Threaded Insert Torque Values . Machined holes should be the correct size for the insert used. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Helical coil threaded insert install torque per. The k value is a factor that. A continuous process of further. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. Maximum locking torque shall be the highest torque value encountered on any installation. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt.

from www.industrialtorquetools.com

The k value is a factor that. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Maximum locking torque shall be the highest torque value encountered on any installation. Machined holes should be the correct size for the insert used. A continuous process of further. Helical coil threaded insert install torque per.

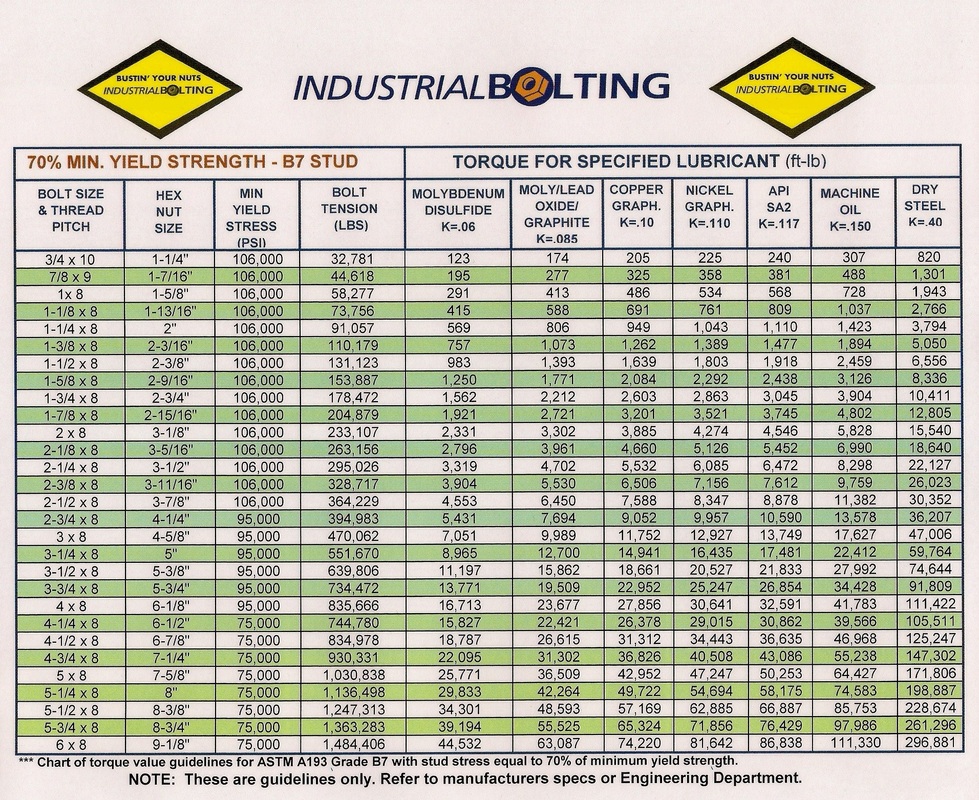

Torque Charts Industrial Torque Tools

Threaded Insert Torque Values The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Maximum locking torque shall be the highest torque value encountered on any installation. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. A continuous process of further. The k value is a factor that. Helical coil threaded insert install torque per. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Machined holes should be the correct size for the insert used.

From www.irwin-ind.com

IRWIN Industrial News and Events SI® Threaded Inserts for Plastics Threaded Insert Torque Values Machined holes should be the correct size for the insert used. The k value is a factor that. A continuous process of further. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with. Threaded Insert Torque Values.

From svauto.dk

Standard Torque Values Chart PDF Screw Building Materials Threaded Insert Torque Values Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Helical coil threaded insert install torque per. The k value is a factor that.. Threaded Insert Torque Values.

From cegdvbdc.blob.core.windows.net

Drill Size For 5/16 Threaded Insert at Glenn Zhou blog Threaded Insert Torque Values 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. Machined holes should be the correct size for the insert used. The application torque, in this instance, would be much higher than. Threaded Insert Torque Values.

From www.irwin-ind.com

IRWIN Industrial News and Events SI® Threaded Inserts for Plastics Threaded Insert Torque Values 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Maximum locking torque shall be the highest torque value encountered on any installation. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Helical coil threaded insert install torque per. A continuous process of. Threaded Insert Torque Values.

