Pump Driver Definition . In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. In the majority of cases, the driver in a centrifugal. They are inexpensive, simple, and eliminate all side loads on the pump bearings. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. The centrifugal pump is the most widely used pump in the world. A pump and a driver. Direct drives consist of a shaft connecting a motor and pump. At a minimum, a centrifugal pumping unit includes at least two components:

from sirhclabs.com

They are inexpensive, simple, and eliminate all side loads on the pump bearings. A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. The centrifugal pump is the most widely used pump in the world. In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. In the majority of cases, the driver in a centrifugal. Direct drives consist of a shaft connecting a motor and pump. A pump and a driver. In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. At a minimum, a centrifugal pumping unit includes at least two components:

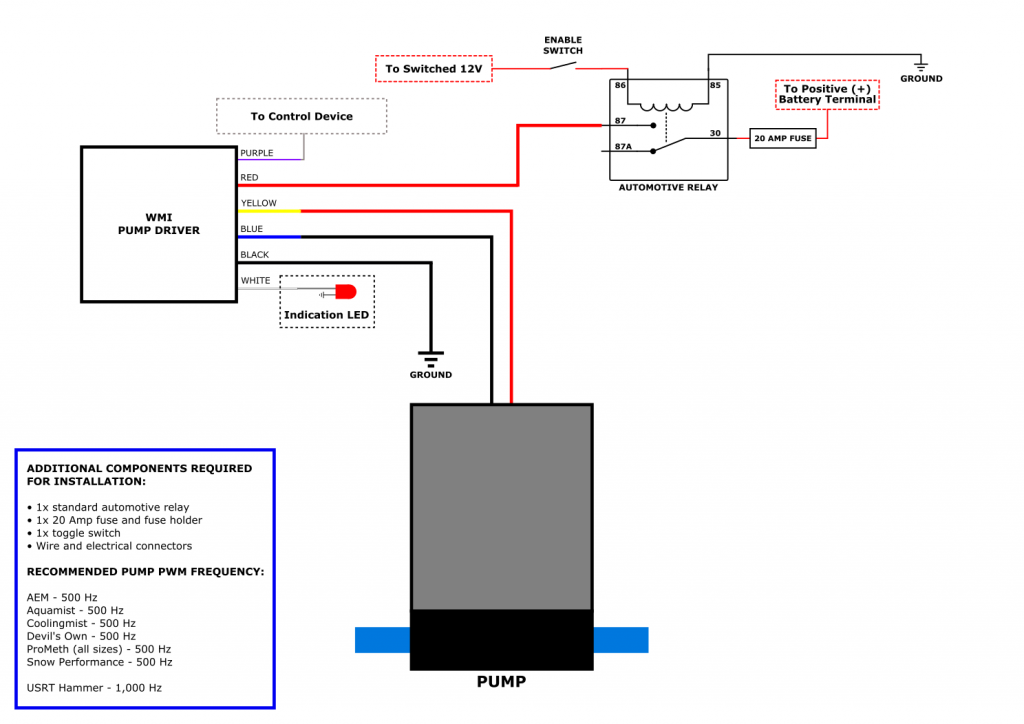

Water/Methanol Injection Pump Driver SIRHC Labs

Pump Driver Definition Direct drives consist of a shaft connecting a motor and pump. Direct drives consist of a shaft connecting a motor and pump. A pump and a driver. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. The centrifugal pump is the most widely used pump in the world. They are inexpensive, simple, and eliminate all side loads on the pump bearings. A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. In the majority of cases, the driver in a centrifugal. In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. At a minimum, a centrifugal pumping unit includes at least two components: In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine.

From www.scribd.com

Pumps and Drivers PDF Pump Driver Definition In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. In the majority of cases, the driver in a centrifugal. They are inexpensive, simple, and eliminate all side loads on the pump bearings. A pump and. Pump Driver Definition.

From www.slideserve.com

PPT MAKING THE RIGHT CHOICE FOR A FIRE PUMP DRIVER AND POWER SOURCE; DIESEL ENGINE, OR Pump Driver Definition A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. In the majority of cases, the driver in a centrifugal. The centrifugal pump is the most widely used pump. Pump Driver Definition.

From engineeringlearn.com

What is Pump? Types of Pump, Uses, Working & Application [with Pictures] Engineering Learn Pump Driver Definition A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. At a minimum, a centrifugal pumping unit includes at least two components: In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. In the majority of cases,. Pump Driver Definition.

From www.pumpsandsystems.com

Selection Tips for Pump Drivers Pumps & Systems Pump Driver Definition In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. They are inexpensive, simple, and eliminate all side loads on the pump bearings. In this article, we will learn the basic definition, parts, types, how does. Pump Driver Definition.

From www.youtube.com

What is Pump? Pump Introduction and Working Principle animation YouTube Pump Driver Definition A pump and a driver. In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. Direct drives consist of a shaft connecting a motor and pump. In the majority of cases, the driver in a centrifugal. The centrifugal pump is the most widely used pump in the world. A hydraulic. Pump Driver Definition.

