Pumps Are Connected In Parallel To Increase The . However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. Two pumps set up with one pump as an installed spare. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. When pumps are operating in parallel configurations, the flow rate is additive for a given pump total dynamic head (tdh). To find the solution to the problem, the first thing i ask for is the system curve. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. In other words, pumps can run in parallel or separately, covering a wide range of expected flows. Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. Two pumps set up to run individually and/or in parallel.

from www.chegg.com

To find the solution to the problem, the first thing i ask for is the system curve. However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. In other words, pumps can run in parallel or separately, covering a wide range of expected flows. When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. When pumps are operating in parallel configurations, the flow rate is additive for a given pump total dynamic head (tdh). In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. Two pumps set up to run individually and/or in parallel. Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability.

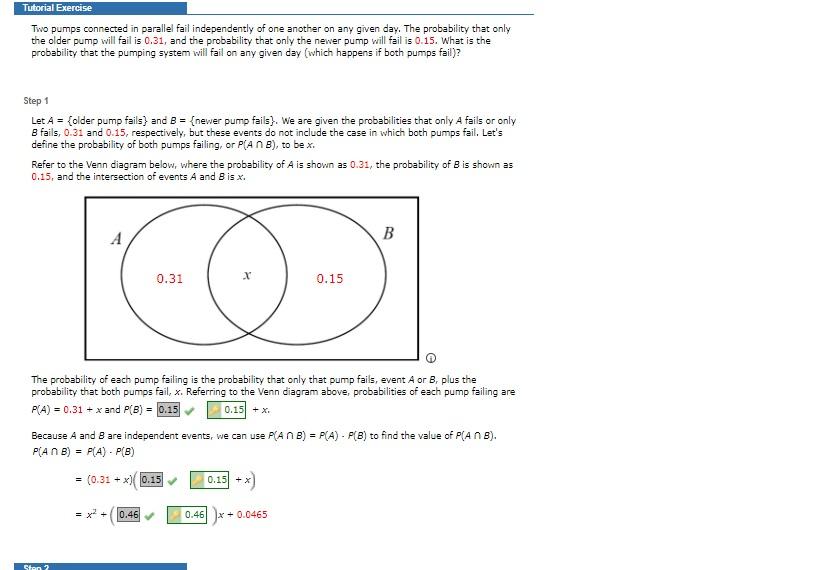

Solved Tutorial Exercise Two pumps connected in parallel

Pumps Are Connected In Parallel To Increase The However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. Two pumps set up to run individually and/or in parallel. In other words, pumps can run in parallel or separately, covering a wide range of expected flows. When pumps are operating in parallel configurations, the flow rate is additive for a given pump total dynamic head (tdh). However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. To find the solution to the problem, the first thing i ask for is the system curve. In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. Two pumps set up with one pump as an installed spare.

From www.youtube.com

Hydraulic Machines 510 Operating Point and connection of two pumps Pumps Are Connected In Parallel To Increase The Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. Two pumps set up with one pump as an installed spare. In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. When pumps are operating in parallel configurations, the flow. Pumps Are Connected In Parallel To Increase The.

From kb.eng-software.com

Increase System Capacity Using Pumps in Parallel Engineered Software Pumps Are Connected In Parallel To Increase The When pumps are operating in parallel configurations, the flow rate is additive for a given pump total dynamic head (tdh). When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the. Pumps Are Connected In Parallel To Increase The.

From www.youtube.com

Parallel pump operation concept in depth YouTube Pumps Are Connected In Parallel To Increase The In other words, pumps can run in parallel or separately, covering a wide range of expected flows. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow. Pumps Are Connected In Parallel To Increase The.

From labmidwest.com

Variable Speed Series and Parallel Pumps LAB Midwest Pumps Are Connected In Parallel To Increase The In other words, pumps can run in parallel or separately, covering a wide range of expected flows. Two pumps set up to run individually and/or in parallel. In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. Two pumps set up with one pump as an installed spare. Operating pumps in parallel means. Pumps Are Connected In Parallel To Increase The.

From www.youtube.com

Pumps in series and parallel with solved examples YouTube Pumps Are Connected In Parallel To Increase The Two pumps set up to run individually and/or in parallel. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. Centrifugal pumps are frequently operated in. Pumps Are Connected In Parallel To Increase The.

From www.researchgate.net

The distributed control framework for parallelconnected pumps Pumps Are Connected In Parallel To Increase The Two pumps set up to run individually and/or in parallel. When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. Two pumps set up with one pump as an installed spare. In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. To find. Pumps Are Connected In Parallel To Increase The.

