Wire Edm Diy . [action box] aims to change that with a diy wire edm machine. Slow, expensive, and limited to conductive materials I plan on adding more pictures and figures to this post once i get around to making them. This video shows the design, build and use of a diy wire edm lathe. This has been on our diy cnc machine radar for quite some time, and finally we have done it. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire. The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to. Diy wire edm is finally a reality! I combined 2 milling methods. A highfeed mill that cuts using 7 degree angle. Can create complex shapes, smooth finishes, and high precision. In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath.

from www.cncmasters.com

This has been on our diy cnc machine radar for quite some time, and finally we have done it. A highfeed mill that cuts using 7 degree angle. This video shows the design, build and use of a diy wire edm lathe. Slow, expensive, and limited to conductive materials I plan on adding more pictures and figures to this post once i get around to making them. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Diy wire edm is finally a reality! In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to. [action box] aims to change that with a diy wire edm machine.

Wire EDM Machine Buyer’s Guide

Wire Edm Diy A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. A highfeed mill that cuts using 7 degree angle. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. This video shows the design, build and use of a diy wire edm lathe. [action box] aims to change that with a diy wire edm machine. Diy wire edm is finally a reality! In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to. Can create complex shapes, smooth finishes, and high precision. I combined 2 milling methods. This has been on our diy cnc machine radar for quite some time, and finally we have done it. I plan on adding more pictures and figures to this post once i get around to making them. I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire. Slow, expensive, and limited to conductive materials

From www.daytool.com

EDM Day Tool & Mfg Wire Edm Diy Slow, expensive, and limited to conductive materials Can create complex shapes, smooth finishes, and high precision. In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. This has been on our diy cnc machine radar for quite some time, and finally we have done it. The process can be as. Wire Edm Diy.

From www.canadianmetalworking.com

Understanding the power of wire EDM Wire Edm Diy In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. A highfeed. Wire Edm Diy.

From mtm.cba.mit.edu

Desktop Wire EDM MTM Wire Edm Diy I plan on adding more pictures and figures to this post once i get around to making them. I combined 2 milling methods. Slow, expensive, and limited to conductive materials The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to. In. Wire Edm Diy.

From www.xecnc.com

BAXEDMBX17 cuttin 40mm aluminum with a DIY wire EDM machine XECNC Wire Edm Diy A highfeed mill that cuts using 7 degree angle. In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. Diy wire edm is finally a reality! I plan on adding more pictures and figures to this post once i get around to making them. [action box] aims to change that. Wire Edm Diy.

From www.absolutewireedm.com

How Wire EDM Works Missouri's Wire EDM machine shop Wire Edm Diy I combined 2 milling methods. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Slow, expensive, and limited to conductive materials A highfeed mill that cuts using 7 degree angle. [action box] aims to change that with a diy wire edm machine. This video shows the design, build and use of a diy. Wire Edm Diy.

From www.youtube.com

DIY Wire EDM first test YouTube Wire Edm Diy This video shows the design, build and use of a diy wire edm lathe. The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to. This has been on our diy cnc machine radar for quite some time, and finally we have. Wire Edm Diy.

From www.youtube.com

how to use slow speed wire EDM fixture?AONE offer you onestop service Wire Edm Diy I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire. A highfeed mill that cuts using 7 degree angle. [action box] aims to change that with a diy wire edm machine. I plan on adding more pictures and figures to this post once i get around to making. Wire Edm Diy.

From www.vancouverwireedm.com

Vancouver Wire EDM Wire EDM Tips for Machinists Wire Edm Diy In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. This video shows the design, build and use of a diy wire edm lathe. A highfeed mill that cuts using 7 degree angle. I combined 2 milling methods. A cnc machining method that uses a charged metal wire to cut. Wire Edm Diy.

From www.youtube.com

QUICK WIRE EDM TOOLING SETUP YouTube Wire Edm Diy A highfeed mill that cuts using 7 degree angle. The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to. In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. Slow, expensive,. Wire Edm Diy.

