Cutting Threads In Titanium . However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Top tips when machining titanium alloys: As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be strong enough to resist cutting pressure.

from modelengineeringinthailand.com

As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be strong enough to resist cutting pressure. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. Top tips when machining titanium alloys: Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet.

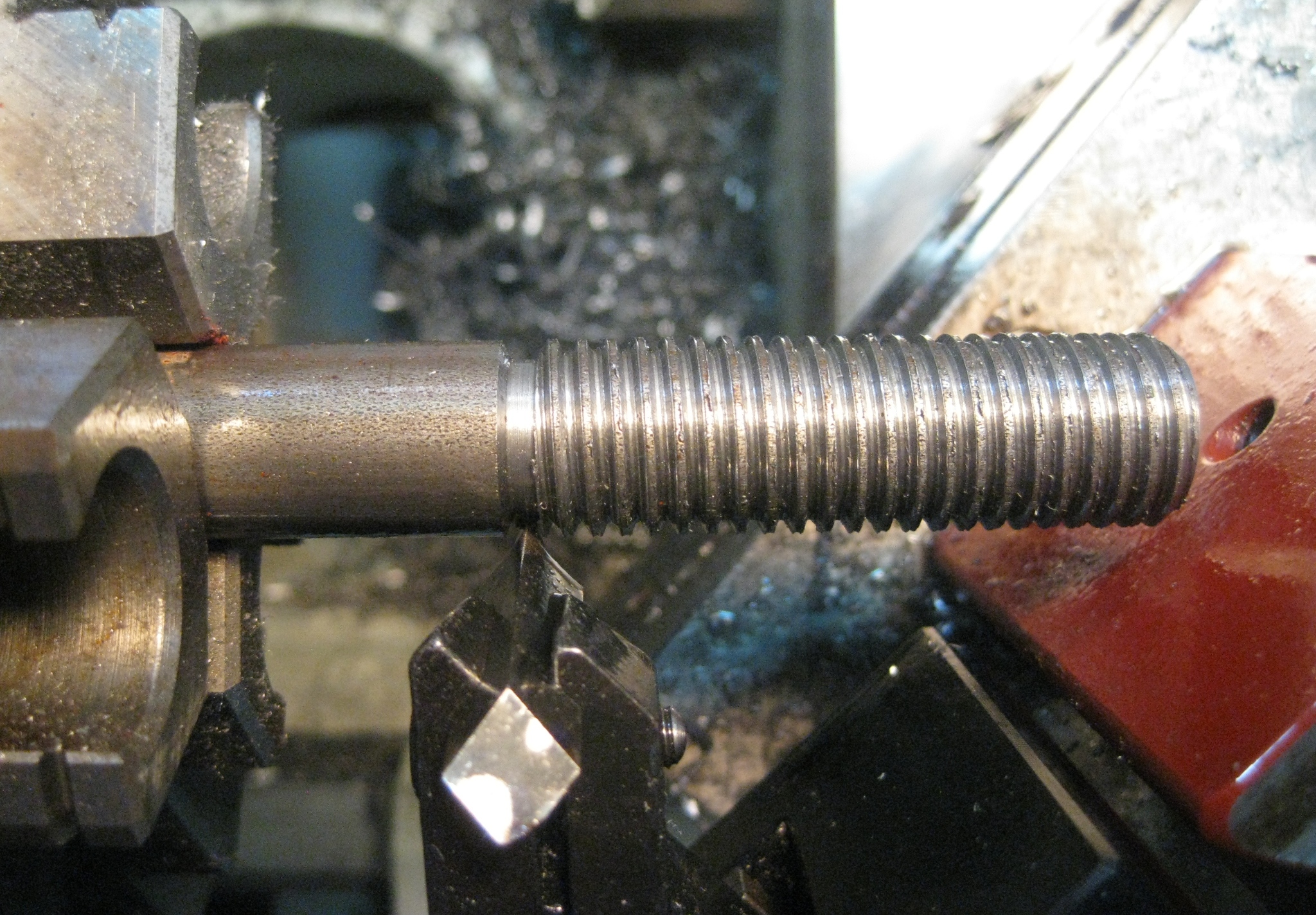

Screwcutting 5/8″ Whit Threads On The Kinwa CH 430X1100 Lathe

Cutting Threads In Titanium Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. Top tips when machining titanium alloys: Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be strong enough to resist cutting pressure.

