How High Should A Die Table Be . This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. Do you know how to optimize your die cast design? The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. What is the ideal wall thickness for die castings? For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. Learn to design for thin walls, tolerance zones, and appropriate draught angles. Wall thickness, typically is 2mm for aluminum die casting. Study this order of steps carefully;. The table below shows the correct percentage to compute the inside radius for some common material types.

from www.unknownbrewing.com

Do you know how to optimize your die cast design? The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. What is the ideal wall thickness for die castings? Wall thickness, typically is 2mm for aluminum die casting. This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. Study this order of steps carefully;. For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. The table below shows the correct percentage to compute the inside radius for some common material types. Learn to design for thin walls, tolerance zones, and appropriate draught angles.

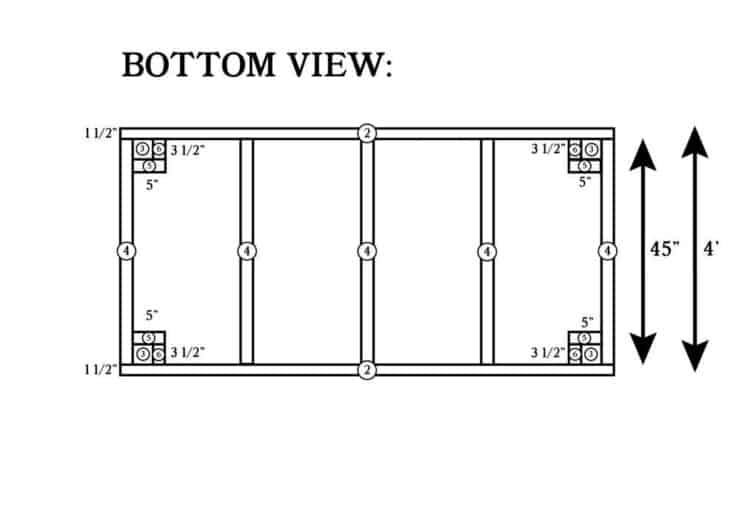

18 Creative DIY Beer Die Table Plans for Fun Gatherings

How High Should A Die Table Be Learn to design for thin walls, tolerance zones, and appropriate draught angles. The table below shows the correct percentage to compute the inside radius for some common material types. Learn to design for thin walls, tolerance zones, and appropriate draught angles. Study this order of steps carefully;. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. Do you know how to optimize your die cast design? For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. Wall thickness, typically is 2mm for aluminum die casting. What is the ideal wall thickness for die castings? This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2.

From www.mdpi.com

Efficient Disposal of Basic Fuchsin Dye from Aqueous Media Using ZrO2/MgMn2O4/Mg(Mg0.333Mn1.333 How High Should A Die Table Be Learn to design for thin walls, tolerance zones, and appropriate draught angles. The table below shows the correct percentage to compute the inside radius for some common material types. Study this order of steps carefully;. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be. How High Should A Die Table Be.

From www.unknownbrewing.com

18 Creative DIY Beer Die Table Plans for Fun Gatherings How High Should A Die Table Be The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. Do you know how to optimize your die cast design? What is the ideal wall thickness for die castings? This section illustrates the 14 steps required for designing a die to. How High Should A Die Table Be.

From greenvalleyinc.com

Die Tables Green Valley Manufacturing How High Should A Die Table Be Do you know how to optimize your die cast design? Study this order of steps carefully;. Learn to design for thin walls, tolerance zones, and appropriate draught angles. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. For instance, if. How High Should A Die Table Be.

From greenvalleyinc.com

Die Tables Green Valley Manufacturing How High Should A Die Table Be Wall thickness, typically is 2mm for aluminum die casting. The table below shows the correct percentage to compute the inside radius for some common material types. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. The shut height of the die the distance from the top. How High Should A Die Table Be.

From www.mdpi.com

Molecules Free FullText “Green” nZVIBiochar as Fenton Catalyst Perspective of Closingthe How High Should A Die Table Be This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. Learn to design for thin walls, tolerance zones, and appropriate draught angles. The table below shows the correct percentage to compute the inside radius for some common material types. The die designer originates designs of dies used to stamp and. How High Should A Die Table Be.

From greenvalleyinc.com

Die Maintenance Tables Green Valley Manufacturing How High Should A Die Table Be This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. Learn to design for thin walls, tolerance zones, and appropriate draught angles. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the. How High Should A Die Table Be.

