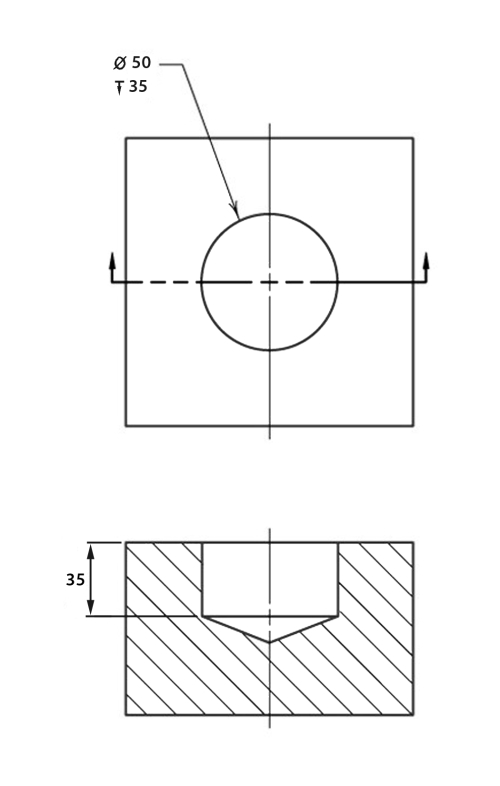

Depth Of Blind Hole . machining blind holes that have limited depth has advantages and disadvantages. to specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. The depth for tapping blind holes varies based on the tap type, the material you’re working with, and the application’s specific requirements. Drilling a blind hole requires careful consideration of the hole depth, proper tools, and techniques to ensure accurate and efficient results. Generally, it’s advisable to tap to a depth three times the the downward arrow symbol (↧) represents the depth to which the hole is threaded (tapping depth). Vernier depth gauges or digital depth gauges are commonly employed. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. This article explores the specifics of blind holes and their importance in enhancing primary reliability, reducing material waste, and providing designers and mechanics with versatile options in part creation. For larger blind holes, calipers with depth measurement capabilities can be utilized. While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to the drill bit. How to drill a blind hole? this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Highly precise measurements are achieved using depth micrometers. for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the hole gets deeper.

from www.mcgill.ca

Highly precise measurements are achieved using depth micrometers. the downward arrow symbol (↧) represents the depth to which the hole is threaded (tapping depth). This article explores the specifics of blind holes and their importance in enhancing primary reliability, reducing material waste, and providing designers and mechanics with versatile options in part creation. While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to the drill bit. how deep can i tap a blind hole? The depth for tapping blind holes varies based on the tap type, the material you’re working with, and the application’s specific requirements. to specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. machining blind holes that have limited depth has advantages and disadvantages. Use depth gauges to measure the depth of blind holes accurately. How to drill a blind hole?

Principles of Dimensioning Engineering Design McGill University

Depth Of Blind Hole While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to the drill bit. to specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. Use depth gauges to measure the depth of blind holes accurately. This article explores the specifics of blind holes and their importance in enhancing primary reliability, reducing material waste, and providing designers and mechanics with versatile options in part creation. how deep can i tap a blind hole? Drilling a blind hole requires careful consideration of the hole depth, proper tools, and techniques to ensure accurate and efficient results. How to drill a blind hole? The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the hole gets deeper. Highly precise measurements are achieved using depth micrometers. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Vernier depth gauges or digital depth gauges are commonly employed. the downward arrow symbol (↧) represents the depth to which the hole is threaded (tapping depth). The depth for tapping blind holes varies based on the tap type, the material you’re working with, and the application’s specific requirements. While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to the drill bit. For larger blind holes, calipers with depth measurement capabilities can be utilized.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Depth Of Blind Hole how deep can i tap a blind hole? this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. This article explores the specifics of. Depth Of Blind Hole.

From www.mcgill.ca

Principles of Dimensioning Engineering Design McGill University Depth Of Blind Hole The depth for tapping blind holes varies based on the tap type, the material you’re working with, and the application’s specific requirements. For larger blind holes, calipers with depth measurement capabilities can be utilized. for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the. Depth Of Blind Hole.

From brazilmetalparts.com

Threading Standard Holes Depth Of Blind Hole This article explores the specifics of blind holes and their importance in enhancing primary reliability, reducing material waste, and providing designers and mechanics with versatile options in part creation. machining blind holes that have limited depth has advantages and disadvantages. Generally, it’s advisable to tap to a depth three times the how deep can i tap a blind. Depth Of Blind Hole.

From www.protolabs.com

Threading Key Inserts Depth Of Blind Hole for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the hole gets deeper. The depth for tapping blind holes varies based on the tap type, the material you’re working with, and the application’s specific requirements. how deep can i tap a blind hole?. Depth Of Blind Hole.

From www.researchgate.net

The coupling coefficient vs the depth of the blind hole at different Depth Of Blind Hole How to drill a blind hole? For larger blind holes, calipers with depth measurement capabilities can be utilized. The depth for tapping blind holes varies based on the tap type, the material you’re working with, and the application’s specific requirements. Highly precise measurements are achieved using depth micrometers. While drilling, stop and examine the hole depth periodically using a depth. Depth Of Blind Hole.

