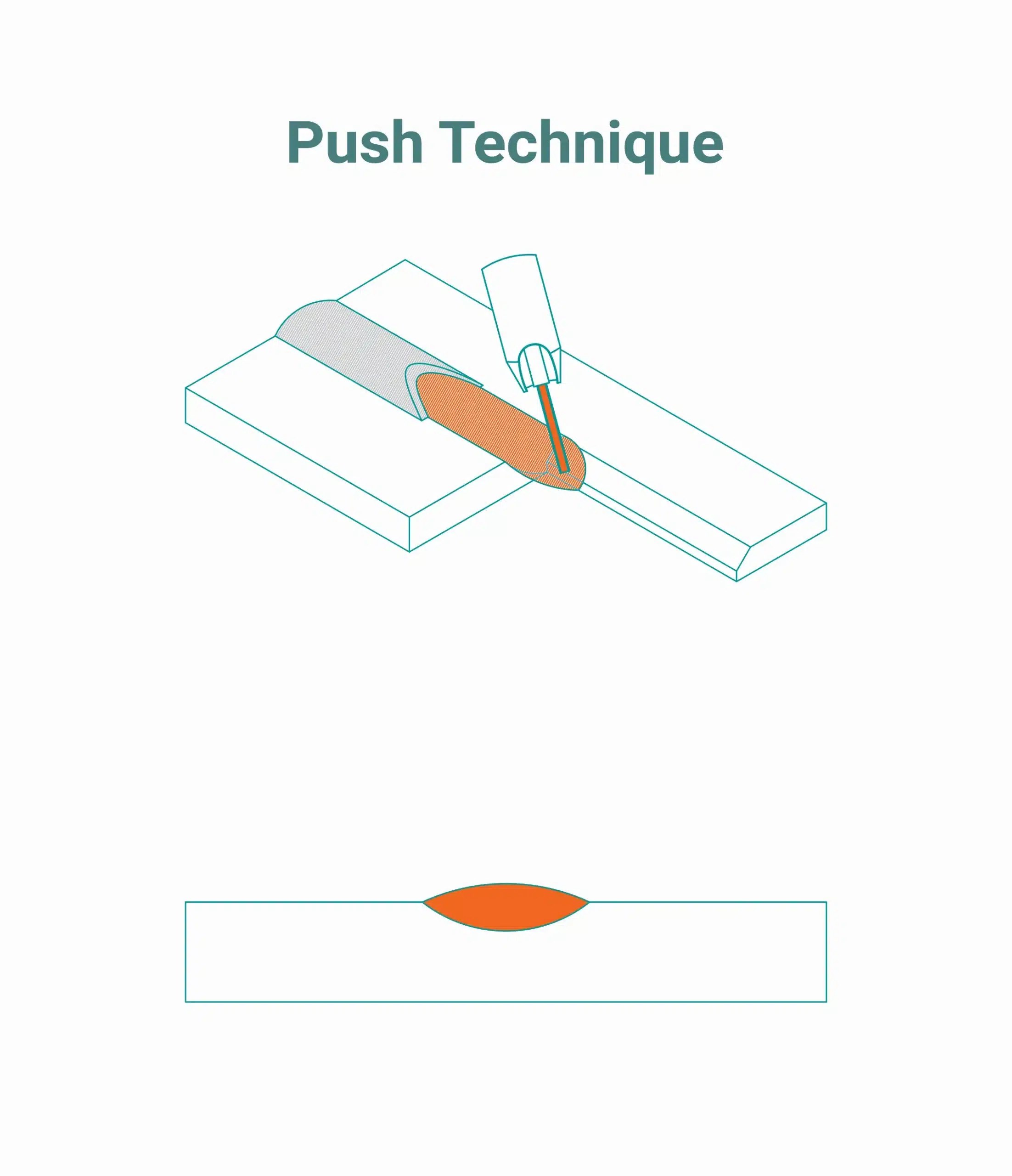

Pull Vs Push Mig Welding . This approach is like smoothly brushing paint on a surface. What are the differences between pushing and pulling? The push welding technique is ideal for deep penetration and when there is more area. The push and pull techniques refer to the direction in which the welding torch is moved. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. With slag, pull is the most suitable method. Among the pivotal decisions in mig welding is the choice between two fundamental techniques: It produces a flatter, broader weld, offering an advantage when welding materials like. The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency of your welds. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice.

