Best Aluminum For Forming . Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. The following are some of the best aluminum alloys for bending: The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. Which alloys respond best to forming? It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. This is generalizing, of course, as there are ways to form 6061. One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you.

from www.aluminumextrudedprofiles.com

Which alloys respond best to forming? One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. This is generalizing, of course, as there are ways to form 6061. Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. The following are some of the best aluminum alloys for bending:

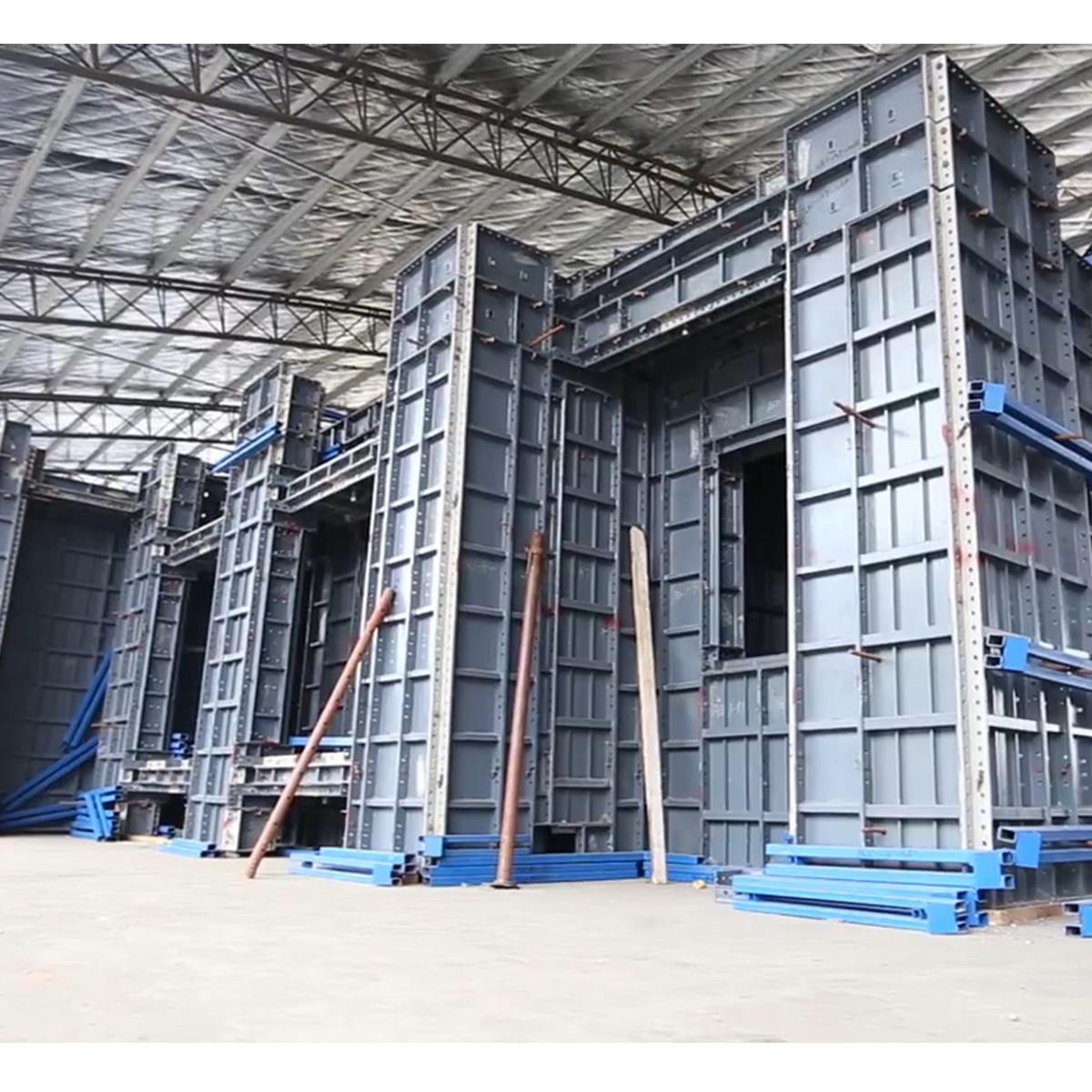

4mm 25KG/SQM Heavy Duty Building Aluminum Formwork Profiles

Best Aluminum For Forming The following are some of the best aluminum alloys for bending: The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. The following are some of the best aluminum alloys for bending: Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. Which alloys respond best to forming? This is generalizing, of course, as there are ways to form 6061.