From www.researchgate.net

The measured depth of the blind holes Download Scientific Diagram Depth Of Blind Hole the downward arrow symbol (↧) represents the depth to which the hole is threaded (tapping depth). The depth for tapping blind holes varies based on the tap type, the material you’re working with, and the application’s specific requirements. how deep can i tap a blind hole? The depth can be controlled by directly specifying the depth of the. Depth Of Blind Hole.

From www.chegg.com

Solved 1) The drawing below shows a crosssection of a blind Depth Of Blind Hole Generally, it’s advisable to tap to a depth three times the to specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. machining blind holes that have limited depth has advantages and disadvantages. Vernier depth gauges or digital depth gauges are commonly employed. this article will explore what a. Depth Of Blind Hole.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Depth Of Blind Hole The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. how deep can i tap a blind hole? for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the hole gets. Depth Of Blind Hole.

From www.researchgate.net

Waspaloy blindhole repair sample (hole depth 6.5 mm, hole diameter Depth Of Blind Hole Highly precise measurements are achieved using depth micrometers. While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to the drill bit. how deep can i tap a blind hole? Use depth gauges to measure the depth of blind holes accurately. the downward arrow symbol (↧) represents the depth. Depth Of Blind Hole.

From www.cnccookbook.com

Blind Hole Tapping Secrets [ Stop Breaking Taps! ] Depth Of Blind Hole Use depth gauges to measure the depth of blind holes accurately. Drilling a blind hole requires careful consideration of the hole depth, proper tools, and techniques to ensure accurate and efficient results. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. for easy and efficient. Depth Of Blind Hole.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Depth Of Blind Hole this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Highly precise measurements are achieved using depth micrometers. machining blind holes that have limited depth has advantages and disadvantages. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount. Depth Of Blind Hole.

From www.xometry.com

7 Tips to Help You Design for CNC Machining Xometry Depth Of Blind Hole Generally, it’s advisable to tap to a depth three times the this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the hole. Depth Of Blind Hole.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Depth Of Blind Hole Vernier depth gauges or digital depth gauges are commonly employed. Generally, it’s advisable to tap to a depth three times the For larger blind holes, calipers with depth measurement capabilities can be utilized. machining blind holes that have limited depth has advantages and disadvantages. Use depth gauges to measure the depth of blind holes accurately. this article will. Depth Of Blind Hole.

From toolsmechanism.com

How to Mark Blind Holes for Drilling? Tools Mechanism Depth Of Blind Hole the downward arrow symbol (↧) represents the depth to which the hole is threaded (tapping depth). Vernier depth gauges or digital depth gauges are commonly employed. how deep can i tap a blind hole? Generally, it’s advisable to tap to a depth three times the This article explores the specifics of blind holes and their importance in enhancing. Depth Of Blind Hole.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Depth Of Blind Hole The depth for tapping blind holes varies based on the tap type, the material you’re working with, and the application’s specific requirements. for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the hole gets deeper. Highly precise measurements are achieved using depth micrometers. For. Depth Of Blind Hole.

From www.researchgate.net

Fast hole EDM drilling models of blindhole stage and breakthroughhole Depth Of Blind Hole Use depth gauges to measure the depth of blind holes accurately. This article explores the specifics of blind holes and their importance in enhancing primary reliability, reducing material waste, and providing designers and mechanics with versatile options in part creation. While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to. Depth Of Blind Hole.

From www.slideserve.com

PPT Engineering Graphics PowerPoint Presentation ID7068169 Depth Of Blind Hole for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the hole gets deeper. how deep can i tap a blind hole? Highly precise measurements are achieved using depth micrometers. While drilling, stop and examine the hole depth periodically using a depth gauge or. Depth Of Blind Hole.

From dxopdvxrr.blob.core.windows.net

Blind Hole Manifold at Jeffrey Britton blog Depth Of Blind Hole While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to the drill bit. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. The depth for tapping blind holes varies based on the tap type, the material you’re. Depth Of Blind Hole.

From www.linkedin.com

The difference between "countersunk hole, through hole, blind hole" Depth Of Blind Hole Highly precise measurements are achieved using depth micrometers. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to the drill bit. How to drill a blind hole?. Depth Of Blind Hole.

From www.slideserve.com

PPT Holes PowerPoint Presentation ID2107959 Depth Of Blind Hole for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the hole gets deeper. Use depth gauges to measure the depth of blind holes accurately. this article will explore what a blind hole is, how to make blind holes, and why they are essential. Depth Of Blind Hole.

From www.scribd.com

Threaded Blind Hole Depths PDF Depth Of Blind Hole Generally, it’s advisable to tap to a depth three times the This article explores the specifics of blind holes and their importance in enhancing primary reliability, reducing material waste, and providing designers and mechanics with versatile options in part creation. Drilling a blind hole requires careful consideration of the hole depth, proper tools, and techniques to ensure accurate and efficient. Depth Of Blind Hole.