from weldingpros.net

Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency of your welds. The push and pull techniques refer to the direction in which the welding torch is moved. What are the differences between pushing and pulling? The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. With slag, pull is the most suitable method. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. It produces a flatter, broader weld, offering an advantage when welding materials like. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. Among the pivotal decisions in mig welding is the choice between two fundamental techniques: The push welding technique is ideal for deep penetration and when there is more area.

How to MIG Weld Techniques & Tips For Successful MIG Welds

Pull Vs Push Mig Welding The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. What are the differences between pushing and pulling? The push welding technique is ideal for deep penetration and when there is more area. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. Among the pivotal decisions in mig welding is the choice between two fundamental techniques: With slag, pull is the most suitable method. The push and pull techniques refer to the direction in which the welding torch is moved. Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency of your welds. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. This approach is like smoothly brushing paint on a surface. It produces a flatter, broader weld, offering an advantage when welding materials like. The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired.

From theweldingapprentice.com

Do You Push Or Pull MIG Welding? Welding Apprentice Gear Pull Vs Push Mig Welding The push welding technique is ideal for deep penetration and when there is more area. With slag, pull is the most suitable method. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding. Pull Vs Push Mig Welding.

From weldingvilla.com

The Ultimate Guide to MIG Welding Aluminium Like a Pro Pull Vs Push Mig Welding The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. What are the differences between pushing and pulling? Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. Arc welding processes, such as mig welding, tig welding, or. Pull Vs Push Mig Welding.

From migtigstickweld.com

Do You Push or Pull When MIG Welding? Direction Matters! Pull Vs Push Mig Welding The push welding technique is ideal for deep penetration and when there is more area. The push and pull techniques refer to the direction in which the welding torch is moved. Among the pivotal decisions in mig welding is the choice between two fundamental techniques: Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat. Pull Vs Push Mig Welding.

From shopyeswelder.com

Push Vs Pull Welding Explained YesWelder Pull Vs Push Mig Welding It produces a flatter, broader weld, offering an advantage when welding materials like. The push and pull techniques refer to the direction in which the welding torch is moved. The push welding technique is ideal for deep penetration and when there is more area. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of. Pull Vs Push Mig Welding.

From mungfali.com

Push Vs Pull Mig Welding Pull Vs Push Mig Welding What are the differences between pushing and pulling? It produces a flatter, broader weld, offering an advantage when welding materials like. This approach is like smoothly brushing paint on a surface. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the. Pull Vs Push Mig Welding.

From welderslab.com

Do You Push or Pull a MIG Welder Which is Better Pull Vs Push Mig Welding The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. The push and pull techniques refer to the direction in which the welding torch is moved. Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency of your welds. What are the. Pull Vs Push Mig Welding.

From www.youtube.com

How To Rethread A Push Pull MIG Welding System YouTube Pull Vs Push Mig Welding This approach is like smoothly brushing paint on a surface. The push and pull techniques refer to the direction in which the welding torch is moved. With slag, pull is the most suitable method. Among the pivotal decisions in mig welding is the choice between two fundamental techniques: The push welding technique is ideal for deep penetration and when there. Pull Vs Push Mig Welding.

From www.mig-welding.co.uk

Aluminium MIG Welding Pull Vs Push Mig Welding Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. Push. Pull Vs Push Mig Welding.

From mungfali.com

Push Vs Pull Mig Welding Pull Vs Push Mig Welding With slag, pull is the most suitable method. Among the pivotal decisions in mig welding is the choice between two fundamental techniques: The push and pull techniques refer to the direction in which the welding torch is moved. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. What are the. Pull Vs Push Mig Welding.

From weldingpros.net

How to MIG Weld Techniques & Tips For Successful MIG Welds Pull Vs Push Mig Welding Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. This approach is like smoothly brushing paint on a surface. With slag, pull is the most suitable method. The push and pull techniques refer to the direction in which the welding torch is moved. What are the differences between pushing and. Pull Vs Push Mig Welding.