From www.deppmann.com

HVAC Hydronic System Parallel Pump Operation and Curves RLD Pumps Are Connected In Parallel To Increase The Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. Two pumps set up with one pump as an installed spare. To find the solution to the problem, the first thing i ask for is the system curve. Two pumps set up to. Pumps Are Connected In Parallel To Increase The.

From www.researchgate.net

8 Pump curve for 2 pumps in parallel Download Scientific Diagram Pumps Are Connected In Parallel To Increase The Two pumps set up to run individually and/or in parallel. Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge.. Pumps Are Connected In Parallel To Increase The.

From pumpfocus.com

9.6 Parallel pump operation Pumpfocus Pumps Are Connected In Parallel To Increase The Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. Two pumps set up to run. Pumps Are Connected In Parallel To Increase The.

From circuitengineeclair.z21.web.core.windows.net

Pump In Parallel And Series Pumps Are Connected In Parallel To Increase The Two pumps set up to run individually and/or in parallel. When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. In other words, pumps can run in parallel or separately, covering a wide range of expected flows. When two or more pumps are arranged in parallel their resulting performance curve. Pumps Are Connected In Parallel To Increase The.

From www.chegg.com

2 A pumping station has two identical pumps connected Pumps Are Connected In Parallel To Increase The To find the solution to the problem, the first thing i ask for is the system curve. When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. Two pumps set up to run individually and/or in parallel. When using. Pumps Are Connected In Parallel To Increase The.

From www.scribd.com

Parallel and Series Pump Hydraulics Pump Pumps Are Connected In Parallel To Increase The When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. In other words, pumps can run in parallel or separately, covering a wide range of expected flows. When pumps are operating in parallel configurations, the flow rate is additive. Pumps Are Connected In Parallel To Increase The.

From www.chegg.com

Solved 2. Two identical centrifugal pumps, connected in Pumps Are Connected In Parallel To Increase The However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. Two pumps set up with one pump as an installed spare. In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. To find the solution to the problem, the first thing i. Pumps Are Connected In Parallel To Increase The.

From www.chegg.com

Solved Tutorial Exercise Two pumps connected in parallel Pumps Are Connected In Parallel To Increase The When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. Operating pumps in parallel means multiple. Pumps Are Connected In Parallel To Increase The.

From circuitengineeclair.z21.web.core.windows.net

Pump In Parallel And Series Pumps Are Connected In Parallel To Increase The However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. When two or more pumps are arranged in parallel their resulting performance curve is obtained by. Pumps Are Connected In Parallel To Increase The.

From www.researchgate.net

8 Pump curve for 2 pumps in parallel Download Scientific Diagram Pumps Are Connected In Parallel To Increase The Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. In other words, pumps can run in parallel or separately, covering a wide range of expected flows. Two pumps set up to run individually and/or in parallel. To find the solution to the. Pumps Are Connected In Parallel To Increase The.

From didactic-equipment.com

Series Parallel pump, educational equipment for schools, Hydrodynamics Pumps Are Connected In Parallel To Increase The In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and. Pumps Are Connected In Parallel To Increase The.

From www.researchgate.net

Performance curve when two pumps are connected in parallel. Download Pumps Are Connected In Parallel To Increase The When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. In other words, pumps can run. Pumps Are Connected In Parallel To Increase The.

From blog.hayespump.com

How to Operate Pumps in Parallel Hayes Pump Pumps Are Connected In Parallel To Increase The When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. Centrifugal pumps are frequently operated in. Pumps Are Connected In Parallel To Increase The.

From www.tecquipment.com

Series and Parallel Pumps TecQuipment Pumps Are Connected In Parallel To Increase The In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. To find the solution to the problem, the first thing i ask for is the system curve. When two or. Pumps Are Connected In Parallel To Increase The.

From www.tecquipment.com

Series and Parallel Pumps Pumps Are Connected In Parallel To Increase The When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. Two pumps set up to run individually and/or in parallel. Two pumps set. Pumps Are Connected In Parallel To Increase The.

From pumpfocus.com

9.6 Parallel pump operation Pumpfocus Pumps Are Connected In Parallel To Increase The Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. When pumps. Pumps Are Connected In Parallel To Increase The.

From www.pumps.org

Five Keys to Understanding Parallel Pump Optimization Pumps Are Connected In Parallel To Increase The Two pumps set up with one pump as an installed spare. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. Two pumps set up to run individually and/or in parallel. To find the solution to the problem, the first thing i ask for is the system. Pumps Are Connected In Parallel To Increase The.

