros and. Drill Point Angle For Different Materials.

From www.pinterest.com

split point drill bit geometry Google Sök Afiador de brocas Drill Point Angle For Different Materials are you overwhelmed by the options of materials, coatings, and geometries? learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. the two most common drill. Drill Point Angle For Different Materials.

From www.pinterest.pt

Drill bit angle and speed chart Drill bits, Drill, Drill bit sharpening Drill Point Angle For Different Materials learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. are you overwhelmed by the options of materials, coatings, and geometries? the more common twist drill point geometries often are not the best for the job at hand. the general purpose drill points found on most. Drill Point Angle For Different Materials.

From www.drillbitwarehouse.com

Exploring the Different Types of Twist Drill Point Angles Drill Point Angle For Different Materials They are typically used for cutting into soft metals such as. are you overwhelmed by the options of materials, coatings, and geometries? learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. learn the difference between 118° and 135° drill bit angles and how to choose the. Drill Point Angle For Different Materials.

From exomsgwcs.blob.core.windows.net

Drill Twist Bit at Esther Weeks blog Drill Point Angle For Different Materials learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. By choosing the best point for the material being drilled,. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. learn how the point angle, helix angle. Drill Point Angle For Different Materials.

From www.mudgefasteners.com

How to Select a Drill Point Size Drill Point Angle For Different Materials This guide breaks down the key factors to consider when. are you overwhelmed by the options of materials, coatings, and geometries? By choosing the best point for the material being drilled,. They are typically used for cutting into soft metals such as. the general purpose drill points found on most jobber drills are 118° angled drills. Find out. Drill Point Angle For Different Materials.

From aidanfreeman.z13.web.core.windows.net

Drill Point Angle Chart Drill Point Angle For Different Materials the more common twist drill point geometries often are not the best for the job at hand. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and. Drill Point Angle For Different Materials.

From www.pinterest.com.mx

"Different materials will be more easily drilled using Drill Point Angle For Different Materials By choosing the best point for the material being drilled,. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. This guide breaks down the key factors. Drill Point Angle For Different Materials.

From www.researchgate.net

(A) Steel cylindrical 2 mm diameter drill with negative point angle Drill Point Angle For Different Materials The point angle is measured like this: Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. the two most common drill bit angles, or to be precise, drill bit point angles, are 118 degrees and 135 degrees. They are typically used for cutting into soft metals such. Drill Point Angle For Different Materials.

From www.youtube.com

DRILL BIT ANGLES (हिन्दी)l ड्रिल के कोण Drill Angles Types Of Drill Drill Point Angle For Different Materials This guide breaks down the key factors to consider when. are you overwhelmed by the options of materials, coatings, and geometries? the general purpose drill points found on most jobber drills are 118° angled drills. learn the difference between 118° and 135° drill bit angles and how to choose the right one for different materials. They are. Drill Point Angle For Different Materials.

From www.youtube.com

Drill Point Angle with the PG1000 YouTube Drill Point Angle For Different Materials By choosing the best point for the material being drilled,. the general purpose drill points found on most jobber drills are 118° angled drills. are you overwhelmed by the options of materials, coatings, and geometries? learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. Find out. Drill Point Angle For Different Materials.

From www.pinterest.com

Best Drill Bit Type for Wood, Metal, Glass, & Plastic Materials Guide Drill Point Angle For Different Materials the more common twist drill point geometries often are not the best for the job at hand. By choosing the best point for the material being drilled,. They are typically used for cutting into soft metals such as. Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency.. Drill Point Angle For Different Materials.

From www.drillbitwarehouse.com

Exploring the Different Types of Twist Drill Point Angles Drill Point Angle For Different Materials Find out the pros and cons of standard and split point drill bits and how they affect drilling accuracy and efficiency. the general purpose drill points found on most jobber drills are 118° angled drills. learn how the point angle, helix angle and other features of a twist drill influence tool life and hole tolerance. learn the. Drill Point Angle For Different Materials.