From www.mscdirect.com

Tips for Cutting Titanium Alloys in Your Machine Shop Better MRO Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. As titanium and its. Cutting Threads In Titanium.

From www.youtube.com

How to Cut Screw Threads on a CNC Lathe Using G32 YouTube Cutting Threads In Titanium As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be strong enough to resist cutting pressure. However, heat management and appropriate chip evacuation, when paired with the correct coating,. Cutting Threads In Titanium.

From hibike.com.tw

KOWA Spoke Cutting & Threading Machine Hibike Cutting Threads In Titanium Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to. Cutting Threads In Titanium.

From www.youtube.com

Thread Cutting Tips Using Rare Two Piece Dies YouTube Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower. Cutting Threads In Titanium.

From swaterjet.com

Waterjet Cutting Titanium The best Titanium processing tools Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Top tips when machining titanium alloys: Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. As titanium and its many alloys continue to grow in use across various industries, more machinists will. Cutting Threads In Titanium.

From blog.thepipingmart.com

5 Types of Screw Threads and Their Uses Cutting Threads In Titanium As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. However, heat management and appropriate chip evacuation, when paired with the. Cutting Threads In Titanium.

From www.fastening-solutions.co.uk

Fast What are the differences between cut and rolled threads? Cutting Threads In Titanium Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. Top tips when machining titanium alloys: A sharp cutting edge minimizes. Cutting Threads In Titanium.

From www.youtube.com

Cutting Internal Threads on the Metal Lathe Threading a Custom Nova Cutting Threads In Titanium Top tips when machining titanium alloys: Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. A sharp cutting edge minimizes. Cutting Threads In Titanium.

From gmindustry.en.made-in-china.com

Behappy 40 PCS Tap and Die Set, Metric Tap and Die Set Titanium Coated Cutting Threads In Titanium Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. As titanium and its. Cutting Threads In Titanium.

From www.youtube.com

Easy Method To Cut Tapered Threads On The Lathe YouTube Cutting Threads In Titanium Top tips when machining titanium alloys: Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively. Cutting Threads In Titanium.

From www.youtube.com

How to cut a thread on a manual lathe (Intermediate method ideal for Cutting Threads In Titanium Top tips when machining titanium alloys: Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. As titanium and its many alloys continue to grow in use across various industries, more machinists will. Cutting Threads In Titanium.

From www.youtube.com

threading titanium on diy cnc lathe YouTube Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Top tips when machining titanium alloys: A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be strong enough to resist cutting pressure. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths (. Cutting Threads In Titanium.

From www.alliedtitanium.com

0046905 Titanium Slotted Threaded Insert with 3/410 UNC Internal Cutting Threads In Titanium Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. Top tips when machining titanium alloys: A sharp cutting edge minimizes cutting forces in titanium, but. Cutting Threads In Titanium.

From be-cu.com

Titanium Laser Cutting Services Laser Cut Titanium Parts Cutting Threads In Titanium Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful. Cutting Threads In Titanium.

From www.banggood.com

10pcs wnmg0804 titanium coated carbide insert wnmg432 cutting tool for Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Top tips when machining titanium alloys: Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or. Cutting Threads In Titanium.

From www.youtube.com

thread cutting YouTube Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult. Cutting Threads In Titanium.

From www.youtube.com

THREAD CUTTING on a LATHE YouTube Cutting Threads In Titanium Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or. Cutting Threads In Titanium.

From www.thefabricator.com

Tools designed for threading titanium alloys Cutting Threads In Titanium Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. As titanium and its many alloys continue to grow in use across various industries, more machinists. Cutting Threads In Titanium.

From www.youtube.com

How To Cut Threads On A Lathe YouTube Cutting Threads In Titanium Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be. Cutting Threads In Titanium.