From www.youtube.com

Setting up for Push Pull Gun Welding Millermatic® 355 YouTube Pull Vs Push Mig Welding The push welding technique is ideal for deep penetration and when there is more area. What are the differences between pushing and pulling? The push and pull techniques refer to the direction in which the welding torch is moved. It produces a flatter, broader weld, offering an advantage when welding materials like. Among the pivotal decisions in mig welding is. Pull Vs Push Mig Welding.

From www.fabricatingandmetalworking.com

Fabricating & Metalworking Pull Vs Push Mig Welding Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. What are the differences between pushing and pulling? Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency of your welds. The push welding technique is ideal for deep penetration and when there is more area.. Pull Vs Push Mig Welding.

From www.mig-welding.co.uk

Learning MIG Welding Pull Vs Push Mig Welding The push and pull techniques refer to the direction in which the welding torch is moved. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. Choosing between push and pull mig welding techniques. Pull Vs Push Mig Welding.

From weldguru.com

Push vs. Pull When MIG Welding Which is Right? Pull Vs Push Mig Welding Among the pivotal decisions in mig welding is the choice between two fundamental techniques: Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency of your welds. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt. Pull Vs Push Mig Welding.

From weldguru.com

Push vs. Pull When MIG Welding Which is Right? Pull Vs Push Mig Welding This approach is like smoothly brushing paint on a surface. The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to. Pull Vs Push Mig Welding.

From www.pinterest.com

SHOULD YOU PUSH OR PULL A MIG WELD? FLAT OR RIPPLE BEAD? WELDING TIPS Pull Vs Push Mig Welding Among the pivotal decisions in mig welding is the choice between two fundamental techniques: Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. What are the differences between pushing and pulling? The choice. Pull Vs Push Mig Welding.

From mrd.psych.tu-dresden.de

Push Pull When MIG Welding Which Is Right?, 57 OFF Pull Vs Push Mig Welding This approach is like smoothly brushing paint on a surface. The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. The push welding technique is ideal for deep penetration and when there is more area. It produces a flatter, broader weld, offering an advantage when welding materials. Pull Vs Push Mig Welding.

From www.reddit.com

When MIG welding, do you lot push or pull. Reason I ask is because I’ve Pull Vs Push Mig Welding Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. It produces a flatter, broader. Pull Vs Push Mig Welding.

From fitwelding.com

Push Pull Aluminum MiG Welder Advantages and Disadvantages Fit Welding Pull Vs Push Mig Welding It produces a flatter, broader weld, offering an advantage when welding materials like. The push and pull techniques refer to the direction in which the welding torch is moved. This approach is like smoothly brushing paint on a surface. With slag, pull is the most suitable method. The push welding technique is ideal for deep penetration and when there is. Pull Vs Push Mig Welding.

From mungfali.com

Push Vs Pull Mig Welding Pull Vs Push Mig Welding Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency of your welds. It produces a flatter, broader weld, offering an advantage when welding materials like. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. Among the pivotal decisions in mig welding is the choice. Pull Vs Push Mig Welding.

From theweldingapprentice.com

Do You Push Or Pull MIG Welding? Welding Apprentice Gear Pull Vs Push Mig Welding Among the pivotal decisions in mig welding is the choice between two fundamental techniques: It produces a flatter, broader weld, offering an advantage when welding materials like. The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. Arc welding processes, such as mig welding, tig welding, or. Pull Vs Push Mig Welding.

From migtigstickweld.com

Do You Push or Pull When MIG Welding? Direction Matters! Pull Vs Push Mig Welding With slag, pull is the most suitable method. What are the differences between pushing and pulling? This approach is like smoothly brushing paint on a surface. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency. Pull Vs Push Mig Welding.

From www.youtube.com

PUSH vs. PULL MIG Welding Cut and Etch YouTube Pull Vs Push Mig Welding This approach is like smoothly brushing paint on a surface. The push welding technique is ideal for deep penetration and when there is more area. It produces a flatter, broader weld, offering an advantage when welding materials like. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. Arc welding processes,. Pull Vs Push Mig Welding.

