Plain Milling Vs Face Milling . So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. What is the difference between face milling and side milling? While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable.

from autoplasticsworld.com

Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. What is the difference between face milling and side milling? Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section.

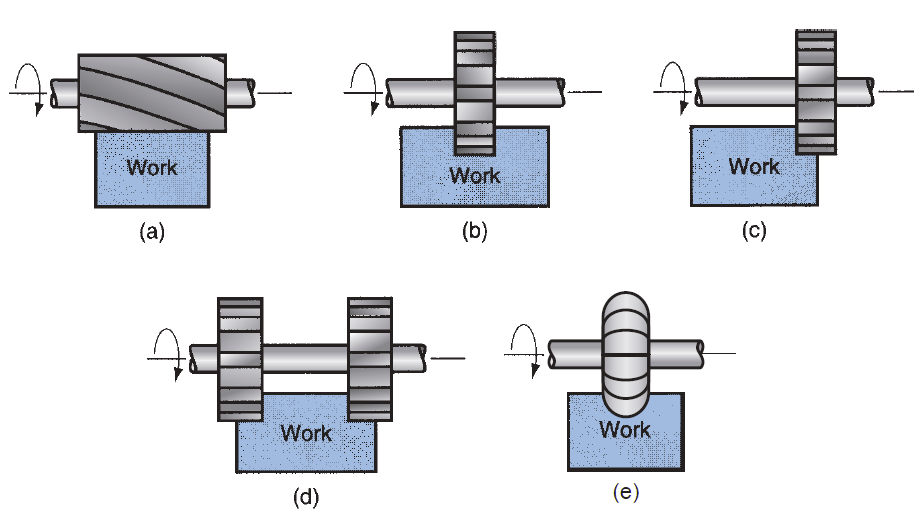

Exploring Milling Operations Types and Applications

Plain Milling Vs Face Milling So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. What is the difference between face milling and side milling? I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end.

From www.easiahome.com

Face MillingDefinition, Process,Operations,Differences Plain Milling Vs Face Milling Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Face milling is better adapted to removing large amounts. Plain Milling Vs Face Milling.

From www.autodesk.com

6face milling Fusion Blog Plain Milling Vs Face Milling What is the difference between face milling and side milling? I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. So we’ve established. Plain Milling Vs Face Milling.

From wiki.unionfab.cn

Face Mill vs. End Mill A Complete Comparison Guide Plain Milling Vs Face Milling Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. So. Plain Milling Vs Face Milling.

From samhotool.com

The Ultimate Guide End Mill vs Face Mill SAMHO Plain Milling Vs Face Milling Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. While both aim. Plain Milling Vs Face Milling.

From topsbest-precision.com

Face Milling vs End Milling:What’s the Difference? Custom Precision Plain Milling Vs Face Milling Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. I would like to know if anybody. Plain Milling Vs Face Milling.

From www.kemalmfg.com

Face Milling 101 Process, Differences, And Practical Tips Kemal Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat. Plain Milling Vs Face Milling.

From step.manufacturingtransformation.io

The Face Milling Series Seco Online Academy Plain Milling Vs Face Milling So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. Face milling. Plain Milling Vs Face Milling.

From einvoice.fpt.com.vn

Face Milling Definition, Process, Differences, Practical, 50 OFF Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. What. Plain Milling Vs Face Milling.

From www.slideserve.com

PPT Machining Operations by Ed Red PowerPoint Presentation, free Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. What is the difference between face milling and side milling? Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. I would like to know if anybody still slab/plain mills for production with. Plain Milling Vs Face Milling.

From www.slideserve.com

PPT Chapter4 MILLING PROCESS PowerPoint Presentation, free download Plain Milling Vs Face Milling Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. While both aim. Plain Milling Vs Face Milling.

From www.slideserve.com

PPT Machining and Machine Tools PowerPoint Presentation, free Plain Milling Vs Face Milling What is the difference between face milling and side milling? Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. While both aim to remove material from a workpiece with. Plain Milling Vs Face Milling.

From www.rtprototype.com

End Milling vs Face Milling What's the Difference? Ruitai Mould Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while. Plain Milling Vs Face Milling.

From www.lathematters.com

Face Mill vs. End Mill Main Differences Explained! Plain Milling Vs Face Milling I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. What is the difference between face milling and side milling? So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. While both aim to. Plain Milling Vs Face Milling.

From slideplayer.com

Material Removal Processes Cutting ppt download Plain Milling Vs Face Milling So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. What is the difference between face milling and side milling? Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and. Plain Milling Vs Face Milling.

From www.canadianmetalworking.com

About face milling Plain Milling Vs Face Milling Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. Face milling focuses on milling the top surface. Plain Milling Vs Face Milling.