From modelengineeringinthailand.com

Screwcutting 5/8″ Whit Threads On The Kinwa CH 430X1100 Lathe Cutting Threads In Titanium Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Top tips when machining titanium alloys: Titanium alloys’ elasticity, which is beneficial and desirable for finished parts,. Cutting Threads In Titanium.

From www.finepart.com

Micro Waterjet Cutting Titanium Precision Cutting Titanium Finepart Cutting Threads In Titanium A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be strong enough to resist cutting pressure. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths (. Cutting Threads In Titanium.

From www.youtube.com

HOW TO THREAD ON LATHE MACHINE. EXTERNAL AND INTERNAL THREADS YouTube Cutting Threads In Titanium Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be strong enough to resist cutting pressure. However, heat management and appropriate chip evacuation, when paired with the correct. Cutting Threads In Titanium.

From www.youtube.com

Single Point Threading on the Lathe I YouTube Cutting Threads In Titanium Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy. Cutting Threads In Titanium.

From www.banggood.com

drillpro 10pcs 313mm hss titanium coated twist drill bit set wood Cutting Threads In Titanium Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison. Cutting Threads In Titanium.

From www.youtube.com

Threading titanium rod YouTube Cutting Threads In Titanium Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively. Cutting Threads In Titanium.

From www.youtube.com

How To Pickup an Internal Thread for Repairs !!! YouTube Cutting Threads In Titanium Top tips when machining titanium alloys: Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. A sharp cutting edge minimizes cutting forces in titanium, but. Cutting Threads In Titanium.

From www.youtube.com

cutting an external thread YouTube Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. As titanium and its many alloys continue to grow in use across various industries, more machinists will. Cutting Threads In Titanium.

From www.alliedtitanium.com

0093790 Titanium Slotted Threaded Insert with M61 pitch Internal Cutting Threads In Titanium As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. Top tips when machining titanium alloys: A sharp cutting edge minimizes cutting forces in titanium, but the. Cutting Threads In Titanium.

From www.dreamstime.com

Cutting Tool. Threading in the Hole Stock Photo Image of hole, spiral Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be. Cutting Threads In Titanium.

From www.anchorboltexpress.com

Roll Thread vs. Cut Thread Anchor Bolt Express Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be strong. Cutting Threads In Titanium.

From www.youtube.com

Square_Thread Amazing Finish Square Thread Cutting With HSS Tool Cutting Threads In Titanium Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. Top tips when machining titanium alloys: Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce. Cutting Threads In Titanium.

From www.harveyperformance.com

8 Unique Facts About Thread Forming Taps In The Loupe Cutting Threads In Titanium Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. Titanium alloys’ elasticity, which is beneficial and desirable for finished parts, encourages deflection and vibration during heavy machining cuts. Top tips when machining titanium alloys: Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce. Cutting Threads In Titanium.

From www.youtube.com

SNS 350 Threading Titanium Studs, Single Point Threading YouTube Cutting Threads In Titanium Top tips when machining titanium alloys: Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.) have relatively low tensile strengths ( σt) and produce relatively lower cutting forces in comparison to that generated. As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. However, heat management and appropriate. Cutting Threads In Titanium.

From www.youtube.com

The Easiest & Safest Method Of Screw Cutting Threads On The Lathe Cutting Threads In Titanium However, heat management and appropriate chip evacuation, when paired with the correct coating, will enable a successful run. Top tips when machining titanium alloys: Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. As titanium and its many alloys continue to grow in use across various industries, more machinists will. Cutting Threads In Titanium.

From www.youtube.com

Lathe 152 External Thread Cutting YouTube Cutting Threads In Titanium As titanium and its many alloys continue to grow in use across various industries, more machinists will be tasked with cutting this difficult material. Top tips when machining titanium alloys: A sharp cutting edge minimizes cutting forces in titanium, but the cutting edge also needs to be strong enough to resist cutting pressure. Alpha (α) titanium alloys (ti5al2.5sn, ti8al1mo1v, etc.). Cutting Threads In Titanium.