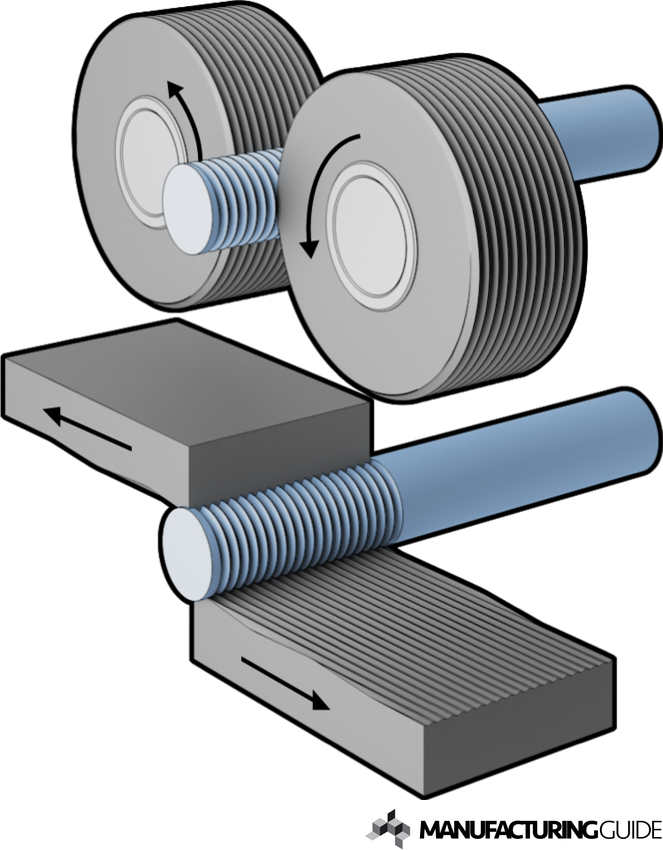

What Is A Thread Roller . The process is different from. Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part.

from www.manufacturingguide.com

The process is different from. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads.

Thread Rolling Find suppliers, processes & material

What Is A Thread Roller Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. The process is different from. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. The process is different from. Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,.. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Thread. What Is A Thread Roller.

From www.mytoolssa.co.za

THREAD ROLLING Machines My Tools SA What Is A Thread Roller Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. The process is different from. Thread rolling is a process where threads are formed on. What Is A Thread Roller.

From www.fhmachinery.com

Thread Rollers FH Machinery Inc. What Is A Thread Roller The process is different from. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is a metal forging process that forms. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller The process is different from. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece. What Is A Thread Roller.

From www.fhmachinery.com

Tesker 840 Thread Roller FH Machinery Inc. What Is A Thread Roller The process is different from. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is a threading. What Is A Thread Roller.

From www.haritonmachinery.com

Waterbury Farrel Model 60 Horizontal Hand Feed Thread Roller Hariton What Is A Thread Roller As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is a metal forging process that forms threads into the mirror image. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. As the blank cylinder is penetrated by the dies, the metal flows. What Is A Thread Roller.

From thegatewaymag.com

Applying Pressure The Benefits of Thread Rolling The Gateway to New What Is A Thread Roller Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. The process is different from. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is a cold. What Is A Thread Roller.

From machinehub.com

HARTFORD M 312 Thread Rollers Machine Hub What Is A Thread Roller Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,.. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread. What Is A Thread Roller.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? What Is A Thread Roller Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads.. What Is A Thread Roller.

From mikehardware.com

Thread Rolling Process of Screws The Basics MIKEHARDWARE What Is A Thread Roller The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. As the blank cylinder is. What Is A Thread Roller.

From alwepo.com

What Is Thread Rolling? Definition, Types, Process, Machines, And What Is A Thread Roller Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. What Is A Thread Roller.

From www.fhmachinery.com

Reed D44EH Cylindrical Thread Roller FH Machinery Inc. What Is A Thread Roller Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is a metal forging process that forms threads into the mirror image of. What Is A Thread Roller.

From www.youtube.com

What is thread rolling machine main parts and working of thread What Is A Thread Roller The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is a process where threads are formed on the bolt by displacing the material using a. What Is A Thread Roller.

From www.youtube.com

Rolled Threads Unlimited Unified Thread Rolling Example YouTube What Is A Thread Roller Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. The fastest, most economical. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is a process where threads are formed on the bolt by displacing the material using a. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. As the blank cylinder is. What Is A Thread Roller.

From www.youtube.com

Tesker Thread Rolling Process YouTube What Is A Thread Roller Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. The process is different from. The fastest, most economical method for producing highly accurate threads, thread rolling allows for. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the. What Is A Thread Roller.

From www.manufacturingguide.com

Thread Rolling Find suppliers, processes & material What Is A Thread Roller Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose. What Is A Thread Roller.

From www.csrebarsplice.com

Thread RollerThread RollerCHANGSHA DLADTO REBAR SPLICE CO.,LTD What Is A Thread Roller Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface.. What Is A Thread Roller.

From www.haritonmachinery.com

5/16″ Tanisaka Model 10400 High Speed Flat Die Thread Roller Hariton What Is A Thread Roller The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is a threading process that deforms a metal stock by rolling it between dies,. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Instead of removing material to create threads, thread rolling redistributes the material of the. What Is A Thread Roller.

From www.ygmtools.com

What is Thread Rolling? YGMTOOLS What Is A Thread Roller Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is a threading. What Is A Thread Roller.

From www.fhmachinery.com

10 Saspi Model GV210 Thread Roller FH Machinery Inc. What Is A Thread Roller Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. The. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads,. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die.. What Is A Thread Roller.

From www.linkedin.com

What is Thread Rolling? What Is A Thread Roller Thread rolling is a process where threads are formed on the bolt by displacing the material using a die. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Thread rolling is a threading process that deforms a metal stock by rolling it between dies, creating external threads on the surface. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. As the blank cylinder is penetrated by the dies, the metal flows. What Is A Thread Roller.

From www.fhmachinery.com

Reed D44EH Cylindrical Thread Roller FH Machinery Inc. What Is A Thread Roller Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the. What Is A Thread Roller.

From templateoptions.machinehub.com

WATERBURY FARREL 10 Threading Machines, Flat Die Thread Rollers What Is A Thread Roller Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. The process is different from. Thread rolling is a process where threads are formed on the bolt by. What Is A Thread Roller.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is A Thread Roller Instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the. What Is A Thread Roller.