From www.youtube.com

Parallel vs Series Pumps / Applied Fluid Dynamics Class 056 YouTube Pumps Are Connected In Parallel To Increase The To find the solution to the problem, the first thing i ask for is the system curve. Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. Two pumps set up with one pump as an installed spare. Pumps are operated in parallel. Pumps Are Connected In Parallel To Increase The.

From www.deppmann.com

Parallel Pumping What is it and Why do it R.L. Deppmann Pumps Are Connected In Parallel To Increase The To find the solution to the problem, the first thing i ask for is the system curve. In other words, pumps can run in parallel or separately, covering a wide range of expected flows. In summary, operating pumps in parallel can increase the overall capacity and efficiency of a pumping system. Pumps are operated in parallel when two or more. Pumps Are Connected In Parallel To Increase The.

From pumpindustry.com.au

Understanding pump curves 3 centrifugal pumps in parallel Fig 2 Pumps Are Connected In Parallel To Increase The When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the same head as indicated in the figure below. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. When using pumps in parallel, choose. Pumps Are Connected In Parallel To Increase The.

From circuitengineeclair.z21.web.core.windows.net

Pd Pumps In Parallel Pumps Are Connected In Parallel To Increase The Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. Two pumps set up to run individually and/or in parallel. When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flow rates at the. Pumps Are Connected In Parallel To Increase The.

From centrifugalpumpskushisoku.blogspot.com

Centrifugal Pumps Centrifugal Pumps In Parallel Pumps Are Connected In Parallel To Increase The In other words, pumps can run in parallel or separately, covering a wide range of expected flows. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. Two pumps set up to run individually and/or in parallel. Two pumps set up with one pump as an installed. Pumps Are Connected In Parallel To Increase The.

From wirepartverduzco.z13.web.core.windows.net

Pd Pumps In Parallel Pumps Are Connected In Parallel To Increase The Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. However, achieving optimal flow distribution among pumps requires careful design,. Pumps Are Connected In Parallel To Increase The.

From www.researchgate.net

The operating point of centrifugal pumps connected in parallel under Pumps Are Connected In Parallel To Increase The Two pumps set up with one pump as an installed spare. However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. When pumps are operating in. Pumps Are Connected In Parallel To Increase The.

From www.youtube.com

PUMP IN SERIES AND PARALLEL PUMPS CURVES COMBINATION OF PUMPS IN Pumps Are Connected In Parallel To Increase The When pumps are operating in parallel configurations, the flow rate is additive for a given pump total dynamic head (tdh). When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the. Pumps Are Connected In Parallel To Increase The.

From www.anyanswer.org

When pumps are connected in series then? Any Answer Pumps Are Connected In Parallel To Increase The Two pumps set up with one pump as an installed spare. Pumps are operated in parallel when two or more pumps are connected to a common discharge line and share the same suction conditions. To find the solution to the problem, the first thing i ask for is the system curve. However, achieving optimal flow distribution among pumps requires careful. Pumps Are Connected In Parallel To Increase The.

From www.chegg.com

Solved 3. Two pumps connected in parallel have a common Pumps Are Connected In Parallel To Increase The When pumps are operating in parallel configurations, the flow rate is additive for a given pump total dynamic head (tdh). Two pumps set up with one pump as an installed spare. When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. When two or more pumps are arranged in parallel. Pumps Are Connected In Parallel To Increase The.

From www.researchgate.net

The operating point of centrifugal pumps connected in parallel under Pumps Are Connected In Parallel To Increase The Two pumps set up with one pump as an installed spare. Operating pumps in parallel means multiple pumps take suction (inlet) from and discharge (outlet) to a common header, meaning the suction and discharge. When pumps are operating in parallel configurations, the flow rate is additive for a given pump total dynamic head (tdh). When using pumps in parallel, choose. Pumps Are Connected In Parallel To Increase The.

From fyortkxvc.blob.core.windows.net

Pumps In Parallel Increase Pressure at Christine Mosley blog Pumps Are Connected In Parallel To Increase The However, achieving optimal flow distribution among pumps requires careful design, control, and monitoring to ensure performance, energy efficiency, and system stability. When using pumps in parallel, choose pumps with similar characteristics to balance load distribution, utilize a control system to balance. To find the solution to the problem, the first thing i ask for is the system curve. In summary,. Pumps Are Connected In Parallel To Increase The.