From kdmfab.com

The Complete Guide for Aluminum Fabrication Best Aluminum For Forming Which alloys respond best to forming? One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s. Best Aluminum For Forming.

From dewilddieidee101.blogspot.com

Aluminum Sheet Metal Forming sheetmetal forming/ shaping with wooden form. YouTube Best Aluminum For Forming Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will. Best Aluminum For Forming.

From www.hotrod.com

Basic Techniques To MetalShaping From Home Hot Rod Network Best Aluminum For Forming It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx,. Best Aluminum For Forming.

From eziil.com

Basics of Metal Forming Process An Ultimate Guide Best Aluminum For Forming This is generalizing, of course, as there are ways to form 6061. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. Which alloys respond best to forming? One of the most useful characteristics. Best Aluminum For Forming.

From workshopinsider.com

The Last Guide to Sheet Metal Forming You Will Ever Need Best Aluminum For Forming Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. Which alloys respond best to forming? One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. It’s commonly used in. Best Aluminum For Forming.

From www.youtube.com

Metal Shaping with Lazze Stretching Aluminum in a Bead Roller YouTube Best Aluminum For Forming One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. It’s commonly used in the manufacture of cooking. Best Aluminum For Forming.

From onesky.ph

What Manufacturers Need to Know About Forming Aluminum One Sky Blog Best Aluminum For Forming Which alloys respond best to forming? Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. The following are some. Best Aluminum For Forming.

From www.otalum.com

Aluminium Formwork Supplier, Aluminium Formwork Construction Best Aluminum For Forming Which alloys respond best to forming? The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. This is generalizing, of course, as there are ways to form 6061. The following are some of the best aluminum alloys for bending: One of the most useful characteristics of aluminium. Best Aluminum For Forming.

From www.thefabricator.com

R&D Update Forming aluminum alloys at elevated temperatures, Part 1 The Fabricator Best Aluminum For Forming Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. Which alloys respond best to forming? It’s commonly used in the manufacture of cooking utensils, roofing, and. Best Aluminum For Forming.

From www.aluminumextrudedprofiles.com

4mm 25KG/SQM Heavy Duty Building Aluminum Formwork Profiles Best Aluminum For Forming Which alloys respond best to forming? It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy,. Best Aluminum For Forming.

From www.youtube.com

Aluminum Fabrication Sheet Metal Forming and Punching Blanking dies YouTube Best Aluminum For Forming Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. Which alloys respond best to forming? The following are some of the best aluminum alloys for bending: For example, as shown in the chart in figure 1, the best materials for forming. Best Aluminum For Forming.

From www.vrogue.co

Metal Forming Basic Types Diagram Classification vrogue.co Best Aluminum For Forming This is generalizing, of course, as there are ways to form 6061. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. Ideally, part designers should know that when it comes to aluminum grades,. Best Aluminum For Forming.

From www.youtube.com

Stretch Forming Aluminum Extrusion YouTube Best Aluminum For Forming Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. The following are some of the best aluminum alloys for bending: The aluminum series’ ability to bend tends to. Best Aluminum For Forming.

From blog.misumiusa.com

Types of Aluminum Extrusion and Profiles MISUMI Blog Best Aluminum For Forming The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. The following are some of the best aluminum alloys for bending: This is generalizing, of course, as there are ways to form 6061. Whether it’s taking the time to prototype your application or ensuring that you pick. Best Aluminum For Forming.

From www.totalcontec.com

Aluminum Formwork TotalContec Best Aluminum For Forming Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. Which alloys respond best to forming? It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape. Best Aluminum For Forming.

From sinogar.en.made-in-china.com

Concrete Aluminum Formwork System Aluminium Formwork Construction Materials and Aluminium Profiles Best Aluminum For Forming The following are some of the best aluminum alloys for bending: Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. Which alloys respond best to forming? It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. This is generalizing, of course, as there are ways to. Best Aluminum For Forming.

From www.toprollformer.com

Automatic Aluminum Panel 84R Cold Roll Forming machine MACHINERY MechEng Source Co., Ltd Best Aluminum For Forming Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. This is generalizing, of course, as there are ways to form 6061. It’s commonly used in the manufacture. Best Aluminum For Forming.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Best Aluminum For Forming Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. The aluminum. Best Aluminum For Forming.