From beststudwelders.com

Push or Pull When MIG Welding Which Is Better? best stud welders Pull Vs Push Mig Welding Among the pivotal decisions in mig welding is the choice between two fundamental techniques: With slag, pull is the most suitable method. It produces a flatter, broader weld, offering an advantage when welding materials like. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. What are the differences between pushing. Pull Vs Push Mig Welding.

From www.youtube.com

Push vs. Pull Methods in MIG Welding YouTube Pull Vs Push Mig Welding What are the differences between pushing and pulling? Among the pivotal decisions in mig welding is the choice between two fundamental techniques: Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. Push or. Pull Vs Push Mig Welding.

From www.youtube.com

MIG Welding Technique Push vs Drag Part 2 Test YouTube Pull Vs Push Mig Welding The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. The push and pull techniques refer to the direction in which the welding torch is moved. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. With slag,. Pull Vs Push Mig Welding.

From weldguru.com

Push vs. Pull When MIG Welding Which is Right? Pull Vs Push Mig Welding This approach is like smoothly brushing paint on a surface. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. It produces a flatter, broader weld, offering an advantage when welding materials like. With. Pull Vs Push Mig Welding.

From www.researchgate.net

Schematic detail of the procedures " pushing " and " pulling " the Pull Vs Push Mig Welding Among the pivotal decisions in mig welding is the choice between two fundamental techniques: The push welding technique is ideal for deep penetration and when there is more area. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and. Pull Vs Push Mig Welding.

From weldingwatch.com

Do You Push or Pull When MIG Welding? WeldingWatch Pull Vs Push Mig Welding It produces a flatter, broader weld, offering an advantage when welding materials like. The push welding technique is ideal for deep penetration and when there is more area. Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. What are the differences between pushing and pulling? With slag, pull is the. Pull Vs Push Mig Welding.

From www.youtube.com

MIG Inductance & Push Vs. Pull Techniques Welding Tips & Tricks Pull Vs Push Mig Welding It produces a flatter, broader weld, offering an advantage when welding materials like. Among the pivotal decisions in mig welding is the choice between two fundamental techniques: Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. Arc welding processes, such as mig welding, tig welding, or stick welding, use the. Pull Vs Push Mig Welding.

From www.theweldguru.com

How Strong is a MIG Weld? The Welding Guru Pull Vs Push Mig Welding Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. This approach is like smoothly brushing paint on a surface. Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency of your welds. With slag, pull is the most suitable method. It produces a flatter, broader. Pull Vs Push Mig Welding.

From www.youtube.com

MIG Welding Techniques Push vs. Pull YouTube Pull Vs Push Mig Welding Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. This approach is like smoothly brushing paint on a surface. Choosing between push and pull mig welding techniques can significantly affect the quality and. Pull Vs Push Mig Welding.

From www.hotrod.com

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Pull Vs Push Mig Welding It produces a flatter, broader weld, offering an advantage when welding materials like. The choice between the push and pull techniques in mig welding depends on various factors, including material thickness, joint design, and the desired. What are the differences between pushing and pulling? With slag, pull is the most suitable method. Arc welding processes, such as mig welding, tig. Pull Vs Push Mig Welding.

From www.youtube.com

MIG Welding Pushing vs. Pulling the Pool YouTube Pull Vs Push Mig Welding Among the pivotal decisions in mig welding is the choice between two fundamental techniques: Push or pull, and which is correct for mig welding, depends on the equipment, material, process, and personal choice. Choosing between push and pull mig welding techniques can significantly affect the quality and efficiency of your welds. It produces a flatter, broader weld, offering an advantage. Pull Vs Push Mig Welding.

From weld-ready.ca

Comparc Push Pull Gun 25' Weldready Canada Pull Vs Push Mig Welding The push welding technique is ideal for deep penetration and when there is more area. Arc welding processes, such as mig welding, tig welding, or stick welding, use the heat of the welding arc established between the electrode and base metal to melt the pieces and filler wire and fuse everything. Among the pivotal decisions in mig welding is the. Pull Vs Push Mig Welding.