From www.slideserve.com

PPT Chapter 23 Machining Processes Used to Produce Various Shapes Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. What is the difference between face milling and side milling? Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. Conversely, side milling involves milling the workpiece’s sides,. Plain Milling Vs Face Milling.

From autoplasticsworld.com

Exploring Milling Operations Types and Applications Plain Milling Vs Face Milling I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and. Plain Milling Vs Face Milling.

From www.youtube.com

02_04_P4 Calculating Cutting Speed, Feed, and Machining Time for Face Plain Milling Vs Face Milling What is the difference between face milling and side milling? Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality,. Plain Milling Vs Face Milling.

From toolnotes.com

Milling Operations ToolNotes Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Face milling is better adapted to removing large amounts of material quickly, while. Plain Milling Vs Face Milling.

From www.canadianmetalworking.com

About face milling Plain Milling Vs Face Milling I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. So we’ve established that both methods remove metal from a workpiece, but face. Plain Milling Vs Face Milling.

From www.youtube.com

Define and working of Gang Milling, Straddle Milling,Face Milling YouTube Plain Milling Vs Face Milling Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling. Plain Milling Vs Face Milling.

From www.lathematters.com

Face Milling vs Peripheral Milling What's The Difference? Plain Milling Vs Face Milling I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. What is the difference between face milling and side milling? Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. So we’ve established that both methods remove metal from a workpiece, but face milling is better. Plain Milling Vs Face Milling.

From prototool.com

Face Milling Basics and Advancements Plain Milling Vs Face Milling I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. Face milling is better adapted to removing large amounts of material quickly, while peripheral. Plain Milling Vs Face Milling.

From mellowpine.com

Face Milling in Machining How's it Done? MellowPine Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Face milling is better adapted to removing large amounts of material quickly, while. Plain Milling Vs Face Milling.

From lathehub.com

Face Milling Vs Peripheral Milling Maximize Efficiency Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. Face milling is better adapted to removing large amounts of material. Plain Milling Vs Face Milling.

From mechutopia.com

Milling & Face Milling Ultimate Guide Mechutopia Plain Milling Vs Face Milling Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Conversely, side milling involves milling the workpiece’s sides, expanding the. Plain Milling Vs Face Milling.

From www.slideserve.com

PPT Chapter 22 MACHINING OPERATIONS AND MACHINE TOOLS PowerPoint Plain Milling Vs Face Milling What is the difference between face milling and side milling? Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper. Plain Milling Vs Face Milling.

From www.rtprototype.com

End Milling vs Face Milling What's the Difference? Ruitai Mould Plain Milling Vs Face Milling Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. So we’ve established that both methods remove metal from a workpiece, but face milling is better for flat surfaces with stellar quality, while end. Conversely, side milling involves milling the workpiece’s sides, expanding the milling action. While both aim to remove material from. Plain Milling Vs Face Milling.

From www.lathematters.com

Face Mill vs. End Mill Main Differences Explained! Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. What is the difference between face milling and side milling? I would like to know if anybody still. Plain Milling Vs Face Milling.

From www.china-machining.com

Plain Milling Understanding this Fascinating Production Process Plain Milling Vs Face Milling Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have. Plain Milling Vs Face Milling.

From www.slideserve.com

PPT Machining and Machine Tools PowerPoint Presentation, free Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. What is the difference between face milling and side milling? Face milling focuses on milling the top surface of a workpiece, utilizing the cutting tool’s upper section. I would like to know if anybody still. Plain Milling Vs Face Milling.

From ksp-group.ir

فرز سی ان سی فرز cnc چیست ؟ خاوران صنعت پاسارگاد Plain Milling Vs Face Milling I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. What is the difference between face milling and side milling?. Plain Milling Vs Face Milling.

From www.slideserve.com

PPT Lecture 8 THEORY OF METAL MACHINING PowerPoint Presentation Plain Milling Vs Face Milling I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. What is the difference between face milling and side milling? While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. Conversely, side milling. Plain Milling Vs Face Milling.

From themechanicalengineering.com

Milling Machine Definition, Parts, Operation, Working Principle Plain Milling Vs Face Milling While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. What is the difference between face milling and side milling? I would like to know if anybody still slab/plain mills for production with high metal removal rates, and whether that's a viable. Face milling is. Plain Milling Vs Face Milling.

From toolnotes.com

Milling Operations ToolNotes Plain Milling Vs Face Milling Face milling is better adapted to removing large amounts of material quickly, while peripheral milling is used for precise operations and can produce more uniform and regular surface. While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have key differences, specifically in. What is the difference between face milling. Plain Milling Vs Face Milling.