From studylib.net

Pump and PumpDrive. The Ideal Combination. Pump Driver Definition At a minimum, a centrifugal pumping unit includes at least two components: In the majority of cases, the driver in a centrifugal. They are inexpensive, simple, and eliminate all side loads on the pump bearings. The centrifugal pump is the most widely used pump in the world. A pump and a driver. In most cases the pump driver will be. Pump Driver Definition.

From www.energypower.com.au

3406 Fire Pump Driver Overview Energy Power Systems Pump Driver Definition In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. In the majority of cases, the driver in a centrifugal. Direct drives consist of a shaft connecting a motor and pump. The centrifugal pump is the. Pump Driver Definition.

From extrudesign.com

Heads And Efficiencies of a Centrifugal Pump ExtruDesign Pump Driver Definition Direct drives consist of a shaft connecting a motor and pump. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. A pump and a driver. In the majority of cases, the driver in a centrifugal. The centrifugal pump is the most widely used pump in the world. In most cases the. Pump Driver Definition.

From www.pumpdepot.us

COELBO Wallmounted pump driver for a single pump at variable speed, 230V, 1&3PHASE, 362.5 PSI Pump Driver Definition At a minimum, a centrifugal pumping unit includes at least two components: In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. Direct drives consist of a shaft connecting a motor and pump. A pump and a driver. A hydraulic pump drive (also referred to as a pump drive) is a device. Pump Driver Definition.

From www.youtube.com

What is pump I Pump Basics I Definition of Pump I Working Principle YouTube Pump Driver Definition In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. At a minimum,. Pump Driver Definition.

From eddypump.com

Essential Guide to Submersible Pump Maintenance, Life Expectancy, and Operation Pump Driver Definition Direct drives consist of a shaft connecting a motor and pump. The centrifugal pump is the most widely used pump in the world. A pump and a driver. At a minimum, a centrifugal pumping unit includes at least two components: In the majority of cases, the driver in a centrifugal. In this article, we will learn the basic definition, parts,. Pump Driver Definition.

From www.introtopumps.com

What is a Centrifugal Pump Intro to Pumps Pump Driver Definition In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. The centrifugal pump is the most widely used pump in the world. They are inexpensive, simple, and eliminate all side loads on the pump bearings. At. Pump Driver Definition.

From techblog.ctgclean.com

Pumps Pump Performance Curves CTG Technical Blog Pump Driver Definition Direct drives consist of a shaft connecting a motor and pump. A pump and a driver. At a minimum, a centrifugal pumping unit includes at least two components: The centrifugal pump is the most widely used pump in the world. In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine.. Pump Driver Definition.

From www.slideserve.com

PPT Fire Detection and Suppression PowerPoint Presentation, free download ID333897 Pump Driver Definition In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. In this article, we will learn. Pump Driver Definition.

From www.youtube.com

Electronics 4 Phase 5 Pin high speed motor driving (turbomolecular pump driver) YouTube Pump Driver Definition In the majority of cases, the driver in a centrifugal. They are inexpensive, simple, and eliminate all side loads on the pump bearings. A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. In most cases the pump driver will be an alternating current (ac) electric induction. Pump Driver Definition.

From sirhclabs.com

Water/Methanol Injection Pump Driver SIRHC Labs Pump Driver Definition In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. At a minimum, a centrifugal pumping unit includes at least two components: The centrifugal pump is the most widely used pump in the world. In this. Pump Driver Definition.

From blog.thepipingmart.com

13 Different Types Of Pumps and Their Uses Pump Driver Definition In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. The centrifugal pump is the most widely used. Pump Driver Definition.

From www.mechanical-knowledge.com

Pump Definition, Types, Advantages and Disadvantages Pump Driver Definition Direct drives consist of a shaft connecting a motor and pump. A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. In its most basic form, a pump drive. Pump Driver Definition.

From www.airandhydraulic.com

Definition of pumpsAll types of pumps definitionsAdvantages and disadvantages Pump Driver Definition A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. At a minimum, a centrifugal pumping unit includes at least two components: They are inexpensive, simple, and eliminate all side loads on the pump bearings. The centrifugal pump is the most widely used pump in the world.. Pump Driver Definition.

From www.slideserve.com

PPT MAKING THE RIGHT CHOICE FOR A FIRE PUMP DRIVER AND POWER SOURCE; DIESEL ENGINE, OR Pump Driver Definition In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. At a minimum, a centrifugal pumping unit includes at least two components: The centrifugal pump is the most widely used pump in the world. In its most basic form, a pump drive is a simple gearbox that is placed between an engine. Pump Driver Definition.

From repairfixmichael9840n9.z22.web.core.windows.net

Ford F250 Fuel Pump Driver Module Location Pump Driver Definition A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. They are inexpensive, simple, and eliminate all side loads on the pump bearings. In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's. Pump Driver Definition.

