Bolt Clamp Calculator . Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to tighten a bolt to a specific clamping. Torque (nm) = k × d × p. \ (f\) is the clamping force, \. \ [ f = t / (k \cdot d) \] where: The formula for bolt tightening torque calculation is: Bolted joints are commonly used in machinery to securely connect two or more components together. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction The clamping force exerted by a bolt can be estimated using the formula:

from www.nord-lock.com

Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Torque (nm) = k × d × p. The formula for bolt tightening torque calculation is: \ [ f = t / (k \cdot d) \] where: Bolted joints are commonly used in machinery to securely connect two or more components together. \ (f\) is the clamping force, \. The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to tighten a bolt to a specific clamping. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability.

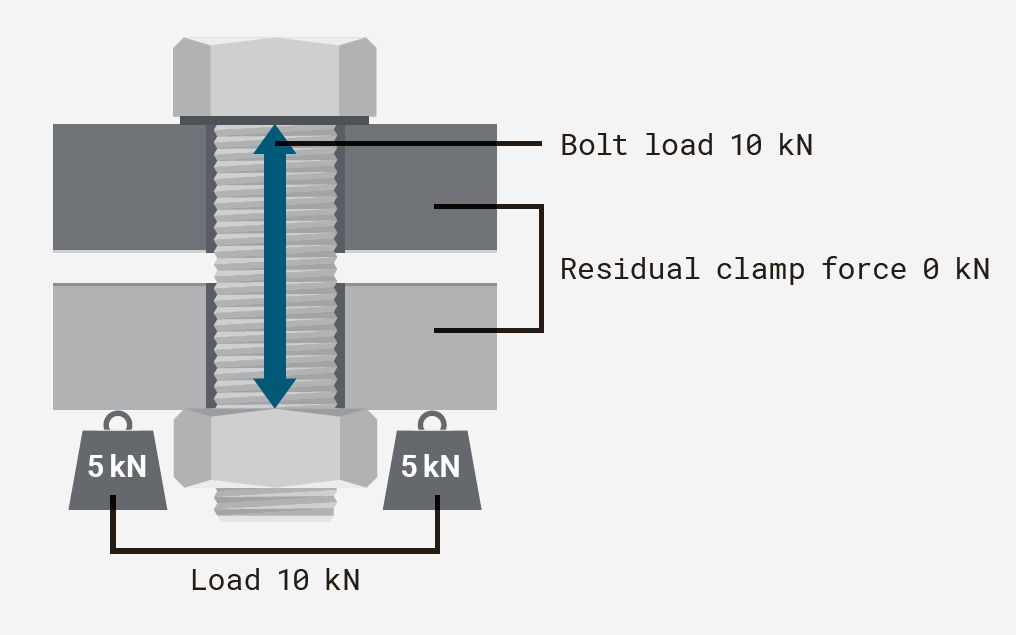

What happens to preload and clamp force when external loads are applied

Bolt Clamp Calculator Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. \ [ f = t / (k \cdot d) \] where: The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to tighten a bolt to a specific clamping. Torque (nm) = k × d × p. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. Bolted joints are commonly used in machinery to securely connect two or more components together. Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. The clamping force exerted by a bolt can be estimated using the formula: Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. The formula for bolt tightening torque calculation is: \ (f\) is the clamping force, \.

From www.researchgate.net

Schematic of a bolted joint with conical assumption of the clamp zone Bolt Clamp Calculator The formula for bolt tightening torque calculation is: Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to tighten a bolt to a specific clamping. The clamping force. Bolt Clamp Calculator.

From www.youtube.com

ENGR380 Lecture19 Stiffness of Bolted Joint YouTube Bolt Clamp Calculator Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction \ [ f = t / (k \cdot d) \] where: This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. Torque (nm) = k. Bolt Clamp Calculator.

From present5.com

THREADED JOINTS THREADED JOINTS Threaded joints are Bolt Clamp Calculator Torque (nm) = k × d × p. The clamping force exerted by a bolt can be estimated using the formula: The formula for bolt tightening torque calculation is: The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to tighten a bolt to a specific clamping. Where k is the torque. Bolt Clamp Calculator.

From www.nord-lock.com

What happens to preload and clamp force when external loads are applied Bolt Clamp Calculator The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to tighten a bolt to a specific clamping. \ [ f = t / (k \cdot d) \] where: Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. Torque (nm) = k. Bolt Clamp Calculator.