From www.youtube.com

diy wire edm test 2 YouTube Wire Edm Diy Can create complex shapes, smooth finishes, and high precision. [action box] aims to change that with a diy wire edm machine. Diy wire edm is finally a reality! I combined 2 milling methods. The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite. Wire Edm Diy.

From www.xecnc.com

Building a PULSE EDM with the DIY book of Ben Fleming Part 1 XECNC Wire Edm Diy Can create complex shapes, smooth finishes, and high precision. I plan on adding more pictures and figures to this post once i get around to making them. This has been on our diy cnc machine radar for quite some time, and finally we have done it. The process can be as simple as using a small diameter metal tube to. Wire Edm Diy.

From www.mantools.co.za

Wire EDM/ Cutting Manhattan Tools Wire Edm Diy A highfeed mill that cuts using 7 degree angle. This has been on our diy cnc machine radar for quite some time, and finally we have done it. [action box] aims to change that with a diy wire edm machine. This video shows the design, build and use of a diy wire edm lathe. Can create complex shapes, smooth finishes,. Wire Edm Diy.

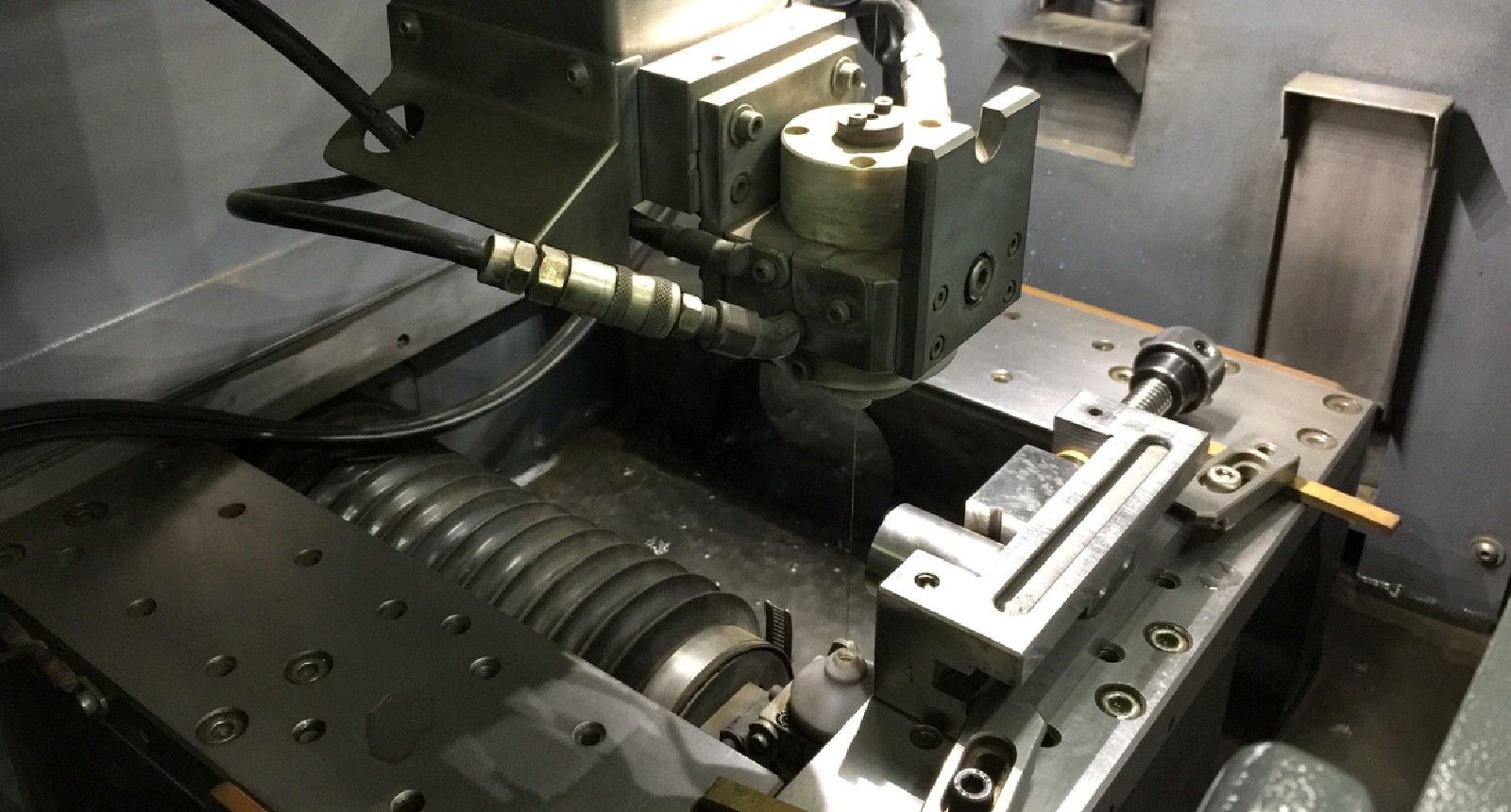

From www.cncedmtool.com

HPEDM Wire EDM vise for clamping round workpiece High Precision CNC Wire Edm Diy This has been on our diy cnc machine radar for quite some time, and finally we have done it. Diy wire edm is finally a reality! A highfeed mill that cuts using 7 degree angle. [action box] aims to change that with a diy wire edm machine. I found a way to make old wire edm cut 150% or better. Wire Edm Diy.

From hackaday.com

Homemade EDM Machine Moves From Prototype To Production Hackaday Wire Edm Diy This video shows the design, build and use of a diy wire edm lathe. [action box] aims to change that with a diy wire edm machine. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Diy wire edm is finally a reality! Can create complex shapes, smooth finishes, and high precision. I combined. Wire Edm Diy.

From www.lazada.com.ph

Wire Edm Machine Electric Wire Puller Peeling Automatic Hand Crank Wire Edm Diy Slow, expensive, and limited to conductive materials I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire. In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. The process can be as simple as using a small diameter. Wire Edm Diy.