From www.mdpi.com

Water Free FullText Biodegradation and Decolorization of Textile Azo Dyes by Paramecium How High Should A Die Table Be Learn to design for thin walls, tolerance zones, and appropriate draught angles. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. Do. How High Should A Die Table Be.

From veriform.ca

Custom Die Change Tables VeriForm Metal Fabricating Done Right! How High Should A Die Table Be The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. Study this order of steps carefully;. Do you. How High Should A Die Table Be.

From greenvalleyinc.com

Die Tables Green Valley Manufacturing How High Should A Die Table Be The table below shows the correct percentage to compute the inside radius for some common material types. Do you know how to optimize your die cast design? Study this order of steps carefully;. Learn to design for thin walls, tolerance zones, and appropriate draught angles. For instance, if you find that the perfect die opening is 0.424 in., the closest. How High Should A Die Table Be.

From nursing.sdsu.edu

Doctor of Nursing Practice SDSU How High Should A Die Table Be What is the ideal wall thickness for die castings? The table below shows the correct percentage to compute the inside radius for some common material types. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. This section illustrates the 14 steps required for designing a die. How High Should A Die Table Be.

From greenvalleyinc.com

Die Maintenance Tables Green Valley Manufacturing How High Should A Die Table Be This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. What is the ideal wall thickness for die castings? Do you know how to optimize your die cast design? Study this order of steps carefully;. Learn to design for thin walls, tolerance zones, and appropriate draught angles. The shut height. How High Should A Die Table Be.

From www.unknownbrewing.com

18 Creative DIY Beer Die Table Plans for Fun Gatherings How High Should A Die Table Be Do you know how to optimize your die cast design? The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. For. How High Should A Die Table Be.

From www.mdpi.com

Efficient Disposal of Basic Fuchsin Dye from Aqueous Media Using ZrO2/MgMn2O4/Mg(Mg0.333Mn1.333 How High Should A Die Table Be Wall thickness, typically is 2mm for aluminum die casting. For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. What is the ideal wall thickness for die castings? Learn to design for thin walls, tolerance zones, and appropriate draught angles. Do you know how to optimize. How High Should A Die Table Be.

From greenvalleyinc.com

Die Tables Green Valley Manufacturing How High Should A Die Table Be The table below shows the correct percentage to compute the inside radius for some common material types. Study this order of steps carefully;. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. Do you know how to optimize your die cast design? Learn to design for. How High Should A Die Table Be.

From www.mdpi.com

Macromol Free FullText Influencing the Shape Recovery and Thermomechanical Properties of How High Should A Die Table Be Study this order of steps carefully;. Do you know how to optimize your die cast design? The table below shows the correct percentage to compute the inside radius for some common material types. This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. What is the ideal wall thickness for. How High Should A Die Table Be.

From www.mdpi.com

Free FullText Simple Synthesis and Characterization of Cobalt Ferrite How High Should A Die Table Be The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. The table below shows the correct percentage to compute the inside radius for some common material types. The die designer originates designs of dies used to stamp and form parts from. How High Should A Die Table Be.

From greenvalleyinc.com

Die Maintenance Tables Green Valley Manufacturing How High Should A Die Table Be Learn to design for thin walls, tolerance zones, and appropriate draught angles. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. Do you know how to optimize your die cast design? The shut height of the die the distance from the top of the punch holder. How High Should A Die Table Be.

From www.mdpi.com

Energies Free FullText Characterization and Comparison of DSSCs Fabricated with Black How High Should A Die Table Be For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. Study this order of steps carefully;. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. This. How High Should A Die Table Be.

From www.unknownbrewing.com

18 Creative DIY Beer Die Table Plans for Fun Gatherings How High Should A Die Table Be For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. Do you know how to optimize your die cast design? This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. The table below shows the correct. How High Should A Die Table Be.

From www.cosmopolitan.com

This is why you should dye your hair for the new season How High Should A Die Table Be Wall thickness, typically is 2mm for aluminum die casting. The table below shows the correct percentage to compute the inside radius for some common material types. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. The shut height of the die the distance from the top. How High Should A Die Table Be.

From www.mdpi.com

Sustainability Free FullText A Study of Treatment of Reactive Red 45 Dye by Advanced How High Should A Die Table Be The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. Wall thickness, typically is 2mm for aluminum. How High Should A Die Table Be.

From cabinguy.com

Building a Beer Die Table Cabin Guy How High Should A Die Table Be Do you know how to optimize your die cast design? Study this order of steps carefully;. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. What is the ideal wall thickness for die castings? This section illustrates the 14 steps. How High Should A Die Table Be.

