Optical Wafer Inspection System . Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. (1) the defect detectability evaluation, (2) the diverse optical. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas:

from www.bridgetronic.com

Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. (1) the defect detectability evaluation, (2) the diverse optical. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process.

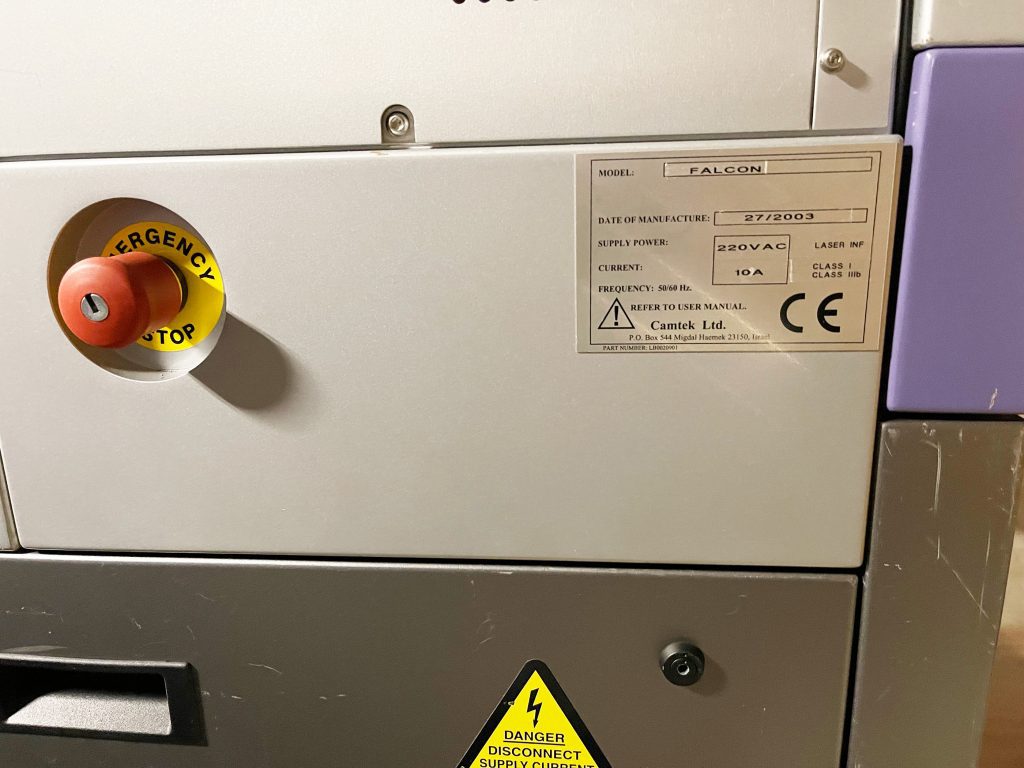

CamtekFalconOptical Wafer Inspection System63287 Bridge Tronic Global

Optical Wafer Inspection System Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: (1) the defect detectability evaluation, (2) the diverse optical.

From www.bridgetronic.com

CamtekFalcon 200 ALBOptical Wafer Inspection System63285 Bridge Tronic Global Optical Wafer Inspection System (1) the defect detectability evaluation, (2) the diverse optical. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. The wafer defect inspection system. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalconOptical Wafer Inspection System63287 Bridge Tronic Global Optical Wafer Inspection System Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. (1) the defect detectability evaluation, (2) the diverse optical. In this article, we give a comprehensive review of the emerging topics in. Optical Wafer Inspection System.

From www.semanticscholar.org

Figure 1 from DUV Optical Wafer Inspection System for 65nm Technology Node Semantic Scholar Optical Wafer Inspection System In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process. Optical Wafer Inspection System.

From www.bridgetronic.com

SemiProbePattern Optical Wafer Visual Inspection systems WIS AOI48093 Bridge Tronic Global Optical Wafer Inspection System The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. (1) the defect detectability evaluation, (2) the diverse optical. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalconOptical Wafer Inspection System63287 Bridge Tronic Global Optical Wafer Inspection System The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. In this article, we give a comprehensive review of the emerging topics in the past decade with. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200Optical Wafer Inspection System63286 Bridge Tronic Global Optical Wafer Inspection System (1) the defect detectability evaluation, (2) the diverse optical. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. The kronos ™ 1190 patterned. Optical Wafer Inspection System.

From www.prnewswire.com

KLATencor Introduces Comprehensive Wafer Inspection and Review Portfolio for Leading IC Optical Wafer Inspection System (1) the defect detectability evaluation, (2) the diverse optical. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The wafer defect inspection system. Optical Wafer Inspection System.

From www.lighttrans.com

Optical System for Inspection of MicroStructured Wafer LightTrans Optical Wafer Inspection System Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for. Optical Wafer Inspection System.

From www.wvis.com.tw

Wafer Inspection System With Vision Inspection System Co.,Ltd. Optical Wafer Inspection System The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200 ALBOptical Wafer Inspection System63285 Bridge Tronic Global Optical Wafer Inspection System The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. (1) the defect detectability evaluation, (2) the diverse optical. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The kronos ™ 1190 patterned wafer inspection system with high resolution optics. Optical Wafer Inspection System.

From www.lighttrans.com

Optical System for Inspection of MicroStructured Wafer Optical Wafer Inspection System In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address.. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200 SOptical Wafer Inspection System49207 Bridge Tronic Global Optical Wafer Inspection System The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three. Optical Wafer Inspection System.