From static.parkmed.com

Bolt Clamping Force Calculations EngineerExcel, 40 OFF Bolt Clamp Calculator Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. \ [ f = t / (k \cdot d) \] where: Torque (nm) = k × d × p. The formula for bolt tightening torque calculation is: The clamping force exerted by a bolt can be estimated using the formula: This. Bolt Clamp Calculator.

From www.futek.com

Bolt Clamping Force Bolt Torque to Clamping Force Bolt Load Measurement Bolt Clamp Calculator \ [ f = t / (k \cdot d) \] where: Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction \ (f\) is the clamping force, \. The formula for bolt tightening torque calculation is: Compared to other types of fasteners, they are favored because of. Bolt Clamp Calculator.

From engineerexcel.com

Bolt Clamping Force Calculations EngineerExcel Bolt Clamp Calculator This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to tighten a bolt to a specific clamping. Where k is the torque coefficient, d is the nominal diameter of. Bolt Clamp Calculator.

From engineerexcel.com

Bolt Clamping Force Calculations EngineerExcel Bolt Clamp Calculator Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. Bolted joints are commonly used in machinery to securely connect two or more components together. The clamping force exerted by a bolt can be estimated using the formula: Calculate the axial clamping force of a bolt using the clamping. Bolt Clamp Calculator.

From whatispiping.com

Design of Bolted Connections or Bolted Joints What Is Piping Bolt Clamp Calculator This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Compared to other types of fasteners, they are favored because of their strength in supporting. Bolt Clamp Calculator.

From www.scribd.com

BOLT LOAD CAPACITY TABLE Screw Mechanical Engineering Bolt Clamp Calculator \ (f\) is the clamping force, \. The clamping force exerted by a bolt can be estimated using the formula: Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. \ [ f = t / (k \cdot d) \] where: Torque (nm) = k × d × p. Bolted joints. Bolt Clamp Calculator.

From smartbolts.com

How It Works SmartBolts Bolt Clamp Calculator Bolted joints are commonly used in machinery to securely connect two or more components together. Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. \ (f\) is the clamping force, \. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction. Bolt Clamp Calculator.

From static.parkmed.com

Bolt Clamping Force Calculations EngineerExcel, 40 OFF Bolt Clamp Calculator Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. \ [ f = t / (k \cdot d) \] where: The skyciv bolt torque calculator is a free tool. Bolt Clamp Calculator.

From www.youtube.com

Bolt and Member Stiffness Bolt and Nut Selection Example 1 YouTube Bolt Clamp Calculator The formula for bolt tightening torque calculation is: Torque (nm) = k × d × p. Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. \ [ f = t / (k \cdot d) \] where: Compared to other types of fasteners, they are favored because of their strength in. Bolt Clamp Calculator.

From answertion.com

How to find clamping force from bolt preload? Q&A Answertion Bolt Clamp Calculator Torque (nm) = k × d × p. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. The clamping force exerted by a bolt can be estimated using the formula: Bolted joints are commonly used in machinery to securely connect two or more components together. Calculate the. Bolt Clamp Calculator.

From www.excelcalcs.com

Quick and Dirty Bolt Sizing Calculation.xls Bolt Clamp Calculator \ [ f = t / (k \cdot d) \] where: This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. Torque (nm) = k × d × p. Bolted joints are commonly used in machinery to securely connect two or more components together. The formula for bolt. Bolt Clamp Calculator.

From callumbryant.z19.web.core.windows.net

Square Ubolt Size Chart Bolt Clamp Calculator \ [ f = t / (k \cdot d) \] where: \ (f\) is the clamping force, \. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. The clamping force exerted by a bolt can be estimated using the formula: Where k is the torque coefficient, d. Bolt Clamp Calculator.

From www.scribd.com

Bolt Clamp Load Chart Bolt Clamp Calculator This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction \ (f\) is the clamping force, \. Torque (nm) = k × d × p.. Bolt Clamp Calculator.

From www.pinterest.com

bolt torque chart Bolt, Drill bit sizes, Chart Bolt Clamp Calculator Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Bolted joints are commonly used in machinery to securely connect two or more components together. Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. \ (f\) is. Bolt Clamp Calculator.

From smartbolts.com

Using Torque to Measure Clamp Force An Inconvenient Truth Bolt Clamp Calculator The clamping force exerted by a bolt can be estimated using the formula: Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Torque (nm) = k ×. Bolt Clamp Calculator.

From engineersfield.com

Bolt Proof load values & nominal stress area calculation Engineersfield Bolt Clamp Calculator Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction The clamping force exerted by a bolt can be estimated using the formula: The formula for. Bolt Clamp Calculator.