From onesky.ph

What Manufacturers Need to Know About Forming Aluminum One Sky Blog Best Aluminum For Forming The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. The following are some of the best aluminum alloys. Best Aluminum For Forming.

From preciseforms.com

Modular Aluminum Forms for Concrete Construction Best Aluminum For Forming Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. This is generalizing, of course, as there are ways. Best Aluminum For Forming.

From preciseforms.com

Aluminum Forms for Concrete Construction Precise Forms Best Aluminum For Forming For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. This is generalizing, of course, as there are ways to form 6061. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. Which alloys respond best to. Best Aluminum For Forming.

From engineeringlearn.com

6 Types of Aluminum Uses and Grades [Explained with Complete Details] Engineering Learn Best Aluminum For Forming One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. Which alloys respond best to forming? The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. The following are some of the best aluminum alloys. Best Aluminum For Forming.

From www.getoformwork.com

What is aluminum formwork system? Best Aluminum For Forming The following are some of the best aluminum alloys for bending: Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. Which alloys respond best to forming? The aluminum series’ ability to bend tends to decrease as you move down the list. Best Aluminum For Forming.

From www.filbuild.com

Aluminum Panel Form Components Philippines Best Aluminum For Forming Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. The following. Best Aluminum For Forming.

From ms-machining.com

Best Aluminum Alloy Die Castings Aluminum for die Castings Best Aluminum For Forming The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. The following are some of the best. Best Aluminum For Forming.

From www.youtube.com

Roll forming aluminium by Holden Aluminium Technologies YouTube Best Aluminum For Forming The following are some of the best aluminum alloys for bending: This is generalizing, of course, as there are ways to form 6061. One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. Whether it’s taking the time to prototype your application or ensuring that you pick just. Best Aluminum For Forming.

From www.wileymetal.com

Five Common Applications of Aluminum Extrusion Wiley Metal Best Aluminum For Forming Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. This is generalizing, of course, as there are ways to form 6061. One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. It’s commonly used in the manufacture. Best Aluminum For Forming.

From www.forgings.bz

Aluminum Companies Aluminum Services Best Aluminum For Forming The following are some of the best aluminum alloys for bending: Whether it’s taking the time to prototype your application or ensuring that you pick just the right alloy, it’s possible to overcome the challenges posed by forming aluminum. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. For example, as shown in the chart in. Best Aluminum For Forming.

From sinopro.ae

Full aluminum formwork systems Aluminum shutters Wall formwork,slab formwork and column formwork Best Aluminum For Forming This is generalizing, of course, as there are ways to form 6061. Which alloys respond best to forming? One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. The following are some of the best aluminum alloys for bending: For example, as shown in the chart in figure. Best Aluminum For Forming.

From www.adtomall.com

Aluminum Formwork System Best Aluminum For Forming For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. The following are some of the best aluminum alloys for bending: One of the most useful characteristics of aluminium is its formability, and one way to form the metal into. Best Aluminum For Forming.

From www.wileymetal.com

5 Bending and Stretch Forming Methods for Aluminum Extrusion Wiley Metal Best Aluminum For Forming The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. Whether it’s taking the time to prototype your application or ensuring that you pick just. Best Aluminum For Forming.

From www.allmetalsfab.com

Metal Forming & Rolling Service All Metals Fabrication Ogden, Utah Best Aluminum For Forming For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. Whether it’s taking the time to prototype. Best Aluminum For Forming.

From sinocncmachining.com

The Ultimate Guide to Faqs Stretch Forming Aluminum Sheet ETCN Best Aluminum For Forming It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to t4 and t6. One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you. Ideally, part. Best Aluminum For Forming.

From www.adtomall.com

6061T6 Aluminum Formwork System Best Aluminum For Forming For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. It’s commonly used in the manufacture of cooking utensils, roofing, and transportation parts. This is generalizing, of course, as there are ways to form 6061. The following are some of. Best Aluminum For Forming.

From www.cmrp.com

Custom Sheet Metal Bending Custom Rolled Sheet Metal Best Aluminum For Forming Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. For example, as shown in the chart in figure 1, the best materials for forming on a press brake are those aluminum alloys within the 3xxx, 5xxx, and 6xxx series. The following are some of the best aluminum alloys for. Best Aluminum For Forming.