Carbon Fiber Resin Melting Point . Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. They are embedded in a ductile. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current.

from tdyldiy.com

The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Carbon fibers are stiff and possess high strength comparable with that of high strength steel. They are embedded in a ductile. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current.

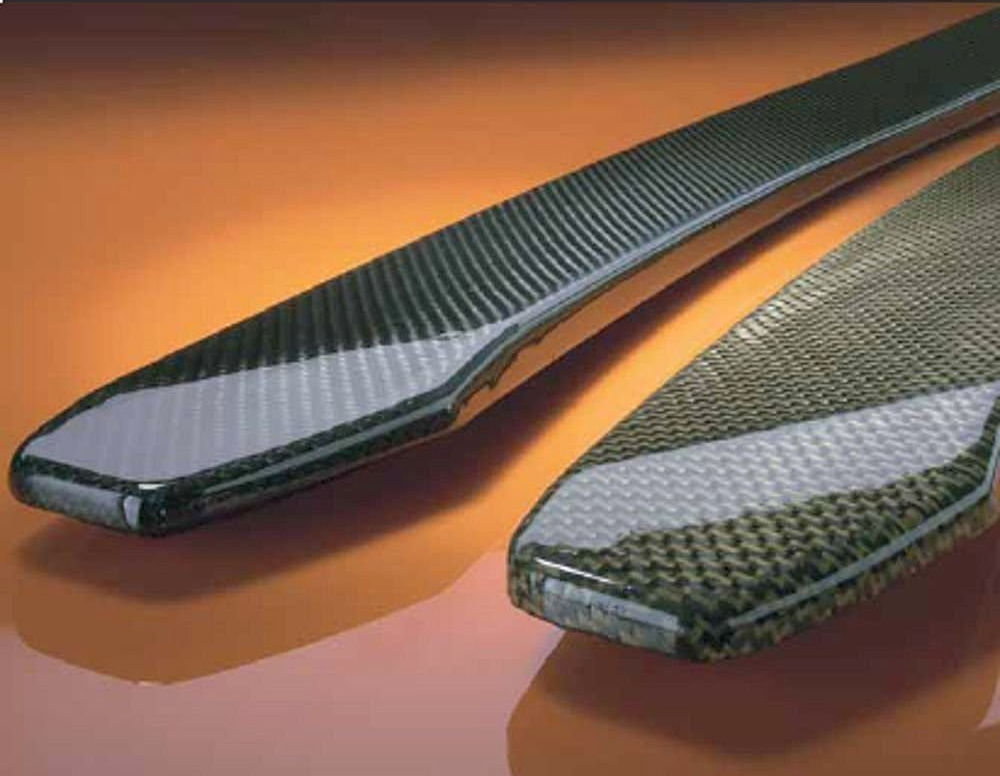

High Hardness Epoxy Resin for Carbon Fiber Products Coating

Carbon Fiber Resin Melting Point Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. They are embedded in a ductile. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the.

From www.researchgate.net

Surface configurations of embedded carbon fiberreinforced polymer Carbon Fiber Resin Melting Point The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Carbon fiber composites have a density of 1.55 g/cm 3. Carbon Fiber Resin Melting Point.

From automotive.sika.com

Composite Systems Advanced Resins Sika Automotive Carbon Fiber Resin Melting Point Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3. Carbon Fiber Resin Melting Point.

From www.nuclear-power.com

Carbon Melting Point Boiling Point Carbon Fiber Resin Melting Point They are embedded in a ductile. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3. Carbon Fiber Resin Melting Point.

From www.turnology.com

Carbon Fiber A Lesson in CompositesTurnology Carbon Fiber Resin Melting Point Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have a density of. Carbon Fiber Resin Melting Point.

From erusuconsultants.com

Carbon Fiber use in Construction Erusu Consultants Carbon Fiber Resin Melting Point Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3. Carbon Fiber Resin Melting Point.

From www.powerblanket.com

Best Epoxy Curing Solutions Heated Blankets Powerblanket Carbon Fiber Resin Melting Point They are embedded in a ductile. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. The. Carbon Fiber Resin Melting Point.

From www.youtube.com

Carbon Fiber DIY Resin Transfer Molding RTM Part 1 YouTube Carbon Fiber Resin Melting Point Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Carbon fibers are stiff and possess high strength. Carbon Fiber Resin Melting Point.

From www.mdpi.com

Polymers Free FullText A Study on Carbon Fiber Composites with Low Carbon Fiber Resin Melting Point Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Carbon fiber composites have. Carbon Fiber Resin Melting Point.

From www.mdpi.com

Polymers Free FullText Recycling and Reutilization of Waste Carbon Carbon Fiber Resin Melting Point Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum. Carbon Fiber Resin Melting Point.

From www.ar15.com

What is the melting point of Carbon fiber? Page 1 Carbon Fiber Resin Melting Point The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Carbon fiber composites. Carbon Fiber Resin Melting Point.

From www2.mdpi.com

C Free FullText OneStep Densification of Carbon/Carbon Composites Carbon Fiber Resin Melting Point The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Carbon fibers are stiff and. Carbon Fiber Resin Melting Point.

From www.mdpi.com

Polymers Free FullText Mechanical Properties of Thermoplastic Carbon Fiber Resin Melting Point Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. The melting point of carbon fiber constant. Carbon Fiber Resin Melting Point.

From tdyldiy.com

High Hardness Epoxy Resin for Carbon Fiber Products Coating Carbon Fiber Resin Melting Point Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. They are embedded in a ductile. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Carbon. Carbon Fiber Resin Melting Point.