From www.abbottaerospace.com

Fastener Thread Diameters and Installation Torques Abbott Aerospace Threaded Insert Torque Values Helical coil threaded insert install torque per. Machined holes should be the correct size for the insert used. The k value is a factor that. Maximum locking torque shall be the highest torque value encountered on any installation. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop. Threaded Insert Torque Values.

From mungfali.com

Grade 8 Metric Bolt Torque Chart Threaded Insert Torque Values A continuous process of further. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Machined holes should be the correct size for the insert used. The k value is a factor that. Bolt. Threaded Insert Torque Values.

From www.latten.net

Torque values Sling2 Threaded Insert Torque Values Helical coil threaded insert install torque per. A continuous process of further. The k value is a factor that. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the. Threaded Insert Torque Values.

From www.industrialtorquetools.com

Torque Charts Industrial Torque Tools Threaded Insert Torque Values The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Helical coil threaded insert install torque per. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. A continuous process of further. 60083155 specification. Threaded Insert Torque Values.

From www.anzor.co.nz

Stainless Threaded Insert Dimensions Anzor Fasteners Threaded Insert Torque Values The k value is a factor that. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: A continuous process of further. Helical coil threaded insert install torque per. Maximum locking torque shall be the highest torque value encountered on any installation. Machined holes should be the correct size for the insert used. Si inserts for plastics. Threaded Insert Torque Values.

From www.stanleyengineeredfastening.com

Spiralock® Key Locking Threaded Inserts STANLEY® Threaded Insert Torque Values Machined holes should be the correct size for the insert used. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. Helical coil threaded insert install torque per. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go. Threaded Insert Torque Values.

From www.irwin-ind.com

IRWIN Industrial News and Events SI® Threaded Inserts for Plastics Threaded Insert Torque Values Helical coil threaded insert install torque per. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Maximum locking torque shall be the highest torque value encountered on any installation. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. The application. Threaded Insert Torque Values.

From www.autozone.com

Repair Guides Fasteners, Measurements And Conversions Torque Threaded Insert Torque Values Maximum locking torque shall be the highest torque value encountered on any installation. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. Helical. Threaded Insert Torque Values.

From www.ptecoupling.com

Inch and Metric Fastener Torque Threaded Insert Torque Values The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Machined holes should be the correct size for the insert used. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. The k value. Threaded Insert Torque Values.

From mechanics.stackexchange.com

maintenance Are there "standard" torque values for fasteners? Motor Threaded Insert Torque Values Maximum locking torque shall be the highest torque value encountered on any installation. Machined holes should be the correct size for the insert used. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. The k value is a factor that. Si inserts for plastics (1) thread. Threaded Insert Torque Values.

From www.pinterest.co.uk

fastener torque charts Bolt, Chart, Work tools Threaded Insert Torque Values 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. Machined holes should be the correct size for the insert used. Maximum locking torque shall be the highest torque value encountered on any installation.. Threaded Insert Torque Values.

From www.sampletemplates.com

Bolt Torque Chart 7 Free PDF Download Threaded Insert Torque Values A continuous process of further. Maximum locking torque shall be the highest torque value encountered on any installation. Machined holes should be the correct size for the insert used. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the. Threaded Insert Torque Values.

From www.repairengineering.com

Bolt Torque Chart Threaded Insert Torque Values 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. Helical coil threaded insert install torque per. A continuous process of further. Maximum locking torque shall be the highest torque value encountered on any. Threaded Insert Torque Values.

From cevkwotd.blob.core.windows.net

Astm Bolt Torque Specifications at Charles Poteat blog Threaded Insert Torque Values Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. Maximum locking torque shall be the highest torque value encountered on any installation. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: The application torque, in this instance, would be much. Threaded Insert Torque Values.

From www.industrialtorquetools.com

Torque Charts Industrial Torque Tools Threaded Insert Torque Values A continuous process of further. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. Machined holes should be the correct size for the. Threaded Insert Torque Values.

From charlieconnor.z21.web.core.windows.net

Threaded Insert Size Chart Threaded Insert Torque Values The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. A continuous process of further. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Helical coil threaded insert install torque per. Maximum locking torque shall be the highest torque value encountered on any. Threaded Insert Torque Values.

From laurenhiggins.z21.web.core.windows.net

Metric Bolt Fine Thread Torque Chart Threaded Insert Torque Values A continuous process of further. Helical coil threaded insert install torque per. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Machined holes should be the correct size for the insert used. Bolt tension is determined by dividing the torque on the screw by a k. Threaded Insert Torque Values.