From www.toray-eng.com

Wafer internal defect inspection system "INSPECTRA® IR" Series Optical Semiconductor Wafer Optical Wafer Inspection System In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. (1) the defect detectability evaluation, (2) the diverse optical. The enlight ® 2 brightfield optical inspection system is part of applied’s. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200 ALBOptical Wafer Inspection System63285 Bridge Tronic Global Optical Wafer Inspection System The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the.. Optical Wafer Inspection System.

From news.nestia.com

Optical wafer defect inspection at the 10 nm technology node and beyond Nestia Optical Wafer Inspection System Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200Optical Wafer Inspection System63286 Bridge Tronic Global Optical Wafer Inspection System In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: (1) the defect detectability evaluation, (2) the diverse optical. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. Wafer inspection in semiconductor manufacturing,. Optical Wafer Inspection System.

From www.semanticscholar.org

Figure 2 from New DUV Optical Wafer Inspection System Semantic Scholar Optical Wafer Inspection System The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. (1) the defect detectability evaluation, (2) the diverse optical. In this article, we give a comprehensive review of the emerging topics in. Optical Wafer Inspection System.

From www.toray-eng.com

Review System "RV3000" Optical Semiconductor Wafer Inspection System Product Information Optical Wafer Inspection System In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: (1) the defect detectability evaluation, (2) the diverse optical. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. The kronos ™ 1190 patterned. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalconOptical Wafer Inspection System63287 Bridge Tronic Global Optical Wafer Inspection System The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. (1) the defect detectability evaluation, (2) the diverse optical. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. In this article, we give a. Optical Wafer Inspection System.

From studylib.net

New DUV Optical Wafer Inspection System Optical Wafer Inspection System The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. (1) the defect detectability evaluation, (2) the diverse optical. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. In this article, we give a comprehensive. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200 ALBOptical Wafer Inspection System63285 Bridge Tronic Global Optical Wafer Inspection System The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains. Optical Wafer Inspection System.

From www.appliedmaterials.com

Advanced Logic and Memory Need New Tools for Optical Wafer Inspection Optical Wafer Inspection System The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. (1) the defect detectability evaluation, (2) the diverse optical. In this article, we give a. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200Optical Wafer Inspection System63286 Bridge Tronic Global Optical Wafer Inspection System Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. (1) the defect detectability evaluation, (2) the diverse optical. The wafer defect inspection system detects physical defects and pattern defects on wafers. Optical Wafer Inspection System.

From metrology.news

Enlight optical wafer inspection system Metrology and Quality News Online Magazine Optical Wafer Inspection System In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. (1) the defect detectability evaluation, (2) the diverse optical. The enlight ® 2 brightfield optical. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200 ALBOptical Wafer Inspection System63285 Bridge Tronic Global Optical Wafer Inspection System The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. (1) the defect detectability evaluation, (2) the diverse optical. The wafer defect inspection system detects physical defects and pattern defects on. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200 ALBOptical Wafer Inspection System63285 Bridge Tronic Global Optical Wafer Inspection System Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for. Optical Wafer Inspection System.

From www.toray-eng.com

Wafer Inspection System "INSPECTRA®" Series Optical Semiconductor Wafer Inspection System Optical Wafer Inspection System The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200 ALBOptical Wafer Inspection System63285 Bridge Tronic Global Optical Wafer Inspection System Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can. Optical Wafer Inspection System.

From mavink.com

Wafer Inspection System Optical Wafer Inspection System The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. (1) the defect detectability evaluation, (2) the diverse optical. The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. In this article, we give a comprehensive. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200 SOptical Wafer Inspection System49207 Bridge Tronic Global Optical Wafer Inspection System In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing process control so that chipmakers can achieve the. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalconOptical Wafer Inspection System63287 Bridge Tronic Global Optical Wafer Inspection System The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: The enlight ® 2 brightfield optical inspection system is part of applied’s approach to reinventing. Optical Wafer Inspection System.

From www.semanticscholar.org

Figure 1 from DUV Optical Wafer Inspection System for 65nm Technology Node Semantic Scholar Optical Wafer Inspection System The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. (1) the defect detectability evaluation, (2) the diverse optical. The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best. Optical Wafer Inspection System.

From www.toray-eng.com

Overlay measurement system "OM7000H" Optical Semiconductor Wafer Inspection System Product Optical Wafer Inspection System (1) the defect detectability evaluation, (2) the diverse optical. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas: Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. The kronos ™ 1190 patterned wafer inspection system with high resolution optics. Optical Wafer Inspection System.

From caltexsystems.com

Wafer Inspection System Caltex Digital Microscopes Optical Wafer Inspection System The kronos ™ 1190 patterned wafer inspection system with high resolution optics provides best in class sensitivity to critical defects for process. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. (1) the defect detectability evaluation, (2) the diverse optical. In this article, we give a comprehensive review of the emerging topics in. Optical Wafer Inspection System.

From www.bridgetronic.com

CamtekFalcon 200Optical Wafer Inspection System63286 Bridge Tronic Global Optical Wafer Inspection System The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Wafer inspection in semiconductor manufacturing, involves the meticulous examination of semiconductor wafers to identify and address. In this article, we give a comprehensive review of the emerging topics in the past decade with a focus on three specific areas:. Optical Wafer Inspection System.