From www.slideserve.com

PPT Holes In AutoCAD PowerPoint Presentation, free download ID5331488 Depth Of Blind Hole Use depth gauges to measure the depth of blind holes accurately. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Highly precise measurements are achieved using depth micrometers. Drilling a blind hole requires careful consideration of the hole depth, proper tools, and techniques to ensure accurate and. Depth Of Blind Hole.

From toolsjoint.com

3 Types of Screw Holes You Need to Know Tools Joint Depth Of Blind Hole to specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. the downward arrow symbol (↧) represents the depth to which the hole is threaded (tapping depth). Use depth gauges to measure the depth of blind holes accurately. The depth can be controlled by directly specifying the depth of the. Depth Of Blind Hole.

From www.researchgate.net

The coupling coefficient vs the depth of the blind hole at different Depth Of Blind Hole How to drill a blind hole? While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to the drill bit. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. this article will explore what a blind. Depth Of Blind Hole.

From www.slideserve.com

PPT Holes PowerPoint Presentation ID2107959 Depth Of Blind Hole How to drill a blind hole? Highly precise measurements are achieved using depth micrometers. to specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. Generally, it’s advisable to tap to a depth three times the this article will explore what a blind hole is, how to make blind holes,. Depth Of Blind Hole.

From www.xometry.com

What Are Blind Holes in Engineering and Machining? Xometry Depth Of Blind Hole how deep can i tap a blind hole? The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. For larger blind holes, calipers with. Depth Of Blind Hole.

From forums.autodesk.com

Solved Blind (90°) Hole depth drawing dimension not displaying Depth Of Blind Hole While drilling, stop and examine the hole depth periodically using a depth gauge or a piece of tape attached to the drill bit. This article explores the specifics of blind holes and their importance in enhancing primary reliability, reducing material waste, and providing designers and mechanics with versatile options in part creation. how deep can i tap a blind. Depth Of Blind Hole.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Depth Of Blind Hole machining blind holes that have limited depth has advantages and disadvantages. to specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. the downward arrow symbol (↧) represents the depth to which the hole is threaded (tapping depth). this article will explore what a blind hole is, how. Depth Of Blind Hole.

From transwikia.com

Air trapped inside threaded "blind" hole vs. hole integrity Motor Depth Of Blind Hole Highly precise measurements are achieved using depth micrometers. Drilling a blind hole requires careful consideration of the hole depth, proper tools, and techniques to ensure accurate and efficient results. Use depth gauges to measure the depth of blind holes accurately. how deep can i tap a blind hole? this article will explore what a blind hole is, how. Depth Of Blind Hole.

From www.machinistguides.com

Guide to Holes on Blueprints [Types, Symbols & Features] Machinist Guides Depth Of Blind Hole Vernier depth gauges or digital depth gauges are commonly employed. how deep can i tap a blind hole? How to drill a blind hole? Drilling a blind hole requires careful consideration of the hole depth, proper tools, and techniques to ensure accurate and efficient results. For larger blind holes, calipers with depth measurement capabilities can be utilized. The depth. Depth Of Blind Hole.

From www.xometry.com

Spotface vs. Counterbore Holes in Machining Differences and Uses Xometry Depth Of Blind Hole machining blind holes that have limited depth has advantages and disadvantages. Drilling a blind hole requires careful consideration of the hole depth, proper tools, and techniques to ensure accurate and efficient results. the downward arrow symbol (↧) represents the depth to which the hole is threaded (tapping depth). to specify a blind hole requires listing the diameter. Depth Of Blind Hole.

From www.researchgate.net

The coupling coefficient vs the depth of the blind hole at different Depth Of Blind Hole The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. how deep can i tap a blind hole? Generally, it’s advisable to tap to a depth three times the The depth for tapping blind holes varies based on the tap type, the material you’re working with,. Depth Of Blind Hole.

From blindza.blogspot.com

Blind Tapped Hole Dimensioning BLINDZA Depth Of Blind Hole Vernier depth gauges or digital depth gauges are commonly employed. for easy and efficient blind hole machining, start by drilling the hole slowly to cut a pilot hole, then increase the speed gradually as the hole gets deeper. How to drill a blind hole? to specify a blind hole requires listing the diameter of the hole and a. Depth Of Blind Hole.

From www.researchgate.net

The coupling coefficient vs the depth of the blind hole at different Depth Of Blind Hole Vernier depth gauges or digital depth gauges are commonly employed. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Drilling a blind hole requires careful consideration of the hole depth, proper tools, and techniques to ensure accurate and efficient results. Use depth gauges to measure the depth. Depth Of Blind Hole.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Depth Of Blind Hole machining blind holes that have limited depth has advantages and disadvantages. the downward arrow symbol (↧) represents the depth to which the hole is threaded (tapping depth). The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Vernier depth gauges or digital depth gauges are. Depth Of Blind Hole.