From www.mdpi.com

IJERPH Free FullText Adsorption of Magenta Dye on PbO Doped MgZnO Interpretation of How High Should A Die Table Be For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. Study this order of steps carefully;. The table below shows the correct percentage to compute the inside radius for some common material types. Do you know how to optimize your die cast design? The shut height. How High Should A Die Table Be.

From www.mdpi.com

Materials Free FullText Impact of Nitroxyl Radicals on Photovoltaic Conversion Properties How High Should A Die Table Be This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. The table below shows the correct percentage to compute the inside radius for some common material types. Wall thickness, typically is 2mm for aluminum die casting. What is the ideal wall thickness for die castings? The die designer originates designs. How High Should A Die Table Be.

From www.statology.org

3 Dice Probability Chart (With Probabilities) How High Should A Die Table Be Learn to design for thin walls, tolerance zones, and appropriate draught angles. Wall thickness, typically is 2mm for aluminum die casting. What is the ideal wall thickness for die castings? The table below shows the correct percentage to compute the inside radius for some common material types. Study this order of steps carefully;. For instance, if you find that the. How High Should A Die Table Be.

From greenvalleyinc.com

2 x 4,000 lb. Die Table (173891) Green Valley Manufacturing How High Should A Die Table Be The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. What is the ideal wall thickness for die. How High Should A Die Table Be.

From www.1stdibs.com

Sculptural Console Table, Sideboard Made of Solid Walnut Wood, Narrow Console For Sale at How High Should A Die Table Be Do you know how to optimize your die cast design? What is the ideal wall thickness for die castings? Wall thickness, typically is 2mm for aluminum die casting. Study this order of steps carefully;. Learn to design for thin walls, tolerance zones, and appropriate draught angles. For instance, if you find that the perfect die opening is 0.424 in., the. How High Should A Die Table Be.

From www.amazon.com

Tie Dye Birthday Party Supplies, 60's Hippie Theme Tablecloth 3Pcs Groovy Hippie How High Should A Die Table Be The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. Learn to design for thin walls, tolerance zones, and appropriate draught angles. Wall thickness, typically is 2mm for aluminum die casting. Study this order of steps carefully;. The die designer originates. How High Should A Die Table Be.

From www.mdpi.com

Efficient Decolorization of the PolyAzo Dye Sirius Grey by Coriolopsis gallica LaccaseMediator How High Should A Die Table Be What is the ideal wall thickness for die castings? The table below shows the correct percentage to compute the inside radius for some common material types. Do you know how to optimize your die cast design? The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always. How High Should A Die Table Be.

From www.amazon.com

Newwiee 3 Pcs Tie Dye Tablecloth Rainbow Table Cloth 54 x 108 Inches Plastic How High Should A Die Table Be Do you know how to optimize your die cast design? The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. For. How High Should A Die Table Be.

From www.mdpi.com

Agronomy Free FullText The Biogenic Synthesis of Cobalt Monometallic and CobaltZinc How High Should A Die Table Be Do you know how to optimize your die cast design? For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. Study this order of steps carefully;. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and. How High Should A Die Table Be.

From www.mdpi.com

Colorants Free FullText Enhanced Dyeing of Polypropylene Using FluorineOxygen Gas Mixtures How High Should A Die Table Be Wall thickness, typically is 2mm for aluminum die casting. For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be either one with a die. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on. How High Should A Die Table Be.

From www.mdpi.com

Water Free FullText Different Adsorption Behaviors and Mechanisms of Anionic Azo Dyes on How High Should A Die Table Be The table below shows the correct percentage to compute the inside radius for some common material types. The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. This section illustrates the 14 steps required for designing a die to produce the. How High Should A Die Table Be.

From www.unknownbrewing.com

18 Creative DIY Beer Die Table Plans for Fun Gatherings How High Should A Die Table Be The shut height of the die the distance from the top of the punch holder to the bottom of the die holder should always be given on the drawing. The die designer originates designs of dies used to stamp and form parts from sheet metal, assemble parts together, and perform a variety. For instance, if you find that the perfect. How High Should A Die Table Be.

From www.mdpi.com

Water Free FullText Synthesis of Mesoporous RuZnOgC3N4 Nanoparticles and Their How High Should A Die Table Be Learn to design for thin walls, tolerance zones, and appropriate draught angles. This section illustrates the 14 steps required for designing a die to produce the sample part shown in figure 1.2. Wall thickness, typically is 2mm for aluminum die casting. For instance, if you find that the perfect die opening is 0.424 in., the closest available die may be. How High Should A Die Table Be.