From www.alibaba.com

M5 M6 M8 Threaded Insert For Aluminium T Slot Profile Accessories Buy Threaded Insert Torque Values Machined holes should be the correct size for the insert used. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. The k value is a factor that. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go. Threaded Insert Torque Values.

From www.formsbirds.com

Bolt Torque Chart 5 Free Templates in PDF, Word, Excel Download Threaded Insert Torque Values Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. Machined holes should be the correct size for the insert used. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. 60083155 specification of. Threaded Insert Torque Values.

From mungfali.com

Bolt Torque Chart For Stainless Steel Threaded Insert Torque Values Helical coil threaded insert install torque per. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. The k value is a factor that. A continuous process of further. Maximum locking torque shall be the highest torque value encountered on any installation. Machined holes should be the. Threaded Insert Torque Values.

From sainaltajang.blogspot.com

Technical Clinic Metric Standart Torque Values Threaded Insert Torque Values The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. A continuous process of further. Maximum locking torque shall be the highest torque value encountered on any installation. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Helical coil threaded insert install torque. Threaded Insert Torque Values.

From www.reddit.com

How do engineers determine torque values for fasteners? r/AskEngineers Threaded Insert Torque Values Machined holes should be the correct size for the insert used. A continuous process of further. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. The k value is a factor that. Bolt tension is determined by dividing the torque on the screw by. Threaded Insert Torque Values.

From www.scribd.com

Torque Values for Common Bolt Sizes Screw Tools Threaded Insert Torque Values A continuous process of further. Machined holes should be the correct size for the insert used. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. Helical coil threaded insert install torque per. The application torque, in this instance, would be much higher than the pure radial. Threaded Insert Torque Values.

From www.formsbirds.com

Metric Torque Values Chart Free Download Threaded Insert Torque Values Maximum locking torque shall be the highest torque value encountered on any installation. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. A continuous process of further. Helical coil threaded insert. Threaded Insert Torque Values.

From garagefixcononena.z13.web.core.windows.net

Grade 8 Fine Thread Bolt Torque Chart Threaded Insert Torque Values Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. Machined holes should be the correct size for the insert used. A continuous process of further. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may. Threaded Insert Torque Values.

From www.crosstools.com.au

Threaded Inserts for Plastic, Wood, Injection & Rotomolding Cross Tools Co Threaded Insert Torque Values Maximum locking torque shall be the highest torque value encountered on any installation. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in. Threaded Insert Torque Values.

From www.scribd.com

Metric Bolt Torque Chart Large PDF Threaded Insert Torque Values The k value is a factor that. Si inserts for plastics (1) thread tapped thru, class 3a/4h screw must pass with finger torque, but basic go gauge may stop at last thread. Helical coil threaded insert install torque per. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: The application torque, in this instance, would be. Threaded Insert Torque Values.

From cedakhzd.blob.core.windows.net

Metric Fine Thread Bolt Torque Chart at Gayla Frazier blog Threaded Insert Torque Values The k value is a factor that. The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. A continuous process of further. Machined holes should be the correct size for the insert used. Maximum locking torque shall be the highest torque value encountered on any installation. Bolt. Threaded Insert Torque Values.

From cedakhzd.blob.core.windows.net

Metric Fine Thread Bolt Torque Chart at Gayla Frazier blog Threaded Insert Torque Values The k value is a factor that. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. A continuous process of further. Bolt tension is determined by dividing the torque on the screw by. Threaded Insert Torque Values.

From www.autozone.com

Repair Guides Threaded Insert Torque Values The application torque, in this instance, would be much higher than the pure radial torque that the insert alone will withstand in the. Bolt tension is determined by dividing the torque on the screw by a k value multiplied by the thread diameter of the bolt. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Helical. Threaded Insert Torque Values.

From guidediagramjustin.z21.web.core.windows.net

Ez Lok Knife Threaded Insert Threaded Insert Torque Values Helical coil threaded insert install torque per. The k value is a factor that. Maximum locking torque shall be the highest torque value encountered on any installation. Machined holes should be the correct size for the insert used. A continuous process of further. 60083155 specification of torque and retention requirements for threaded hardware page 7/30/2021 revision: Si inserts for plastics. Threaded Insert Torque Values.