From www.youtube.com

Homemade Wire EDM YouTube Wire Edm Diy This video shows the design, build and use of a diy wire edm lathe. This has been on our diy cnc machine radar for quite some time, and finally we have done it. I plan on adding more pictures and figures to this post once i get around to making them. I combined 2 milling methods. A cnc machining method. Wire Edm Diy.

From www.cncmasters.com

Wire EDM Machine Buyer’s Guide Wire Edm Diy I plan on adding more pictures and figures to this post once i get around to making them. This video shows the design, build and use of a diy wire edm lathe. Slow, expensive, and limited to conductive materials A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. I found a way to. Wire Edm Diy.

From actionbox.ca

DIY Wire EDM Action BOX Wire Edm Diy I plan on adding more pictures and figures to this post once i get around to making them. [action box] aims to change that with a diy wire edm machine. Slow, expensive, and limited to conductive materials Can create complex shapes, smooth finishes, and high precision. The process can be as simple as using a small diameter metal tube to. Wire Edm Diy.

From www.pinterest.com

Wire EDM by Rich_Carlstedt Homemade wire EDM constructed according Wire Edm Diy A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. This video shows the design, build and use of a diy wire edm lathe. I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire. Diy wire edm is finally a reality! The. Wire Edm Diy.

From hackaday.com

Bringing The Power Of EDM To The Home Shop Hackaday Wire Edm Diy The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to. In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. Can create complex shapes, smooth finishes, and high precision. A highfeed. Wire Edm Diy.

From actionbox.ca

DIY Wire EDM Action BOX Wire Edm Diy Diy wire edm is finally a reality! This video shows the design, build and use of a diy wire edm lathe. I combined 2 milling methods. This has been on our diy cnc machine radar for quite some time, and finally we have done it. In wire edm, a fine brass wire is used as an electrode to slowly erode. Wire Edm Diy.