From calcdevice.com

Twobolt Clamp Calculator Axial load Bolt Clamp Calculator Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. \ (f\) is the clamping force, \. Calculate the axial clamping force of a bolt using the clamping force. Bolt Clamp Calculator.

From www.mudgefasteners.com

Determining Torque The Facts About Required Torque, Tension and Clamp Bolt Clamp Calculator The formula for bolt tightening torque calculation is: \ (f\) is the clamping force, \. Bolted joints are commonly used in machinery to securely connect two or more components together. Torque (nm) = k × d × p. The clamping force exerted by a bolt can be estimated using the formula: Where k is the torque coefficient, d is the. Bolt Clamp Calculator.

From www.murraycorp.com

Heavy Duty TBolt Band Clamps Bolt Clamp Calculator Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction The skyciv bolt torque calculator is a free tool to help determine the correct amount of. Bolt Clamp Calculator.

From engineerexcel.com

Bolt Preload Calculator EngineerExcel Bolt Clamp Calculator Torque (nm) = k × d × p. Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. \ (f\) is the clamping force, \. Bolted joints are commonly used in machinery to securely connect two or more components together. Compared to other types of fasteners, they are favored because of. Bolt Clamp Calculator.

From calcdevice.com

Bolt Tightening of a Bar Mounted Clamp Online Calculator Bolt Clamp Calculator Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. Torque (nm) = k × d × p. Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. The formula for bolt tightening torque calculation is: Calculate the axial clamping. Bolt Clamp Calculator.

From www.celofasteners.com

Clamping force in plastic assemblies Bolt Clamp Calculator The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to tighten a bolt to a specific clamping. Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. Where k is the torque coefficient, d is the nominal diameter of the. Bolt Clamp Calculator.

From www.scribd.com

Metric Bolt Torque Table Screw Kilogram Bolt Clamp Calculator Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. The clamping force exerted by a bolt can be estimated using the formula: Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. The skyciv bolt torque calculator is a. Bolt Clamp Calculator.

From mpcindustries.com

DS040AHSS Tbolt clamps Tridon® Industries Bolt Clamp Calculator The clamping force exerted by a bolt can be estimated using the formula: Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. \ [ f =. Bolt Clamp Calculator.

From calculatorvcd.blogspot.com

Tensile Strength Of Bolt Calculation CALCULATOR VCD Bolt Clamp Calculator \ [ f = t / (k \cdot d) \] where: Torque (nm) = k × d × p. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. \ (f\) is the clamping force, \. Where k is the torque coefficient, d is the nominal diameter of. Bolt Clamp Calculator.

From www.youtube.com

injection molding how to calculate clamping force YouTube Bolt Clamp Calculator Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction The formula for bolt tightening torque calculation is: The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to tighten a bolt to a specific clamping. Torque (nm) =. Bolt Clamp Calculator.

From engineersedge.com

Bolt Pattern Group Pullout Excel Spreadsheet Calculator Bolt Clamp Calculator \ [ f = t / (k \cdot d) \] where: The clamping force exerted by a bolt can be estimated using the formula: Torque (nm) = k × d × p. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied and coefficient of turning friction for the given. \ (f\) is the clamping force,. Bolt Clamp Calculator.

From ncalculators.com

Brake Clamp Load Calculator Bolt Clamp Calculator The clamping force exerted by a bolt can be estimated using the formula: \ [ f = t / (k \cdot d) \] where: Bolted joints are commonly used in machinery to securely connect two or more components together. \ (f\) is the clamping force, \. This fastener bolt torque calculator will estimate the unknown torque, diameter, axial force applied. Bolt Clamp Calculator.

From www.scribd.com

Clamp Calculation 3 PDF Continuum Mechanics Physics Bolt Clamp Calculator Compared to other types of fasteners, they are favored because of their strength in supporting loads, ease of disassembly, and reliability. \ [ f = t / (k \cdot d) \] where: Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. The formula for bolt tightening torque calculation is: Calculate. Bolt Clamp Calculator.

From www.sampletemplates.com

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word Bolt Clamp Calculator Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. Torque (nm) = k × d × p. Bolted joints are commonly used in machinery to securely connect two or more components together. \ [ f = t / (k \cdot d) \] where: \ (f\) is the clamping force, \.. Bolt Clamp Calculator.

From technobuildersgroup.com

Two Bolt Clamp Techno Builders Group Bolt Clamp Calculator Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's. Bolted joints are commonly used in machinery to securely connect two or more components together. \ (f\) is the clamping force, \. The skyciv bolt torque calculator is a free tool to help determine the correct amount of torque needed to. Bolt Clamp Calculator.