From www.antala.uk

Prepreg Carbon Fibre Resins Antala Ltd. Carbon Fiber Resin Melting Point They are embedded in a ductile. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Carbon fibers. Carbon Fiber Resin Melting Point.

From www.researchgate.net

DSC curve of phenolic resin in curing. Download Scientific Diagram Carbon Fiber Resin Melting Point They are embedded in a ductile. Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. The melting point. Carbon Fiber Resin Melting Point.

From managingcomposites.com

Failure sequences of carbon fiber specimens! Managing Composites Carbon Fiber Resin Melting Point Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. They are embedded in a ductile. The melting. Carbon Fiber Resin Melting Point.

From us.mitsubishi-chemical.com

MCC Develops Highly Heatresistant CFRP Using Phenolic Resin Carbon Fiber Resin Melting Point The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Carbon fibers are. Carbon Fiber Resin Melting Point.

From www.ar15.com

What is the melting point of Carbon fiber? Page 1 Carbon Fiber Resin Melting Point They are embedded in a ductile. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%,. Carbon Fiber Resin Melting Point.

From fyojiqsdq.blob.core.windows.net

Is Carbon Fiber Resin The Same As Fiberglass Resin at Alfred Weatherly blog Carbon Fiber Resin Melting Point They are embedded in a ductile. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Carbon fibers. Carbon Fiber Resin Melting Point.

From renewable-carbon.eu

Natural fibres show outstandingly low CO2 footprint compared to glass Carbon Fiber Resin Melting Point The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. They are embedded in a ductile. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization. Carbon Fiber Resin Melting Point.

From www.moldplasticinjection.com

Carbon Fiber Moulding Manufacturers Carbon Fiber Resin Melting Point They are embedded in a ductile. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%),. Carbon Fiber Resin Melting Point.

From www.mdpi.com

Nanomaterials Free FullText Interfacial Strengthening and Self Carbon Fiber Resin Melting Point Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. The melting. Carbon Fiber Resin Melting Point.

From encyclopedia.pub

Carbon FiberReinforced Polymer Composites Encyclopedia MDPI Carbon Fiber Resin Melting Point The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fibers are stiff and possess high strength comparable with that of high strength steel. They are embedded in a ductile. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case. Carbon Fiber Resin Melting Point.

From fiberglasswarehouse.com

Tips and Tricks for Working with Carbon Fiber and Resin Fiberglass Carbon Fiber Resin Melting Point Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. The melting point of carbon fiber constant. Carbon Fiber Resin Melting Point.

From www.sinograf.com

CARBON FIBRES WHAT ARE THEY AND WHAT DISTINGUISHES THEM? Sinograf Carbon Fiber Resin Melting Point Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. They are. Carbon Fiber Resin Melting Point.

From markforged.com

Replacing Aluminum Parts with 3D Printed Carbon Fiber Carbon Fiber Resin Melting Point Carbon fibers are stiff and possess high strength comparable with that of high strength steel. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). They are embedded in a ductile. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have. Carbon Fiber Resin Melting Point.

From www.darkaero.com

Five Things You May Not Know About Carbon Fiber Carbon Fiber Resin Melting Point The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Carbon fiber composites have. Carbon Fiber Resin Melting Point.

From www.mdpi.com

Materials Free FullText Improving the Vertical Thermal Carbon Fiber Resin Melting Point Carbon fibers are stiff and possess high strength comparable with that of high strength steel. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Relationships between carbon fiber. Carbon Fiber Resin Melting Point.

From www.etsy.com

1/2 White Resin Carbon Fiber Plate Carbonwaves Carbon Etsy Carbon Fiber Resin Melting Point They are embedded in a ductile. Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Carbon fibers, on. Carbon Fiber Resin Melting Point.

From www.researchgate.net

Typical range of melt flow rate (MFR) values for PEHD and PP resins Carbon Fiber Resin Melting Point Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. The melting point of carbon fiber constant. Carbon Fiber Resin Melting Point.

From material-properties.org

Carbon Fiber Density, Strength,, Melting Point Carbon Fiber Resin Melting Point Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fiber composites. Carbon Fiber Resin Melting Point.

From www.mdpi.com

Polymers Free FullText Carbonaceous Materials Coated Carbon Fibre Carbon Fiber Resin Melting Point Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. The melting. Carbon Fiber Resin Melting Point.

From xxtcl.sxicc.ac.cn

Review of chemical recycling and reuse of carbon fiber reinforced epoxy Carbon Fiber Resin Melting Point Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have a density of 1.55 g/cm 3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm 3 and 4.5 g/cm 3 for titanium or 7.9 g/cm 3 for. They are embedded in a ductile. The melting. Carbon Fiber Resin Melting Point.

From blog.thepipingmart.com

Melting Points of Carbon and Tungsten Carbon Fiber Resin Melting Point They are embedded in a ductile. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Carbon fibers are stiff and possess high strength comparable with that of high strength steel. Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites have. Carbon Fiber Resin Melting Point.

From www.mdpi.com

Polymers Free FullText Polyethylene Terephthalate (PET) Bottleto Carbon Fiber Resin Melting Point Carbon fibers, on the other hand, are made from pitch precursors through a series of processes that include stabilization to prevent the. The melting point of carbon fiber constant displays the value of the melting point for carbon fiber (3657 °c). Relationships between carbon fiber microstructure and material performance is undertaken in order to assess the current. Carbon fiber composites. Carbon Fiber Resin Melting Point.