From truyenhinhcapsongthu.net

Vacuum Pump What Is It? How Does It Work? Types Of Pumps Pump Driver Definition A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. At a minimum, a centrifugal pumping unit includes at least two components: The centrifugal pump is the most widely used pump in the world. In this article, we will learn the basic definition, parts, types, how does. Pump Driver Definition.

From www.homedepot.com

Pump Mounted Driver 921180 The Home Depot Pump Driver Definition In the majority of cases, the driver in a centrifugal. A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. At a minimum, a centrifugal pumping unit includes at least two components: In this article, we will learn the basic definition, parts, types, how does centrifugal pump. Pump Driver Definition.

From www.mechanicalbooster.com

What is Positive Displacement Pump Definition, Types and Working? Mechanical Booster Pump Driver Definition A pump and a driver. In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. In the majority of cases, the driver in a centrifugal. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. They are inexpensive, simple, and eliminate all. Pump Driver Definition.

From www.youtube.com

Define the term Reciprocating Pump. Classify them. YouTube Pump Driver Definition The centrifugal pump is the most widely used pump in the world. At a minimum, a centrifugal pumping unit includes at least two components: In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works,. Pump Driver Definition.

From www.quantex-arc.com

Quantex launches its first commercial pump driver QDriveAlpha Quantex Arc Recyclable Pump Pump Driver Definition The centrifugal pump is the most widely used pump in the world. At a minimum, a centrifugal pumping unit includes at least two components: Direct drives consist of a shaft connecting a motor and pump. In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. A pump and a driver.. Pump Driver Definition.

From www.slideserve.com

PPT Fire Detection and Suppression PowerPoint Presentation, free download ID333897 Pump Driver Definition Direct drives consist of a shaft connecting a motor and pump. The centrifugal pump is the most widely used pump in the world. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. They are inexpensive, simple, and eliminate all side loads on the pump bearings. At a minimum, a centrifugal pumping. Pump Driver Definition.

From kingengineering.pk

Centrifugal Pump types, definition and features King Engineering Pump Driver Definition In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. A pump and a driver. They are inexpensive, simple, and eliminate all side loads on the pump bearings. In most cases the pump driver will be. Pump Driver Definition.

From www.airandhydraulic.com

Definition of pumpsAll types of pumps definitionsAdvantages and disadvantages Pump Driver Definition A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. A pump and a driver. In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. At a minimum, a centrifugal pumping unit includes at least two components:. Pump Driver Definition.

From engineeringlearn.com

Rotary Vane Pump Definition, Types, Working, Components, Application, Advantages, Disadvantages Pump Driver Definition In the majority of cases, the driver in a centrifugal. Direct drives consist of a shaft connecting a motor and pump. At a minimum, a centrifugal pumping unit includes at least two components: A hydraulic pump drive (also referred to as a pump drive) is a device that connects a prime mover to a hydraulic pump. They are inexpensive, simple,. Pump Driver Definition.

From www.youtube.com

Fluid Mechanics Topic 7.3.3 Definition of pump efficiency & turbine efficiency YouTube Pump Driver Definition A pump and a driver. In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. In. Pump Driver Definition.

From www.engineeringinhindi.com

What Is a Pump? History of Pumps Types of Pump with brief explanation application Pump Driver Definition In most cases the pump driver will be an alternating current (ac) electric induction motor or an internal combustion engine. In the majority of cases, the driver in a centrifugal. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. A hydraulic pump drive (also referred to as a pump drive) is. Pump Driver Definition.

From www.pumpsandsystems.com

How to Define & Measure Centrifugal Pump Efficiency Part 1 Pumps & Systems Pump Driver Definition In the majority of cases, the driver in a centrifugal. The centrifugal pump is the most widely used pump in the world. Direct drives consist of a shaft connecting a motor and pump. They are inexpensive, simple, and eliminate all side loads on the pump bearings. In most cases the pump driver will be an alternating current (ac) electric induction. Pump Driver Definition.

From mechanicalboost.com

What is a Pump? What are the types of Pumps? Pump Driver Definition At a minimum, a centrifugal pumping unit includes at least two components: In its most basic form, a pump drive is a simple gearbox that is placed between an engine or electric motor and a system's hydraulic pump (s) to provide a way to couple them. Direct drives consist of a shaft connecting a motor and pump. In this article,. Pump Driver Definition.

From www.energypower.com.au

3406 Fire Pump Driver Overview Energy Power Systems Pump Driver Definition They are inexpensive, simple, and eliminate all side loads on the pump bearings. In this article, we will learn the basic definition, parts, types, how does centrifugal pump works, various diagrams,. In the majority of cases, the driver in a centrifugal. The centrifugal pump is the most widely used pump in the world. At a minimum, a centrifugal pumping unit. Pump Driver Definition.