From www.youtube.com

Precision Spinning and Indexing on Wire EDM YouTube Wire Edm Diy This has been on our diy cnc machine radar for quite some time, and finally we have done it. [action box] aims to change that with a diy wire edm machine. Slow, expensive, and limited to conductive materials I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire.. Wire Edm Diy.

From rapidholdingsystems.com

Wire EDM Tooling Wire cut EDM machine Vises and Extension clamps Wire Edm Diy The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. This has been on our diy cnc machine radar for quite some time, and finally. Wire Edm Diy.

From www.youtube.com

DIY wire EDM, NC burn YouTube Wire Edm Diy In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. This has been on our diy cnc machine radar for quite some time, and finally we have done it. Diy wire edm is finally a reality! I plan on adding more pictures and figures to this post once i get. Wire Edm Diy.

From alowecare.com

Gia công cắt dây CNC ( CNC Wire Cut & EDM) ALOWECARE Wire Edm Diy This has been on our diy cnc machine radar for quite some time, and finally we have done it. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. Can create complex shapes, smooth. Wire Edm Diy.

From www.xactedm.com

Small Part Machining Metal Manufacturing Partner I Wire EDM Wire Edm Diy I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire. The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to. A cnc machining method that uses a charged metal. Wire Edm Diy.

From prototype-shortrun.com

How Wire EDM Services Are Used to Create Intricate Parts Wire Edm Diy A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. This video shows the design, build and use of a diy wire edm lathe. In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. I combined 2 milling methods. [action box] aims to change. Wire Edm Diy.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Diy This has been on our diy cnc machine radar for quite some time, and finally we have done it. Diy wire edm is finally a reality! Can create complex shapes, smooth finishes, and high precision. A highfeed mill that cuts using 7 degree angle. I found a way to make old wire edm cut 150% or better the thicker the. Wire Edm Diy.

From www.youtube.com

DIY Desktop Wire EDM machine Spark2 YouTube Wire Edm Diy A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Diy wire edm is finally a reality! In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. Slow, expensive, and limited to conductive materials I found a way to make old wire edm cut. Wire Edm Diy.

From www.youtube.com

DIY wire edm cutting a number YouTube Wire Edm Diy I combined 2 milling methods. In wire edm, a fine brass wire is used as an electrode to slowly erode metal in a dielectric bath. Diy wire edm is finally a reality! A highfeed mill that cuts using 7 degree angle. I plan on adding more pictures and figures to this post once i get around to making them. Slow,. Wire Edm Diy.

From huldakelso.blogspot.com

wire edm machine how it works Hulda Kelso Wire Edm Diy Diy wire edm is finally a reality! This video shows the design, build and use of a diy wire edm lathe. I combined 2 milling methods. I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire. This has been on our diy cnc machine radar for quite some. Wire Edm Diy.

From www.xecnc.com

Wire EDM a gear wheel XECNC Wire Edm Diy A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. I found a way to make old wire edm cut 150% or better the thicker the better and use half the wire. The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block. Wire Edm Diy.

From hackaday.io

Sinker EDM Machine Hackaday.io Wire Edm Diy Slow, expensive, and limited to conductive materials A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Diy wire edm is finally a reality! I plan on adding more pictures and figures to this post once i get around to making them. This has been on our diy cnc machine radar for quite some. Wire Edm Diy.

From www.bobcad-europe.com

WIREEDM BobCAD Europe Wire Edm Diy Slow, expensive, and limited to conductive materials This video shows the design, build and use of a diy wire edm lathe. I combined 2 milling methods. A highfeed mill that cuts using 7 degree angle. Diy wire edm is finally a reality! Can create complex shapes, smooth finishes, and high precision. A cnc machining method that uses a charged metal. Wire Edm Diy.

From www.cnclasertech.com

How We Made A Wire EDM Machine At Home CNC LASER Wire Edm Diy This has been on our diy cnc machine radar for quite some time, and finally we have done it. I combined 2 milling methods. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. I found a way to make old wire edm cut 150% or better the thicker the better and use half. Wire Edm Diy.